|

REPORT WRITING BASICS - KEEP IT SIMPLE

REPORT WRITING BASICS - KEEP IT SIMPLE

You will need blank forms or a computer and appropriate software

to

write your log analysis report. I currently use a spreadsheet

and word processor off the shelf, but corporate policy may force you to use more

cumbersome packages. The commentary should be written uniquely for each job, to

cover the who, why, what, when, where, results, and recommendations. Some “copy

and paste” is allowed but try to provide some original insights into each job.

Illustrative examples of crossplots, raw logs, answer plots, and

tables of results, for example net pay summaries, are commonly

included. Equations should be used only to explain a concept - the

complete computer code is not required. Copies of all depth plots

are usually delivered with the report as separate electronic images.

Tables are also delivered separately as electronic spreadsheets.

Tables

of results and graphs are usually

copied to the text document. These should be embedded near the

appropriate text, if possible. Large tables may appear at the end of

the report. Tables

of results and graphs are usually

copied to the text document. These should be embedded near the

appropriate text, if possible. Large tables may appear at the end of

the report.

A

typical petrophysics report contains some or all of the following

topivs:

1.

Introduction or Executive Summary: this should include who the job

was done for, the overall objective of the project, names and

locations of wells and zones of interest, and a brief geological /

mineralogical description of the zones of interest.

2.

Data Available; describe log types and ages, core, XRD, petrography,

sample descriptions, perforation and test intervals, production

histories; comment on quality of each and especially what was

missing that could have been useful.

3.

Analysis Method; in words, explain the individual method used to

calculate shale volume, porosity, lithology, water resistivity,

water saturation, permeability, and net pay; describe how parameters

were selected, and how well log analysis results match core and lab

data; keep equations to a bare minimum. In unconventional

reservoirs, describe what factors about the reservoir are

unconventional and describe how additional parameters such as TOC

weight fraction and kerogen volume were calculated. If mechanical

properties were calculated, describe the log reconstruction method,

list the basic properties that were derived, and the presence of any

lab data that might be used for calibration.

4.

Discussion of Results; may be omitted if covered in methodology;

compare log analysis results to core and lab data, production

history, etc, on a well by well basis.

5.

Conclusions and Recommendations; discuss data quality, results

quality compared to core, missing data, further lab work needed;

come to a conclusion - the well (pool, project) is ......

6.

Disclaimer; you were not there, you didn't do it, and it's not your

fault anyway.

Your

name is on the report, be proud of it. Log analysis reports hang

around in well files for years. Don't leave a shoddy product that

will come back to haunt you.

Use

clear, positive statements. Write as if talking out loud to an

equal, but keep it organized and logical. Every sentence needs

at least one noun and one verb.

We all

learned to do this in high school physics lab, so it's not really

that hard.

Keep

it short and sweet - most petrophysical reports on small projects

are less than five pages of text plus cover page and tables of

results.

A full

field study may contain hundreds of pages from numerous authors, with geology, geophysics,

engineering, and simulation sections, 100's of maps and graphs and

well log displays. Keeping all this well organized and useful will

take some skill and effort. Short

reports don't need an executive summary but long reports definitely

do. Long reports also need a table of contents, table of

illustrations, and a clearly organized structure.

HOW

NOT TO

WRITE A REPORT

HOW

NOT TO

WRITE A REPORT

"Requisite

to a clear understanding of the interpretation of mud-gas

data is consideration of the source of hydrocarbons as

they occur in the drilling mud. To assist in this consideration,

a simple drilling model is proposed which illustrates

the impact of bit penetration through hydrocarbon accumulations.

A series of cases is presented where variations in the

configuration of the mud-gas data indicated specific differences

in the response of the hydrocarbon bearing zone to bit

penetration and subsequent rig operations.

The

model will show that the geometry of the gas kick recorded

by the instrumentation and plotted with respect to time

is directly related to significant characteristics of

the hydrocarbon zone as well as the impact of concurrent

drilling operations. It will become apparent that the

configuration of the gas kick as recorded directly from

the drilling mud is of greater interpretive significance

than the magnitude of the gas kick. When instrument chart

data recorded versus time is digitized and plotted in

graph format versus depth, the magnitude of the gas kick

may be faithfully reproduced but the configuration of

the kick is usually lost.

Thus

it becomes obvious that basic and vital interpretation

must derive from a detailed analysis of the instrument

charts themselves and not solely from a plotted graph.

The basic function of the plotted graph should be to collate,

according to depth, pertinent data produced from various

sources. This graph then provides a broader understanding

of the hydrocarbon accumulation and a convenient means

for future reference.

