|

fracture LOCATION FROM CONVENTIONAL LOGS

fracture LOCATION FROM CONVENTIONAL LOGS

The use of open hole logs to identify fractures is a common

analytical procedure. It is qualitative at best but there can

be semi-quantitative fracture intensity indicators, based on

the frequency of occurrence of particular artifacts on the

log curves. This Section describes how to identify those

signatures.

Most

well logs respond in some way to the presence of fractures. Each

major log type is discussed in the following Sections with respect

to its fracture response. Not all logs detect fractures in all

situations, and very few see all fractures present in the logged

interval. Bear in mind that other borehole and formation responses

will be superimposed on each log. Moreover, it is not normal to

analyze a single log in isolation, but to review all log curves

together to synthesize the best, most coherent, result.

The

list of possibilities is shown here:

1.

resistivity

2. spontaneous potential

3. caliper

4. micro resistivity

5. dipmeter and fracture

identification log

6. density, neutron, and

photoelectric effect

7. gamma ray and spectral

gamma ray

8. temperature

9. sonic travel time

10. sonic amplitude, and

sonic wave train

11. resistivity image log

12. acoustic image log

Because

we are stuck with the existing logs in the well files, this Section

covers the assessment of fractures from all these commonly available

logs, even though image logs are usually the preferred choice when

available.

Example of a 4-arn dipmeter log displayed as a Fracture

Identification Log (FIL) - dark shading indicates resistivity

differences between adjacent pads, probably caused by fractures or

borehole breakout.

1. Resistivity Logs

1. Resistivity Logs

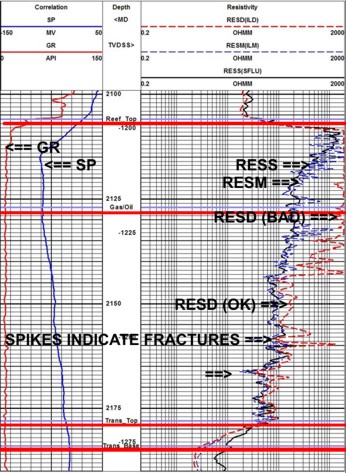

Amethod,

applicable to both old and new logs, is to look for cross over of

the shallow and deep resistivity. If mud resistivity is less than

the formation resistivity, as is true in many cases, then the

shallow resistivity curve will cross over the deep resistivity in a

fractured interval and read lower resistivity, due to invasion of

the fractures. Normally the shallow curve reads higher than the

deep, except in salt mud systems.

Shallow resistivity cross over shows fractures on Laterolog

curves (left illustration). Dipmeter curve overlay presented as a

Fracture Identification Log (FIL) shows fractures at same depths

(black shading on

►

The

shallow curve may also appear noisy or spiky.

Remember

that the deep laterologs are averaging 3 or more vertical feet of

rock and that the shallow sees about 1.5 feet, so the differences

between the two logs is subdued by this. In thinly laminated shaly

sands, the cross over is probably due to shale, not fractures. Check

the sample descriptions.

For

improved resolution, an even shallower focused measurement can be

made with a proximity, microlaterolog, or micro spherically focused

log, and compared with the deep resistivity log.

All

are pad type instruments and survey a smaller portion of the

borehole, but all have been successfully used to aid fracture

detection. Pad type devices do not see the entire borehole, so only

a few of the fractures are logged. However, if the borehole is oval

because of fractures, most of them will be seen because they are

located on the long axis of the hole, where the pad rides. The sharp

conductivity anomalies may, at first be confused with a loss of pad

contact. Check to see that the tool is reading higher than mud

resistivity. All

are pad type instruments and survey a smaller portion of the

borehole, but all have been successfully used to aid fracture

detection. Pad type devices do not see the entire borehole, so only

a few of the fractures are logged. However, if the borehole is oval

because of fractures, most of them will be seen because they are

located on the long axis of the hole, where the pad rides. The sharp

conductivity anomalies may, at first be confused with a loss of pad

contact. Check to see that the tool is reading higher than mud

resistivity.

