|

OIL SAND BASICS

OIL SAND BASICS

Peter Pond called them "tar

sands" in 1778 and in

the early days of the oil business, tar sands were commonly

called tar sands with a little bit of pride. The largest oil

deposit in the world with a 400 year life span could not be

sneered at. In today's politically-correct double-speak, we

now call them "oil sands", not be be confused with

conventional oil sands. So, at the suggestion of a good

friend of mine, this page has been edited to remove the

offensive word wherever possible.

Conventional crude

oil is classified as light, medium, or heavy

according to its measured API gravity.

-

Light crude oil has an API gravity higher

than 31.1 (i.e., less than 870 kg/m3)

- Medium oil

has an API gravity between 22.3 and 31.1 (i.e.,

870 to 920 kg/m3)

-

Heavy crude oil has an API gravity below

22.3 (i.e., 920 to 1000 kg/m3)

Extra heavy crude

oil with API gravity less than 10 ( >1000 kg/m3)

is referred to as

bitumen. Bitumen derived from

oil sands in Alberta has an API gravity of

around 8. It can be diluted with lighter

hydrocarbons to produce

diluted bitumen, which has an API gravity of

less than 22.3 (equivalent to conventional heavy

oil), or further upgraded to an API gravity of 31 to

33 as

synthetic crude (equivalent to conventional

light oil).

Oil sands (tar sands, bitumen sands) are mined or depleted

by steam assisted gravity drainage (SAGD) or in-situ fire

floods. In all these situations an adequate reservoir

description is needed to assess the economics and progress

of any project.

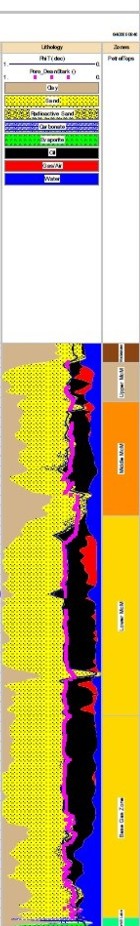

The best oil sands are clean,

medium to coarse grained, unconsolidated sands. However, they may be interbedded with finer, siltier, and shalier sands or overlain by

lower quality reservoir rock. The log analysis needs to describe

these variations, especially laterally continuous barriers to

vertical flow of steam and oil movement.

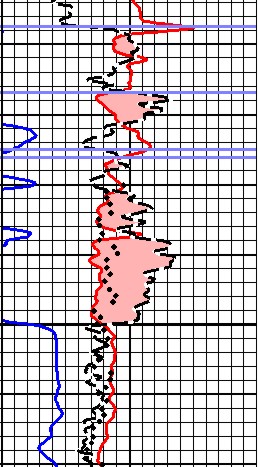

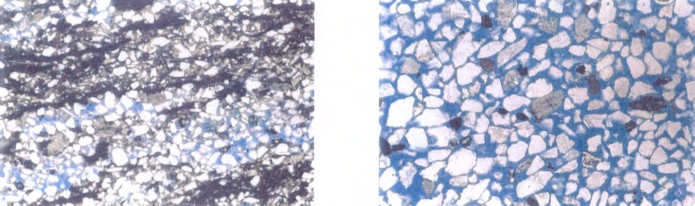

Oil sands at 63 times magnification:

shaly sand (left) with Vsh > 35%,

clean sand (right) with Vsh < 5%.

The

fluid column can be more complicated than conventional

reservoirs. Here are some possibilities:

1. bitumen with or without bottom water

2. top water over bitumen with or without bottom water

3. gas over bitumen with or without bottom water

4. gas over top water over bitumen with or without bottom water

5. any of the above with gas distributed unevenly in the main bitumen

zone.

The oil sands of Alberta appear to be an easy task for a

petrophysicist. After all, the sands are pretty clean, quite porous,

and the fluid properties are reasonably well known. Even a novice

geologist should be able to do it. However, a series of forensic log

analyses over the last 30 years or so suggest that there are some

basic misunderstandings about how oil sand cores are analyzed and

how to calibrate log analysis results to that data.

In each case, the forensic analysis was undertaken at the request of

a client who was unsatisfied with prior work that did not appear to

provide an adequate description of the hydrocarbon potential in an

oil sands reservoir.

Standard

petrophysical analysis models are used for the volumetric

determination of clay, porosity, water, and oil, and from this a

realistic permeability estimate. Unfortunately, the Dean-Stark core

analysis method, widely used to assess oil sand cores, does not

measure volumes. Instead, the technique measures oil mass, water

mass, and mineral mass. These are converted to mass fraction and

then to calculated porosity and water saturation. Rarely, there may

be some helium porosity and permeability data, but this is difficult

in unconsolidated oil sands. Standard

petrophysical analysis models are used for the volumetric

determination of clay, porosity, water, and oil, and from this a

realistic permeability estimate. Unfortunately, the Dean-Stark core

analysis method, widely used to assess oil sand cores, does not

measure volumes. Instead, the technique measures oil mass, water

mass, and mineral mass. These are converted to mass fraction and

then to calculated porosity and water saturation. Rarely, there may

be some helium porosity and permeability data, but this is difficult

in unconsolidated oil sands.

