Petrophysical Training

Licenses

|

PRESSURE CONTROL BASICS

PRESSURE CONTROL BASICS

Portions of this page are from Petroleum Engineer's Handbook

(PEH) online version.

Pressure control during wireline operations,

such as perforating and production logging, is critical to

the health and safety of workers at the wellsite nearby

residents, domestic animals, and wildlife, not to mention

the nearby environment and the financial health of the oil

company and its executives and shareholders. Government

regulations and engineering best-practices keep failures to

a minimum, bur a few blowouts and gas leaks hit the evening

news often enough to suggest that someone messed up

somewhere.

This page describes the basic equipment and terminology

related to pressure control at the well.

The pressure control employed during wireline operations is intended

to contain pressure originating from the wellbore. During open hole

operations, the pressure might result from a well-kick. If

serious, the blowout preventer (BOP) would he closed, severing the

wireline and dropping the logging tools to bottom of the hole.

Heavier mud would be pumped in through the kill-line. With the well

stabilized, the BOP would be opened and the wireline and tools fished

from the borehole. Logging would resume and the well completed,

suspended, or abandoned.

During cased hole wireline work, the well may be capable of

producing at high pressure, either during or immediately after the

wireline procedure. A fair amount of research and planning is needed

to be sure the correct equipment is in place and tested before

trying to run the job.

PRESSURE CONTROL EQUIPMENT

PRESSURE CONTROL EQUIPMENT

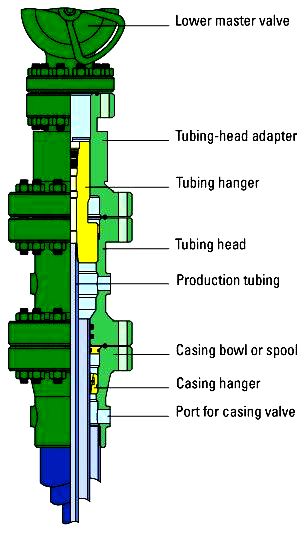

This equipment starts with a connection to the top of the casing,

which forms the foundation for a semi-permanent fixture called the

well head. This is the control system during normal production,

and consists

of pipes, joints, valves, chokes, and pressure gauges

or sensors.

Additional equipment is added to the top of the well head during

wireline operations in cased holes..

Well head pressure control equipment must be rated to well over the

expected well-head pressure. Normal ratings for wireline pressure

control equipment is 5,000, 10,000, 15,000, and 20,000 psi.

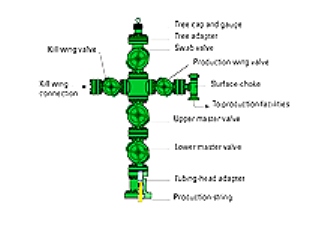

The well head is also called well

head assembly, well head stack, or

“Christmas tree”.

Cut-away view of a typical well

head (left) and "Christmas tree" style well head (right).

Schlumberger images

The following describes the components of the equipment added to the

well head temporarily to allow safe wireline operations in cased

holes. They are listed in order from top of well head upward to top

of final assembly. This material is from Wikipedia and

Schlumberger Glossary, edited for clarity.

Flange

Flange

A flange attaches to the top of the

well head assembly, usually with some sort of adapter for the rest

of the pressure control. A metal gasket is placed between the top of

the well head and the flange to seal against well pressure.

Quick-connect sub

Quick-connect sub

A subassembly device that is bolted to

the top of the BOP stack that is designed to eliminate traditional

bolt-flanges to connect lubricator heads and utilize tapered-wedge

and lock ring designs. This allows the same security of traditional

pressure control connections

Tool trap

Tool trap

A tool trap has the same purpose as a head catcher

in that it prevents the tools from inadvertently dropping down the

hole. This device is normally located just above the well control

valves, providing protection to these important barriers from a

dropped tool. The tool trap has to be open in order to allow the

tools to enter the well, and is normally built to allow tools to be

recovered through the tool trap even when it is in the closed

position.

Wireline valve

Wireline valve

A wireline control valve, also

called a wireline blowout preventer (BOP), is an enclosed device with

one or more rams capable of closing over the wireline in an

emergency. A dual wireline valve has two sets of rams and some have

the capability of pumping grease in the space between the rams to

seal against well pressure.

Lubricator

Lubricator

The lubricator

is a high strength,

pressure tested,

pipe fitted above the

wireline BOP

that allows tools to be put into a high pressure

well. The top of the lubricator assembly includes a high pressure

grease-injection section and sealing elements. The tools are placed

in the lubricator and the lubricator pressurized to wellbore

pressure. Then the top valves of the well head are opened to enable

the tools to fall or be pumped into the wellbore under pressure. To

remove the tools, the reverse process is used: the tools are pulled

up into the lubricator under wellbore pressure, the well head valves

are closed, the lubricator pressure is bled off, and then the

lubricator may be opened to remove the tools.

Pump-in sub

Pump-in sub

Pump-in subs, also called a flow-tee, allow for

the injection of fluid into the pressure control string. Normally

these are used for wellsite pressure testing, which is typically

performed between every run into the well. They can also be used to

bleed off pressure from the string after a run in the well, or to

pump in kill fluids to control a wild well.

Grease injector head

Grease injector head

The grease injector head is an assembly

of components used to contain wellhead fluids and pressure during

wireline operations. The wireline passes through a close-tolerance

tube assembly as it moves. High-pressure grease is pumped into the

surrounding annulus to effect a pressure-tight dynamic seal that is

maintained during the operation by injecting more grease as

required. A slight leakage of grease is normal, and the addition of

fresh grease ensures the seal is maintained.

Pack-off subs

Pack-off subs

Pack-off subs utilize hydraulic pressure on a

two brass fittings which compress a rubber sealing element to create

a seal around the wireline. Pack-offs can be hand pumped or

compressed through a motorized pumping unit.

Line wiper

Line wiper

A line wiper operates in much the same

way as a pack-off sub, except that the rubber element is

much

softer. Hydraulic pumps exert force on the rubber element until a

light pressure is exerted on the wireline, cleaning grease and well

fluid off the line as it moves past the wiper.

Ball check valve

Ball check valve

If the wireline were to become severed

from the tool, a ball check valve can seal the well off from the

surface. During wireline operations, a steel ball sits to the side

of a confined area within the grease head while the cable runs in

and out of the hole. If the wireline exits that confined area under

pressure, the pressure will force the steel ball up toward the hole

where the wireline had been. The ball's diameter is larger than that

of the hole, so the ball effectively seals off pressure to the

surface.

Head catcher

Head catcher

A head catcher, also called tool

catcher, is a device placed at the top of the lubricator section.

Should the wireline tools be forced into the top of the lubricator

section, the head catcher, which looks like a small claw, will clamp

down on the fishing neck of the tool. This action prevents the tools

from falling downhole should the line pull out of the

rope socket. Pressure is applied to the head catcher to release the

tools.

|

|