|

WIRELINE DEPTH DETERMINATION BASICS

WIRELINE DEPTH DETERMINATION BASICS

Depth is the singular measurement that ties together all other

measurements made in a wellbore. Integration of all the

petrophysical measurements at a particular depth allows us to

evaluate reservoir properties. Well completion, stimulation, and

remedial workover activities can then be related to these depths.

The most commonly used depth measurement is that from wireline

logging operations. Driller’s depth and cuttings sample depths may

also be used, but the latter can be quite inaccurate. Wireline

depths can be calibrated for line stretch and temperature expansion.

Driller’s depth is determined by measuring the length of each drill

pipe length that is run into the hole. Added to this is the length

of the bottom hole assembly (BHA) and the position of the travelling

block that carries the pipe in and out of the hole. The respective

lengths are measured with a steel tape measure and recorded on a form

or in a computer program. Pipe stretch and thermal expansion

corrections may be applied in deep, hot boreholes.

Sample depths are estimated based on mud circulation rate and

checked by measuring the time taken to circulate a recognizable

chemical from surface and back again. Sample depths are then refined

by noting drilling rate variations with the lithology of the

samples.

For wireline depth determination, the wireline logging cable is the

“tape measure”. It is “read” by a device called a “measuring wheel”

that rides on the cable and creates depth indicating pulses as the

cable moves up or down in the wellbore. The logging tool

measurements are made and recorded at some fixed depth increment,

for example 6 inches (0.1524 meters) or 0.100 meters. High

resolution data can be recorded at 10 or 20 times the standard

sample rate. The output from this depth measurement is called Raw

Depth.

Magnetic marks are usually placed on the wireline cable under

constant tension at the service company field location. These are

usually spaced every 100 feet and are used to help calibrate the Raw

Depths that come from the measuring wheel pulses. The result is

called Calibrated Depth.

Calibrated depth corrected for elastic cable stretch, temperature,

and tension regime is called Corrected Depth and represents the

best estimate of the depth in a wellbore.

True Along Hole depth (TAH) is the true and correct position in a

well bore, determined by the length along the center of the drilled

hole from a surface reference point (e.g. rotary table, kelly

bushing, wellhead casing flange) to a measurement point, typically a

measuring point of the logging tool.

Loggers, or wireline, (WL) Depth is the depth measured by the

logging service provider and provided as either “Raw”, “Calibrated”

or “Corrected” depth, as defined above.

Indicated Depth is any depth measurement provided that is neither

calibrated nor corrected, and assumes only consistency of

measurement methodology.

Wireline depth is, to date, the only measurement system that can

provide a calibrated and verifiable measurement system, and this

sets it apart from other depth measurements. WL depth is derived

with the cable in tension, and can be provided using a measureable

tension regime that allows the elastic stretch to be modelled and

calculated with known degrees of accuracy. This is not possible with

Drillers Depth.

Corrected depth is calculated from calibrated depth, using elastic

cable stretch and temperature induced line elongation corrections..

Temperature Elongation Corrections

Temperature Elongation Corrections

Temperature elongation, or linear thermal expansion,

is a fixed correction dependent upon the line properties and the

temperature gradient. For linear geothermal gradients

at bottom hole:

1: LTE = 0.5 * (BHTDEP * KTE * (BHT – SUFT))

At any other depth:

2: LTE = 0.5 * (DEPTH * KTE * (FT – SUFT))

Where:

LTE = linear thermal expanaion (feet or meters)

BHTDEP = depth at bottom hole (feet or meters)

DEPTH = depth at any formation (feet or meters)

KTE = thermal expansion coefficient (feet/degF or meters/degC)

BHT = bottom hole temperature (degF or degC)

FT = formation temperature (degF or degC)

SUFT = surface temperature (degF or degC)

Use of this formula has to be adjusted where there are obvious

variations in geothermal gradient. Individual expansion coefficient

for lines varies strongly between line types. Linear thermal

expansion correction can be as much as 1/3 of the total correction.

