|

COAL BED METHANE BASICS

COAL BED METHANE BASICS

Coal-bed methane (CBM) is an economic source of

natural gas that is generated and stored in

coal beds. It is a widely occurring, exploitable resource that

can be easily recovered and used near the well or where

gas-pipeline infrastructure currently exists.

Coal acts as both source rock and

reservoir rock for methane. Methane is generated by microbial

(biogenic) or thermal (thermogenic) processes shortly after

burial, and throughout the diagenetic cycle resulting from

further burial.

Much of this gas is physically "sorbed" on coal surfaces.

Some higher ends may also be produced by coal, such as ethane,

and propane, but usually only a few percent of the total gas.

Adsorption is the process of gaining gas on a microporous

surface. Desorption is the process of releasing gas from such a

surface.

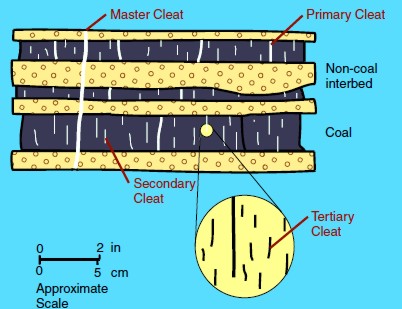

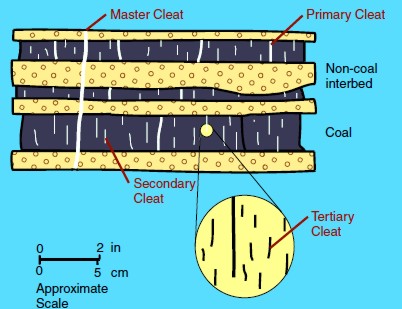

The

space between these surfaces are called cleats and range in size from obvious macrofractures to virtually invisible nanofractures.

These cleat patterns are crucial for gas production because they

allow for the

release of sorbed gas within coal beds and migration to the well

bore

Illustration of cleats, large to tiny Illustration of cleats, large to tiny

One gram of coal can contain as much

surface area as several football fields and therefore is capable

of sorbing large quantities of methane. One short ton (2000

pounds mass) of coal can store about 1,300 m3 of methane.

Depending on reservoir pressure, not all the storage capacity is

filled with gas.

Coal-bed gas content must have reached near-saturation,

either by biogenic or thermogenic gas-generation processes, to be

economically viable. Cleats must be present to allow for

connectivity between sorption sites. If the coal-bed horizons

are buried deeply (>2000 meters), cleats are closed because of

overburden pressure acting on the structurally weak coal bed.

Cleats can also be filled with other minerals, reducing their

effective permeability.

Methane

sorbed within coal beds is regulated by the hydrodynamic

pressure gradient. Methane is maintained within the coal bed as

long as the water table remains above the gas-saturated coal. If

the water table is lowered by basin or climatic changes, then

methane stored within the coal is reduced by release to the

atmosphere. Methane

sorbed within coal beds is regulated by the hydrodynamic

pressure gradient. Methane is maintained within the coal bed as

long as the water table remains above the gas-saturated coal. If

the water table is lowered by basin or climatic changes, then

methane stored within the coal is reduced by release to the

atmosphere.

Many coal beds need to be de-watered before they can

produce gas. Some coal beds have been de-watered naturally or by

crossflows due to previous drilling for oil or gas in nearby

wells. Poor quality cement jobs are a major cause of such

crossflows.

