|

POROSITY BASICS

POROSITY BASICS

There are many petrophysical models for

calculating poroosity from well logs. For a summary, see

Crain's Usage Rules for Selecting

Porosity Methods.

Porosity is the volume of the non-solid portion of the rock filled

with fluids, divided by the total volume of the rock. Primary porosity is the porosity developed by the original sedimentation

process by which the rock was created. In reports, it is often

referred to in terms of percentages, while in calculations it

is always a decimal fraction.

Secondary porosity is created by processes other than primary

cementation and compaction of the sediments. An example of secondary

porosity can be found in the solution of limestone or dolomite

by ground waters, a process which creates vugs or caverns. Fracturing

also creates secondary porosity. Dolomitization results in the

shrinking of solid rock volume as the material transforms from

calcite to dolomite, giving a corresponding increase in porosity.

Log

analysts define porosity somewhat differently, due to the nature of

the measuring techniques. These definitions are described later in

this Chapter.

POROSITY IN SANDSTONES

POROSITY IN SANDSTONES

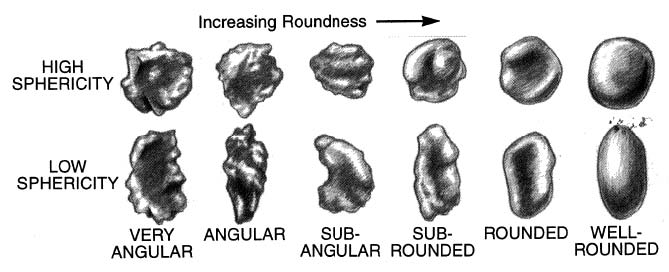

We tend to think of sandstones as being composed of

quartz grains, but this is a false impression based on too many

idealized cinematic beaches and cast-away island songs. Most

sandstones are made of many different minerals; some have no quartz

at all. So in the following discussion, please think of sand grains

as being composed of a variety of minerals, not necessarily pure

quartz.

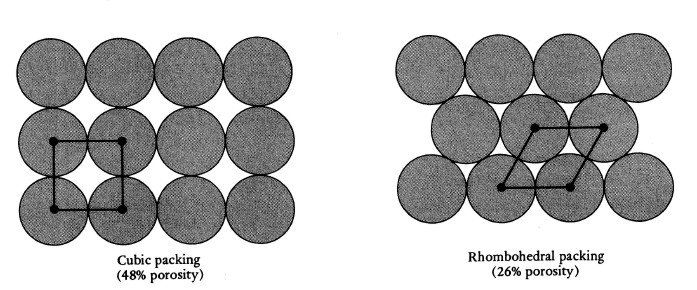

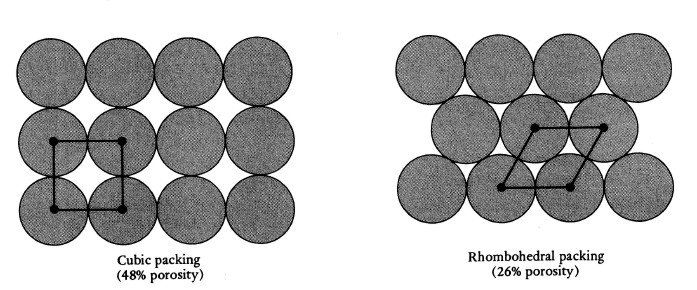

To acquire an appreciation for the values of porosity generally

encountered, assume round balls of the same size are stacked on

top of each other in columns. Calculations will show a porosity

of 47.6%. Spherical sand grains 1/10 the size of the balls stacked

one on top of the other will have the same porosity, 47.6%.

If the same balls are packed in the closest possible arrangement

in which the upper ball sits in the valley between the four lower

balls, the porosity is reduced to 25.9%. Again,

changing the size of the balls will not change the porosity as

long as all the balls are the same size.

