|

CUMULATIVE FLOW CAPAcITY BASICS

CUMULATIVE FLOW CAPAcITY BASICS

Flow capacity is the product of permeability and reservoir

interval thickness: KH = Perm * THICK. The result is

measured in mD-feet or mD-meters. When summed across a

reservoir and normalized between 0 and 100%, it is called

the cumulative flow capacity or KH% curve. Flow capacity

translates directly into estimated productivity and

ultimately into cash flow.

The KH% curve is plotted versus depth on a scale of 0 to

100%, accumulated from the base of a reservoir to the top.

Thus the curve will gradually shift to the right as KH%

increasers upward.

There will be portions of the curve that are nearly vertical

and other portions with a slope toward higher KH%. Vertical

intervals show zones that failed cutoffs or with

insignificant flow capacity. Intervals showing slope on the

KH% curve are the best candidates for completion,

stimulation, or horizontal well placement. Intervals with a

vertical KH% curve are not good candidates for further

expenditures, regardless of their other apparent "good"

qualities..

The KH% curve will have the same shape as a spinner

flowmeter survey

on a production log. Since spinner surveys are not possible

in wells that cannot flow continuously to surface (eg.

pumping oil wells or uncompleted wells), the KH% curve may

be the only indicator of production potential in such wells.

It is also very much less expensive than a spinner survey or

a poorly planned completion.

Completing a well for production is a balancing act between

completion costs and production optimization. A high

quality petrophysical analysis that includes a permeability

calculation is a first step. The cumulative flow capacity (KH%)

curve, derived from that permeability, can help you make decisions about where to

complete the well, or where to place a horizontal well.

PERFORATION OPTIMIZATION

PERFORATION OPTIMIZATION

To save money, we try to minimize the perforation interval,

consistent with obtaining the maximum oil or gas production

rate, with minimum water or gas cap production. This usually means

perforating from the top of net pay to some deeper depth

within the net pay, omitting any intervals where the pay

flag is not turned on.

If there is a water contact in the reservoir, the lower depth

of the perfs should be as far above the contact as reasonably possible.

Aquifer influx will push oil up to the perfs over time. If

there is a gas cap, it is normally preserved until the oil

is produced, so the perfs are placed somewhat below the gas

cap to allow for gas cap expansion. When the oil is

depleted, the gas cap can be explored.

In gas-expansion-drive reservoirs, there is no significant

moveable water to worry about and the entire interval can be

perforated without fear of water production. Variations in

reservoir quality may make some portions look wetter than

others; these are just finer grained rocks and are still

worthy of being completed in many cases.

When vertical fractures exist, the perf interval must be as

far from both water and gas contacts as possible, and

drawdown pressure kept as low as reasonable, to reduce the

risk of gas or water inflow through the perfs.

OPTIMIZING

HORIZONTAL WELL PLACEMENT

OPTIMIZING

HORIZONTAL WELL PLACEMENT

The optimum position for a horizontal well is often

determined from a petrophysical analysis of the vertical pilot hole. The same rules

apply as for locating perforations. In both cases, you want

to complete the interval that will produce the most

hydrocarbons with the least complications. Stay above the

water, stay below the gas when trying for an oil well, stay out of

bounding shales or coal. In shale gas plays, the liquids-rich

interval may be the most desirable location, and this may be above a

leaner gas-only interval. A resistivity-at-bit and a gamma ray log

on the drill string will assist in steering the wellbore.

The initial location should be near the middle of the best flow

capacity in the desired reservoir, assuming that a hydraulic

fracture will be designed to penetrate both upward and downward to

cover the interval. In very thick reservoirs, there may be potential

to drill and frac more than one interval from the same drill pad or

platform.

CALCULATING THE CUMULATIVE FLOW CAPACITY (KH%) CURVE

CALCULATING THE CUMULATIVE FLOW CAPACITY (KH%) CURVE

Optimizing perforation interval

or horizontal well placement can be aided by creating

a cumulative flow capacity or productivity curve, based on the permeability

derived from the petrophysical analysis of the prospective

pay zone:

0: KHcuml = 0.0

1: KHi = Perm * INCR

2: KHtotal = SUM (KHi * PayFlag)

3: KHcuml = KHi + KHcuml

4: KH% = 100 - 100 * KHcuml / KHtotal

Where:

Perm = permeability of each incremental layer (mD)

INCR = log data sample rate (feet or meters)

KHi = flow capacity for each data sample increment (mD-ft or mD-m)

KHtotal = total flow capacity for pay interval (mD-ft or mD-m)

PayFlag = 0 if not Pay, = 1 if Pay

KHcuml = cumulative flow capacity (mD-ft or mD-m)

KH% = percent flow capacity (0% at base of pay, 100% at top of pay)

The KH% curve is presented with 0% at the left and 100% on

the right. This will match the shape of a spinner survey

from a flowmeter, with zero production capacity at base of

pay and 100% at top of pay.

Intervals with the steepest slope on the KH% curve are the most productive

and should be perforated if not too close to water or gas.

Where the KH% curve is near vertical, no perfs are required.

Place horizontal well at or slightly below midpoint of the

steepest slope of the KH% curve. This may vary depending on

frac design and rock mechanical properties.

