Petrophysical Training

Licenses

|

SAMPLE DESCRIPTION BASICS SAMPLE DESCRIPTION BASICS

The wellsite geologist is responsible for inspection of rock samples

as they are gathered and preparation of the sample log. He may

delegate this to the mud loggers if they are on site. The wellsite

geologist also is responsible for a myriad of other tasks, including

ordering geological supplies, picking the location of cores and

tests, packing and shipping recovered cores and fluid samples,

calling for and supervising wireline logging operations, velocity

surveys, mud logging crews, and other survey personnel, liaison with

drilling crews and home office, and above all, must be a good

cribbage or gin rummy player.

The sample log, often called the stratigraphic log, strat log, or

geology log, is a record of the rock samples retrieved from the

drilling mud, and is one of the primary sources of rock and fluid

descriptions for the well. It consists of a verbal description of

the rock type as well as qualitative or interpretive data concerning

evidence of the fluid content of the rock. Sample description is

sometimes called formation evaluation, but this term usually covers

a broader scope, including drill stem test a and log analysis.

Cuttings are collected, washed, and described at 5 to 20 foot (2 to

5 meter) intervals unless extremely rapid penetration rate makes

this impractical. In such cases, they would then be collected as

often as possible, but no less than once for each time drilling is

resumed after a pipe connection. A constant sampling rate is chosen,

depending on the lithology expected.

Sample chips are quite small, so large scale features such as

fractures, bedding planes, and fossils often cannot be seen. Samples

can be contaminated by rock sloughing from above, or may be lost due

to lost circulation, pulverization, or careless well site

procedures.

Washed sample of a siltstone magnified 20 times

Washed rock chips are observed under a microscope (10 to 20 power)

and described as to mineralogy, colour, texture, rounding, sorting,

grain size, cementing minerals, porosity, porosity type,

permeability, macro fossils, and fractures. These are qualitative

descriptions. Quantitative values usually come from core

analysis and log data, but semi-quantitative lithology analysis is

possible under the microscope. Obvious formation tops, marker beds, and

lithology changes are listed. Drill stem test recoveries, coring

intervals and coring times, logs run, bit changes, and other

logistical data which might

influence the understanding of the sample log are given.

Obvious formation tops, marker beds, and lithology changes

are listed. Drill stem test recoveries, coring intervals and coring

times, logs run, bit changes, and other logistical data which might

influence the understanding of the sample log are given.

Sample descriptions will include an estimate of visual

porosity, porosity type, grain size, sorting, roundness, and colour,

as well as shale distribution, brittleness, laminations, and colour. Sample descriptions will include an estimate of visual

porosity, porosity type, grain size, sorting, roundness, and colour,

as well as shale distribution, brittleness, laminations, and colour.

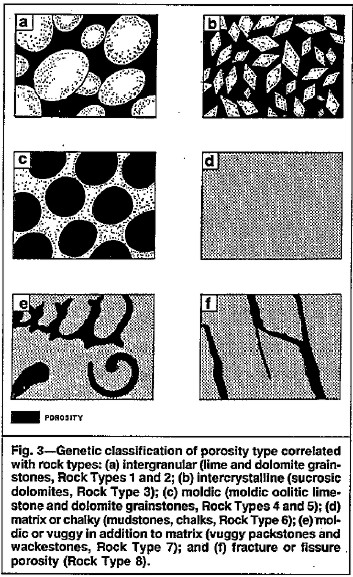

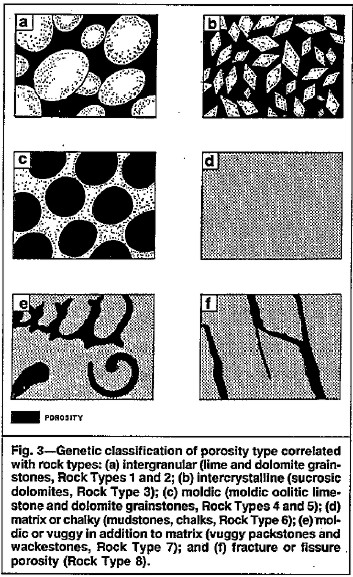

Primary

porosity is the porosity developed by the original sedimentation

process by which the rock was created. In reports, it is often

referred to in terms of percentages, while in calculations it is

always a decimal fraction.