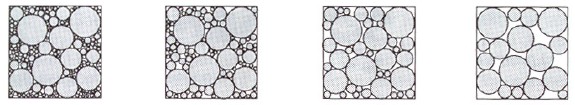

Cubic packing 47% porosity (left) Rhombic packing 26%

porosity (right)

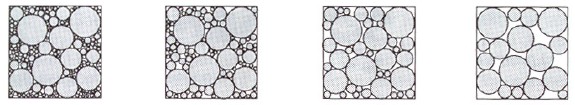

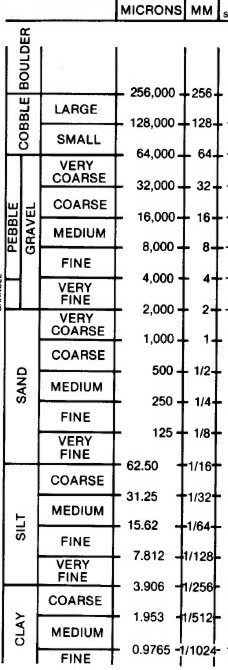

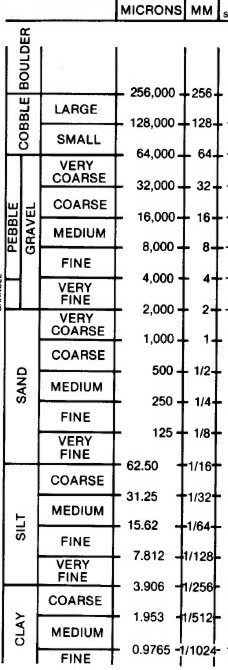

Mixing the sizes of the balls will create lower

porosity, since small ones can fit in spaces created between the

larger ones. The term "sorting" is used to describe the distribution

of grain sizes in a sandstone. Very well sorted rocks have fairly

uniform grain size and high porosity. Poorly sorted sands have a

wide range of grain size and poor porosity, illustrated below. Grain

size classifications are shown on the scale at right, below.

Poorly Sorted

Moderately Sorted

Well Sorted

Very Well Sorted

Low Porosity

Poor Porosity

Good Porosity

Excellent Porosity

The highest porosity

normally anticipated is 47.6%. A more probable

porosity is in the mid-twenties. The normal range of porosities

in granular systems is 5% to 35%. The highest porosity

normally anticipated is 47.6%. A more probable

porosity is in the mid-twenties. The normal range of porosities

in granular systems is 5% to 35%.

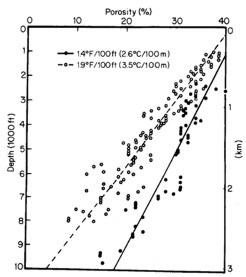

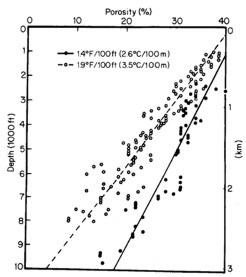

In general, porosities tend to be lower in deeper and older rocks.

This decrease in porosity is primarily due to overburden

stresses on the rock, and cementation. There are many exceptions

to this general trend, when normal overburden conditions do not

prevail.

Shales closely follow the same porosity depth trend as

sandstones. For example,

in a recent mud the porosity may measure about 40%. It decreases

rapidly with depth and overburden pressure until, at a depth of

about 10,000 feet, normal porosities are less than 5%. Shales

are plastic and therefore, compress more easily than sands.

These basic trends of porosity versus depth are not as noticeable

in carbonates, where porosity is more a function of depositional

environment and secondary processes, both unrelated to depth of

burial.

Porosity in a real shale is not effective; that is, the water cannot

move as quickly as in a sandstone with the same apparent porosity.

Water in shale can be expelled over large geologic time periods,

but it will not flow in the usual sense of the word.

However, many

intervals that have been traditionally thought of as "shale" are

really silty shales or sandy shales. These may have sufficient

porosity to store hydrocarbons that might flow. This is especially

true for gas, and many "gas shales" are silty shales with effective

porosity. Other gas shales are mostly shale and gas is stored on the

surface of kerogen within the shale. This is adsorbed gas.

Laminated shaly sands are also called gas shales in some literature.

While they are definitely shaly and contain gas, the petrophysical

model is quite different from gas shales or gas silts, so the

"laminated" adjective should be retained.

Porosity in shaly

sands varies with the amount and distribution of the clay minerals

within the sandstone. The common distributions and their effect on

porosity are shown below.

The Effect of Clay distribution on Porosity in a Shaly Sand.