It is tempting to compare log analysis volumetrics to the Dean-Stark

calculated volumetrics, and adjust log analysis parameters to obtain

a “good match”. The biggest problem is that this form of core

analysis gives a measure of porosity that is sometimes called “total

porosity”, which includes clay bound water. In real life, some of

the clay bound water is not driven off by the Dean-Stark method, so

the core porosity falls somewhere between total and effective

porosity.

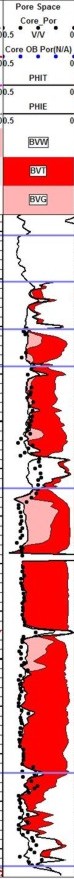

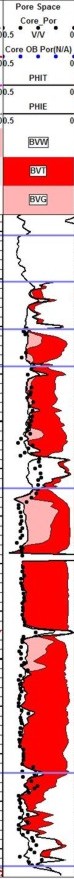

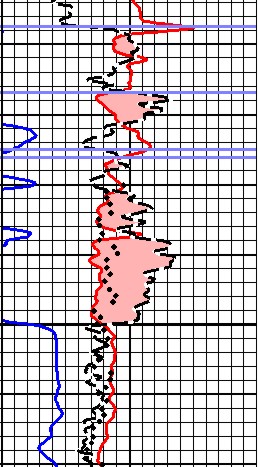

Dean-Stark core analysis (black dots) compared to total porosity

(black curve) and effective porosity (left edge of red shading).

The calculated water saturation from Dean-Stark also falls somewhere

between total and effective, when some clay is present. Since log

analysis gives effective porosity and saturation, we are comparing

apples to aardvarks. The message is that log analysis cannot be

calibrated directly to the core volumetric data when clay is

present. Virtually all oil sands have some clay content somewhere

in the interval of interest.

But we CAN calibrate to Dean-Stark core data in the mass fraction

domain, by converting the volumetric petrophysical analysis results

to mass fraction. That allows us to compare apples to apples, and

let the aardvarks go about their own business. Oil sand quality is

judged by its oil mass fraction and net pay is determined by an oil

mass fraction cutoff, not porosity and water saturation as in

conventional oil. So oil mass fraction is a mandatory output from a

petrophysical analysis. This approach is also useful for heavy oil

plays (API gravity = 10 -18).

There are additional problems to resolve, as will be discussed

below.

Oil in carbonates is also

extractable with SAGD, fire floods, or solvent floods. Gas is

usually less of an issue because there is less likelihood of

biogenic gas generation, but gas caps may exist in some plays.

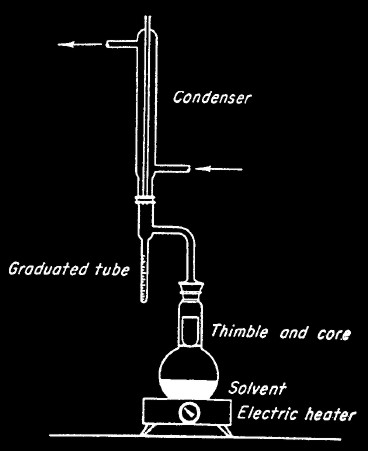

DEAN-STARK CORE ANALYSIS METHOD

DEAN-STARK CORE ANALYSIS METHOD

This method is used in poorly consolidated rocks such as

oil sands and involves

disaggregating the samples and weighing their constituent

components. Samples are usually frozen or wrapped in plastic to

preserve the contents during transport.

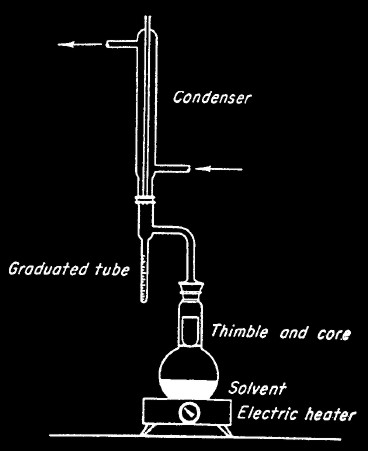

Dean-Stark laboratory apparatus

In the lab, the still

frozen cores are slabbed for photography and description, then

samples are selected and weighed.

Samples are then heated and crumbled to drive off water, and

weighed again. The weight loss gives the water weight. Solvents

are used to remove oil. The sample is weighed again and

the weight loss is the weight of oil. The matrix rock is

separated into clay and mineral components by flotation, dried

and weighed again, giving the weight of clay and weight of the

mineral grains.