Secondary porosity is

created by processes other than primary cementation and compaction

of the sediments. An example of secondary porosity can be found in

the solution of limestone or dolomite by ground waters, a process

which creates vugs or caverns. Fracturing also creates secondary

porosity. Dolomitization results in the shrinking of solid rock

volume as the material transforms from calcite to dolomite, giving a

corresponding increase in porosity.

Porosity Types: a. intergranulas, b. Sucrosic,

c. Moldic or Oolitic, d.

Matrix or Chalky,

e. Moldic or Vuggy, e.

Fracture porosity.

Intergranular porosity is

primary, the

balance are secondary.

For details,See

Also:

Shale Basics

Porosity Basics

Oil show indicators are found by examination of the rock samples for

oil stain, bleeding, fluorescence, or cut. Stain is the trace of asphaltic material left behind on drill cuttings after the oil has

been washed off during drilling. Stain left by high quality oil has

a typical iridescent sheen, visible in normal light. Bleeding is the

exudation of oil from the pores due to pressure release as the

sample is brought to the surface.

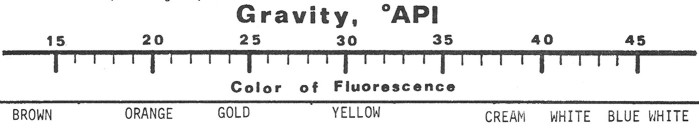

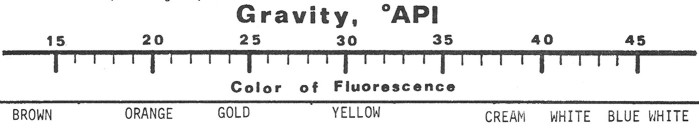

Fluorescence represents oil's distinctive ability of emitting light

in the visible range when exposed to ultraviolet light.

Unfortunately, quite a number of minerals and many refined products

are fluorescent, so there is a certain amount of technique involved

in distinguishing between primary hydrocarbons and refined products

or fluorescent minerals.

A simple chemical test may be carried out to determine whether

fluorescence in drill cuttings is a result of oil or some

fluorescing mineral. This is easily and quickly established by

immersing some of the drill cuttings in a petroleum solvent (chlorothene,

trichlorothene, ether, or acetone). If the fluorescence is derived

from mineral sources, the minerals will not dissolve in the solvent

and the solvent will remain colorless under ultraviolet light.

However, if hydrocarbons are present in the rock, they will

disseminate into the solvent, giving the entire solvent a

distinctive color under ultraviolet light. This sheen under UV light

is called cut and the colour of the cut indicates the quality of the

oil. Pale blue-white is high gravity (light) oil, yellow is medium

gravity, and orange-brown for low gravity (heavy) oil.

Lightly washed wet samples should also be examined, and not dried,

because light oils and condensates may evaporate. Under UV light, a

differentiation should be made between mineral fluorescence, natural

hydrocarbon fluorescence, and fluorescence from introduced oils and

grease. Natural hydrocarbon fluorescence will usually be lithology

specific, while introduced hydrocarbon fluorescence will be

associated with all lithologies. A note of percentage of cuttings

exhibiting natural hydrocarbon fluorescence and the color and

intensity should be made. Mineral fluorescence is determined by the

test for cut.

Under ordinary light, the oil stain or oil bleeding from the sample

may be visible. It should be noted for its volume and its intensity,

and efforts made to distinguish introduced oil. Bleeding often

indicates low permeability. Light oils are more prone to exhibit

irridescence, while dark stains tend to indicate heavier crudes.

To test for hydrocarbon cut, a small sample is placed in a spot

plate, the solvent is introduced, and the color, intensity, and rate

of cut are observed in ordinary and ultraviolet light. The sample is

crushed and the test is repeated. If there is no cut at this stage,

any fluorescence is probably mineral derived. Generally, the heavier

the oil, the greater the cut; however, asphaltic oils show a greater

cut than paraffinic oils of the same gravity.

The chromatography of the oil should be noted. A drop sample of

hydrocarbon contaminated solvent should be placed on filter paper

and observed under ordinary and ultraviolet light. The

characteristics of any separation should be noted, including the

number of rings formed.

Larger samples, or a number of smaller samples, may be placed in a

test tube and examined in a similar manner as in a spot plate; the

sample should be crushed and the solvent introduced. A standard

method should be employed so comparisons can be made with nearby

wells, ie., 1 cc of crushed cuttings in 2 cc of solvent in a

standard 10 cc test tube.

A control test tube of 3 cc solvent should also be set up, and a

comparison against white paper is then observed. Again, a drop of

hydrocarbon contaminated solvent should be tested for chromatography

as before.

To test for gas in the cuttings, place an unwashed sample in a

blender or food processor, add water, and analyze the resulting gas. This is done by running a sample of the headspace gas into the gas chromatograph

operated by the mud logging crew.

Sample containing carbonates, either as a main constituent or as a

cement, can be tested further for oil by adding a small amount of

hydrochloric acid. Hydrocarbons present in a sample, either natural

or introduced, will cause carbon dioxide bubbles, released by the

action of hydrochloric acid on carbonates, to enlarge by forming an

oil film around the bubbles. Thus, the reaction is more prone to

frothing. This test is very sensitive, but it does not differentiate

between natural and introduced hydrocarbons.

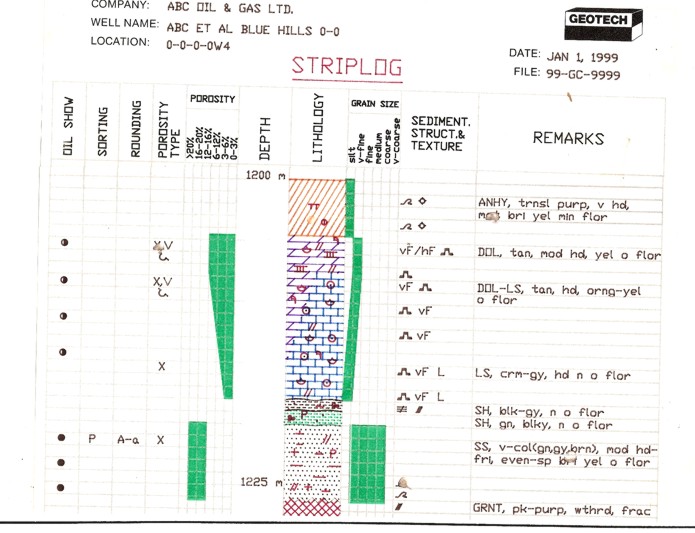

The sample log can take many forms: a written narrative, a graph

versus depth with a schematic drawing (along with abbreviated verbal

descriptions), or a mud log, which describes the rock samples, as

well as fluids, recovered in the mud. Drilling data such as

penetration rate may also be included.

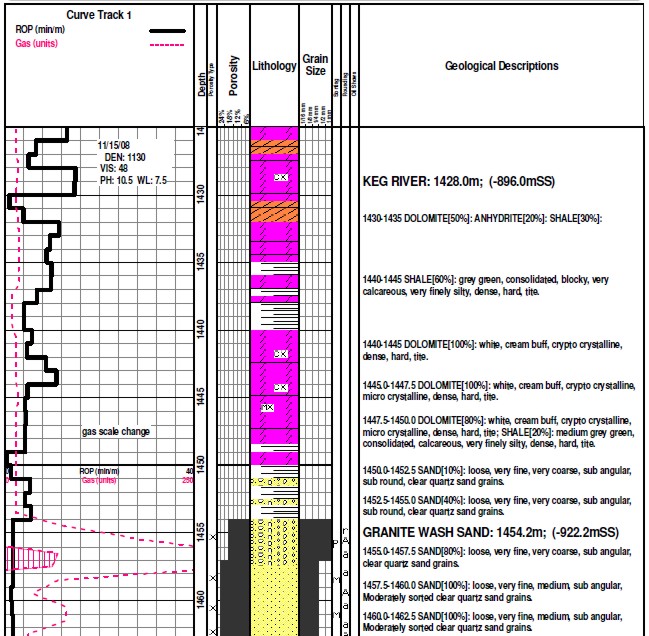

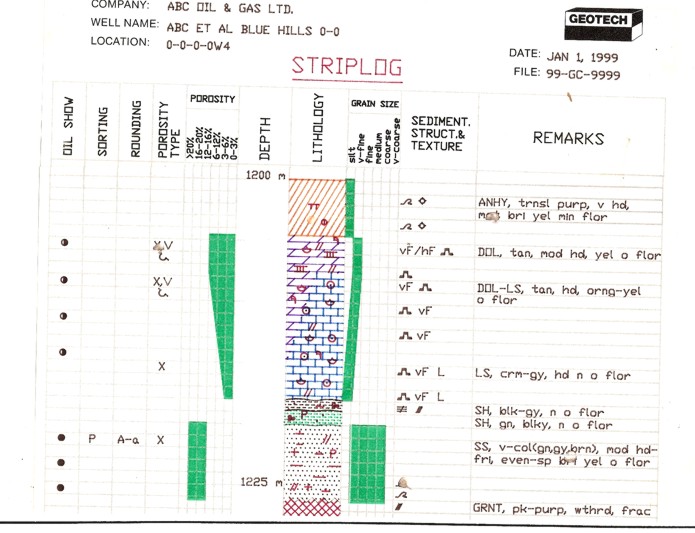

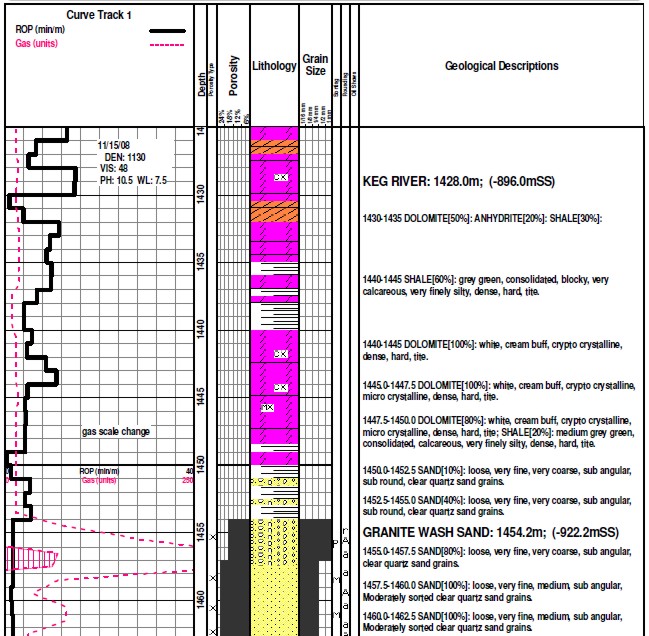

Example of a sample description log

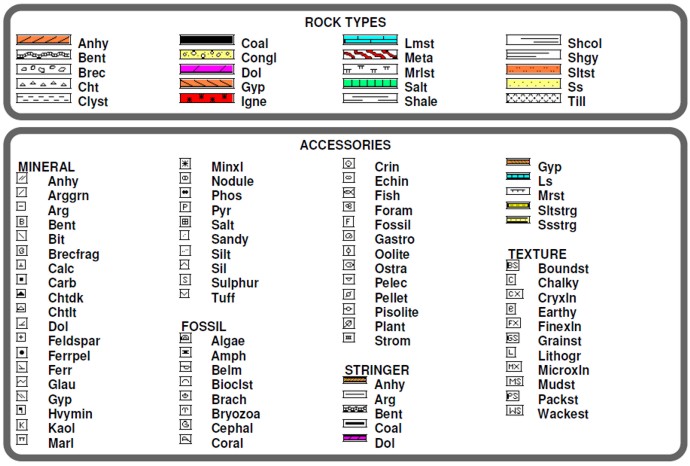

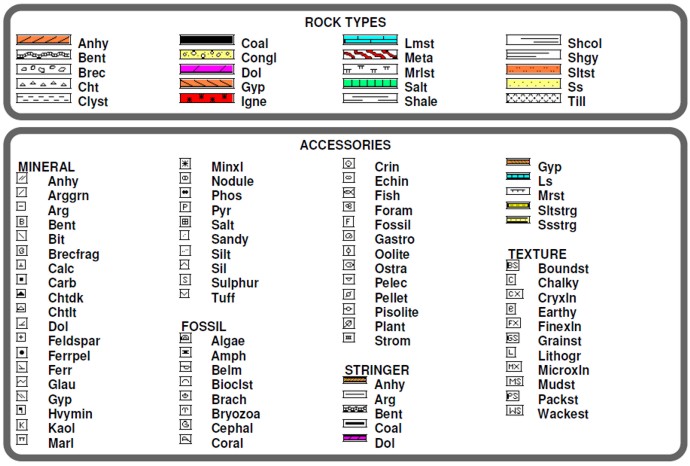

Below is a a sample of the colours and symbols in use for lithology

descriptions on modern sample description logs. For a complete list of

abbreviations and symbols used in geological sample descriptions,

see This List.

Colour codes and symbols used to plot lithology and accessory

features on a sample description log

All sample log results are reported daily by telephone, FAX, or

email and recorded on a standard report form for distribution within

the oil company. Hydrocarbon shows are especially desirable; a show

is defined as any indication of hydrocarbons, ie., stain,

fluorescence, or cut, or any increase in drilling mud gas of

reasonable percentage above background.

LAG

TIME LAG

TIME

Depth information is obtained from the driller's log, which records

depth versus the time of day. However, these depths cannot be used

directly. We wish the mud log data to be presented at the depth of

the drill bit, but the mud log measurements are made at the surface.

The time it takes for the mud to move from the bit to the surface

must be accounted for in positioning samples and gas kick data on

the log. This time is called the lag time and depends on the

velocity of the mud in the annulus between the drill pipe and the

rock. This in turn depends on the mud pump speed and displacement,

which are usually constant

for reasonable periods of time.

The lag time can

vary from a few minutes in an air drilled hole, to hours in a deep

mud filled hole. If lag time is much shorter than expected or

multiple lags are found, it usually means a leak in the drill pipe

which must be repaired immediately. The most reliable method of

establishing the lag time is to use a tracing material such as oats,

corn, paint, or calcium carbide. Carbide will produce a bubble of

acetylene gas. Typically, a sample of tracing material is introduced

into the drill pipe during a connection and circulated down through

the bit jets and back up the annulus. The use of calcium carbide as

a lag tracer has a secondary benefit. It permits verification that

the entire gas detection system is functioning. Since it is

necessary for the gas detector to extract, pump to the logging unit,

and sense the acetylene gas, it verifies the integrity of the entire

system.

This is only part of the story, as the time it takes the tracer to

go down the inside of the drill pipe must first be calculated from

the pump displacement, pump speed, pipe diameter, and pipe length.

The calculated downward time is deducted from the total measured

time to find the lag time.

SAMPLE DESCRIPTION LOG EXAMPLES

SAMPLE DESCRIPTION LOG EXAMPLES

Below are examples of sample

description logs from various eras.

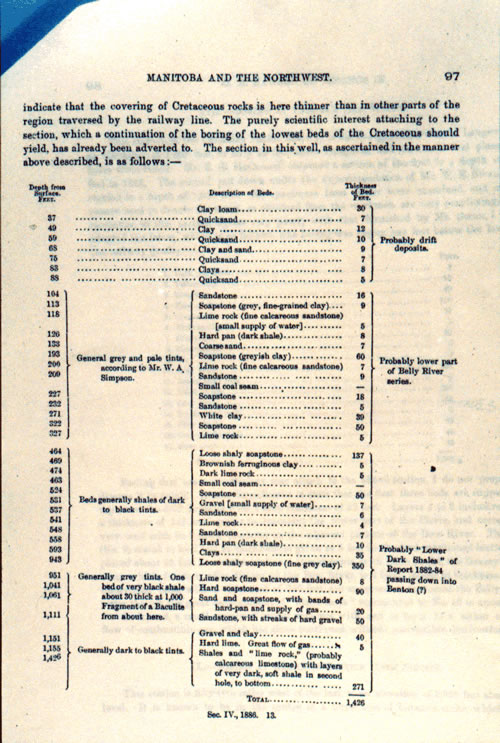

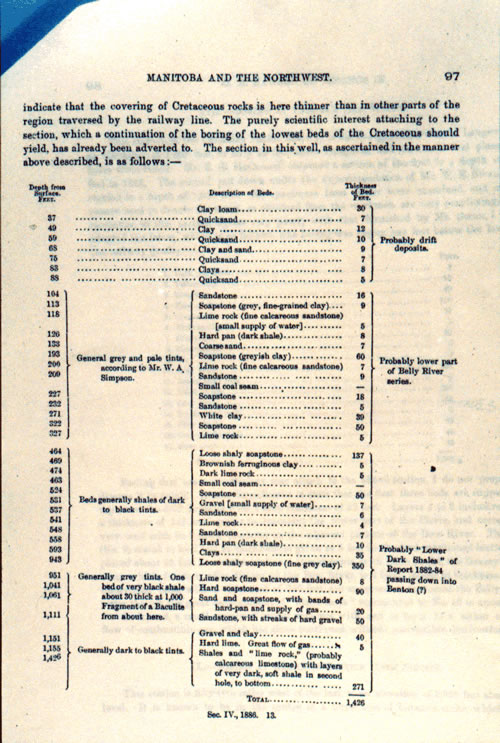

One of the first well logs in Western Canada

from Proceedings and Transactions of the Royal

Society of Canada

for the Year 1886 Volume IV.

Glenbow Archives

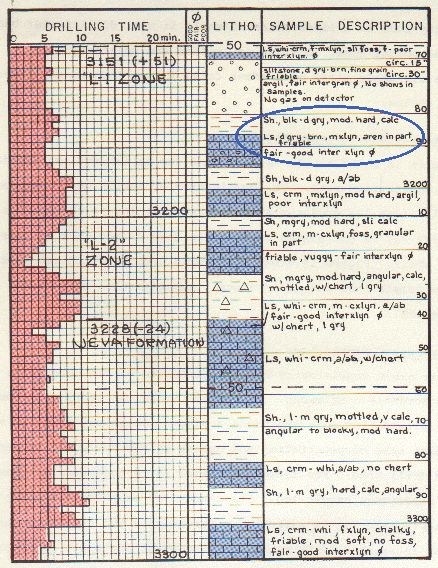

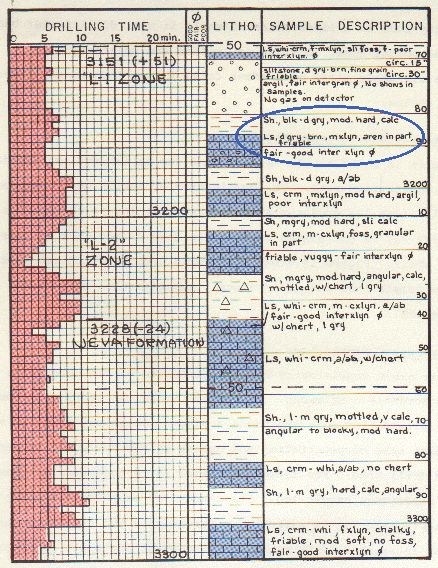

A hand drawn sample log typical of the 1940 to 1970 era.

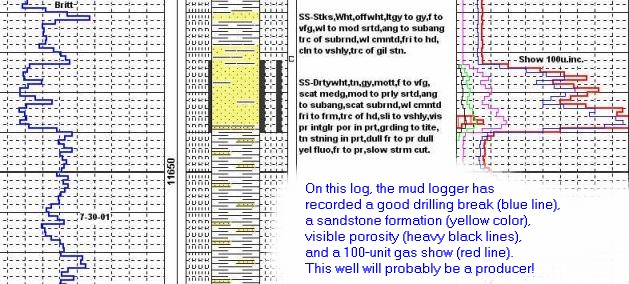

A computer drawn sample log of the 1980's. Hand drafted logs could

be drawn as neatly as this using lettering guides.

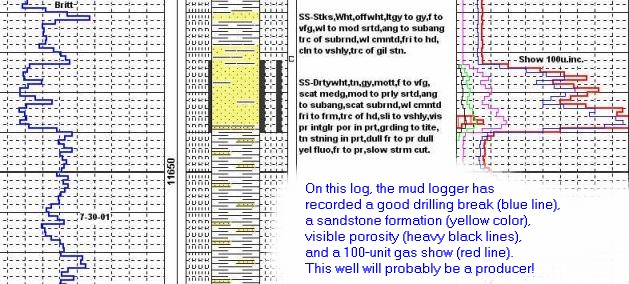

Modern sample log using colour and computer graphics symbols.

|

|