◄

Induction log example showing low resistivity spikes on all three

resistivity curves, suggesting the presence of fractures. This is

the same well as the core listing given earlier, which also

indicated numerous vertical fractures.

While the various eras of laterolog tools are helpful in

locating fractures in many situations, the induction log may also do

the job in medium resistivity environments. Here the shallow

resistivity curve may cross over the deep resistivity, dropping to

lower resistivity values. Since the deeper curves see a larger

volume of rock, they may be less affected by a conductive fracture.

If one or more of the deeper induction resistivity curves also

spikes to lower resistivity, we can assume that the fracture is

relatively deep and therefore significant. It would not be possible

to determine whether the fracture is natural or induced by stress

relief, but the deeper fractures are often presumed to be natural.

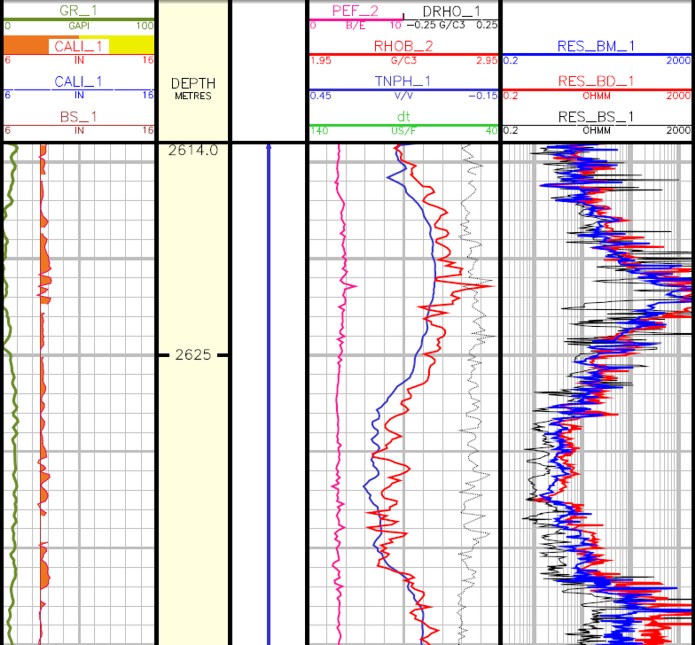

Example of LWD logs in a horizontal well showing heavily fractured

interval on all three resisivity curves. Shallow resistivity is much

less than the deep resistivity, but there are numerous intervals

where the deep curve is also influenced by the water invading the

fractures. Density, neutron, PE, and GR are unaffected by the

fractures in this well, but the LWD caliper (shaded red in Track 1)

shows the erosion and breakouts.

Spontaneous Potential

Logs

Spontaneous Potential

Logs

The spontaneous potential normally does not develop well in

carbonate rocks, due to high resistivity and the long distance to a

nearby shale. However, some SP excursion is usually seen opposite

very porous or permeable carbonate zones, or opposite lower porosity

fractured zones. Fracture detection by the SP is possible in a low

porosity or low permeability bed if fracturing has occurred and if

the fractures contain a formation water of a different salinity than

that in the borehole. Development of an SP is not a direct

measurement of porosity or permeability.

The

SP is a voltage generated by electrochemical reactions between

the mud filtrate, formation water, and a nearby impermeable shale

barrier. No fluid movement takes place. In addition, a streaming

potential can be generated when mud filtrate passes through the

mudcake. It is primarily dependent upon mud resistivity and differential

pressure. As differential pressure increases, streaming potential

increases for a constant mud resistivity. Either the normal SP

or the streaming potential can be indicators of permeability and

fractures. A streaming potential only exists while fluid is flowing

and is not normally seen in a stable wellbore.

An

example is shown on the left. Depths are

in meters and grid lines are two meters apart. The fracture zone

below 75 meters is indicated by the shallow resistivity reading

significantly lower than the deep. Over the same interval a small

SP development is superimposed on a straight line SP with a slight

drift to the left. When evaluating SP responses for fractures,

remember that the higher the oil saturation (lower water saturation),

the more the SP will be depressed. Very small excursions of the

log curve may be meaningful. An

example is shown on the left. Depths are

in meters and grid lines are two meters apart. The fracture zone

below 75 meters is indicated by the shallow resistivity reading

significantly lower than the deep. Over the same interval a small

SP development is superimposed on a straight line SP with a slight

drift to the left. When evaluating SP responses for fractures,

remember that the higher the oil saturation (lower water saturation),

the more the SP will be depressed. Very small excursions of the

log curve may be meaningful.