This correction is often applied by the service company at the time

of logging the well based on standard temperature expansion charts

for the cable type in use. For older worn cables, this correction

may be too small.

Stretch Correction

Stretch Correction

The stretch correction equation is:

3: STR = SUM (0.5 * (STENS + CHTENS) * KSTR)

Where:

STR = cable stretch (feet or meters)

STENS = surface tension (lb or Kg)

CHTENS = cable head tension (lb or Kg)

KSTR = cable stretch coefficient (feet/lb or meters/Kg)

Some logging service companies can provide both surface and cable

head tension, some only surface tension, and some provide neither.

When data is missing assumptions will be made, possibly by checking

the availability of analogy data in offset wells.

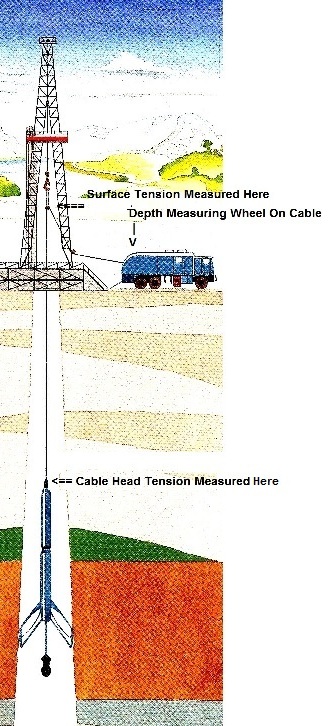

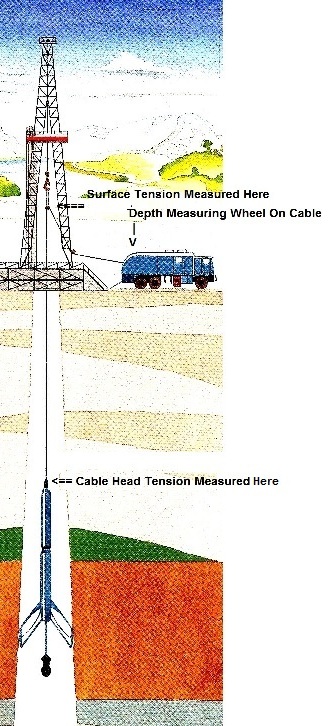

Key

elements of a wireline logging operation

Accurate depth measurement can only be provided while measuring out

of hole. Logging while running in hole is done often, “Down Log”,

but the depth measurement provided can be described as no better

than Indicated Depth as there is no certainty as to the tensional

behaviour of the wireline during the descent.

This correction is often applied by the service company at the time

of logging the well based on standard stretch charts for the cable

type. For older worn cables, this correction may be too small. The

correction may be based on an assumed cable tension even when

tension is measured.

