|

WIRELINE LOGGING BASICS

WIRELINE LOGGING BASICS

To perform a logging operation

on wireline, the measuring instrument, often called a probe, sonde

or logging tool, is lowered into the borehole on the end of an insulated electrical

cable. The cable provides power to the downhole equipment. Additional wires

in the cable carry the recorded measurement back to the surface. The cable

itself is used as the depth measuring device, so that properties measured

by the tools can be related to particular depths in the borehole.

Wireline logs descend into the wellbore under

the force of gravity. In deviated wells, the tools may not travel

all the way to bottom. Roller and powered tractor subassemblies can

be used to assist. These are not especially useful in rough or

horizontal wells, so coiled tubing or pipe conveyed tools are used.

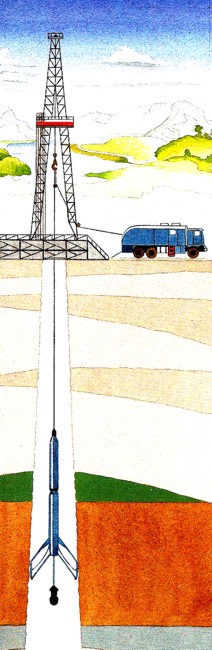

The

wireline logging operation showing logging truck (right),

logging cable strung into the rig, then lowered into the

borehole (left), with logging tools at the end of the cable

(bottom). Logs are usually recorded while being pulled

upward by the winch in the logging truck. Most logs can also be

run as an integral part of the drill string (logging while

drilling or LWD) or attached to coiled tubing. These methods are

useful in deviated, horizontal, or other hostile well

environments. The

wireline logging operation showing logging truck (right),

logging cable strung into the rig, then lowered into the

borehole (left), with logging tools at the end of the cable

(bottom). Logs are usually recorded while being pulled

upward by the winch in the logging truck. Most logs can also be

run as an integral part of the drill string (logging while

drilling or LWD) or attached to coiled tubing. These methods are

useful in deviated, horizontal, or other hostile well

environments.

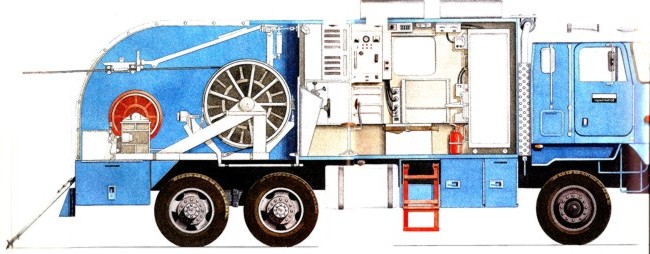

Cutaway view of a modern logging

truck showing winch with logging cable (left) and computerized

operator's station (center)

A

logging tool is made up of a sonde and a cartridge. The sonde

is the portion of the tool which gives off energy, receives energy,

or both. The cartridge contains the electrical circuitry or computer

components needed to control the downhole equipment, and to transmit

data to and from the surface.

Combination

logging tools consist of more than one sonde and cartridge, so

that more than one log can be recorded on a single trip into the

wellbore.

Surface

equipment is mounted in a logging truck, van, or skid unit from

which all logging operations are controlled. The logging unit

contains hoisting equipment for lowering and raising the tools

in the hole, and electronic or computer equipment for controlling

and recording the downhole measurements.

Recording the well log involves a number of steps, beginning

with sensing and pre-processing the measurement in the logging

tool itself, transmission of this information to the surface

over several miles of wireline, further processing in the

logging truck computer, data storage on disc or magnetic tape,

and finally display of the data on film or paper.

Measurements are recorded in two forms, analog and

digital. The analog data may be recorded on photographic film,

electronic plotter, or chart recorder. The same data are captured

in digital form on magnetic tape or disc for later use in computer

aided petrophysical analysis. Many instrument control and calibration functions

are now handled by the same computer used to record the digital

data, with some human control. The result is a log, as seen

below.

Example of a Well Log, with a standard 3-track

presentation on the left and an image log on

the right. Curve

names and scales in the scale heading help identify which

curve is which.

All logging tools and surface equipment must be properly

calibrated. Service companies have calibration procedures for

most tools, some of which are based on standards established

by the American Petroleum Institute (API). Each tool must be

calibrated at the surface before placing it in the hole to

make measurements, and must pass certain calibrations after

the measurements are complete to verify that measurement accuracy

has not drifted. Some tools also have downhole calibration

checks.

After reaching total depth, or some other location

of interest in the borehole, measurements are made while pulling

the tool upward over several hundred feet of the borehole.

This is called the repeat run, and is used to determine the

repeatability of the measurements when compared to the main

logging pass. After the repeat run is complete, the tool is

lowered to the bottom of the hole, and the main logging pass

is commenced. During the early portion of these measurements,

the responses are compared to those of the repeat run to determine

that no instrument drift has occurred. Results of all field

calibrations and repeats are attached to the bottom of the

well log record.

In addition to the actual measurements, the well log

itself contains information about the logging process which

supports use and interpretation of the data. The well name,

location, date, surface measurements on the mud system, drill

bit size, casing information, and logging equipment data are

found on the log heading, Any pertinent information or comments

regarding the logging job may be recorded in the remarks section.

The logging equipment is carried to the wellsite on

a truck (for land based operations near roads), or transported

by helicopter on skids (for remote land operations) or are

permanently mounted on offshore rigs. Some typical logging

units are shown below.

Logging Trucks and Skid Units

Computerized surface equipment is now the rule rather

than the exception. Such units, on a truck and with logging

tools on board, can cost over $1,000,000.

|