1: WTwtr = WTsample - WTheated

2: WToil = WTheated - WTminerals&clay

By dividing each weight by its respective density and

adjusting each result for the total weight of the sample, the

volume fraction of each is obtained. Porosity is the sum of

water plus oil volume fractions Because the bound water in

the clay is driven off by the drying sequences, this porosity is

the total porosity. By dividing each weight by its respective density and

adjusting each result for the total weight of the sample, the

volume fraction of each is obtained. Porosity is the sum of

water plus oil volume fractions Because the bound water in

the clay is driven off by the drying sequences, this porosity is

the total porosity.

3: VOLwtr = WTwtr / DENSwtr / WTsample

4: VOLtar = WTtar / DENStar / WTsample

5: PHIcore = VOLwtr + VOLtar

Assuming clay bound water is driven off by heating and drying,

then PHIcore equals total porosity. From comparison to log

analysis results, it appears that some clay bound water remains

in many cases, so PHIcore lies between total and effective

porosity from log analysis.

Example of Dean-Stark porosity (black dots) showing that it is

less than total porosity from

logs (black curve) due to incomplete drying of clay. Trying to match

log porosity

directly to core may be futile in many cases. Porosity scale is 0.50 to

0.00.

If an oil sand

is consolidated enough to be analyzed by conventional core analysis

instead of Dean -Stark methods (which can handle disaggregated

samples), porosity, saturation , and permeability can be obtained.

No permeability estimate can be made during a Dean-Stark analysis so

permeability data in oil sands projects can be quite sparse.

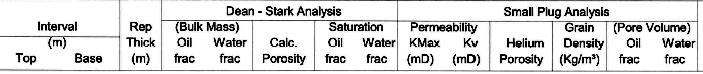

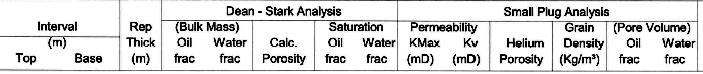

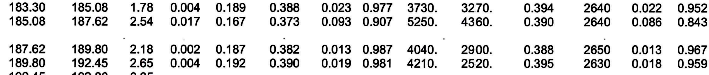

The table below

shows a comparison of the results from both lab methods.

Dean-Stark core analysis in a water

zone in an oil sand play (left side of table) contrasted with

conventional helium porosity analysis .

OIL MASS FROM CORE LISTINGS

OIL MASS FROM CORE LISTINGS

If not provided on the core listing, the equivalent value of

oil mass from core analysis

is derived from porosity, oil saturation, and an assumed oil

density:

1: Woil = PHIcore * Soil * DENSoil

2: Wwtr = PHIcore * Swtr * DENSwtr

3: Wrock = (1 – PHIcore) * GR_DENScore

Where:

Soil = oil volume relative to pore volume

Swtr = water volume relative to pore volume

PHIcore = volume of water + volume of oil

Woil = oil mass fraction

Wwtr = water mass fraction

Wrockcore = rock mass fraction

|

PHIcore |

Star |

Swtr |

Vol Oil |

Vol Wtr |

GR_ DEN |

WT Oil |

WT Sand |

WT Wtr |

WT Rock |

Oil Mass Wtar |

Wtr Mass Wwtr |

Rock ``Mass Wrock |

|

frac |

frac |

frac |

frac |

frac |

kg/m3 |

|

|

|

|

frac |

frac |

frac |

|

0.306 |

0.301 |

0.699 |

0.092 |

0.214 |

2.650 |

0.092 |

1.839 |

0.212 |

2.143 |

0.043 |

0.099 |

0.858 |

|

0.271 |

0.236 |

0.764 |

0.064 |

0.207 |

2.650 |

0.064 |

1.932 |

0.207 |

2.203 |

0.029 |

0.094 |

0.877 |

|

0.279 |

0.306 |

0.694 |

0.085 |

0.194 |

2.650 |

0.085 |

1.911 |

0.193 |

2.189 |

0.039 |

0.088 |

0.873 |

|

0.244 |

0.304 |

0.696 |

0.074 |

0.170 |

2.650 |

0.074 |

2.003 |

0.168 |

2.246 |

0.033 |

0.075 |

0.892 |

|

0.298 |

0.217 |

0.783 |

0.065 |

0.233 |

2.650 |

0.065 |

1.860 |

0.233 |

2.158 |

0.030 |

0.108 |

0.862 |

|

0.273 |

0.298 |

0.702 |

0.081 |

0.192 |

2.650 |

0.081 |

1.927 |

0.191 |

2.199 |

0.037 |

0.087 |

0.876 |

Table 1

(above): When saturations and porosity are known (blue shading), all

other terms can be calculated. GR_DENS must be measured or assumed and DENSwtr and DENStar are usually assumed to be 1000 kg/m3. Some core

analysis reports do the math for you, some do not.

Since GR_DENScore represents a mixture of quartz and

shale, this value should vary with shale volume. However shale

volume is never reported on core analysis, so the composite grain

density from the rock sample is used. If grain density is

not recorded in the core analysis, we must assume a constant of 2650 kg/m3 or lower.