Sand grains are yellow, effective

porosity is blue, and clay (including clay bound water) is coloured black.

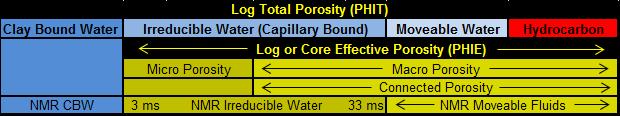

For log analysis

purposes, we define total porosity as the pore space (blue area in

above illustration) plus the clay bound water (part of the black

shading). Effective porosity is defined as the total porosity minus

the clay bound water (blue area only). Further adjustments are

sometimes made to generate useful or connected porosity, which

excludes clay bound water and any unconnected pores, such as

pin-point vugs or isolated pores inside the sand grains.

POROSITY IN CARBONATES

POROSITY IN CARBONATES

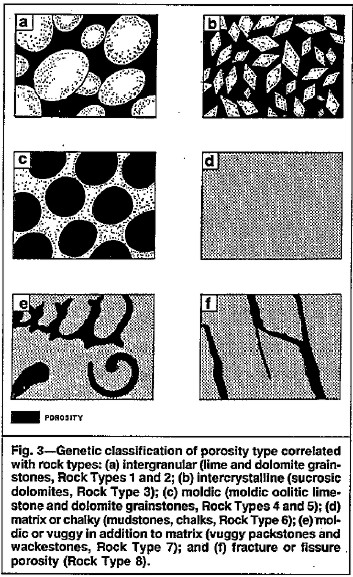

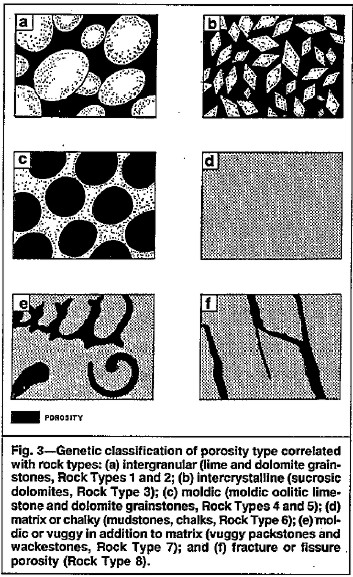

Porosity in

carbonates is more complicated than in sandstones, partly due to

various classification methods and more combinations of carbonate

fabric and associated porosity. Most of the porosity that is useful

in carbonate reservoirs is secondary porosity, formed after

deposition.

The use of the term, Secondary Porosity Index (SPI) by log analysts

has led to much confusion. The term means the porosity defined

by the difference between porosity derived from the sonic log

and the primary porosity. The primary porosity is usually defined

by core analysis or the density neutron log. Depending on the

shape and size of the vugs, fractures, or caverns, the SPI may

or may not be a good indication of secondary porosity.