To

illustrate these concepts, a diagrammatic technique has

been employed which graphically relates the gas detector

response plotted versus time to the actual penetration

of the rock by the drilling bit through the penetration

rate curve plotted versus depth. This technique allows

direct comparison of the geometry of the gas kick to actual

rock penetration."

Scroll down to see four different, easy to read Petrophysical

Reports.

Petrophysical Analysis Report - Conventional

Reservoir

SAMPLE REPORT #1

24 Month 2012

Introduction

We were requested by Some One of Company A

to review the log, core, and test data on the subject well, and to

perform an independent petrophysical analysis on the A and T formations.

Available

Data

Log data for this project is relatively

sparse:

A Fm:

xxx

- xxx m No logs

xxx

- xxx m Induction, SP, Sonic, No GR or Caliper xxx

- xxx m As above plus GR, Caliper, poor quality

density

T Fm:

xxxx

- xxxx m As above

An

analyzed core was available just below the main porous interval

in the T Fm. Reported depths on this core appear to be 11 meters

shallow (approx one pipe joint). A second, deeper core was not

analyzed. No core was taken in the A Fm.

The

top of the T Fm was tested through perforations and produced some

wet gas. Eight separate intervals in the A Fm were tested through

perforations, indicating wet gas in the lower 50 meters.

No

Rw data was provided, so water saturation values from log analysis

are somewhat conjectural. No special core capillary pressure data

is available to help calibrate water saturation.

Analysis Method

Digital log curves for the well were provided by

the client. These were entered into Spectrum 2000 Mindware Ltd's

proprietary log analysis program called Meta/Log.

Shale

volume was determined from the gamma ray where possible and from

the resistivity log where GR was not recorded (250-550 m in A Fm).

The SP is quite flat and too smooth to be a useful shale indicator.

Porosity

was determined by the sonic log corrected for shale. The density

was also tried, but gave misleading results due to poor borehole

condition.

Water

saturation was derived with the Simandoux equation which corrects

for the effects of shale. An Rw equivalent to 85000 ppm NaCl was

used to achieve reasonable water saturations in the T Fm. A value

approximating 45000 ppm was used in the A Fm. There are no obvious

water zones, no RW data from offset wells, and no capillary pressure

data to calibrate water saturation results.

A generic

permeability curve using the Wyllie equation was generated but

not presented on depth plots, as core permeability is much lower

than the estimated values from this method.

Reasonable

cutoffs were chosen from experience in tight sands and hydrocarbon

summaries were printed. The zones that passed all cutoffs are flagged

on the depth plots.

Depth

plots at 1:1000 scale, brief summary listings, and this report

were FAXed to Some One on 24 Month 2012. Hardcopy with plots at

1:500 scale were delivered by courier.

Results

Results are contained in the depth plots and listings

supplied. Briefly these show:

Upper

T Fm: xxxx - xxxx mKB Phi = 0.093, Sw = 0.43, Net = 6.4 m

This zone was perforated and tested gas.

Middle

T Fm: xxxx - xxxx mKB Phi = 0.121, Sw = 0.27, Net = 6.4 m

This zone is not tested.

Lower

A Fm: xxx - xxx mKB Phi = 0.113, Sw = 0.51, Net = 50.4 m

Eight zones within this interval were perforated and tested some gas. Additional

intervals are untested and are flagged on the depth plots.

Upper

A Fm: xxx - xxx mKB Water saturation is speculative so no summations

have been run. Numerous resistivity bumps indicate cleaner sands

in thin intervals which might be gas bearing or they might contain

fresher water, analogous to the Belly River in Alberta.

Conclusions

There are many unknowns and assumptions in this log analysis,

more than in a typical project. Lack of RW data and special core data to calibrate

water saturation in any zone is a severe handicap. Results are based on personal

experience and the production tests.

The

lack of adequate density and neutron log data prevents the calculation

of porosity corrected for heavy minerals. Since volcanic rock fragments

can occur in large quantities in some sands, the porosity shown

here could be several porosity units too low. The sonic log was

calibrated to the core porosity in T Fm, but this core is in poor

quality rock. This does not calibrate the higher porosities. No

calibration was possible in A Fm.

Lack

of a uranium corrected gamma ray log (CGR) hampers shale calculations.

The overall high GR readings indicate either uranium salt precipitation

(usually in fractures), feldspathic sands, or other radioactive

rock fragments. It is impossible with this data set to separate

these events from the shale content. Porosity calculations are

suspect because of this.