FLUID VOLUMES FROM CORE LISTINGS

FLUID VOLUMES FROM CORE LISTINGS

If not provided on the core listing, the equivalent value of

oil

volumes from core analysis

are derived from porosity, oil mass fraction, and an assumed oil

density:

1: Soil = Woil / (PHIcore * DENSoil)

2: Swtr

= Wwtr / (PHIcore * DENSwtr)

OR 2A: Swtr = 1.00 - Soil

Where:

Soil = oil volume relative to pore volume

Swtr = water volume relative to pore volume

PHIcore = volume of water + volume of oil

Woil = oil mass fraction

Wwtr = water mass fraction

|

PHIcore |

Star |

Swtr |

Vol Oil |

Vol Wtr |

GR_ DEN |

WT Oil |

WT Sand |

WT Wtr |

WT Rock |

Oil Mass Wtar |

Wtr Mass Wwtr |

Rock Mass Wrock |

|

frac |

frac |

frac |

frac |

frac |

kg/m3 |

|

|

|

|

frac |

frac |

frac |

|

0.306 |

0.301 |

0.699 |

0.092 |

0.214 |

2.650 |

0.092 |

1.839 |

0.212 |

2.143 |

0.043 |

0.099 |

0.858 |

|

0.271 |

0.236 |

0.764 |

0.064 |

0.207 |

2.650 |

0.064 |

1.932 |

0.207 |

2.203 |

0.029 |

0.094 |

0.877 |

|

0.279 |

0.306 |

0.694 |

0.085 |

0.194 |

2.650 |

0.085 |

1.911 |

0.193 |

2.189 |

0.039 |

0.088 |

0.873 |

|

0.244 |

0.304 |

0.696 |

0.074 |

0.170 |

2.650 |

0.074 |

2.003 |

0.168 |

2.246 |

0.033 |

0.075 |

0.892 |

|

0.298 |

0.217 |

0.783 |

0.065 |

0.233 |

2.650 |

0.065 |

1.860 |

0.233 |

2.158 |

0.030 |

0.108 |

0.862 |

|

0.273 |

0.298 |

0.702 |

0.081 |

0.192 |

2.650 |

0.081 |

1.927 |

0.191 |

2.199 |

0.037 |

0.087 |

0.876 |

Table 2

(above): If oil mass fraction and water mass fraction are known, as

well as core porosity (blue shading), all other terms can be

calculated. Some core analysis reports do the math for you, some do

not.

OIL SAND MATH

OIL SAND MATH

Petrophysical analysis of oil sands follows the standard methods

that have been in use for more than 40 years: The math for these

steps is HERE, except where noted in the

test.

Step 1: Load, edit, and depth shift the full log suite, including

resistivity, SP, GR, density, neutron, PE, caliper, and sonic, where

available. If a thorium or uranium corrected GR (CGR) are available,

load these too. Create a Bad Hole Flag if one is needed.

Step 2: Calculate clay volume. Because some uranium may cause spikes

on the GR, use the minimum of the gamma ray and density-neutron

separation methods. This eliminates false “shale” beds that would

otherwise appear to act as baffles to the flow of steam or oil. The

SP is unlikely to be a useful clay indicator due to the high

resistivity of the oil zone.

Step 3: Calculate clay corrected porosity from the complex lithology

density-neutron crossplot model. This model accounts for heavy

minerals if any are present, compensates for small quantities of gas

if present, and reduces statistical variations in the porosity

values. DO NOT USE THE DENSITY POROSITY LOG ALONE. It will read too

low if heavy minerals are present and too high if gas is present.

The statistical variations at high porosity can give a noisy result.

Some oil sands have enough coal or carbonaceous material to look

like a coal bed. Set a coal trigger on the density and neutron and

set porosity to zero when the trigger is turned on. There is nothing

complex about the complex lithology model, so use it. See “Special

Cases” below if there is gas crossover in the oil zone.

Step 4: Calculate clay corrected water saturation from the Simandoux

or dual-water equations. These default to the Archie model in clean

sands but give more oil in shaly sands.

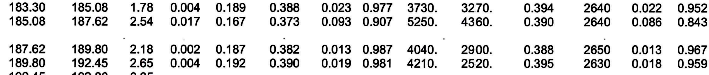

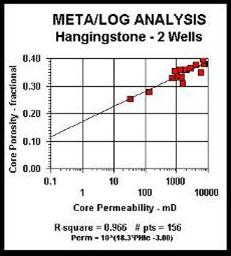

Step

5: Correlate core porosity and core permeability on a

semi-logarithmic graph, if any data is available. The resulting

equation takes the form Perm = 10^(A * PHIe + B) where A is the

slope and B is the intercept at zero porosity on the graph. Step

5: Correlate core porosity and core permeability on a

semi-logarithmic graph, if any data is available. The resulting

equation takes the form Perm = 10^(A * PHIe + B) where A is the

slope and B is the intercept at zero porosity on the graph.