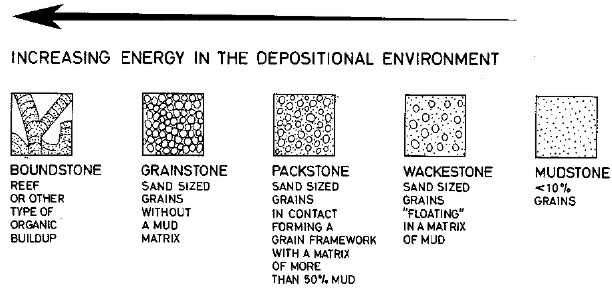

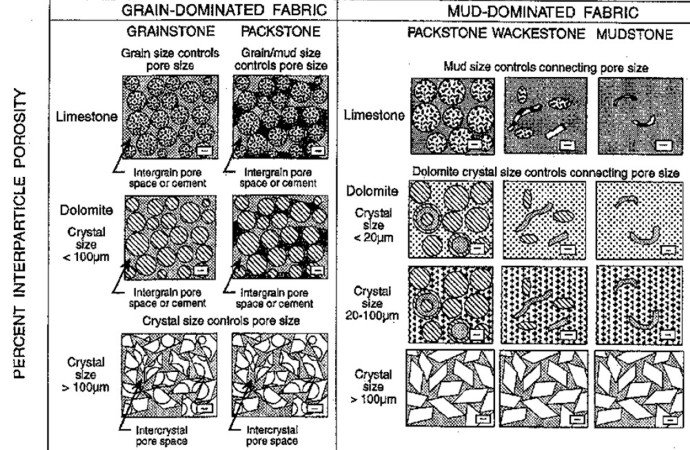

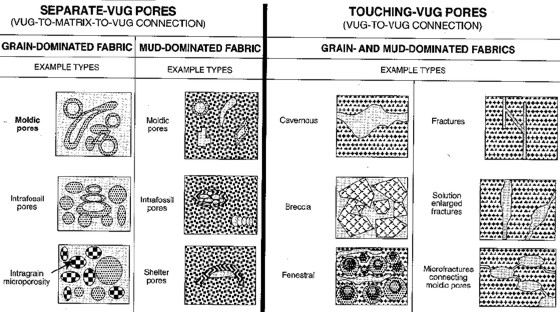

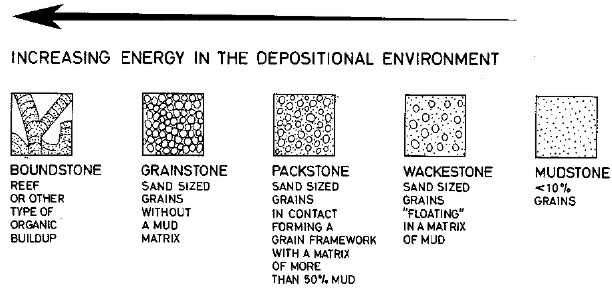

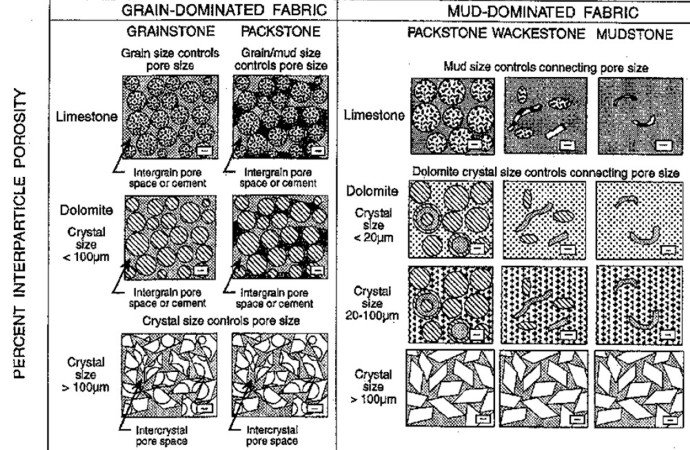

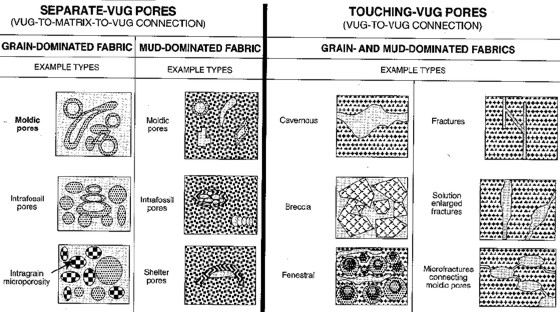

Below

are three different classification methods for carbonate porosity.

Sample descriptions of the same rock will vary, depending on the

wellsite geologist's age, training, and current knowledge of the

geological literature. Dunham's method is the oldest and simplest,

followed by Choquette's method, then by Lucia's, which is by far the

most complex but most complete.

Porosity classifications vary according to the authority cited -

this is Choquette's system

and is widely used.