Log

character and borehole condition indicate a highly stressed, probably

fractured, reservoir.

Results

show many individual sands that probably contain gas. Any one of

these could be leaking through poor cement to surface, or leaking

and charging lower pressure water zones uphole.

Recommendations

The recommended logging program for future wells

is a multi array induction log with SP and GR, a compensated density

neutron log with PEF, GR, and caliper, a natural gamma ray spectral

log, and an array sonic log with compressional, shear, and Stoneley

curves, with GR and caliper. This suite provides sufficient redundancy

to compensate for bad hole conditions, mineral variations, fractures,

and radioactive salts.

A study

should be undertaken to map water resistivity versus depth in the

region, since no RW data was provided for this project.

In

future wells, conventional and special core analysis to obtain

capillary pressure and electrical properties should be contracted

to help calibrate water saturation.

If

possible, available core should be re-analyzed, described, and

special core analysis properties obtained as soon as possible to

allow recalibration of this log analysis.

Respectfully Submitted

E. R. (Ross) Crain, P.Eng.

Consulting Petrophysicist

Petrophysical Analysis Report - Unconventional Reservoir

SAMPLE REPORT #2

24 Month 2014

INTRODUCTION

We were requested by A. Person, P.Geol. of PQR

Resources Inc. to analyze the log and core data over the B Formation

in 3 wells in the subject area.

Final results of the

petrophysical analysis will be used to assist in assessment of

reservoir quality and to assist in stimulation design.

A comprehensive multi-mineral petrophysical analysis was computed

and delivered as electronic images along with this report. Net pay

summaries are included in the body of this report. Rock mechanical

properties were calculated based on reconstructed logs derived from

the petrophysical analysis, for use in stimulation design programs.

The reconstructed logs eliminate gas effect and low quality data

caused by rough borehole.

AVAILABLE DATA

The log suite consisted of density, neutron, PE,

sonic, GR, and resistivity logs. Two wells had crossed-dipole shear

sonic logs and one had a nuclear magnetic resonance log.

No conventional,

side-wall, or shale rock core analysis data were provided. Capillary

pressure data was provided for three samples. Total organic carbon

analysis and X-Ray diffraction mineralogy data was provided for one

well.

ANALYSIS PROCEDURE

Digital log data was

provided by the client. These data were analyzed with a complex

lithology petrophysical model, which accounts for the effects of

heavy minerals and gas, using our proprietary META/LOG analysis

script, running in the PowerLog software package.

TOC and XRD mass

fraction lab measurements were converted to volume fractions based

on the component densities. These were used to calibrate the kerogen

correction to crossplot porosity and to calibrate clay and mineral

volumes in the b-040 -I/094-O-05 well. The parameters and

scale factors derived here were used in the other two wells.

Shale volume was

calculated from the total gamma ray curve using a Clavier

correction. Individual clean and shale lines were chosen for each

zone in each well. Because of the effect of uranium on the total

gamma ray curve, clean and shale lines were adjusted by comparison

with the shale volume calculated from the density-neutron separation

method. The final shale volume was calculated from the average of

the two methods. Results match the clay volume fraction available

from XRD data in well XXX.

Total organic carbon

(TOC) was calculated using the Issler method with resistivity and

density data, and calibrated to the lab data with scale and offset

factors based on the available lab data in well XXX. The log derived

TOC mass fraction matches the available lab data extremely well. The

mass fraction curve was then converted to volume fraction for use in

the porosity calculation.

Porosity was

calculated from the shale corrected complex lithology density

neutron crossplot model. The results from this model are relatively

independent of mineralogy and compensated for gas effects. However,

the effect of kerogen volume is included in this initial result, so

the kerogen volume is subtracted to obtain the final effective

porosity value.

There is no core

porosity data to help calibrate this result. However, there is a

nuclear magnetic log with effective porosity in d-34-K/094-O-05.

This curve matches the calculated effective porosity curve in that

well quite closely. The NMR effective porosity is unaffected by

kerogen and is the best available check on the final effective

porosity in this project.

The PE curve in XXX

well was affected by barite weighted mud. It was reconstructed from

multiple regression based on data in the other two wells.

The dominant

lithology is described as quartz (with clay), some calcite

(increasing somewhat with depth), and minor pyrite. This would need

a three mineral log analysis model since the effect of pyrite on the

lithology calculation can be quite significant. Because of gas

effect, lithology models that use the density or neutron log data

cannot be used, leaving only a two-mineral model based on PE

available.