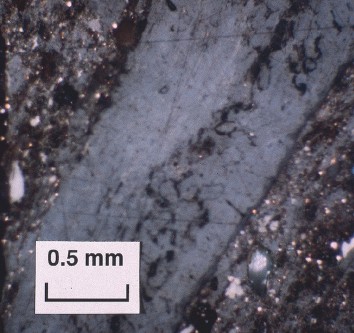

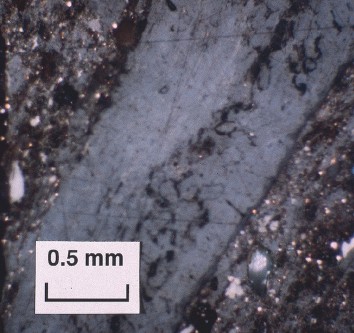

Cleats are tiny (black) but may be numerous

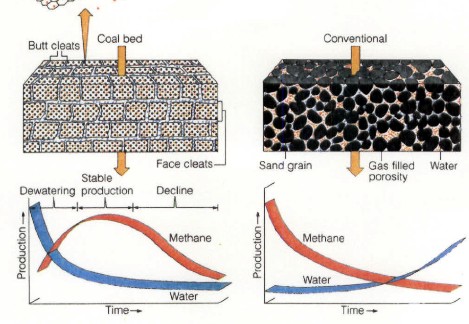

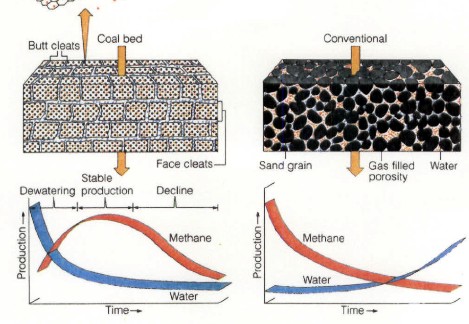

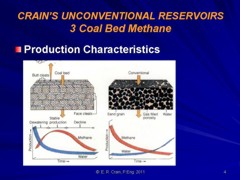

CBM wells, unlike conventional oil and gas producers, usually

show an increase in the amount of production (after initial

de-watering). As a coal is de-watered, the cleat system

progressively opens farther away from the well. As this process

continues, gas flow increases from the expanding volume of

de-watered coal. Water production decreases with time, which

makes gas production from the well more economical.

Comparison of conventional gas production and CBM

production characteristics

Sorption isotherms

Sorption isotherms

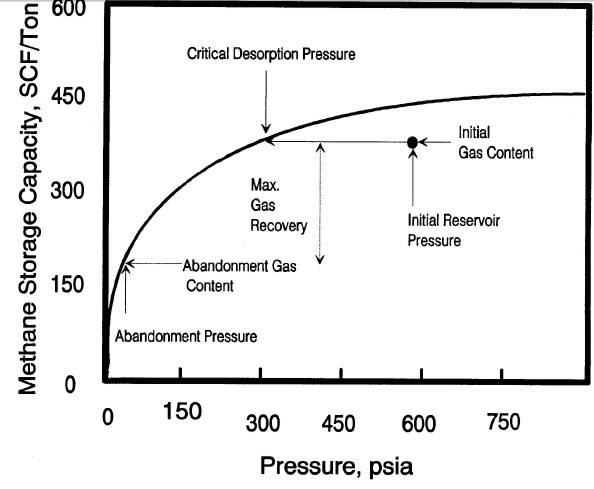

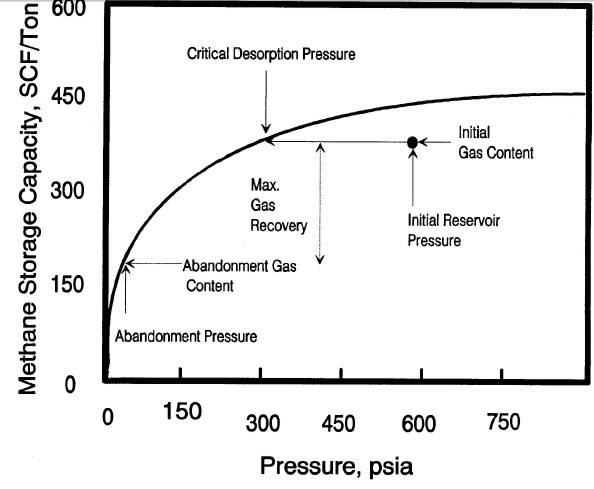

Sorption

isotherms indicate the maximum volume of methane that a coal can

store under equilibrium conditions at a given pressure and

temperature.

Typical sorption isotherm showing initial reservoir gas content

vs pressure, critical desorption pressure, and abandonment

conditions Gas will not flow until reservoir pressure is

less than critical pressure. Recovery factor and recoverable

reserves can be estimated by comparing initial and abandonment

gas content values on the isotherm curve.