Dunham's classification of carbonate textures - these are

independent of the porosity classification

Lucia's classification of carbonates, expanding Dunham's

classification to include porosity type

Lucia's classification extended to

cover connected and unconnected vuggy porosity types

Useful Porosity

Useful Porosity

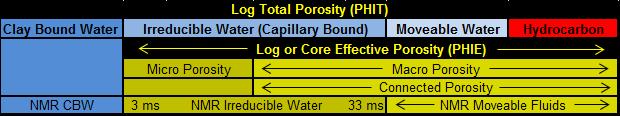

There is a recent trend among petrophysicists and engineers to

partition porosity into a useful and a non-useful fraction. The

concept of useful porosity, as opposed to effective porosity,

is helpful where very small pores exist. These tiny pores do not

connect to other pores and thus do not contribute to useful reservoir

volume or reservoir energy. They are invariably water filled and

nothing flows from them or through them. The tiny pores are called

micro porosity; the larger, more effective, pores are called macro

porosity. Personally, I prefer the term connected and

unconnected (or poorly connected) porosity, as illustrated

below:

Porosity definitions related to

useful or connected porosity. Some micro porosity may not be

observed in conventional core analysis. Most porosity indicating

logs see unconnected porosity, but the sonic log may not see any or

all of the microporosity.

Thus:

1: PHIuse = PHIe - PHImicro

In sandstones, micro porosity is often associated with

intraparticle porosity in volcanic

rock fragments and kaolinite that are part of the sandstone mineral mixture.

In carbonates, micro porosity is associated with micrite, matrix,

fossil skeletons, or pin point vugs. Larger vugs are often

connected.

The quantity of micro porosity cannot always be found directly

from logs but is usually assessed as a constant fraction, KM1,

of the effective porosity. This constant can be found by examination

of thin section visual porosity. Where micro porosity is associated

with silt or a volcanic mineral (Vmin2) in a quartz sandstone:

2: KM1 = Vsilt / (Vqrtz + Vsilt)

OR 2A: KM1 = Vmin2 / (Vqrtz + Vmin2)

3: PHIuse = PHIe * KM1

In some cases, the micro porosity is assumed to be a constant

value instead of a constant fraction of the silt volume, PHIoffset, over an interval (ie, PHImicro is not proportional

to effective porosity). This appears to happen in carbonates with

unconnected pinpoint vugs (PHIppv), micritic carbonates (PHImict),

or carbonates with matrix porosity (PHImatr). In all three cases,

PHIoffset is found by comparing visual porosity in thin sections

to log analysis porosity.

4: PHIuse = PHIe - PHIoffset

In log analysis terminology, matrix porosity usually means effective

porosity (PHIe). However, in petrographic (thin section) analysis,

matrix porosity (PHImatr) is non-useful porosity contained in

the very fine-grained matrix material deposited between the granular

or crystalline rock structure.

PHIppv, PHImict, and PHImatr may be varied according to rules

developed by the analyst for the zone. A crossplot of visual porosity

from thin section analysis versus PHIe from logs is a useful tool

for determining the appropriate correction to obtain PHIuse. Typical

rules might be:

5: PHIuse = PHIe - PHIsec

6: PHIuse = PHIsec

7: PHIuse = PHIe - KMATR * (1 - PHIe) / (1 - KMATR)

8: PHIuse = PHIe - PHIsc * KMICT / PHISavg

KMATR and KMICT would be in the range 0.01 to 0.08, averaging

0.04, and cannot exceed PHIt.

Definitions

of Porosity FOR LOG ANALYSIS PURPOSES Definitions

of Porosity FOR LOG ANALYSIS PURPOSES

The above discussion covers the geological definitions of porosity.

Petrophysicists, log analysts, and engineers use more specific

terms based on the concept of total and effective porosity. Here are the definitions:

|

DFN

1: |

The

formation rock/fluid model is comprised of: |

| |

-

the matrix rock (Vrock) |

| |

-

the pore space (or porosity) within the matrix rock (PHIe) |

| |

-

the shale content of the matrix rock (Vsh) |

| |

|

| By

definition, Vrock + PHIe + Vsh = 1.00 |

| |

|

|

DFN

2: |

The

matrix rock component (Veock) can be subdivided into two or

more constituents |

| |

(Vmin1,

Vmin2, ...