◄

Minor

SP development in fractured zone; spikes to the right suggest a

streaming potential, which in turn suggests a flow of mud

filtrate into the reservoir, probably through fractures.

The

SP deflections to the right at 76, 84, and 132 meters may be caused

by a streaming potential due to mud filtrate flow into the formation

at these depths. This is not certain. Usually streaming potentials

are larger and cover longer intervals. These anomalies may be

caused by telluric currents, northern lights, rig power bumps,

or nearby welding.

Another

SP method is to compare the character of the SP to that of a gamma

ray log over the zone. If the SP develops in a zone which shows

relatively high radioactivity on the gamma ray, this could be

an indication of a permeable fractured zone in which uranium salts

have been precipitated.

Many

factors influence the SP and it is difficult to identify fractures

directly using this method alone, but often it aids in confirming

the possibility of a fractured zone. Care must be taken not to

interpret random variations or drift in the SP baseline as evidence

of permeability.

Having

detected the fractures, it is useful to count the footage, or

meters, of the fractured interval. In the example above,

the zone from 75 meters to the bottom of the log, or about 95

meters, is fractured. About 16 meters of this shows little resistivity

crossover and little SP deflection, giving a net fractured interval

of 79 meters.

Caliper Logs

Caliper Logs

In competent formations, the borehole will often become oblong

when it intersects a fracture. This looks like a hole washout

on a two or three arm caliper, but a 4 or 6 arm caliper will show

the oblong shape. The long axis of the hole is usually parallel

to the strike of folds or faults.

This

method is best when a sensitive caliper with sharp wall contacts

is used. Calipers recorded with most surveys are not very sensitive

and serve purposes other than measuring the hole size. Their design

does not allow for detection of small abrupt changes. Examples

are the three arm bow spring type calipers recorded with sonic

and density log which provide centralization as well as hole size

measurements. The caliper logs which are most helpful are recorded

with the dipmeter, microlog, and modern dual axis calipers on

density neutron logs. Special purpose, very sensitive, calipers

are available from most service companies.

The

caliper recorded with the microlog is designed to float on top

of the mudcake. It will respond and measure the thickness of the

mudcake, instead of measuring borehole rugosity. The presence

of mudcake should be more conclusive of permeability and possible

fracturing than rugosity alone. Dipmeter pads are pressured to

cut through mudcake and usually measure the rough hole if it is

present. Other dipmeter curves are also used to identify fractures.

Mud

rings sometimes form even in front of impermeable zones. Therefore,

mudcake indicators of permeability must be confirmed with another

log if possible.

Rough,

large, or irregular borehole in otherwise competent rock usually

indicates fractures. Mudcake opposite very low porosity usually

indicates fractures. Hole caving due to stress release is very

common, but open fractures are not always present. Not all washouts

indicate fractures; shale, salt, and unconsolidated sands often

erode, but their presence can usually be distinguished by other

log characteristics.

Dipmeter dual axis caliper shows oblong hole

in fractured reservoir

A

good example is shown above. Zone A has a round hole,

roughly in gauge, indicated by the four arm caliper, and the dipmeter

curves show no fractures. Zones B and C show significant hole

elongation on the caliper. Fractures are inferred from this and

confirmed by the dipmeter curves. Fracture orientation is roughly

NE - SW. This information would help determine well spacing; offset

wells to the NW or SE would have to be closer than those in line

with the fracture orientation.

Remember

that a two arm caliper would probably see the long diameter. The

enlarged hole is a clue for fractures if the other log curves

indicate competent rock. A three arm caliper would average the

two diameters, and the hole enlargement may not be as obvious.

Most modern density neutron logs display a dual axis caliper,

and these curves should be checked carefully for evidence of

borehole breakouts.