The Langmuir equation is used to

predict the maximum gas storage capacity of a reservoir and the

equilibrium pressure . Most CBM reservoirs are somewhat

undersaturated, so the stored gas is less than the capacity of the

reservoir. A few are reported to be hypersaturated. The equations

are::

1: K1 = 0.21258 * Tf^0.5

2: K2 = 2.82873 – 0.00268 * Tf

3: K3 = 0.00259 * Tf + 0.50899

4: K4 = 0.00402 * Tf + 2.20342

5: Gmax = 10^(K1 * log(Wfcarb / Wwtr) + K2)

6: Pr = 10^(K3 * log(Wfcarb / Wwtr) + K4)

Where:

Gmax = gas volume at infinite pressure (ft3/ton)

Pr = Langmuir pressure, at which sample’s gas content is ½ Gmax

(atmospheres)

Tf = temperature (ºC)

Wfcarb = mass fraction of fixed carbon (fractional)

Wwtr = mass fraction of moisture (fractional)

Wfcarb and Wwtr are usually

measured in the lab during a Proximate Analysis. Log analysis

methods for obtaining these values are described in

Coal Analysis.

Numerical Example:

Numerical Example:

Given:

Wash Wfcarb

Wwtr

Pf atm Tf

ºC

DEPTH m Note 100 atm = 1466 psi = 10132 kPa

0.20 0.48

0.32 100

30 1000

K1 = 1.2 K2 = 2.7 K3 = 0.6

K4 = 2.3

Gmax = 898.2 Scf/ton Pr = 267.5 atm

CBM GAS CONTENT FROM CORE OR SAMPLE

ANALYSIS

CBM GAS CONTENT FROM CORE OR SAMPLE

ANALYSIS

Finding the actual gas content, Gc, in the lab can be done

directly as part of the Proximate Analysis, or indirectly. The direct method of determining sorption isotherms

involves drilling and cutting core that is immediately placed in

canisters, followed by measurements of the

volume of gas evolved from the coal over time.

The indirect method takes advantage of core or cuttings

that have been stored and does not require fresh core, thus

making this method more economical. Sorption isotherms are

experimentally measured using a powdered coal sample whose

saturated methane content at a single temperature is measured at

about six pressure points.

Moisture content in a coal decreases the sorption

capacity. Because coal loses moisture at a variable rate

subsequent to removal from the borehole, a standard moisture

content is used when measuring sorption isotherms.

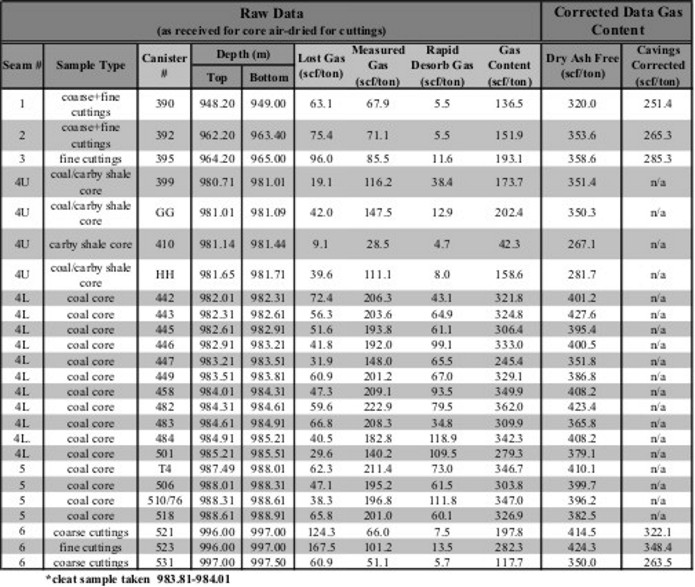

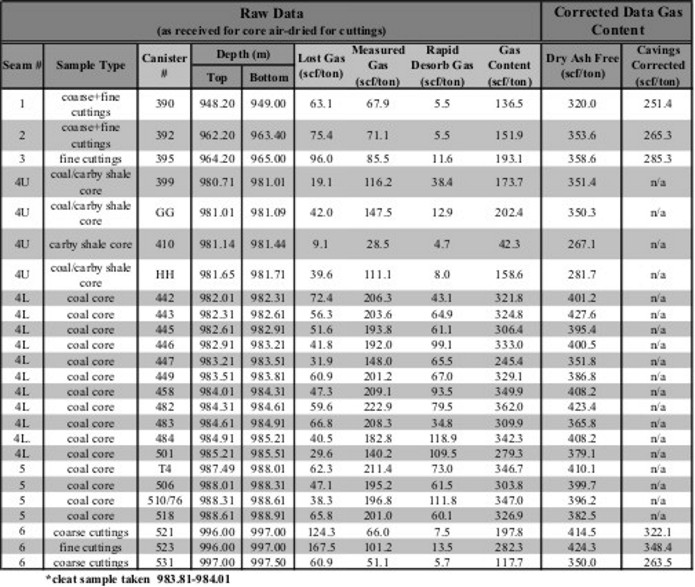

Two gas content values

are recorded. One is the actual gas content of the bulk coal;

the second is related to the dry, ash-free state of the coal, as

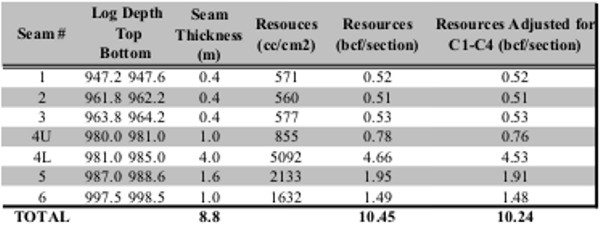

in the table below.

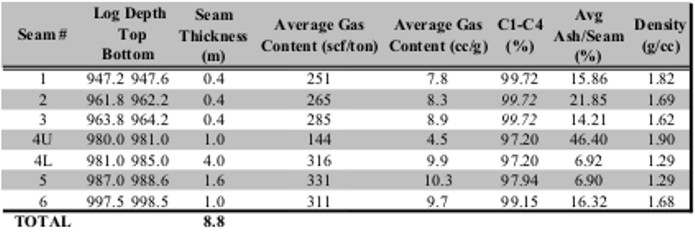

Gas content evaluation of coal beds. Notice that the dry,

ash-free values are considerably higher than the actual measured

values. As well, an estimate of the "lost gas" was made for each

sample to account for gas evolved from the sample before the

lab measurements were made.

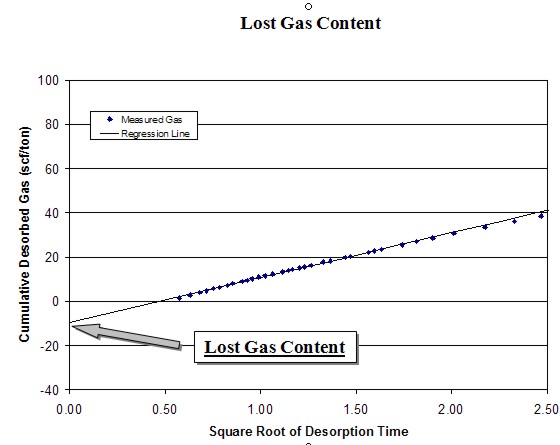

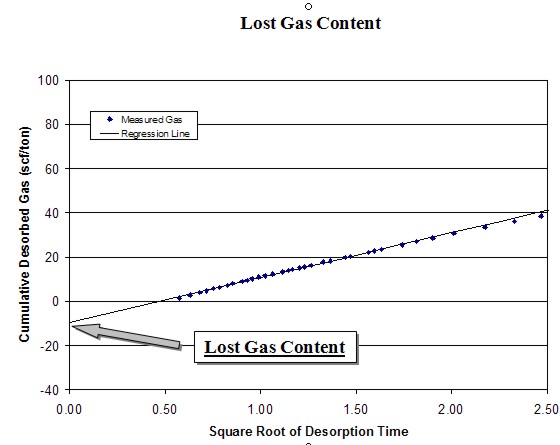

The

desorption data obtained during the first several hours can be

used to calculate the lost gas component. Cumulative desorbed

gas is plotted against the square root of desorption time. A

regression line is drawn through the first 4 to 6 hours of data

points and extrapolated back to time zero.

The

intercept of the regression line at time zero is the lost gas,

added to the actual desorbed gas volume to obtain the total

actual gas. This value is further adjusted using the ash and

water content from the proximate analysis to obtain the dry,

ash-free value. The

desorption data obtained during the first several hours can be

used to calculate the lost gas component. Cumulative desorbed

gas is plotted against the square root of desorption time. A

regression line is drawn through the first 4 to 6 hours of data

points and extrapolated back to time zero.

The

intercept of the regression line at time zero is the lost gas,

added to the actual desorbed gas volume to obtain the total

actual gas. This value is further adjusted using the ash and

water content from the proximate analysis to obtain the dry,

ash-free value.

The sample is allowed to desorb for a period of approximately 3

months or until desorption rates drop below 5cc per day for a period

of one week. Initial desorption volumes are measured using a 1000 cc

volumetric cylinder. Successive measurements use a 500cc and finally

a 250cc volumetric cylinder. The evolving gas pushes water out of

the cylinder, and the volume of water is measured to calculate the

volume of gas released.

Residual gas is the gas that remains in the matrix of the sample

after desorption is complete. To determine the residual gas content,

the sealed samples are heated in a drying oven to 50 C in order to

drive off the remaining gas. As with the measured gas volumes, the

residual gas content is measured by water displacement.

"Rapid desorb" is a technique to decrease the total desorption time.

Rapid desorb allows for the determination of the lost gas component

and the early time measured gas content. After initial desorption

has slowed down, the canisters are placed into a temperature bath

that is greater than 50 C and allowed to fully desorb. The increased

temperature accelerates the desorption rate. With rapid desorb it is

not possible to differentiate residual gas from desorb gas.

All desorption measurements must be corrected to standard

atmospheric temperature and pressure. By correcting to standard

conditions, gas contents from various well locations may be

compared. All canisters must also be corrected for any expansion and

contraction of void volume (headspace) within the canister. If the

headspace is not corrected for, changes in atmospheric pressure or

temperature are not accurately reflected in the desorption data. All

efforts are made to minimize the amount of headspace within each of

the canisters.

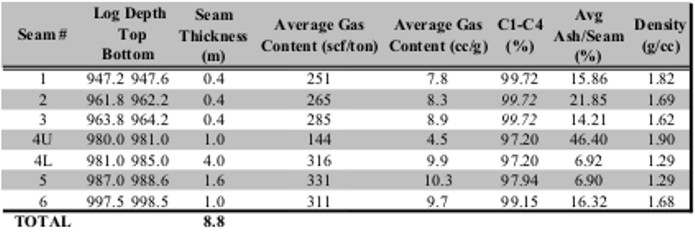

Gas content (Gc) results are usually given as scf/ton or

cc/gram. Multiply Gc in cc/gram by 32.18 to get Gc in scf/ton.

CBM Gas In Place - basic approach

CBM Gas In Place - basic approach

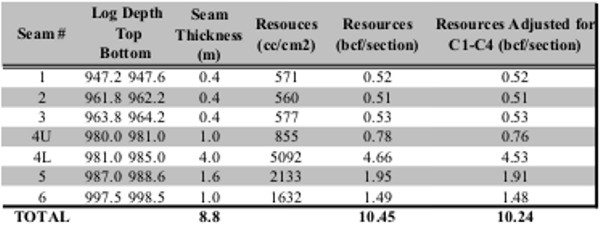

Gas in place is calculated from the isotherm curve,

or from the actual gas content found in the lab, by using coal bed thickness and coal density as measured by well

logs:

7: GIPcbm = KG6 * Gc * DENS * THICK * AREA

Where:

GIPcbm = gas in place (Bcf)

Gc = sorbed gas from isotherm or coal analysis report (scf/ton)

DENS = layer density from log or lab measurement (g/cc)

THICK = coal seam thickness (feet)

AREA (acres)

KG6 = 1.3597*10^-6

If AREA = 640 acres, then GIP = Bcf/Section (=Bcf/sq.mile)

Multiply meters by 3.281 to obtain thickness in feet.

Multiply Gc in cc/gram by 32.18 to get Gc in scf/ton.

COMMENTS

COMMENTS

Typical coal densities are in the range of 1.20 to 2.00

g/cc. Older density logs have a hard time reading less than 1.5

g/cc (FDC logs) but modern LDT logs can do it well. Some paper

logs may not show the backup scale for density less than 2.0

g/cc - check the digital file. If density cannot be obtained

from logs, use lab values or estimates.

CAUTION: If Gc is an actual measurement, the above equation

gives reasonable results.. If Gc is for the dry, ash-free

case or a theoretical value, the GIP from equation 7 must be

adjusted to represent the actual coal by multiplying GIP by (1 -

Vash - Vwtr).

Note that free gas in the cleats is assumed to be negligible in

most coals. In computer software, coal is usually triggered and

PHIe set to zero, and conventional log analysis models used

where there is no coal. Triggers are chosen based on

density, neutron, sonic, or resistivity, or some combination of

these.

Recoverable gas can be estimated by using the sorption curve

at abandonment pressure (Ga) and replacing Gc in Equation 7 with

(Gc - Ga).

Summary table of gas desorption analysis

Gas in place calculation based on proximate analysis and

gas desorption measurements shown

in previous tables.

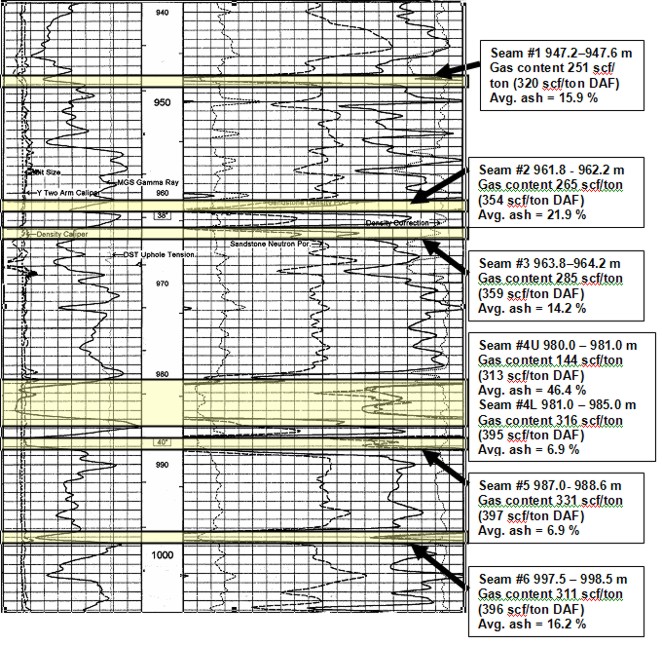

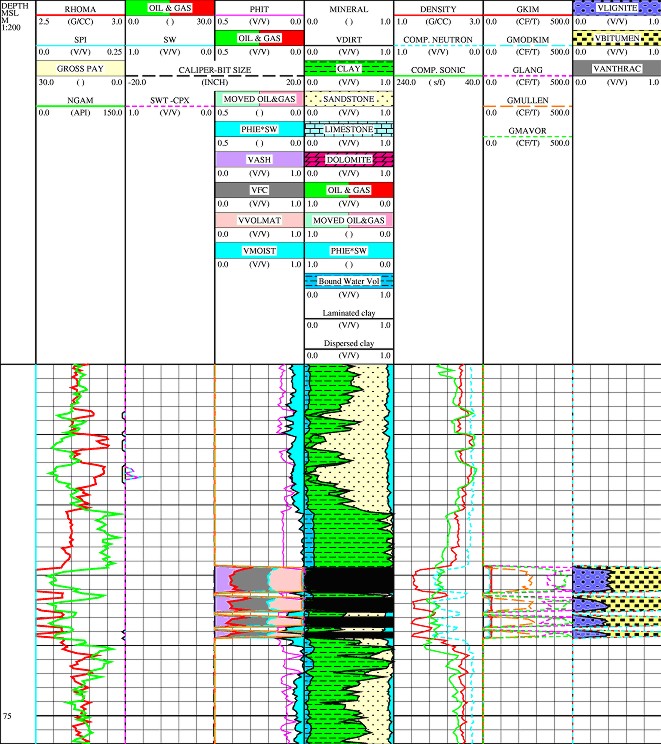

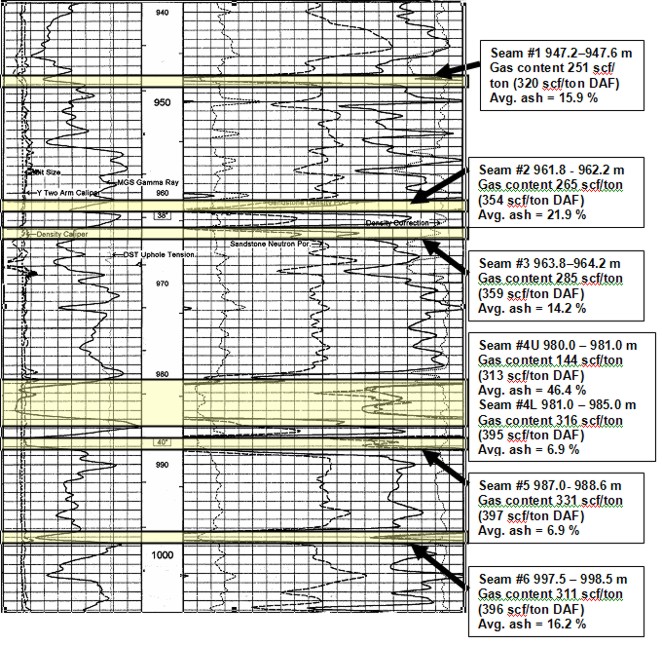

Well log showing location of coal

layers analyzed by proximate and gas desorption analysis. Log curves are GR, CAL, PE,

neutron, density, density correction.

CBM Gas content FROM LOG ANALYSIS

CBM Gas content FROM LOG ANALYSIS

These approaches are used where

measured Gc values are not available and involve more

detailed analysis of the coal itself. This breakdown can be

derived from analysis of core data, called proximate analysis,

or by analysis of log data. See Coal Analysis

Models for details of how to calculate the coal components.

Some of the following methods assume a complete coal analysis is

available from log or core data. Note that

the various authors use a variety of units of measurement, so read

their original papers carefully.

1. Mullen equation, based on

some average data in New Mexico (San Juan Basin):

8: Gc =

1053 – 542 * DENScoal

2. Mavor, Close, McBaner equation,

based on some average data in Utah:

9: Gc =

601.4 – 751.8 * Wash / (1.0 - Wwtr)

3. Kim Equation:

10: Ko = 5.6 + 0.8 * Wfcarb / Wwtr

11: No = 0.39 – 0.1 * Wfcarb / Wwtr

12: Gc = 75 * (1 - Wwtr - Wash) * (Ko *

Pf^No - 0.14 * Tf)

Where:

Gc = sorbed gas estimate (Scf/ton)

Pf = formation pressure (atmospheres)

Tf = formation temperature (ºC)

4. Modified Kim Equation:

13: Gc = 75 * (1 - Wwtr - Wash) * (Ko * (KG7 * DEPTH/100)^No - 0.14 *

KG8 * DEPTH/100 + KG9)

Where:

KG7 = pressure gradient (atm per 100 meters)

KG8 = temperature gradient (ºC per 100 meters)

KG9 = surface temperature (ºC)

DEPTH = average reservoir depth (meters)

Defaults: KG7 = 0.10, KG8 = 1.80,

KG9 = 12

This equation uses local gradients relating Pf and Tf

to depth. Measured values are usually better but

gradient values are useful when no measured data exists. Kim and

modified Kim will give identical results if gradients match measured

values.

5. Mullen’s correlation between SP

development and deliverability:

14: Qg = KG10 * SPmax * THICK

Where:

SPmax = absolute value of maximum SP deflection in coal (mv)

THICK = coal bed thickness (ft)

KG10 = 3100

Qg = gas rate (mmcf/d)

The parameter KG10 should be adjusted for each project area.

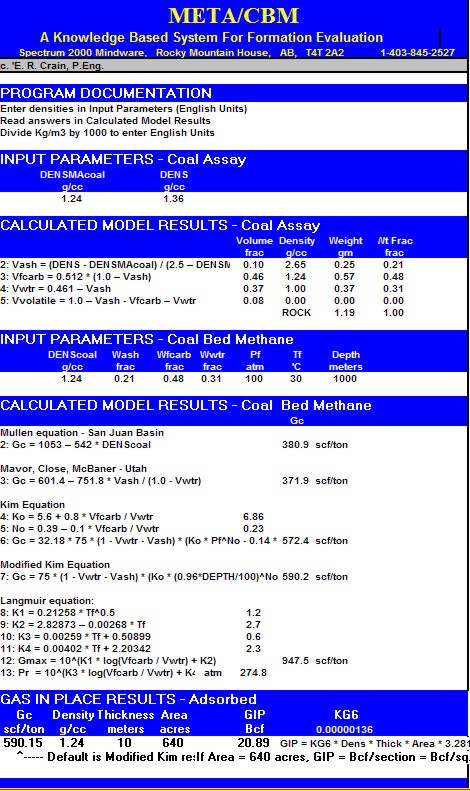

META/LOG "CBM" SPREADSHEET -- CBM Gas content FROM LOG

OR CORE ANALYSIS

META/LOG "CBM" SPREADSHEET -- CBM Gas content FROM LOG

OR CORE ANALYSIS

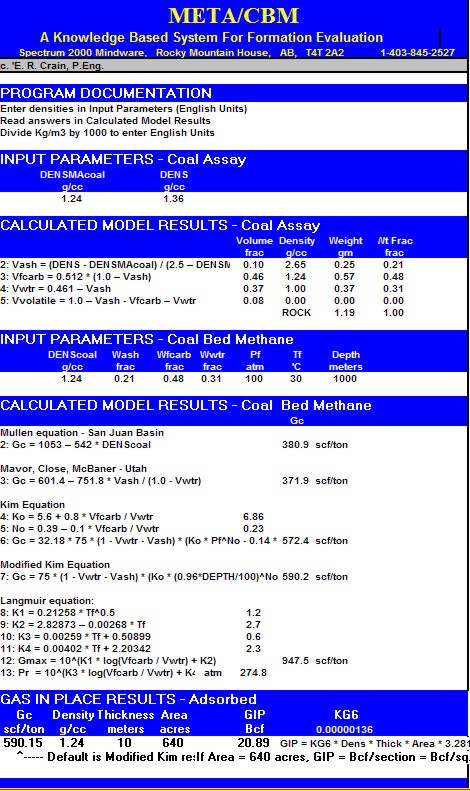

This

spreadsheet calculates a Coal Assay and converts it to a CBM gas

content (Gc) value that can be used to calculate gas in place.

Download this spreadsheet:

SPR-14 META/LOG COAL BED METHANE (CBM) CALCULATOR

Calculate coal assay, coal bed methane, adsorbed gas In

place

Sample output from "META/CBM" spreadsheet for coal bed methane

log analysis.

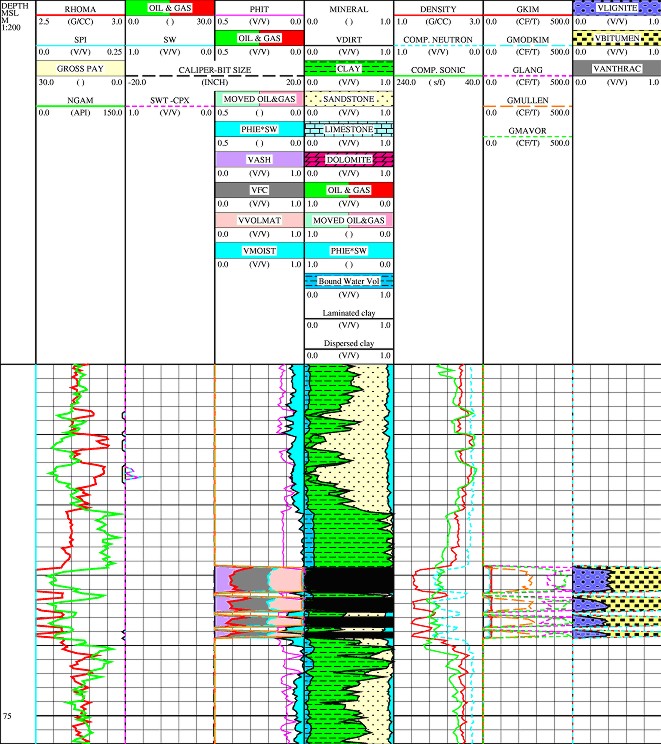

CBM LOG ANALYSIS EXAMPLE CBM LOG ANALYSIS EXAMPLE

Example of coal bed methane log analysis.

Kim and modified Kim gas content curves are shown in 2nd track

from the right. If temperature and pressure gradients matched

measured values, the results should be identical to each other.

The Langmuir gas curve in the same track shows the maximum

storage capacity of the coal.

|

Methane

sorbed within coal beds is regulated by the hydrodynamic

pressure gradient. Methane is maintained within the coal bed as

long as the water table remains above the gas-saturated coal. If

the water table is lowered by basin or climatic changes, then

methane stored within the coal is reduced by release to the

atmosphere.

Methane

sorbed within coal beds is regulated by the hydrodynamic

pressure gradient. Methane is maintained within the coal bed as

long as the water table remains above the gas-saturated coal. If

the water table is lowered by basin or climatic changes, then

methane stored within the coal is reduced by release to the

atmosphere.