Step 6: Calculate permeability as a continuous curve versus depth,

using the regression analysis in Step 5.

Steps 1 through 6 cover the conventional volumetric analysis of an

oil sand, but we are not finished yet.

Step 7: Convert log analysis

volumetrics to mass fraction values.

1: WToil = (1 – Sw) * PHIe * DENSHY

2: WTshl = Vsh * DENSSH

3: WTsnd = (1 - Vsh - PHIe) * DENSMA

4: WTwtr = Sw * PHIe * DENSW

5: WTrock = WToil + WTshl + WTsnd + WTwtr

Oil mass fraction:

6: Woil = WToil / WTrock

7: WT%oil = 100 * Woil

Typical densities are DENSMA = 2650, DENSW = DENSHY = 1000, DENSSH

= 2300 kg/m3.

Step 8: A bitumen pay flag is calculated with a log analysis oil

mass fraction cutoff, usually between 0.050 and 0.085 oil mass

fraction. A gas flag should also be shown on the depth plots where

density neutron crossover occurs on the shale corrected log data.

Step 9: Oil in place is calculated from he standard volumetric

equation. However, some operators, especially surface mining

people, work in tonnes of oil in place. This equation is:

1: OILtonnes = SUM (Woil * DENSoil * THICK) * AREA

Thickness is in meters and Area is in square meters.

If the oil equivalent in barrels or cubic meters is needed, the

standard equation can be used:

2: OOIP = KV3 * SUM(PHIe * Soil * THICK) * AREA / Bo

Where:

KV3 = 7758 bbl for English units KV3 = 1.0 m3 for Metric units

AREA = spacing unit or pool area (acres or square meters)

Bo = oil volume factor (unitless)

OOIP = oil in place as bitumen (bbl or m3)

Recovery factor for surface mining operations is very high, maybe

0.98 or better. For SAGD, RF = 0.35 to 0.50 are used. Since we can't

keep the stream away from the shaly sands, recovery will vary with

the average rock quality in a SAGD project.

Water has a very high latent heat, so the volume of water to be

steamed is as important to the economics as the volume of bitumen.

High water saturation is bad news here, just as in conventional oil.

Top water, top gas, and cap rock integrity are also major SAGD

issues. The petrophysical analysis needs to look at the rocks well

beyond the bitumen interval.

GAS EFFECT

AT LOW PRESSURE

GAS EFFECT

AT LOW PRESSURE

First lets look at the gas problem. If there is no gas crossover,

you can skip this section. The conventional equation for porosity in

a gas sand is: First lets look at the gas problem. If there is no gas crossover,

you can skip this section. The conventional equation for porosity in

a gas sand is:

1: PHIe = ((PHInc^2 + PHIdc^2) / 2) ^ (1 / 2)

This equation is accurate enough for most gas zones,

but in very shallow gas sands, it will underestimate porosity. The

above equation must be replaced by:

2: PHIe = ((PHInc^X + PHIdc^X) / 2) ^ (1 / X)

Where:

X is in the range of 2.0 to 4.0, default = 3.0.

PHIdc and PHInc are shale corrected values of density and neutron

porosity respectively.

Density neutron

crossover in a shallow gas sand with residual oil(shaded

area) and core analysis porosity (dots). The low neutron porosity

indicates little hydrogen content; the effect on the density is much smaller. An X

of 3.0 or higher is needed to calculate effective porosity from logs.

Porosity scale is 0.60 to 0.00

The exponent X is adjusted by trial

and error until a good match to core porosity is obtained.

PARTITIONING GAS and TAR VOLUMES

PARTITIONING GAS and TAR VOLUMES

After

shale volume and porosity have been calculated, water resistivity

can be found in a bottom water zone below the oil, as these rarely

has any residual oil. RW may vary somewhat in the oil sand interval

and this can be adjusted if necessary by comparing calculated oil

mass with core oil mass in non-gassy, relatively shale-free,

intervals. Water saturation is then calculated from a shale

corrected model such as Simandoux.

Many, but not

all, gas zones related to oil sands have some residual oil.

Hydrocarbon saturation is partitioned between bitumen and gas by the

following method: Many, but not

all, gas zones related to oil sands have some residual oil.

Hydrocarbon saturation is partitioned between bitumen and gas by the

following method:

3: Vwtr =

PHIe * Sw

4: Vhyd = PHIe * (1 – Sw)

5: GasTarRatio = Max(0, Min((1 – OIL_MIN), (PHIDc – PHINc) /

MAX_XOVER))

6: Vgas = GasTarRatio * Vhyd

7: Voil = (1 – GasTarRatio) * Vhyd

Oil weight is calculated from log analysis as follows:

8: WToil = Voil * DENSHY

9: WTshl = Vsh * DENSSH

10: WTsnd = (1 - Vsh -

PHIe) * DENSMA

11: WTwtr =

Vwtr *

DENSW

12: WTrock = WToil +

WTshl + WTsnd + WTwtr

Oil mass fraction:

13: Woil = WToil / WTrock

14:

WT%oil = 100 * Wtar

Where:

OIL_MIN = minimum oil volume in gas zone as seen on core analysis, could be zero.

