|

Calibrating Porosity to Core

Data

Calibrating Porosity to Core

Data

The proof of a log analysis is the degree to which the porosity

matches core analysis porosity. The easiest way to check this

is to plot the core analysis porosity on top of the log analysis

on the same depth plot. If the overlay is quite good, no more needs to be done except show off the comparison

and brag a bit. If the core is off depth to the log porosity,

shift the core depths appropriately and re-display the results.

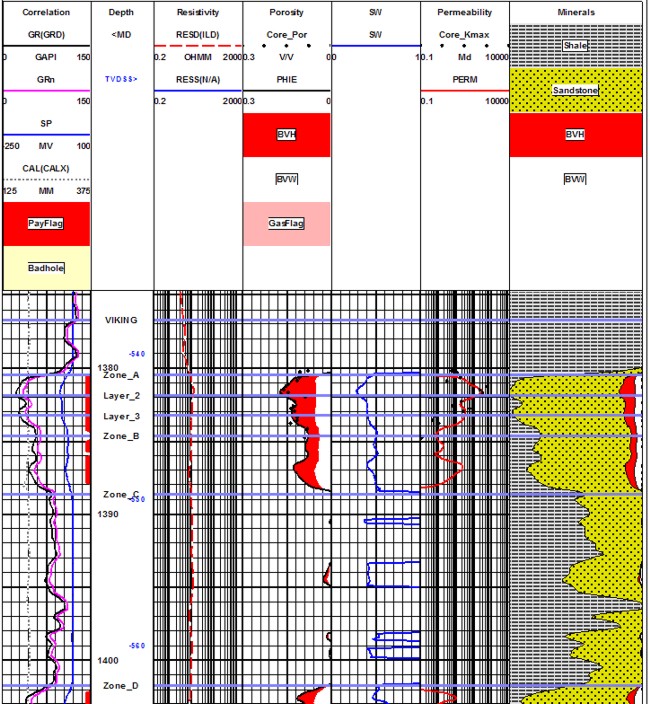

Comparison of Core Porosity with Log Analysis Porosity -

black dots are

core, smooth lines are log analysis.

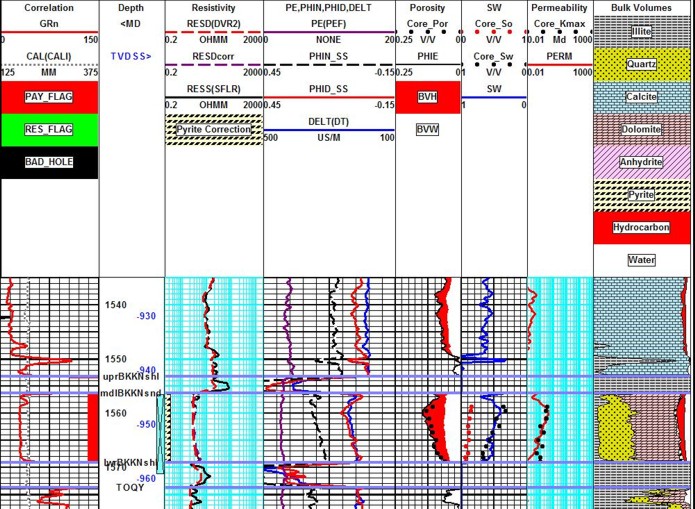

Bakken “Tight Oil” example showing core porosity (black dots), core oil saturation (red dots).

core water saturation (blue dots), and permeability (red dots). Note

excellent agreement between log analysis and core data. Separation

between red dots and blue water saturation curve indicates

significant moveable oil, even though water saturation is relatively

high. Log analysis porosity is from the complex lithology model and

lithology is from a 3-mineral PE-D-N model using quartz, dolomite

and pyrite.

If

the comparison is poor, there are three choices. First make sure

the core data is on depth with the logs and that each log curve

is on depth with each other.

CHOICE 1

(preferred): Adjust shale, matrix, and fluid parameters

in the log analysis model until a better match is achieved. This

may take several attempts and may require choosing a different

mathematical model or mineral assemblage.

CHOICE 1

(preferred): Adjust shale, matrix, and fluid parameters

in the log analysis model until a better match is achieved. This

may take several attempts and may require choosing a different

mathematical model or mineral assemblage.

CHOICE 2: Crossplot core porosity vs log analysis porosity, and

find a regression line that corrects the log result to the core,

of the form:

CHOICE 2: Crossplot core porosity vs log analysis porosity, and

find a regression line that corrects the log result to the core,

of the form:

1: PHIcorr = K1 * PHIe + K2

Where:

PHIcorr = corrected porosity (fractional)

PHIe = effective porosity (fractional)

K1 = slope of regression line

K2 = intercept of regression line

The regression should be the reduced major axis (RMA) method (see

and not a simple least squares regression. RMA

assumes errors occur in both axes and not just in the Y axis data.

An eyeball line may be best as stray outliers can be discarded

quickly. The before and after crossplots can be used to document

the change. Do not use the regression unless the error is reasonably

low (R-squared > 0.8 or so).

CAUTION: Core data must be depth

matched to logs before you do this. And some core data is faulty

or not spread across a wide enough range of values. Porosity or

shale laminations thinner than the tool resolution cause a fair

scatter on crossplots and depth plots. There is no direct

solution to obtain a better match except to match average

porosity from log analysis with average porosity from the core.

CHOICE 3: Perform the regression on a single input log curve instead

of on PHIe, or separately on several curves. Pick the regression

with the least standard deviation or highest R-squared. This creates

a new log analysis model that may be used locally instead of the

universal methods described in this Chapter.