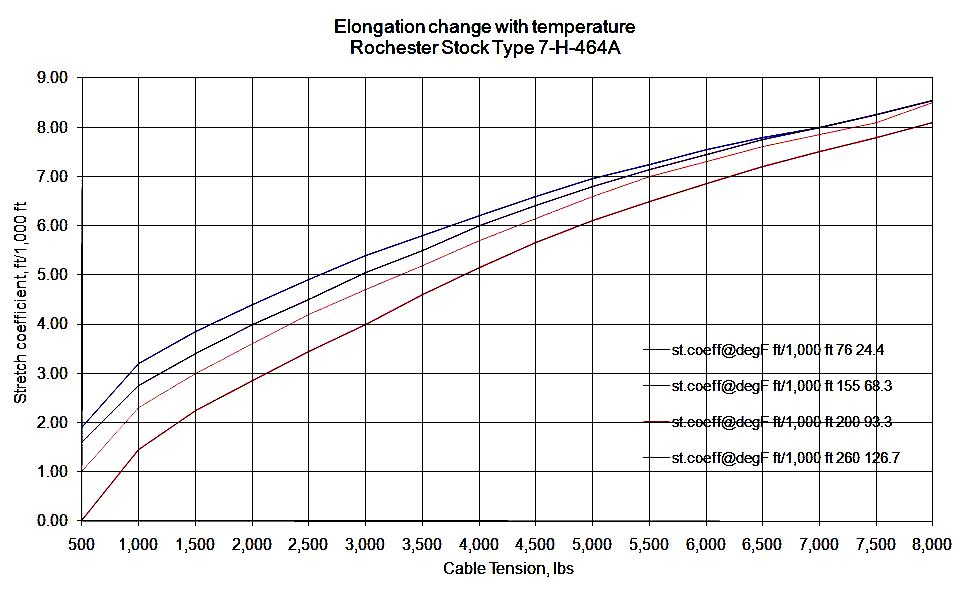

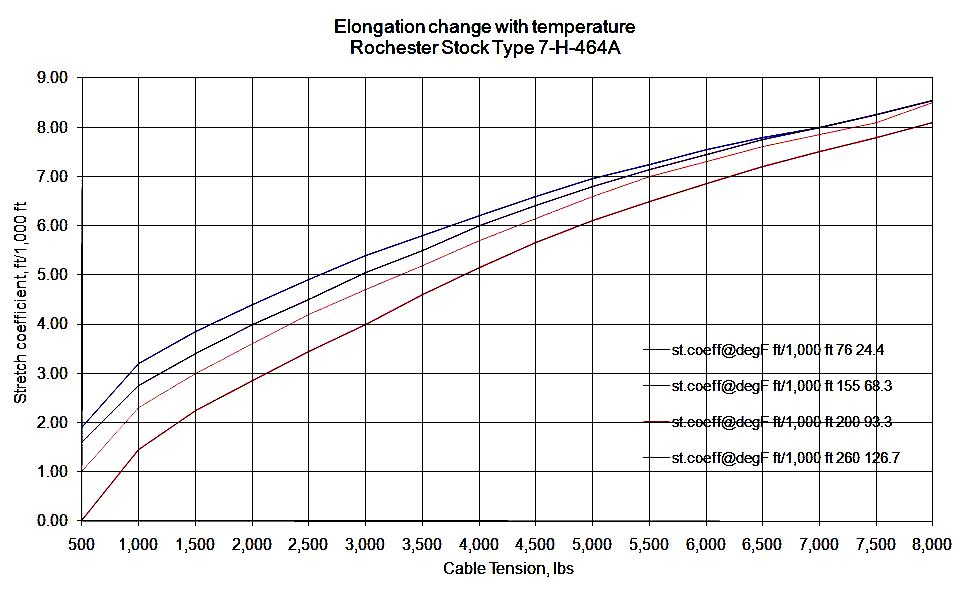

Due o friction between strands, multi-strand cables do not behave as

linear elastic wires, so the stretch coefficient KSTR varies with

applied tension and temperature, so these elements add a further

complication into the effective stretch coefficient that should be

used. It is clear that an accurate and verifiable measurement of

cable stretch coefficient is required to provide a credible

correction result.