To account for

pyrite, pyrite volume was derived from a multiple regression using

all available lithology indicating logs, calibrated to the XRD

pyrite volume. This curve was then used to remove the effect of

pyrite from the PE curve, allowing it to be used in a 2-mineral

model.

Lithology was then

calculated with a 2-mineral model using the pyrite corrected PE

data, with a mineral mixture chosen as quartz and calcite. The final

result is a three mineral model with quartz, calcite, and pyrite

(and clay) that matches the XRD data quite well. All TOC and XRD

data points are plotted on the log analysis depth plots for

comparison.

The Simandoux

equation was used for water saturation calculations. This model

reverts to the Archie equation in the clean zones.

Water resistivity was

set at 0.060 ohm-m at 25C for all zones. Electrical properties were

set at A = 1.00, M = N = 1.65. Formation temperature gradient was

set at 3.13C / 100 m with a surface temperature of 10C. This gives a

formation temperature of 86C at 2430 meters.

No lab measured

electrical properties were available; those used are based on prior

experience in tight sands.

A permeability index

was generated from a standard relationship; the equation is Perm =

10^(20.0 * PHIe – 2.0). There is no core data for calibrating this

value so it should be treated as a qualitative guide. The

permeability derived from the Coates equation was provided for the

NMR log in d-34-K. It has been plotted on the depth plot for

comparison to our calculated results. These permeabilities do not

include that from natural fractures or stimulation.

We were requested to

calculate the acoustic anisotropic coefficient of the interval,

based on differences between the X and Y axis crossed-dipole sonic

log data. Even on an expanded scale log, there was no significant

difference between the two log curves. We conclude that the acoustic

anisotropic coefficient (Kani) is zero.

Using the complete

petrophysical analysis results described above, reconstructed log

curves were generated. This step removes bad hole and gas effects

from the logs so that accurate water-filled rock mechanical

properties can be calculated. This process is also used to create

missing log curves where needed.

Calculated mechanical

properties include Biot’s constant, bulk, shear, and Young’s moduli,

and Poisson’s Ratio. A brittleness coefficient (Lame’s constant,

Lambda) was also calculated. These results are displayed, along with

the lithology track, on a separate depth plot.

These results are not

calibrated as there is no lab data available. However, all results

are within normal limits for water-filled rocks of this type and are

suitable for use in stimulation design programs.

Use of the raw log

curves instead of the reconstructed logs should be strongly

discouraged because the gas effects are quite large and will lead to

calculation of erroneous stimulation parameters.

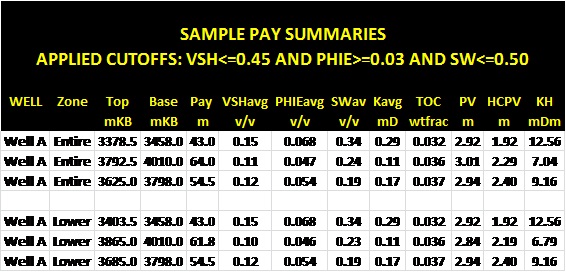

RESULTS

Two sets of net pay flags were generated; one set

used a porosity cutoff of 3% and a saturation cutoff of 50%. The

second used a more lenient set of values, with porosity cutoff of

2.5% and a saturation cutoff of 65%.. A shale volume cutoff of 45%

was used throughout. Both net pay flags are shown on the depth plots

of results. Tables of these results are shown on the next page.

NET PAY SUMMARIES

All data in the above

tables are based on measured log depths.

Free gas in place can

be calculated from these data using appropriate gas volume factor,

temperature, pressure, and area.

The Trican report

provided by the client indicated that adsorbed gas volume would be

small. In any case, adsorbed gas volume cannot be calculated from

the log analysis as there is no gas content (Gc) versus total

organic carbon (TOC) relationship available in the data set

provided.

Results of the log

analysis of the wells are contained in the depth plots, LAS files,

and net pay spreadsheet delivered with this report. All depth plots

are measured depth displays.

CONCLUSIONS

Petrophysical analysis using the shale and kerogen

corrected complex lithology model is believed to be reliable for

porosity and saturation, and can be used to determine original free

gas in place. There is insufficient data to calculate adsorbed gas

in place from this petrophysical analysis.

The permeability

index provided in our work should only be used qualitatively.

Mechanical rock

properties calculated from these results are believed to be reliable

and can be used as input to stimulation design software.

Results match

available TOC and XRD data. However, there is no useable porosity or

permeability control data from conventional or sidewall cores.

Confidence in this analysis could be markedly improved if a cored

well was added to the well complement.