Zone

E again shows a round hole, this time oversize, indicating a washout

in un-fractured rock. This is probably a shale zone, which would

easily be confirmed by a gamma ray or SP log. Shales can erode

to an oblong hole, especially in deviated holes or in folded or

faulted areas.

Micro Resistivity Logs

Micro Resistivity Logs

Micro resistivity logs, such as microlog and micro SFL, indicate

fractures by showing low resistivity spikes opposite open fractures,

and high resistivity spikes opposite healed fractures and tight

or highly cemented layers. In older wells, the microlog, caliper,

and an ES may be the only logs available for use in fracture detection,

and for porosity and permeability for that matter.

The

microlog is one of the most conclusive indications of permeability.

When the dotted curve (2 inch micro normal) reads higher than

the solid curve (1 inch micro inverse), there is some permeability.

This effect is called “positive separation”. The caliper

curve accompanying the microlog resistivity measurements is also

available for mudcake location and thickness determinations. Mudcake

is another indication of permeability.

Micrologs show fracture location

On

the microlog shown above, there are three porous and permeable layers

with positive separation and mudcake, one near the top and one

near the bottom of the log section, and another just below the

7300 foot grid line. The lower layer has a single sharp, low resistivity,

spike. This is a fracture or a thin conductive shale streak. The

balance of the logged interval is impermeable and probably shale,

which could be confirmed by the SP or GR logs.

A

newer microlog run in combination with a proximity log is also shown,

above right. The permeable zone contains three distinct

fractures with several more tiny conductive spikes that could

indicate fractures. Only one is seen by the proximity log.

If

the micro resistivity curves are smooth, permeability is due to

porosity; if low resistivity spikes are present, fractures are

indicated. The microlog is a very reliable fracture indicator,

but like all single pad devices, it only sees a few of the fractures.

If the zone is known to be a carbonate or tight sand, and the

hole size is larger than bit size, an elongated hole and probable

fractures are indicated.

Dipmeter Logs

Dipmeter Logs

High resolution dipmeters with 4, 6, or 8 micro-conductivity log

curves, 2 or 3 opposed calipers, plus directional and orientation

data can indicate fractures by visual observation of log curve

characteristics and from individual dip magnitude and direction

calculations. Hole enlargement in a preferential direction discussed

in the previous Section, usually caused by fractures, is easily

displayed from the multi-arm caliper data, as illustrated below.

Each

dipmeter pad provides a recording of changes in resistivity which

occur along the borehole, usually related to porosity variations,

bedding planes, or fractures. One pad is selected as reference

and its position relative to north is continually recorded. The

other pads are numbered clockwise looking from the top down. This

determines the orientation of all the pads.

The

log is analyzed in a similar fashion to a micro resistivity log.

However, four, six, or eight pads and better focusing make the

dipmeter a popular choice in modern wells, because it is more

sensitive and covers more of the borehole wall. The more elaborate

micro-scanner log has superceded the dipmeter log in many areas

and most comments about the dipmeter also apply to the micro-scanner.

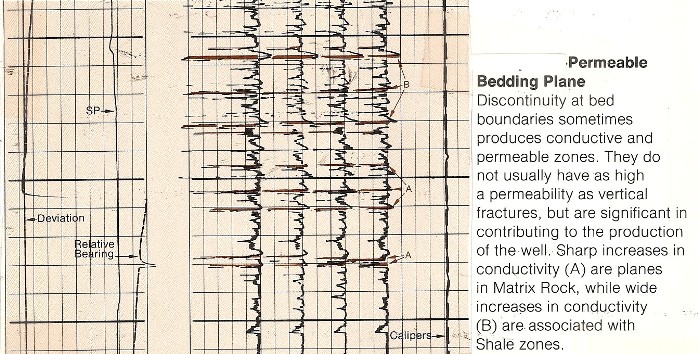

Dipmeter curves show horizontal fractures or

bedding planes

Semi-horizontal

fractures appear as a short conductive anomaly on all four curves.

