|

RECOMMENDED LOGGING PROGRAM

RECOMMENDED LOGGING PROGRAM

The

logging program should be carefully designed to gather all the data

required today, and in the future as well. The program needs to be

written, preferably in a checklist format, describing the logs to be

run, the curve complement on each log, the scales for each curve,

and the interval to be covered. The program forms part of the well

drilling and completion program and is used by the logging engineer

to guide hin as to what is required. The wellsite representative

(geologist, drilling engineer, or petrophysicist) monitors the

performance of the logging operation based on this program.

Crain's

Recommended Logging Program

Crain's

Recommended Logging Program

In the past, too few logs were run, even after the advent of many of

the modern logging and analysis techniques. Thus re-evaluation of

by-passed reserves, definition of geological prospects, and seismic

modeling suffer today for the false economy of the past. The best

procedure to follow is to run a comprehensive suite of logs The

following list will cover all near and long term technical needs for

most situations.

In normal fresh or invert mud systems, use:

1. Array Induction 2 ft bed resolution, with SP, GR

Use Array Laterolog in salt mud or resistivity > 600 ohm-m

2. Array Sonic 2 ft bed resolution, with SP, GR, Caliper

Use Dipole Shear Sonic for unconventional reservoirs or

stressed regimes

3. Density Neutron PE combination, with SP, GR, Caliper, Density

Correction

4. ADD Spectral GR in unconventional, frontier, or radioactive

sands

5. ADD Nuclear Magnetic Resonance in unconventional

wells.

As needed:

6. Resistivity Image for stratigraphic, structural data, fractures

7. Other specialty tools

Not all “Quad Combo” tool sets are equal;, some omit the sonic log,

some “forget” to turn on the PE curve. Carefully specify what you

want and don’t accept less just because thw quote “looks good”. If

what you want is not specifically on the quote, it won’t magically

get run at the wellsite. YOU must be proactive and CHECK

Other needed logs:

After cement job, run ultrasonic cement / pipe integrity log.

After stimulation, run tracer log.

In cased hole with limited or no open hole logs,

run compensated neutron, and

pulsed neutron (RST) for porosity and water saturation, with gamma

ray for shale calculations and correlation. Modern sonic logs can be

run in casing if there is a good cement job. Cased hole resistivity

and density are available in some areas.

These recommendations provide sufficient redundancy to provide

fail-safe log analysis except in the case of massive and numerous

tool failures, or extremely bad (large) hole condition. A reasonable

estimate of shale content, porosity, water saturation, rock

velocity, rock density, lithology, and zone productivity can be made

from this data.

Log quality control is an important

feature of log analysis, both in the field when the log is run, and

in the office when the log is used. All quality checks are relative

- the major concern is to determine in the field that the log can

ultimately be used for all its intended purposes without misleading

the user.

Few logs are perfect. Deviations from perfection should be noted,

and corrected if possible, but many errors or faults will not

invalidate the data presented. Some errors or faults do invalidate

the log, so these should be re-run immediately without the error

(usually a new or different logging tool is needed). If any fault

can obviously be remedied by computer manipulation this should be

done, since the computer time is cheaper than the rig time (and it

is also done at the service company's expense). If the redundancy

built into the suggested logging program is lost due to a tool

failure, then steps should be taken to verify that the logs you do

have can provide at least the minimum data required from the logs.

These requirements are usually met on a routine basis by most

logging companies. If you want better results, or more redundancy

for safety, then you or your representative will have to go to the

well site and monitor quality and performance of the logging

operation.

Logging Tool Bed Resolution

Logging Tool Bed Resolution

The description of logging tool resolution can be broken down into

three components - horizontal resolution (depth of investigation),

vertical resolution (bed definition), and tool accuracy (possible

error in the actual measurement).

The bed resolution is the bed thickness needed for the tool to read

the true formation value, unaffected by the adjacent or surrounding

beds. The depth of investigation is the depth of rock penetrated by

the measuring system, which returns about 90% or more of the

measured signal. This is defined in the table for the optimum case;

that is, the borehole, fluid and rock properties are correct for the

tool described.

TABLE 1: LOGGING TOOL RESOLUTION

Tool Measurement Vertical Bed Resolution Horizontal Depth of Investigation (inches)

SP Spontaneous Potential

12 12

ES 16" Normal

16 12

ES 64" Normal

64 64

ES 18' Lateral

200 100

LES 20' Normal

240 150

IES Deep Induction

60 60

DIL Deep Induction

60 60

DIL Medium Induction

60 40

DIL Laterolog 8

18 18

DIL Spherically Focused

18 18

AIT Induction 12,

24, 48 10, 20, 30, 60, 90

LL3 Laterolog

18 40

LL7 Laterolog

18 40

DLL Deep Laterolog

40 80

DLL Shallow Laterolog

40 60

ARI Laterlog 8,

12, 24, 36 60

MLC R1 Microlog

2 * 2

MLC R2 Microlog

2 * 4

MLLC Microlaterolog

3 * 8

PLC Proximity

3 *12

MSFL Micro Spherically Focused

3 *12

FMS, FMI Image

0.1 0.2

UBI Image

0.3 0.1

BHCS Acoustic Travel Time 12, 24 or

36 0 to 8

FDC Density

18 *12

GRN Neutron

15 12

SNP Sidewall Neutron

15 *12

CNL Compensated Neutron

18 20

GR Gamma Ray 18

(varies) 10

CAL Caliper

8 0

TDT Pulsed Neutron

18 8 to 12

EPT Electromagnetic Prop

2 1

NMR Nuclear Magnetism

18 1

NGT Natural Gamma Ray

18 10

LDT Lithodensity

15 *12

* Pad type tools see a pie-shaped slice of the formation facing

the pad. Balance of the tools see a cylindrical shell around the

borehole.