), such as: |

| |

-

limestone, dolomite, and anhydrite or |

| |

-

quartz, calcite cement, and glauconite |

| |

|

| The

mineral mixture can be quite complex and log analysis may

not resolve all constituents. |

| |

|

|

DFN

3: |

The

shale component (Vsh) can be classified further into: |

| |

-

one or more clays (Vcl1, Vcl2, … ) |

| |

-

silt (Vsilt) |

| |

-

water trapped into the shale matrix due to lack of sufficient

permeability to allow the water to escape |

| |

-

water locked onto the surface of the clay minerals |

| |

-

water absorbed chemically into the molecules of the clay minerals |

| |

|

| The

sum of the three water volumes is called clay bound water

(CBW). CBW varies with shale volume and is zero when Vsh =

0. |

| |

|

| By

definition, Vsh = Vcl + Vsilt + CBW |

| |

|

|

DFN

4: |

Bulk

volume water of shale (BVWSH) is the sum of the three water

volumes listed |

| |

above

in the definition of shale and is determined in a zone that

is considered to be |

| |

100%

shale.

|

| |

|

| By

Definition, CBW = BVWSH * Vsh |

| |

|

|

DFN

5: |

Total

porosity (PHIt) is the sum of: |

| |

-

clay bound water (CBW) |

| |

-

free water, including irreducible water (BVW) |

| |

-

hydrocarbon (BVH) |

| |

|

| Some

of the “free water” is not free to move - it is,

however, not “bound” to the shale. It could also

be called pore water. |

| |

|

|

DFN

6: |

Effective

porosity (PHIe) is the sum of: |

| |

-

free water, including irreducible water (BVW) |

| |

-

hydrocarbon (BVH) |

| |

|

|

DFN

7: |

Effective

porosity is the porosity of the reservoir rock, excluding

clay bound water |

| |

(CBW).

|

| |

PHIe

= PHIt - CBW |

| |

OR

PHIe = PHIt - Vsh * BVWSH |

| |

|

|

DFN

8: |

Free

water (BVW) is further subdivided into: |

| |

-

a mobile portion free to flow out of the reservoir (BVWm) |

| |

-

an immobile or irreducible water volume bound to the matrix

rock by surface tension (BVI or BVWir) |

| |

|

| BVI

is sometimes called “bound water” or "capillary

bound water", but this is confusing (see definition of

clay bound water above), so “irreducible water”

is a better term. |

| |

|

|

DFN

9: |

Hydrocarbon

volume (BVH) can be classified into: |

| |

-

mobile hydrocarbon (BVHm) |

| |

-

residual hydrocarbon (BVHr) |

| |

|

|

DFN

10: |

Free

fluid index (FFI) is the sum of BVWm, BVHm, and BVHr. It is

also called moveable |

| |

fluid

(BVM)

or useful porosity (PHIuse).

|

| |

PHIuse

= BVM = FFI = BVWm + BVHm + BVHr |

| OR |

PHIuse

= PHIe - BVI |

| OR |

PHIuse

= PHIe * (1 - SWir) |

| |

|

| This

definition is needed for older nuclear magnetic logs since

they could not see BVWir. |

Non-useful

porosity occurs as tiny pores that do not connect to any other

pores. They are almost invariably filled with immoveable water

and do not contribute to useful reservoir volume or energy. Such

pores occur in silt, volcanic rock fragments in sandstones, and

in micritic, vuggy, or skeletal carbonates. The NMR may see some

of this non-useful porosity; the jury is still out.

POROSITY INDICATING LOGS

POROSITY INDICATING LOGS

There

are numerous porosity indicating logs, as shown in the box at

right, and many flavours of each, depending on the age, design,

and logging environment. Generic analysis equations, based on

the Log Response Equation, for each basic tool type are contained

in this Chapter. They will work for almost all available tool

types. There may be rare occasions when a customized analysis

model might be required. There

are numerous porosity indicating logs, as shown in the box at

right, and many flavours of each, depending on the age, design,

and logging environment. Generic analysis equations, based on

the Log Response Equation, for each basic tool type are contained

in this Chapter. They will work for almost all available tool

types. There may be rare occasions when a customized analysis

model might be required.

All the porosity models require some assumptions about such things

as fluid type and matrix rock properties. With the exception of

the resistivity log formula, used for analysis of ancient logs,

the methods involve corrections for the effects of shale.

Various methods are presented in other sections of this Handbook to calculate porosity from

individual or combinations of two or more logs. Two-log combinations

are termed crossplot methods, since the log data can be plotted

on the X and Y axes of a graph.

Three or more log combinations require solution by simultaneous

equations, and are usually done on a computer.