CHOICE 3: Perform the regression on a single input log curve instead

of on PHIe, or separately on several curves. Pick the regression

with the least standard deviation or highest R-squared. This creates

a new log analysis model that may be used locally instead of the

universal methods described in this Chapter.

You might need a multi-variant regression to account for all the

minerals and fluids, or even a Principal Components analysis to

obtain a statistical solution.

It

is also common to calibrate simple log analysis porosity methods to crossplot

methods, which in turn might be calibrated to core, by overlay plots or regression. The calibration

can then be carried to wells that do not have sufficient data

for crossplot analysis.

Calibrating Porosity to PETROGRAPHIC

Data

Calibrating Porosity to PETROGRAPHIC

Data

There are many occasions when core analysis porosity is not available

for calibration of log results. The next best data set is petrographic

thin section visual porosity analysis. This usually excludes micro-porosity

so a regression of thin section porosity vs log analysis porosity

will give useful porosity (PHIuse) instead of PHIe. Most people

like this result. Thin sections can often be made from sample

chips when no core exists. Thin section samples are tiny and it

is sometimes difficult to scale-up these results to the whole

reservoir. A large number of samples in varying facies can give

statistically meaningful results. A few samples are probably useless.

|

|

15X

Magnification |

100X

Magnification |

|

Thin Section Images |

| |

Depth,

ft. |

9403.70 |

9407.00 |

9413.50 |

9419.20 |

Porosity

@ NOB (%) |

12.4 |

8.2 |

10.9 |

5.0 |

Air

Perm. @ NOB (md) |

0.296 |

0.034 |

0.338 |

0.0054 |

Grain

Density (g/cc) |

2.81 |

2.83 |

2.82 |

2.79 |

PRIMARY

MINERAL |

|

|

|

|

Dolomite |

60.0 |

81.2 |

80.0 |

79.6 |

Calcite |

Tr |

0.0 |

0.0 |

0. |

Anhydrite |

1.2 |

0.4 |

0.8 |

0.0 |

Pyrite |

2.0 |

1.6 |

1.6 |

1.6 |

Quartz |

0.0 |

0.0 |

0.0 |

0.0 |

Feldspar |

0.0 |

0.0 |

0.0 |

0.0 |

Authigenic

Clay |

0.0 |

0.0 |

0.0 |

0.0 |

Bitumen |

0.0 |

0.0 |

0.0 |

0.0 |

Other |

0.0 |

0.0 |

0.0 |

0.0 |

Total |

63.2 |

83.2 |

82.4 |

81.2 |

SILCLASTICS |

|

|

|

|

Mono

Quartz |

8.8 |

2.0 |

4.4 |

7.2 |

Poly

Quartz |

0.0 |

0.0 |

Tr |

0.0 |

Plagioclase |

2.0 |

0.8 |

0.8 |

1.6 |

Potassium

Feldspar |

3.6 |

1.2 |

0.8 |

3.2 |

Chert |

0.0 |

0.0 |

0.0 |

0.0 |

Rock

Fragments |

0.0 |

0.4 |

0.0 |

0.0 |

Shale

Fragments |

0.0

|

Tr |

0.0 |

0.0 |

Muscovite |

Tr |

0.4 |

0.0 |

Tr |

Biotite |

2.0 |

0.8 |

0.0 |

0.0 |

Heavy

Minerals |

0.0 |

Tr |

0.0 |

0.4 |

Carbonaceous

Fragments |

1.2 |

0.4 |

Tr |

Tr |

Glauconite |

0.0 |

0.0 |

0.0 |

0.0 |

Detrital

Clay Matrix |

3.2 |

1.6 |

1.6 |

1.2 |

Other |

0.0 |

0.0 |

0.0 |

0.0 |

Total |

20.8 |

7.6 |

7.6 |

13.6 |

POROSITY |

|

|

|

|

Primary

Interparticle |

0.0 |

0.0 |

0.0 |

0.0 |

Primary

Intraparticle |

0.0 |

0.0 |

0.0 |

0.0 |

Secondary

Intraparticle

(Carbonate Grains) |

0.0 |

0.0 |

1.2 |

0.0 |

Tertiary

Intraparticle

(Carbonate Grains) |

0.0 |

0.0 |

0.0 |

0.0 |

Secondary

Intraparticle

(Siliciclastic) |

Tr |

0.0 |

Tr |

0.0 |

Vugular |

0.0 |

0.0 |

Tr |

0.0 |

Intercrystalline |

16.0 |

9.2 |

8.4 |

3.6 |

Micropores |

0.0 |

0.0 |

0.0 |

0.0 |

Fracture |

0.0 |

0.0 |

0.4 |

0.8 |

Secondary

Intracrystalline |

Tr |

Tr |

0.0 |

0.4 |

Total |

16.0 |

9.2 |

10.0 |

5.2 |

|

|

|

|

|

|

100.0 |

100.0 |

100.0 |

100.0 |

Typical Thin Section Point Count Analysis with

primary, secondary, and non-useful porosity breakdown

Not all thin section reports are as detailed as this one. Scanning

electron micrograph data (SEM) is also widely used, in the same

way as thin section data.

Calibrating Porosity to SAMPLE

DESCRIPTIONS

Calibrating Porosity to SAMPLE

DESCRIPTIONS

Porosity ranges as seen by microscopic examination of samples

are also used as a guide. This may be useful in the absence of

more quantitative data or where rough hole conditions make log

analysis ambiguous. The black bar graph in the illustration

below shows visual

porosity spanning three ranges. Log analysis should at least see

porosity in the same zones and somewhat in proportion to the variations

in visual porosity values.

Sample Description Log with Microscopic Visual Porosity

(black bar graph in center of plot)

|