Logging Tool Accuracy

Logging Tool Accuracy

Tool accuracy defines the possible error in the measured value. This

may vary as the measured value varies and is a function of tool

design. Additional errors caused by the borehole environment are not

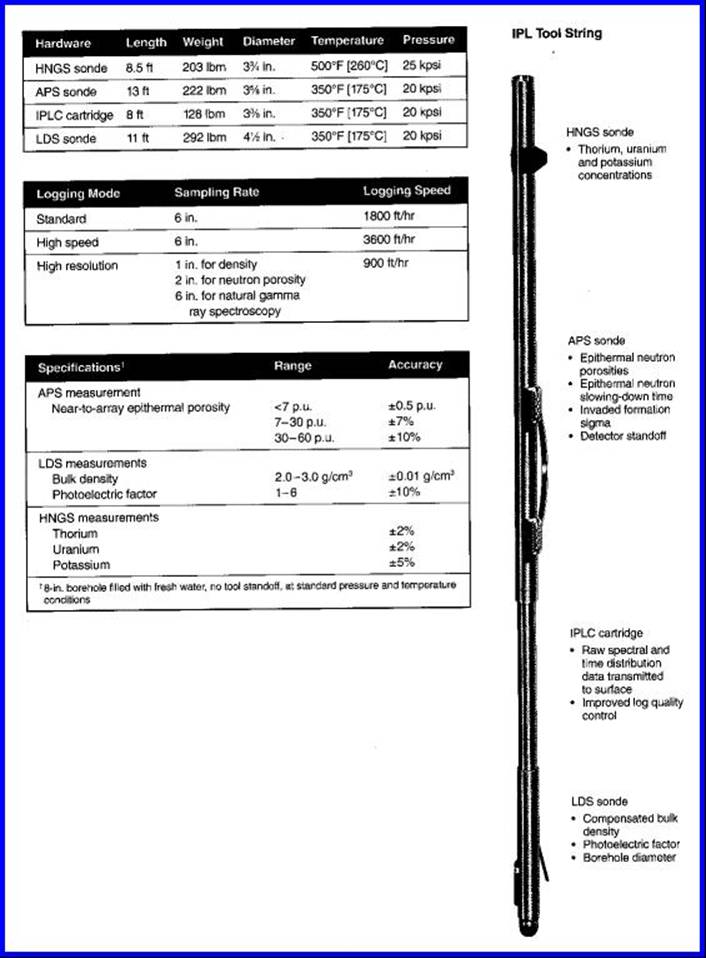

included in this accuracy figure. Table 2 shows tool specifications

and measurement accuracy for the Integrated Porosity Log (IPL), a

modern version of the density neutron log. If the size of the

possible error is of interest to you, you will need to obtain this

data for each tool from each service company. This sample will give

you an idea of the range of accuracy available for a typical modern

tool of today. Older tools are worse.

Sample Tool Specs and Accuracy, from a service company catalog

Logging

Tool Borehole Requirements

Logging

Tool Borehole Requirements

Your choice of logging tools dictates the borehole

environment required , and vice versa; the borehole environment

dictates which tools can be run. The table below suggests some of

these limitations.

|

TABLE 3: BOREHOLE ENVIRONMENT REQUIRED FOR LOGGING TOOLS |

|

Tool |

Mud |

Open Hole |

Cased Hole |

Special |

|

Induction |

All |

Yes |

No |

Poor in Salt Mud |

|

Laterolog |

Conductive |

Yes |

See Note

č |

Special CH tool available |

|

Sonic |

Liquid |

Yes |

See Note

č |

Newer tools only |

|

Density |

All |

Yes |

See Note

č |

Special CH tool available |

|

Neutron |

All |

Yes |

Yes |

|

|

Gamma Ray |

All |

Yes |

Yes |

|

|

SP |

Conductive |

Yes |

No |

|

|

Pulsed Neutron |

All |

Not Common |

Yes |

|

|

Carbon/Oxygen |

All |

Not Common |

Yes |

|

|

Elemental Capture |

All |

Yes |

Yes |

|

|

Resistivity Image |

See Note

č |

Yes |

No |

Special Tool for OBM |

|

Acoustic Image |

Liquid |

Yes |

Only as CBL |

|

|

Microlog, Microlaterolog |

Conductive |

Yes |

No |

|

|

Dipmeter |

See Note

č |

Yes |

No |

Special Tool for OBM |

|

Nuclear Magnetic |

All |

Yes |

No |

|

|

|

|

|

|

|

|

ALL = air, nitrogen, water, oil, diesel, fresh mud, salt

mud, invert mud |

|

LIQUID excludes Air or Nitrogen |

|

CONDUCTIVE excludes air, nitrogen, oil, diesel, invert mud |

|