Stretch coefficient behavior with temperature and line tension

Tension Regimes

Tension Regimes

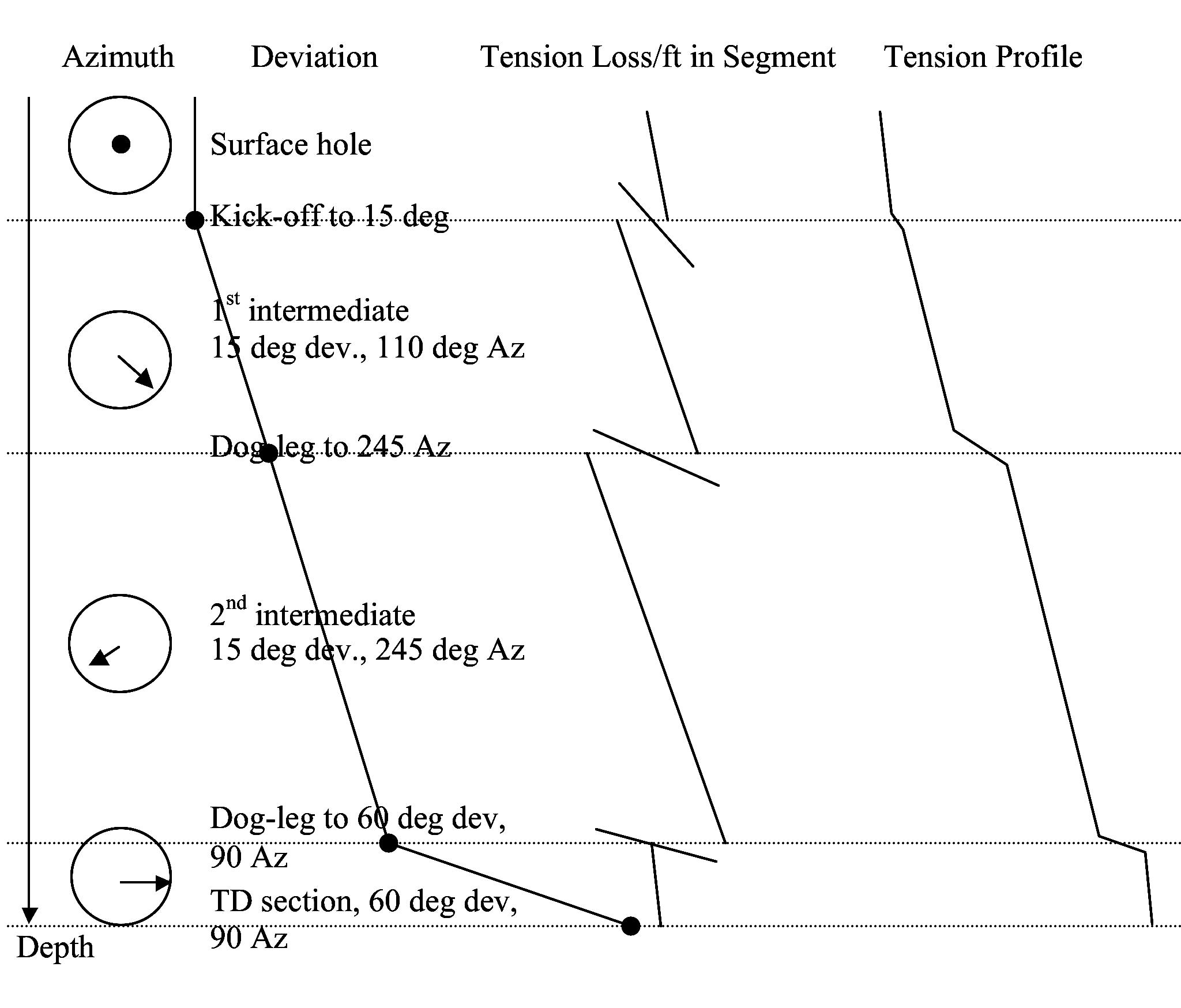

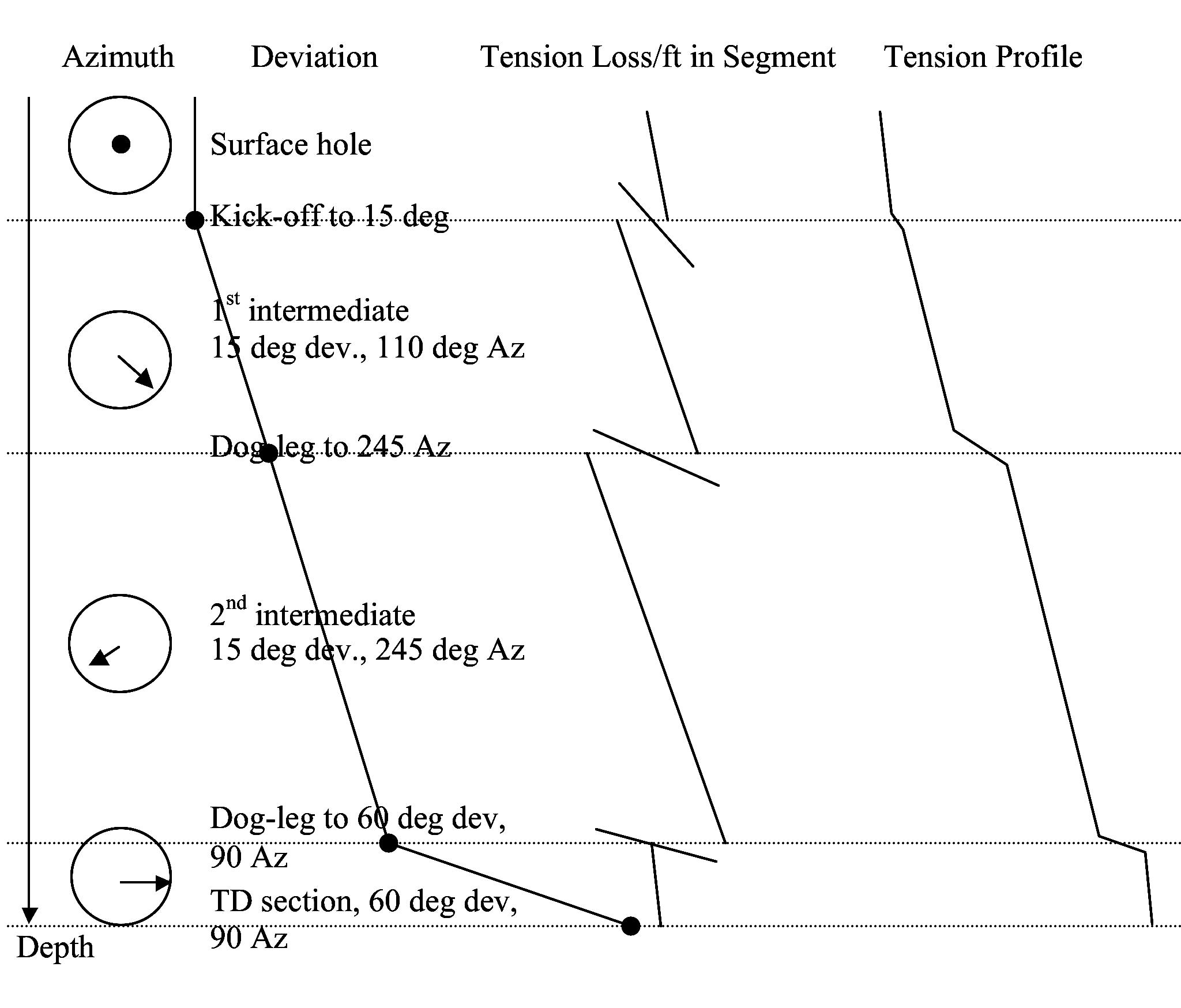

Over the length of a well, the characteristics of tension change

according to parameters such as deviation, well bore geometry, well

constructional characteristics, geology, rock properties, key

seating, tool configuration, etc., and these changes affect the

effective tension, and hence stretch, that the cable is subject to.

In our earlier discussion, it has been assumed that tension and

temperature are linear functions of depth and the corrections

therefore are a function of depth. This is not always the case,

especially for tension.

The measurement of surface and cable head tension over a logged

interval is referred to as a “Tension Regime”. A tension regime is

typically repeatable for the same logging string run in the same

well at the same time. This means that the tension regime can be

mapped, and then used to calculate the stretch correction to be used

in the depth interval defined by each tension regime. This level of

detail is NOT done by the service company at the time of logging the

well.

Tension regime elements combining Into tension profile

The contribution elements of the tension regime can be identified,

and built into so called “segments”, where each segment is

identified by a given loss of tension per length of well. These

stretch attributable to each individual segments then give rise to

the total stretch correction known as Segmented Correction. Equation

3 is then used in each segment with tension terms replaced with

tension at bottom of segment minus tension at top of segment, then

the segment contributions are summed together.

For the full story on this subject, contact haraldb@icteurope.com

|