Examples of these sharp conductive spikes are shown on a 4-pad

dipmeter above. Individual spikes represent bedding

planes or semi-horizontal fractures. Fracture intensity counts

are made by counting the number of spikes per unit length. Modern

thought now suggests that there is no such thing as a horizontal

fracture; they are considered to be poorly indurated laminations.

Regardless of their proper name, they often contribute to well

performance and are easily found with the dipmeter.

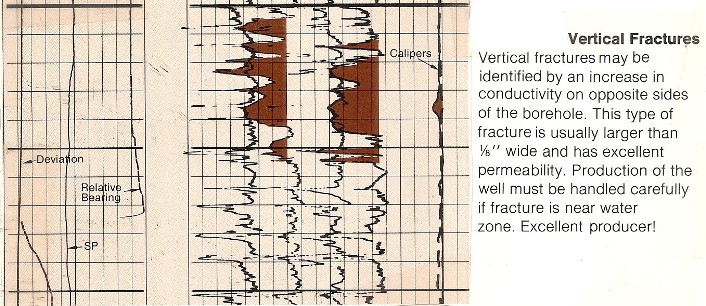

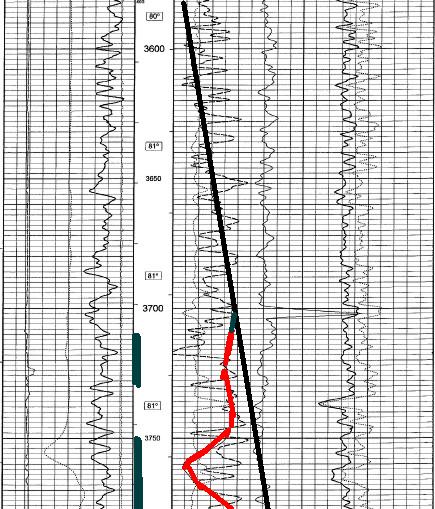

Dipmeter curves show semi-vertical fractures

Semi-vertical

fractures usually cause a relatively long conductive anomaly on

two opposite pads, or on one pad if the fracture is off axis enough

to be missed by the opposite pad. A typical vertical fracture

is shown by the shaded portions on the fracture identification

log (FIL) presentation shown above. This kind of analysis is normally done on

expanded scale playbacks of the raw dipmeter curves. Notice that

the grid lines in these examples are two feet apart, displayed

at 1:20 or 1:40 depth scales. Total length of vertical fractures

compared to total interval is a useful measure of vertical fracture

intensity.

The

fracture anomaly may disappear or jump from one curve to the

next as either the fracture or the tool rotates around the

borehole. Because of this, repeat passes should be made

in zones of scattered fracturing to provide better detection.

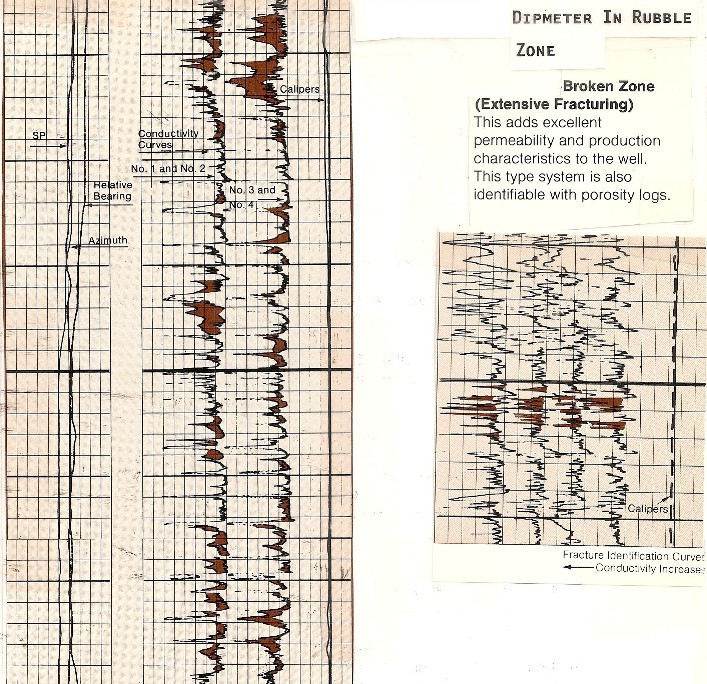

When

all four pads show conductive streaks over a long vertical interval

as below, right side, a badly broken, rubble zone can

be inferred.