Shale corrections are applied to porosity logs to determine effective

porosity. Since shale contains some water, this water must be

subtracted from the total porosity as measured by conventional

logging tools. The mathematical method for finding shale volume

is the same for all the shale distribution types, but the method

for applying the shale correction to the porosity varies.

Correcting for shale is only half the battle. The other half is

to correct for the mineral composition of the rocks. In most carbonate

reservoirs, the lithology is usually reasonably well known from

sample descriptions or can be determined from log response, so

this step is relatively straightforward.

This is not true in sandstones because the mineral makeup of the

sand is NOT usually described in much detail. There is a universal

trend to give sandstones the physical properties of pure quartz,

but this is almost universally NOT appropriate. Most sandstones

contain other minerals besides quartz, such as mica, volcanic rock fragments,

calcite, dolomite, anhydrite, and ferrous minerals, as well as

the shale and clay described above. All of these minerals have

different log responses than quartz.

If a sandstone is assumed to be pure quartz when it is not, the

commonly used properties of quartz will provide a pessimistic

porosity answer.

Thus, authors and service company manuals that present quartz

properties for “sandstone” are misleading their audience

into believing these properties are constant. In more than 40

years of petrophysical analysis, I have never seen a thin section

or XRD report that gave an assay of 100% quartz in any petroleum

reservoir. A 100% quartz sand is very rare. If anyone doubts this

statement, look at the PEF curve. If it reads more than 1.8, you

have “quartz plus other things” in your sandstone.

There is a story (it may even be true) that reserves for the early

North Sea discoveries were seriously underestimated because the

mica in the sands was not accounted for properly. The engineers

used density log porosity without correcting for the real matrix

density. If true, good engineering practice would have undersized

all the offshore equipment and early cash flow and rate of return

on investment would have been significantly reduced. If the myth

that sandstone is pure quartz is perpetuated, there will be more

economic blunders of this type.

To further confuse the uninitiated, many logs show data on a "porosity"

scale. These log curves are transforms of some measured physical

property to an approximate porosity based on some arbitrary parameters.

Examples are density, neutron, or sonic porosity on so-called

Sandstone, Limestone, or Dolomite porosity scales. Porosity as

defined by these transforms is only directly useful if there is

no shale, the scale matches the rock mineralogy. and there are

no accessory minerals. Real reservoirs are rarely this simple.

DO NOT use these porosity transforms without further analysis

unless all the arbitrary assumptions used to create them match

exactly the rock you are analyzing.

Some people call these porosity curves an “interpretation”.

They are not. They are merely a transform of the raw data to a

more attractive scale. The difference between a transform and

an interpretation is critical. Interpretation infers some intelligent

thought went into creating and understanding the result. The service

company running the log does not provide interpretations. YOU

are the interpreter,

There are endless cases where a transform to an inappropriate

porosity scale has caused millions in losses due to poorly informed

analysts who see “gas cross over” when there is no

gas, or who read porosity directly from the transform and either

seriously over estimate or under estimate reservoir effective

porosity.

In spite of these comments, a number of charts and tables in this

Handbook show the word "sandstone'

when they really should say "quartz". I have not edited

the charts and tables taken from common sources, such as service

company chart books, so the common usage of incorrect terminology

is repeated even here.

|

The highest porosity

normally anticipated is 47.6%. A more probable

porosity is in the mid-twenties. The normal range of porosities

in granular systems is 5% to 35%.

The highest porosity

normally anticipated is 47.6%. A more probable

porosity is in the mid-twenties. The normal range of porosities

in granular systems is 5% to 35%.

There

are numerous porosity indicating logs, as shown in the box at

right, and many flavours of each, depending on the age, design,

and logging environment. Generic analysis equations, based on

the Log Response Equation, for each basic tool type are contained

in this Chapter. They will work for almost all available tool

types. There may be rare occasions when a customized analysis

model might be required.

There

are numerous porosity indicating logs, as shown in the box at

right, and many flavours of each, depending on the age, design,

and logging environment. Generic analysis equations, based on

the Log Response Equation, for each basic tool type are contained

in this Chapter. They will work for almost all available tool

types. There may be rare occasions when a customized analysis

model might be required.