Formation tops,

formation names, and perforation intervals were provided by the

client, and were used on our answer and raw data plots for zone

identification purposes only. We express no opinion on the

correctness of the name designations or associated depths.

This is not a

reserves or resource appraisal report.

Respectfully submitted

E. R. (Ross) Crain, P.Eng.

Principal Consultant

Spectrum 2000 Mindware

Disclaimer

All interpretations expressed in this report, and contained in any

attachments thereto, are opinions based on inferences from

geophysical well logs and/or laboratory measurements provided by the

client.

No economic decisions should be made by anyone based solely on the

results or opinions expressed in this report or its attachments. The

reader should exercise prudent business practices along with sound

geological and engineering judgment before any further actions are

undertaken.

Spectrum 2000 Mindware Ltd cannot and does not guarantee the

accuracy or correctness of any interpretations, and we shall not be

liable or responsible for any loss, costs, damages, or expenses

incurred or sustained by anyone resulting from any interpretation

made by our officers, agents, or employees.

We do not represent that this communication, including any files

attached, is free from computer viruses or other faults or defects.

We will not be liable to any person for any loss or damage,

including direct, consequential, or economic loss or damage however

caused, and whether by negligence or otherwise, that may result

directly or indirectly from the receipt or use of this communication

or any files attached to this communication.

Forensic

Petrophysical Report

SAMPLE

REPORT #3

24 Month 2012

Introduction

We were requested

to review the log, core, and production test information provided by

Company B on seven wells in the Dark River

area of Country C. The work was performed for Another One of Noisy

Petroleum Consultants Ltd, team leader of an integrated study to assess

development potential of a deep, tight gas reservoir. Six of the wells

penetrated the gas reservoirs to varying depths and one was an off

structure exploration well (C-1). The six field wells were N-1, 2, 3, 4,

5, and 6. The zone of interest is the P Formation of middle Jurassic age,

between approximately xxxx and xxxx meters below KB.

The P Fm is a thick sand-shale sequence with fluvial braided stream sands

in the upper layers, fluvial channel to terrestrial deposits in the

middle layers, and marine sands in the basal layers. Considerable

volcanic and metamorphic minerals occur in the upper and middle P Fm. The

middle sands are moderately over-pressured and the basal sands even more

so. Basal sands appear to be more continuous than the middle sands. Upper

sands are probably more isolated due to the braided stream environment.

Porosity is typically in the range of 5 to 11 % but permeability seldom

exceeds 0.10 md even in the best sands.

Available Data

Raw data depth

plots of the well logs for the seven wells were provided. These were

re-plots from a log analysis software package and not the original logs.

Typical log suite included gamma ray, SP, caliper, deep and shallow

resistivity, density, neutron, sonic, and PEF (in newer wells). No

spectral gamma ray data was recorded. This would have been very useful in

accounting for the feldspar and other possibly radioactive rock fragments

in the sands.

Log data quality is reasonably good, with more problems from rough hole

conditions in the three older wells (N-6, 2, and C-1). Production test

information was posted on these logs, but the information is incomplete.

It is not always clear which test results belong to which zone as no

depths are recorded here. Perforation depths are contained in other

documents but there was no time available during this phase to assemble

this information for use in reviewing the logs.

Some flow rates or the fact that there may have been no flow is not

consistently noted. Crossflow between zones is evident as some zones

produce more when isolated than when co-mingled with other zones.

A composite log with the same raw data plus petrophysical computed

results, as well as core porosity and permeability, gas mud log curves,

and pressures and permeability from test results were provided. Some of

the core data appears to be from sidewall cores. Core data for N-2 was

analyzed at surface and at overburden conditions and a listing of this

data was provided. No listings for core data in other wells was found but

values are plotted on the composite logs.

Data from tests is mostly after fracturing or acidizing. Test results

were handwritten on these logs and mimic the information posted on the

raw data plots. A graphical presentation of the sample descriptions is

included on this depth plot. In the four newer wells, this is an

excellent data set and correlates well to the log curves. On the three

older wells, the match varies with borehole condition.

A structure map and cross section with the six field wells was provided.

A crossplot of core porosity vs core permeability was provided. Data was

coded by sand quality but the wells or zones included are not listed. It

is not stated whether the data is from whole core, plug, or sidewall

samples. It is probably from N-2.

Thin section petrographic analysis data for N-3, 4, and 5 describe the

mineral composition and visual porosity for a number of samples. In upper

and middle sands, the volcanic rock fragments compose 30 to 60% of the

clastic material. These are termed heavy minerals in log analysis and

must be accounted for in the log analysis model. The exact definition of

which volcanic minerals are present is not given.