Fracture Identification Log (FIL) presentation

of dipmeter curves

To

amplify the fracture detection capability, the dipmeter curves

may have to be rerun or replayed with a different scale to show

all non-fractured zones as saturated (ie., displaying a constant

maximum resistivity). The log should be recorded in the usual

way to get the best dipmeter data. Then with the aid of the computer

in the logging truck, the curves can be displayed in different

formats to emphasize fractures. On existing logs, this can be

done in the computer center if the data tapes can be located.

An

easy way to analyze fractures with the dipmeter consists of comparing

the values of one pad to values of the other pads by replaying

adjacent curve pairs on top of each other. The curves are normalized

in tight, high resistivity zones. The magnitude of the separation

of the curves provides a qualitative indication of the fracture

intensity. This visual overlay technique has been dubbed the Fracture

Identification Log (FIL) by Schlumberger, where the shaded areas represent vertical

fractures. Many other semi-horizontal fractures and permeable

bedding planes are also present, and contribute to production.

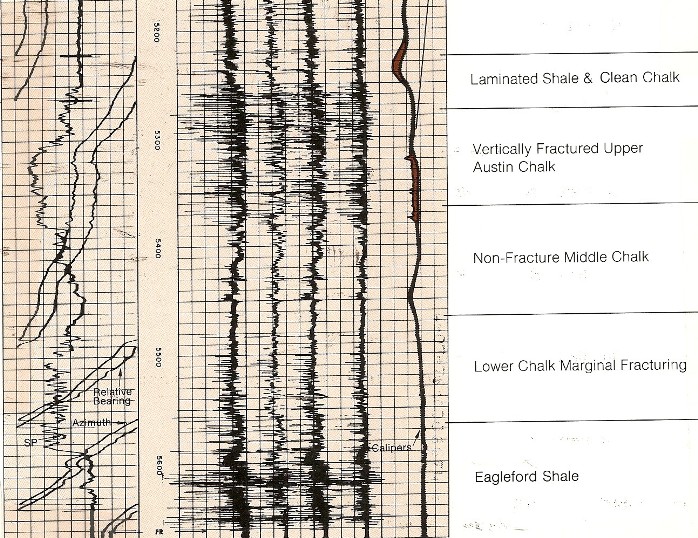

Fracture Identification Log (FIL) in Austin

Chalk

Another

example, from the Austin Chalk (above), shows the heavily

fractured upper zone, the poorly fractured lower zone, and an

intervening zone with no fractures. Notice that the bedding planes

in the shales look a lot like fractures, so a preliminary screening

to identify shale zones is absolutely necessary. People looking

for oil or gas in fractured shale can use this technique to great

advantage.

The

FIL presentation can be made for most types of dipmeters if the

data tapes can be located. For older, pre-tape, dipmeters eyeball

techniques must be used. The Stratigraphic High Resolution Dipmeter

(SHDT), with 8 conductivity curves, is a little more difficult

to use than standard high resolution tools. Vertical fractures

may influence both electrodes on a single pad. An FIL presentation

can be made by turning off one curve from each pad or by presenting

two sets of FIL overlays. The GEODIP presentation may show numerous unconnected bed

boundaries in fractured zones. SYNDIP will often show non planar

dips or no dip correlations at all (bubble coding).

Since

pad orientation is known from the directional data, the fracture

azimuth can be determined. This will indicate the preferential

permeability direction. The azimuth of pad 1 is recorded directly

on low angle dipmeters, but the magnetic declination must be taken

into account.