Permeability does not have to be well-calibrated to use this

technique since the KH% curve is normalized between 0 and

100%.

Use the KH% curve to estimate increased productivity of

bypassed or unperforated intervals. See example below.

CAUTION: The KH% curve is only a guide. It may not always

indicate bypassed pay. The proof is in the production test.

EXAMPLES OF KH% LOGS

EXAMPLES OF KH% LOGS

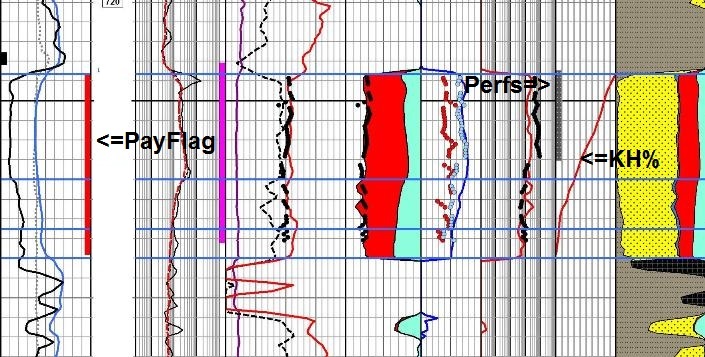

VERTICAL WELL RE-COMPLETION:

The objective is to consider whether the perforated interval is

optimized to obtain the best production characteristics consistent

with the cost of a workover, using the KH% curve as a qualitative

guide.

Grid lines are 1 meter spacing. Tracks 1, 2,

3 show GR, SP, PayFlag, resistivity, PE, neutron, and density

porosity.

Calculated and core porosity in Track 4 with saturations in Track 5,

calculated and core permeability in Track 6. Note excellent match to

core data (coloured dots). Higher SW in lower zone

is due to finer grained sand, not transition to water. KH% in Track

7 starts at base of PayFlag and runs up to top of PayFlag. Arrow

shows base of perforations. KH% curve shows 40% of possible flow

capacity has not been perforated. Since this is a gas expansion

drive reservoir, the perforations should be extended 2.2 meters to

capture at least 30% more flow capacity.

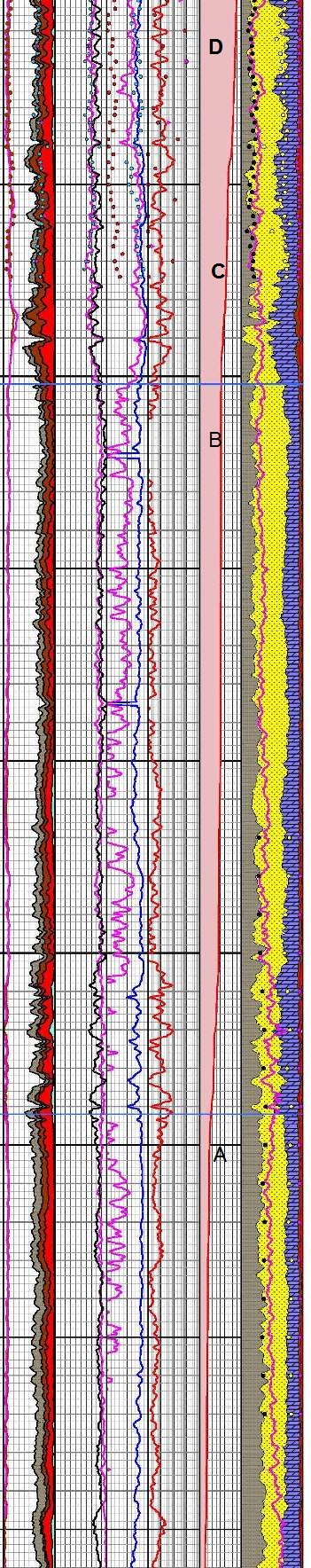

HORIZONTAL

WELL PLACEMENT: HORIZONTAL

WELL PLACEMENT:

The objective is to consider where to place a horizontal well that

will optimize production and minimize stimulation costs, using the KH% curve as a qualitative

guide.

On the example shown at the right, the KH% curve is the second track

from the right (shaded pink), next to the lithology track. To the

left of the KH% track are permeability, saturation, porosity, and

apparent porosity distribution (including clay bound water, kerogen

effect, free gas, and water.

There are two long intervals on this log where the KH% curve has a

significant slope (Layers A and C), separated from each other by a

long interval with virtually no KH contribution (Layer B). Another

zone (Layer D) with virtually no KH contribution lies above Layer C.

In round numbers, Layer C has about 45% of the total well flow

capacity and the lower zone, Layer A, has about 40%.

An optimum location for a horizontal well would probably be near the

middle of Layer A or near the middle of Layer C, assuming a

hydraulic stimulation could be designed and executed that would

extend 25 meters (+/-) above and below the horizontal well. In this

example, either location offers about the same chance for economic

success.

Placing a horizontal well to access both Layers A and C is much more

difficult. The frac job would have to extend 75 meters (+/-) above

and below the well to access the good reservoir, while penetrating

30 to 40 meters of rock that would not contribute much extra

production. It may be more attractive to run two horizontal legs

from the same pad to access both layers independently.

|