No special core electrical properties or capillary pressure data was

provided. No water resistivity or water chemistry for the area was

provided.

Discussion of

Petrophysical Computations

The petrophysical

computation and display of results for five of the seven wells (N-3, 6,

7, 5, and 4) is excellent, with one major problem, discussed below.

The model appears to use gamma ray and density neutron separation as

shale indicators with the minimum of these two methods being used as the

final shale volume.

Porosity is from a shaly sand crossplot of density and neutron data. This

model does not account for heavy minerals, such as volcanic rock

fragments. Since the PEF curve is available on newer wells, it could be

used to generate a heavy mineral correction. Normally, the same result

can be obtained from the density neutron crossplot in a complex lithology

model, but this is not possible (automatically) in a gas zone due to gas

effect masking the heavy mineral effect.

The heavy mineral correction will raise computed porosity compared to the

present values. The correction could add 1 to 4 porosity units depending

on the existing values of density, neutron, heavy mineral content, and shale

volume. Where porosity is low, this is a significant increase in

reservoir volume. Where PEF is not available, a zoned approach using a

density neutron complex lithology model with a forced matrix density

greater than 2.65 gm/cc will achieve similar results.

Since log analysis porosity is significantly less than core porosity in

almost every cored well, this correction should be attempted. As noted

earlier, some of the core data is from sidewall cores, so core porosity

may be a little too high in these cases. The source of the core data

should be ascertained before a final calibration to core is attempted.

Data from the thin section analysis shows some limonite, an iron rich

mineral. This may affect stimulation success and formation damage while

drilling.

Constraints for rough hole effect on the density neutron calculation were

very well done. There are very few spikes or anomalously high porosity

events on these five wells.

In N-7, the sonic log corrected for shale was used for porosity as the

other curves were missing. Results compare favourably to the other four

wells in this group.

Water saturation was computed from a shale corrected model, but there is

no indication of which model or what RW, temperature, or shale properties

were used. The results are reasonable compared to the porosity of these

sands but are quite low when compared to the permeability. This may be

due to highly deformed pores caused by ductile minerals or infilling with

diagenetic minerals. Saturation values will change only slightly if

porosity is increased with the heavy mineral correction.

Existing thin section results would have to be studied further to gain a

better understanding of the porosity-permeability-saturation

relationship. There is insufficient time allocated in this phase for a

thorough review of the thin section data. Further special core studies

are also needed.

Permeability was calculated from a model that varies with the sample

description. It has been calibrated to the core and the plotted log curve

matches the core very precisely. If log analysis porosity is raised with

the heavy mineral correction, this algorithm will have to be adjusted

slightly to retain the excellent fit to the core shown on these wells.

The exact nature of the permeability transform is not mentioned.

A water saturation cutoff was used on these wells to mark pay zones. The

saturation cutoff varies with the sample descriptions in the range 60 to

80%. There is no evidence that a porosity cutoff was used, but it may

have been, as a 5% cutoff was used in N-4. Choosing a net pay cutoff in

tight, deep gas sands is very difficult and may be impossible. The

cutoffs on these plots are satisfactory for identifying zones of

interest, but there is no way to tell at the moment whether they over or under

estimate gas in place.

The log analysis in N-4 could be improved. There is no water saturation

or permeability curve on the plot. The scale of the BVW curve differs

from the PHIe curve, so the visual interpretation of Sw from these curves

is misleading. A 5% porosity cutoff was used to identify interesting

intervals. This is different than the wells described above. This well

should be recomputed with the same model as the previous five. No flows

are reported on the log plots, so this may be a very poor well, but for

gas in place calculations, it needs to be upgraded.

Well C-1 is off structure and has been computed with somewhat different

model and parameters. The shale beds are not shaly enough, so too much

porosity shows in the shaly sands. Too much porosity shows in cleaner

sands where rough hole conditions affect the results. Permeability is

from a different model than other wells and is based on faulty porosity

data. It cannot be used in its present form. Sample descriptions are poor

due to cavings and there is no core data. These problems make it very

difficult to repair this log analysis, but the attempt should be made if

the well is needed for aquifer assessment.

Recommendations

1. Assemble all core

data, classify as to source (sidewall, whole core, plugs),

and review for consistency and usefulness. Re-plot core

porosity vs core permeability. List and compare thin section

visual porosity to core porosity.

2. Summarize thin section lithology breakdown vs depth

to determine the quantity of heavy minerals and feldspar

present.

3. Identify which heavy minerals are present and determine

their grain density and PEF values. Generate the properties

of a generic heavy mineral that is the average of the

minerals identified.