MAX_XOVER = maximum density neutron crossover in a gas zone (fractional)

Vxxx =

volume fraction of a component

WTxxx = weight of a component (grams or Kg)

Wxxx = mass fraction of a component

WT%xxx = weight percent of a component

Comparison of

oil mass from log analysis (solid line) with oil mass from

Dean- Comparison of

oil mass from log analysis (solid line) with oil mass from

Dean-

Stark core analysis (dots) Oil mass scale is 0.30 to 0.00. Zone opposite

this

caption is gas with residual oil; above and below are oil with no

gas.

Typical

densities are DENSMA = 2650, DENSW = DENSHY = 1000, DENSSH =

2300 kg/m3. This is the only way to rigourously calculate Oil Mass.

Other equations have been used, such as the one shown below, but are

less accurate, since shale volume is not explicitly enumerated:

99:

Wtar

= ((1.0 - Sw) * Phie * DENStar) / (DENSrna * (1.0 - Phie))

Here, DENSma is a computed result from the log analysis, and is

usually wrong when gas is present. It hides the shale correction

term and individual rock and fluid parameters cannot be adjusted. I

strongly recommend that this "simplified" version be avoided.

It

should be noted that core data is usually derived from a summation

of fluids process, such as Dean-Stark method, so the porosity from

core matches total porosity better than effective porosity. Ditto

water saturation. That's why we use oil mass and not porosity and

saturation to calibrate log analysis to core data.

Oil mass from log analysis is plotted, as shown at

the right, along with oil mass calculated from core analysis data,

on the depth plots to show the match between log analysis and core

data results.

The match between log analysis oil mass, porosity,

and saturation with corresponding core data is usually excellent

except in the very shaly, non-pay, intervals, mostly because the

core data provided ignores shale and its effect on net grain

density. The match in zones with high gas saturation varies in

quality due to the inherent inaccuracy in the gas/oil partitioning

calculation on the log analysis.

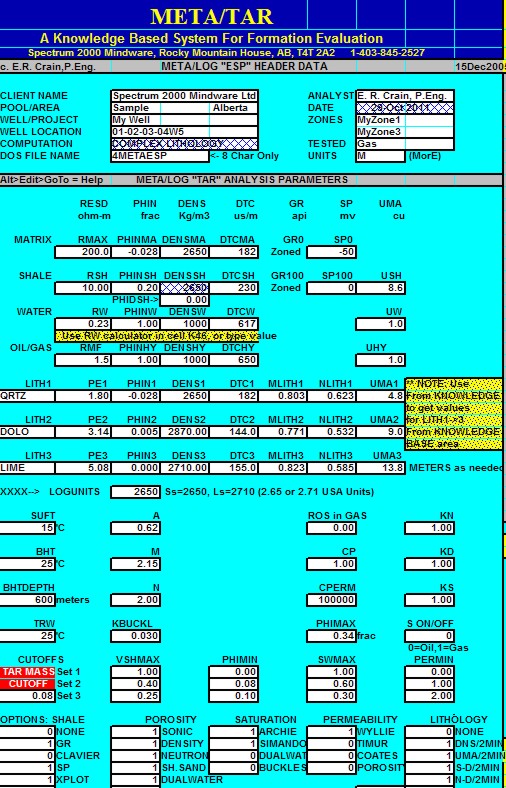

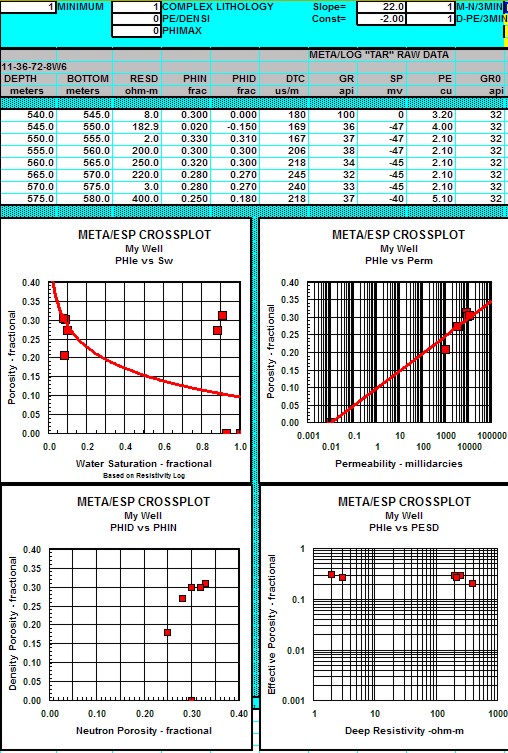

META/LOG

"TAR" SPREADSHEET -- Log Analysis in

Oil Sands META/LOG

"TAR" SPREADSHEET -- Log Analysis in

Oil Sands

This spreadsheet provides a tool for Log Analysis

of Oil Sands, including oil mass, net pay, and

reserves calculations.