DIPMETER MATH

DIPMETER MATH

For

low angle dipmeter

1: PAZ = AZ1 + MAGD

For

high angle dipmeters:

2: PAZ = AHD + RBR + MAGD

Calculate

fracture azimuth:

3: FAZ = PAZ + 90 * (PAD# - 1)

Adjust

angle to fit between 0 and 360 degrees:

4: FAZ = 360 * Frac ((FAZ + 360) / 360)

Where:

AHD = azimuth of hole deviation (degrees)

AZ1 = azimuth of pad number one on log (degrees)

FAZ = azimuth of fracture (degrees)

MAGD = magnetic declination (degrees)

PAZ = azimuth of pad one relative to true north (degrees)

PAD# = pad number on which fracture anomaly occurs

RBR = relative bearing azimuth on log (degrees)

Under

normal conditions, it is easy to read AZ1 on the log opposite

the fracture, add the magnetic declination, and put the result

in the range 0 to 360 degrees, using mental arithmetic. See

previous illustration, left side, shows the pad azimuth for a number of fractures

showing the preferential direction to be in the range 170 to 200

degrees, or roughly south. Fractures to the north are expected

also, but are not as obvious. This may be due to off axis fractures

or poor pad pressure in that direction caused by hole deviation

or bad tool maintenance.

Density, Neutron, and PE Logs Density, Neutron, and PE Logs

If

the density log shows high porosity spikes that are not seen by

the neutron log, usually fractures, large vugs, or caverns exist.

Broken out borehole also causes the same effect, but fractures

are often present when this occurs. Both cases are shown at the

left. If

the density log shows high porosity spikes that are not seen by

the neutron log, usually fractures, large vugs, or caverns exist.

Broken out borehole also causes the same effect, but fractures

are often present when this occurs. Both cases are shown at the

left.

Because

the density tool only looks at a small fraction of the borehole

circumference, only a few of the fractures present will be logged.

The depth of investigation is rather shallow, so mudcake and borehole

rugosity can have an appreciable effect on the total measurement,

despite the fact that it is a pad type contact device with some

borehole compensation applied.

Density log spikes show fractures Density log spikes show fractures

Large

density correction values in competent rock, especially when weighted

muds are used, is a fracture indicator. The fracture network usually

does not increase the total porosity appreciably, but the resultant

increase in compensation, due to the rugosity, mudcake, or fluid

in the fractures, provides an indication of fracturing.

Both

density and density correction curves show fractures better if

the log is recorded with a short time constant. This makes the

log look noisy and possibly useless for its normal purpose. The

time constant on existing logs can only be changed by reprocessing

raw count rate data from the original data tape.

Large

PE values, greater than 5.0 cu., especially when weighted muds

are used, is a fracture indicator. Barite has a very large photoelectric

cross section, 267 as compared with 5.0 for limestone and 3.1

for dolomite. Thus the PE curve should exhibit a very sharp peak

in front of a fracture filled with barite loaded mud cake. On

the log at the right, two very sharp peaks on the PE curve correspond

to fractures. The density correction curve also has a bump for

the presence of heavy mud. Corroboration from other sources is

essential. In light weight muds, an abnormally low PE value, less

than 1.7, indicates, fractures, bad hole condition, or coal. Large

PE values, greater than 5.0 cu., especially when weighted muds

are used, is a fracture indicator. Barite has a very large photoelectric

cross section, 267 as compared with 5.0 for limestone and 3.1

for dolomite. Thus the PE curve should exhibit a very sharp peak

in front of a fracture filled with barite loaded mud cake. On

the log at the right, two very sharp peaks on the PE curve correspond

to fractures. The density correction curve also has a bump for

the presence of heavy mud. Corroboration from other sources is

essential. In light weight muds, an abnormally low PE value, less

than 1.7, indicates, fractures, bad hole condition, or coal.

PE curve shows fractures in barite weighted mud

The

compensated neutron log looks at the entire circumference of the

well bore, but is usually decentralized to minimize borehole effect.

It is not a useful fracture indicator by itself. However, neutron

porosity values are often compared with other sources to indicate

either lithology or the possibility of fractures.

The

sidewall neutron log sees only a small portion of the borehole

wall and may be affected by borehole break out in the same way

as the density log. Break out is often associated with fractures.