4. Re-compute log analysis with a complex lithology model

using the PEF curve or a zoned RHOMA value to correct

porosity for heavy minerals. Re-compute N-4 and C-1 with

the same attention to rough hole as the other wells.

5. Adjust permeability transform to compensate for this

change in the porosity model.

6. When better electrical properties or cap pressure data

becomes available, recalibrate water saturation model.

7. Run net pay, hydrocarbon pore volume, and flow capacity

summations for each individual sand body (do not co-mingle

zones) using no cutoffs except shale volume < 50%.

8. Plot these sums vs test results (flow rate) on a crossplot

to see if any trend exists. If there is a trend, it will

assist in choosing cutoffs for net pay. Since the permeability

transform appears to match core very well, the final cutoff

may be permeability.

9. In new wells, add the gamma ray spectral log to the

logging suite. This will allow a better shale volume calculation

and help distinguish feldspathic sands from shaly sands.

It will also eliminate the false indication of shale caused

by uranium salts in the sands.

10. Additional core should be taken in new wells to cover

representative sand bodies from all environments, particularly

those with volcanic rock fragments as a major component.

11. Existing core and chip samples should be re-described,

and new core and chip samples should be adequately described,

to determine which volcanic minerals are present and in

what quantities.

12. Special core analysis to determine electrical properties,

capillary pressure, and relative permeability should be

performed on existing and new core in cores from each

depositional environment. This is needed to calibrate

initial water saturation and residual gas saturation.

13. New cores should be viewed with SEM and thin section

petrography to determine the pore geometry that leads

to such low permeability and low water saturation in moderate

porosity.

Respectfully Submitted

E. R. (Ross) Crain, P.Eng.

Consulting

Petrophysicist

Research

Petrophysics Report

SAMPLE REPORT #4

24 Month 2012

Introduction

We were requested to review the

log and pressure test data on eight wells and to

perform an independent petrophysical and overpressure

analysis.

The

interval of interest is from sea floor to the top

of Chalk or top of Zechstein evaporites if Chalk

is not present. The main pay zones are the Montrose

sands lying above the Chalk.

The

objective of this project is to evaluate the efficacy

of the standard overpressure indicator method based

on sonic log trend line analysis. The approach

is commonly known as the Eaton method, but similar

discussions have been published many years earlier.

Available Data

Log and pressure data for this project

was provided in digital form. Logs consisted of resistivity,

sonic, gamma ray, and caliper over most of the interval,

and density neutron over lower portions of some wells.

Sonic data was missing in one well and had a large

gap in another.

Formation

pressure data for the Montrose were provided for

six wells.

A

report from the client was provided, which contained

discussion and results of their analysis using

the Eaton method on a number of wells.

Method

Digital log curves, pressure data, and

formation tops for the wells were provided by the client.

These were entered into Spectrum 2000 Mindware Ltd's

proprietary log analysis program called Meta/Log. All

log and pressure data were converted to metric units.

Data recorded inside casing was eliminated and some editing

was done to remove spikes.

Shale

volume was determined from the gamma ray log. Porosity

was determined by the sonic log corrected for shale.

The density neutron crossplot porosity was also

calculated where possible. No water saturation

calculation was made. The equations used were:

Neutron

porosity

PHIN = NPHI : fraction

Density

Porosity

PHID = (RHOB-2.65)/(2.65-1.00) : fraction

Sonic

Porosity

PHIS = (DELT-182)/(656-182) : fraction

Shale

Volume

Vsh = MIN(1,MAX(0,((GR-GRcl)/(GRsh-GRcl)))) : fraction

Effective

Porosity

PHIe = MIN(0.3*(1-VSH),MAX(0,0.5*(PHIN-VSH*0.28+PHID-VSH*0.05))) :fraction

GRcl

and GRsh were chosen uniquely for each well.

These

results were used to determine shale beds suitable

for analysis of overpressure by the Eaton method.

Data below the zone of interest (Montrose) was

deleted from the working files after this analysis

step.

The

calculation steps for the Eaton method are listed

below:

Actual

shale travel time

DELTsh = IF(VSH>0.5,DELT,100) : us/m

Normal

shale travel time compaction trend line

DTnorm = 10^(Log(3.281*175)-((DEPTH/3000)*(Log(175*3.28)-Log(100*3.28)))) :us/m

Difference

between actual and normal sonic values

DTdiff = MAX(0,+DELTSH-DTNORM) : us/m

Overburden

pressure

SOV = (Ln(DEPTH-EKB)-0.5185)/3.47 : gm/cc

Shale

Pore Pressure as a gradient

SPP = SOV-(SOV-1)*(MIN(1,DTNORM/DELT))^3 : gm/cc

Shale

pore pressure as head of water

SPP-M = (SPP-1)*(DEPTH-EKB) : head in meters

Shale

pore pressure as a pressure

PRESsh = 9.81*(SPP-M+DEPTH-EKB) : KPa

RFT

pressure from lookup table

RFTPRES = VLOOKUP(DEPTH,PRESSURE_TABLE,2)*6.89 : KPa

RFT

pressure as a head of water

RFTHEAD = MAX(0,-DEPTH+EKB+RFTPRES/9.81) : head in meters

DTnorm

is the sonic trend line chosen in a shallow shale

zone to represent the normal compaction trend.

The position and slope of this line is very subjective.

The line finally chosen is very similar to the

line used by the client. My first pick fits the

sonic log better but gave less overpressure than

my final pick. There is, in fact, very little valid

sonic data in the shallow sequence to which a line

can be fitted. Depth plots of both my initial and

final lines, along with the sonic log curves for

7 wells, are provided under separate cover. The

final line was picked to account for actual mud

weights used to maintain the holes and to approximate

actual Montrose reservoir pressures at the top

of the gas/oil column.

SOV

is the overburden stress. This equation varies

from place to place. It was supplied by the client

and is assumed to be suitable for this region of

the North Sea. SPP is the shale pore pressure from

the Eaton equation. It is converted to meters of

head of water (SPP-M) and to pressure in KPa (PRESsh).

For comparison, the RFT pressures for any depth

were found in a lookup table (psi) and converted

to head in meters and pressure in KPa.

Depth

plots at 1:10,000 scale were made of all these

results plus the raw log data. A lithology track

was created from the Vsh curve and a depth function

related to the formation name. Thus sandstone,

limestone (chalk), anhydrite, and salt were shown

where appropriate.

Results

Results are contained in the depth plots

supplied under separate cover. There is little difference

between this work and the client's work. We have added

pressure vs depth curves to the plots as these are

sometimes easier to visualize than head of water curves.

The

final compaction trend line was chosen as a compromise.

The initial choice generated very little overpressure,

yet mud weight data supplied by the client suggested

higher pressure results were needed to account

for the mud weights actually used. The final choice

was arrived at after several iterations. The final

trend gives shale overpressure values close to

actual mud weight gradients and close to actual

formation pressures at the top of the Montrose

structure.

Matching

the actual Montrose pressure is not a requirement

of the method. A normally pressured shale is sufficient

to act as a seal, even for the relatively high

buoyancy caused by the large oil and gas column.

It should be noted that none of the Montrose data

shows significant overpressure in the reservoir.

The pressures are close to those expected for the

hydrocarbon buoyancy.

Conclusions

There are many unknowns and assumptions

in log analysis for overpressure. These include the

subjective nature of the normal compaction trend line,

the lack of control on parameters in the SOV and SPP

equations, and the variable silt content within the

shale itself.

The

effect of a gas phase in porosity within the silt

component of the shale cannot be accounted for,

even if it were known to be present. Invasion by

drilling fluid removes most of the gas from the

region seen by the sonic log, so the effect should

be very small. A well log model study could be

undertaken to assess the magnitude of gas effect.

Gas leaking through fractures would probably not

influence this method. If the other unknowns described

in the previous paragraph could be calibrated,

it is unlikely that gas in the silt would pose

additional problems, but the model study suggested

above would quantify this.

It

should be noted that the seismic signal may be

influenced by gas in porosity in the silty shales

or in fractures. Seismic studies for detection

of overpressure may be compromised by this effect,

while the sonic log is not.

The

validity of the Eaton method for calculation of

shale pore pressure has not been proven, since

there are no actual pressure data points within

the shale interval that can be used for calibration.

Recommendations

Results from the Eaton method should

be used only as an indicator of possible overpressured

shales.

Results

should not be used as a quantitative measure of

the amount of overpressure.

Further

work is required from this specific area to validate

the overburden stress (SOV) formula, on which the

Eaton method depends.

Pressures

must be acquired from stray sands within the overpressured

shales to calibrate the terms in the Eaton equation

for SPP and to validate the normal compaction curve

(DTnorm) for use in this specific area..

There

is no reason to believe that the parameters in

these equations are universal constants and they

need confirmation from this area to be used reliably

in this area.

Respectfully Submitted

E.

R. (Ross) Crain, P.Eng.

Consulting

Petrophysicist

|