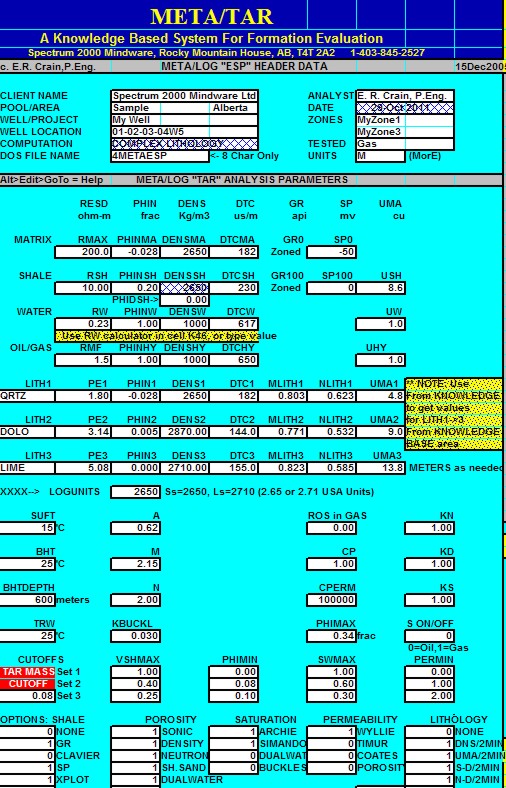

SPR-05 META/LOG ESP Advanced Log Analysis Bitumen Sand Metric

and USA

Bitumen Assay -- shale, porosity,

lithology, saturation, permeability, net pay, tar mass

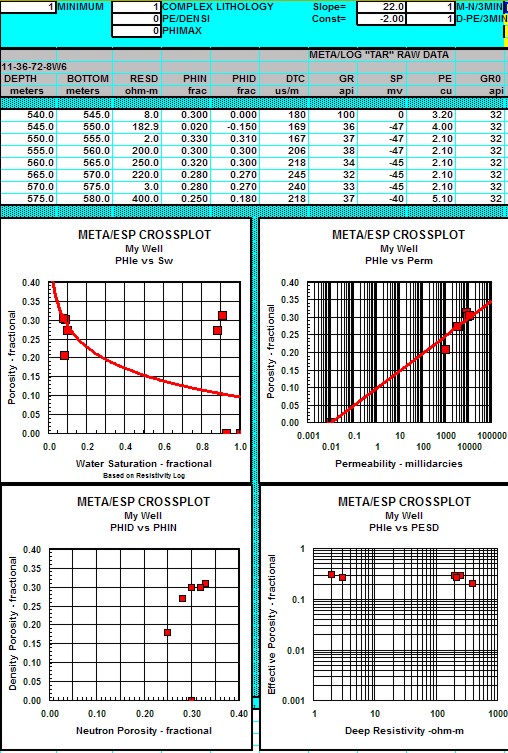

Sample of input data and crossplots for "META/LOG ESP Spreadsheet, used

to analyze oil sand zones.

Sample of "META/TAR" net pay summary table.

