|

THIN SECTION

BASICS

THIN SECTION

BASICS

Petrographical analyses is an essential service providing estimates

of pore size distribution, grain size, sorting, porosity, and mineral

abundances, fabric, rock classification, porosity varieties and

abundances.

Results

include a determination of shale volume, shale

distribution, porosity varieties and abundances

with a discussion of diagenesis, diagenetic

sequence, porosity origins and development,

controls on porosity and permeability. Point

count data is presented in tabular form with

colour photomicrographs accompanied by detailed

descriptions.

Core or chip samples are cleaned in a vapor

phase bath in an attempt to remove solvable excess residual

hydrocarbon. The samples are then impregnated with blue epoxy to

identify porosity and preserve textures, polished and mounted

onto a glass slide. The samples are then ground down to a

thickness of 30 microns and stained with a combined carbonate

stain of Alizarin Red-S (for calcite) and potassium ferricyanide

(for Core or chip samples are cleaned in a vapor

phase bath in an attempt to remove solvable excess residual

hydrocarbon. The samples are then impregnated with blue epoxy to

identify porosity and preserve textures, polished and mounted

onto a glass slide. The samples are then ground down to a

thickness of 30 microns and stained with a combined carbonate

stain of Alizarin Red-S (for calcite) and potassium ferricyanide

(for

ferroan carbonate).

Thin section microphotograph, blue colour is porosity,

other colours are different minerals Thin section microphotograph, blue colour is porosity,

other colours are different minerals

Finally,

a second glass slide is glued on the polished surfaces. The

prepared thin sections are examined petrographically. Individual

minerals are identified by their stained colour and crystal

structure (if visible).

Thin section "visual porosity" is called effective porosity in

petrographic reports. It is usually less than effective porosity

from logs or core analysis because it does not include

microporosity inside grains or rock fragments. Petrographic

reports sometimes refer to core porosity as "total porosity".

This is confusing, as the common usage of "total porosity" is

the sum of effective porosity (core porosity or log analysis

porosity) plus clay bound water. Consider the context.

The petrographic data summary, including framework mineralogy,

diagenetic minerals and cements, textures, grain size range, and

average porosity and permeability, is provided in tabular form.

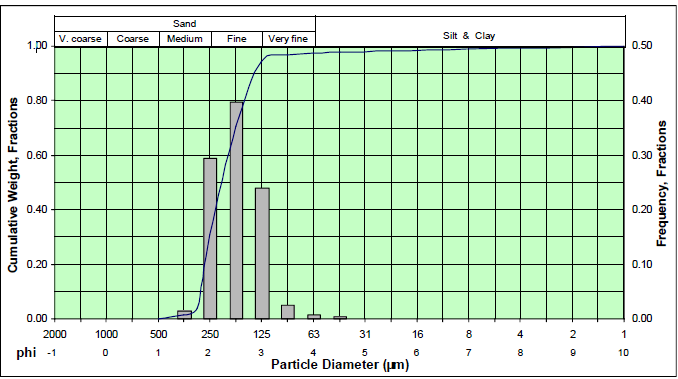

Grain size distribution histogram - tabular data for each sample

will also be supplied

Macro fracturing are usually visible with blue epoxy. To look

for possible micro fractures, a second set of thin sections are

made from the same samples. These are injected with fluorescence

Rhodamine-B red epoxy. These samples are examined and

photographed under ultra-violet (UV) light.

More detailed images may be made by scanning electron microscopy

(SEM) to assess pore geometry and grain texture.

THIN SECTION EXAMPLES

THIN SECTION EXAMPLES

|