No

one would go out of their way to run a density neutron log combination

to identify fractures. However, it is the most common log suite

run today, and must be used if no other fracture logs have been

run. Fortunately the resistivity log, which is nearly always available,

can also help identify fractures and this helps confirm density

and PE anomalies.

Gamma Ray Logs

Gamma Ray Logs

The natural gamma ray spectral log provides a quantitative measurement

of the three primary sources of natural radioactivity observed

in reservoir rocks: potassium, uranium, and thorium. The usual

gamma ray log records the sum of these three radioactive sources.

This log should not be confused with the (induced) gamma ray spectral

log, which is a form of pulsed neutron log run in cased hole to

evaluate lithology and water saturation.

Most

productive formations show a low content of all three radioactive

isotopes. The radioactivity associated with potassium and thorium

is normally attributed to clays in the formation. Since uranium

salts are soluble in both water and oil, zones of high uranium

content indicate fluid movement, subsequent mineral deposition,

and thus a probable zone of permeability, usually a fractured

zone.

An

Austin Chalk example is given at left. Here the upper

section is heavily fractured, the middle is not fractured, and

the bottom fractured in a few places. In nearly all cases the

uranium curve shows high radioactivity at the same depths as the

sonic amplitude and sonic variable density log indicate fractures.

In some cases, uranium may be present in the porosity without

a fracture, as in the shaded portions of the example. In others,

there may be fractures with no uranium.

Just as with any fracture location method, there is no absolute

guarantee of identifying all fractures. An

Austin Chalk example is given at left. Here the upper

section is heavily fractured, the middle is not fractured, and

the bottom fractured in a few places. In nearly all cases the

uranium curve shows high radioactivity at the same depths as the

sonic amplitude and sonic variable density log indicate fractures.

In some cases, uranium may be present in the porosity without

a fracture, as in the shaded portions of the example. In others,

there may be fractures with no uranium.

Just as with any fracture location method, there is no absolute

guarantee of identifying all fractures.

Natural gamma ray spectral log (KUT log) shows fractured

zones in Austin Chalk Natural gamma ray spectral log (KUT log) shows fractured

zones in Austin Chalk

If

uranium data is not available, the apparent shale volume from

SP, gamma ray, and density neutron crossplot are compared. If

the gamma ray derived shale volume is higher than the others,

uranium in fractures may be suspected.

Sandstones

are sometimes radioactive because of clay or feldspars, not fractures.

This can be confirmed by sample descriptions.

In

thinly laminated sand-shale series, the zone will appear radioactive

due to the shale, but may also contain uranium in fractures. To

locate fractures in these beds using the gamma ray method, calculate

shale volume independent of the natural radioactivity, then compare

this to the actual radioactivity, some of which may be due to

uranium in fractures. If a spectral log is available, the assessment

is easier.

The

natural gamma ray spectral log is one of only three methods that

can be used in cased hole to locate fractures. The others are

the array sonic and temperature logs, to be described later.

CAUTION:

In some areas, fractures are never radioactive, so this method

is not always suitable.

Temperature Logs

Temperature Logs

Mud

fluid invasion into a fractured zone can lower its temperature.

If logged before it can return to the geothermal temperature,

the presence of fractures or, at least, invasion can be confirmed.

It is possible that the invasion is merely a function of porosity,

but usually the effect is smaller than for fractures.

Gas

evolving into the mud system, often from tight fractured reservoirs,

may be seen if the mud system is static and under balanced for

sufficient time. The cooling anomaly should disappear above and

below the fracture zone, and will disappear everywhere in a few

hours if no additional flow or invasion takes place.

Temperature log may locate fractures

In

perforated cased holes, and in open hole or barefoot completions,

an injection profile can be run by increasing pressure on the

well head and then logging several passes with a temperature log

spaced over a few hours. The pressure will force fluid above the

zone downward, injecting cooler fluid into the formation. The

larger temperature anomalies are often associated with fractures

or the best permeability zones.

Temperature log in a naturally fractured gas shale shows low

temperature anomaly. Perforated interval is shown in the depth

track.

Temperature log in a naturally fractured gas shale shows low

temperature anomaly. Perforated interval is shown in the depth

track.

|