Oil SAND EXAMPLE

Oil SAND EXAMPLE

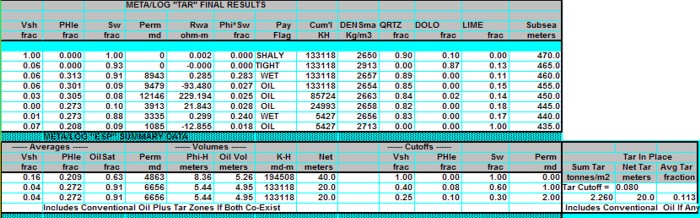

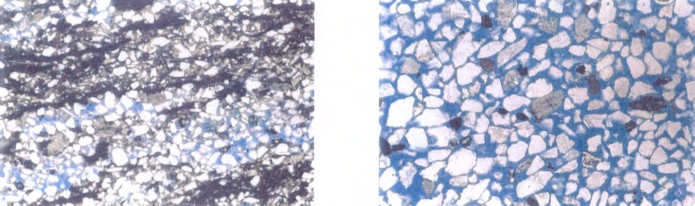

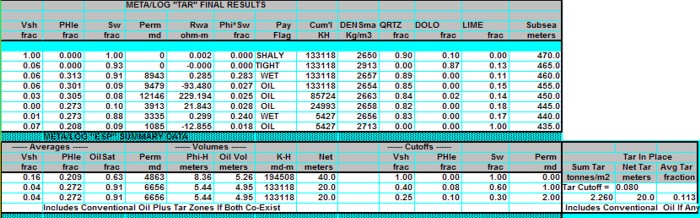

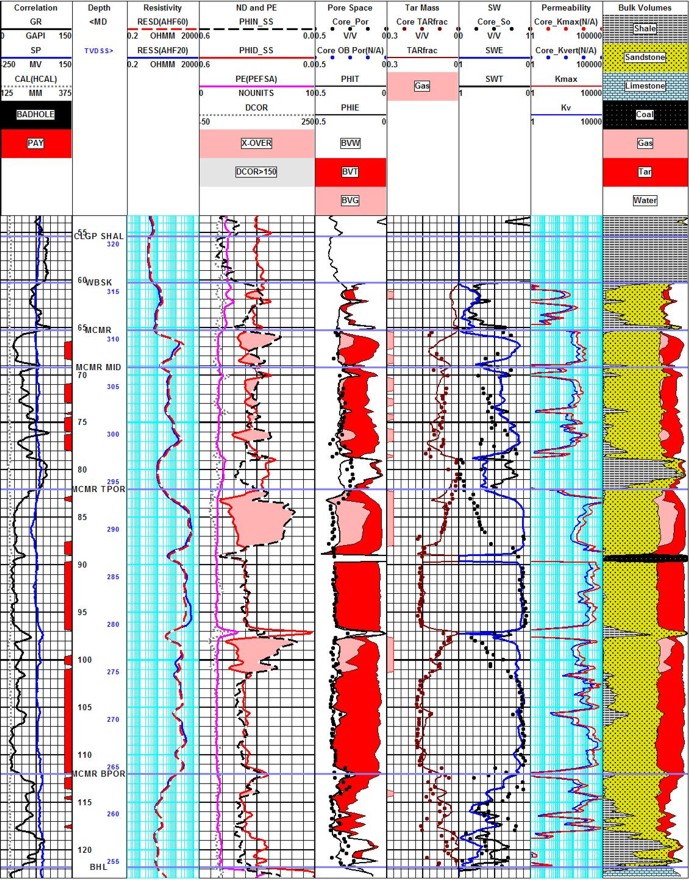

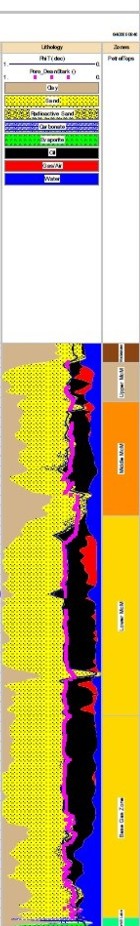

Oil sand analysis with top water, bottom

water, top gas, and mid zone gas. Core and log data match - but oil

mass is the critical measure of success. Core porosity matches total

porosity from logs, due to the nature of the summation of fluids

method used in these unconsolidated sands. Minor coal streaks occur

in this particular area.

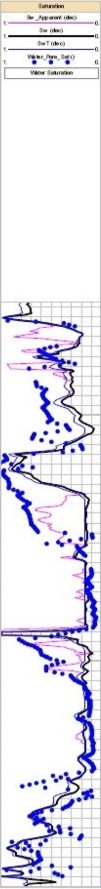

Water Satr'n

Statistical |

Fluids

Model |

Fluids

Determinist |

Oil Mass

ic Model |

ALTERNATE MODELS

ALTERNATE MODELS

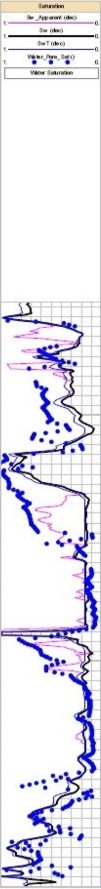

Comparison of petrophysical methods is often

instructive. In the analysis shown at left, a

probabilistic model (far left) is contrasted with a

deterministic model (right). On the probabilistic model,

oil is black, gas is red, water is blue, and clay bound

water is gray. On the deterministic model, oil is red,

gas is yellow, and water is white. Total porosity from

core (black dots) and total porosity from log analysis

are also shown on the deterministic model.

There are differences in

porosity, especially in the low porosity range,

differences in gas content, and differences in bulk

water volume. Core oil mass (right) was used to

calibrate the deterministic model; the match is

excellent in both gassy and non-gassy oil intervals.

The statistical model

was calibrated by comparing core water saturation to log

analysis saturation (far left). The match is poor in

some oil zones, reasonable in others, and of course is

not a meaningful comparison in gassy zones.

The statistical model

was tweaked several times but was never completely satisfying

because the calibration to core was based on saturation

and not on oil mass.

Oil mass comparison is the only

correct way to match log analysis to core analysis in

oil sand projects.

|

|

First lets look at the gas problem. If there is no gas crossover,

you can skip this section. The conventional equation for porosity in

a gas sand is:

First lets look at the gas problem. If there is no gas crossover,

you can skip this section. The conventional equation for porosity in

a gas sand is: