|

IMMATURE OIL Shale BAsics

IMMATURE OIL Shale BAsics

The immature oil shale case is shown on the rest of this

web page. See

tight oil plays for the mature

kerogen special case.,

The

distinguishing characteristic of an immature "oil shale" is that it

contains significant organic carbon but no free oil or gas. This hydrocarbon is

immature, not yet transformed into oil by natural processes, and are usually termed

"source rocks". Some adsorbed and some free gas may also exist.

Immature oil shales require a specialized log analysis model because the

Archie saturation model is often inappropriate.

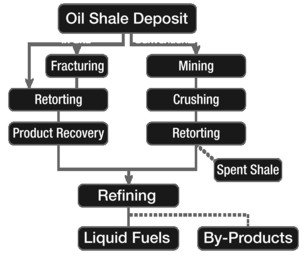

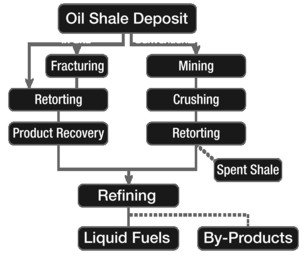

Immature oil shale can be mined on the surface or

at depth and the rock heated in a retort to convert the organic

content to oil. Some valuable by products such as vanadium may

also be extracted, but dry clay, ash, and other minerals are a

serious waste disposal issue. In-situ extraction using

super-heated steam, air, carbon dioxide, or some other heat

transfer system is used to convert the organic carbon to oil.

Collector wells then extract the oil.

Immature oil shales have been exploited since the mid 1800's. An

interesting radio show gives a brief history and an over-hyped

future for the Colorado -Utah-Wyoming immature oil shales as

seen from the post-war perspective of 1946. Click

HERE to listen.

You can fast-forward over the first 5 minutes to avoid some

really bad scene-setting dialogue. And they "forgot" to mention

that Canada was the first to commercially produce kerosene from

shale oil in 1846.

CLASSIFYING OIL Shale

CLASSIFYING OIL Shale

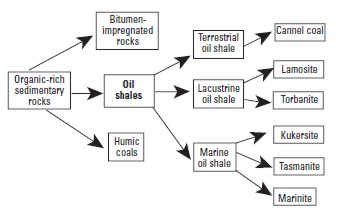

Immature oil shale has received many

different names over the years, such as cannel coal, boghead

coal, alum shale, stellarite, albertite, kerosene shale,

bituminite, gas coal, algal coal, wollongite, schistes

bitumineux, torbanite, and kukersite. Some of these names are

still used for certain types of oil shale. Recently, however,

attempts have been made to systematically classify the many

different types of oil shale on the basis of the depositional

environment of the deposit, the petrographic character of the

organic matter, and the precursor organisms from which the

organic matter was derived.

Flowchart for extracting oil from immature oil shale

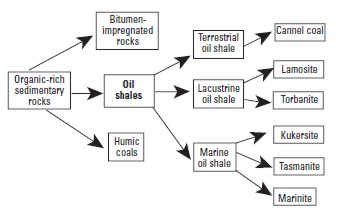

Oil shale classification chart

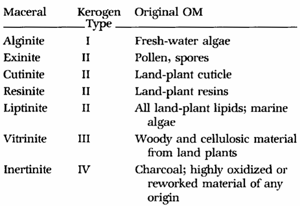

A

useful classification of oil shales was developed by A.C.

Hutton. He divided oil shale into three groups based on their

deposition environment: terrestrial, lacustrine, and marine, and

further by the origin of their organic matter.

Terrestrial oil shales include those

composed of lipid-rich organic matter such as resin spores, waxy

cuticles, and corky tissue of roots and stems of vascular

terrestrial plants commonly found in coal-forming swamps and

bogs. Lacustrine oil shales include organic matter derived from

algae that lived in fresh, brackish, or saline lakes. Marine oil

shales are composed of organic matter derived from marine algae

unicellular organisms, and marine dinoflagellates.

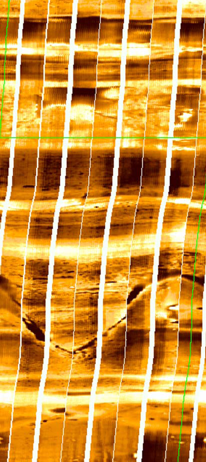

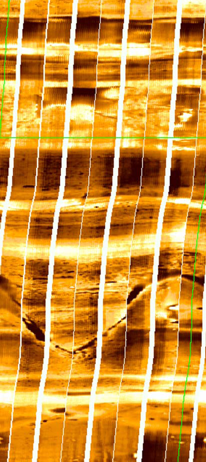

Resistivity image log in lacustrine

oil shale. White is high resistivity, Resistivity image log in lacustrine

oil shale. White is high resistivity,

black is low resistivity.

Within

these three groups, Hutton recognized six specific oil-shale

types, as shown in the diagram above:

1. Cannel coal is

brown to black oil shale composed of resins, spores, waxes, and

cutinaceous and corky materials derived from terrestrial

vascular plants together with varied amounts of vitrinite and

inertinite. Cannel coals originate in oxygen-deficient ponds or

shallow lakes in peat-forming swamps and bogs.

2. Lamosite is pale, grayish-brown and dark gray to black oil

shale in which the chief organic constituent is lamalginite

derived from lacustrine planktonic algae. Other minor components

include vitrinite, inertinite, telalginite, and bitumen. The

Green River oil-shale deposits in western United States and a

number of the Tertiary lacustrine deposits in eastern

Queensland, Australia, are lamosites.

3. Marinite is a gray to dark gray to black oil shale of

marine origin in which the chief organic components are

lamalginite and bituminite derived chiefly from marine

phytoplankton. Marinite may also contain small amounts of

bitumen, telalginite, and vitrinite. Marinites are deposited

typically in epeiric seas such as on broad shallow marine

shelves or inland seas where wave action is restricted and

currents are minimal. The Devonian–Mississippian oil shales of

eastern United States are typical marinites. Such deposits are

generally widespread covering hundreds to thousands of square

kilometers, but they are relatively thin, often less than 100 m.

4. Torbanite, named

after Torbane Hill in Scotland, is a black oil shale whose

organic matter is composed mainly of telalginite found in fresh-

to brackish-water lakes. The deposits are commonly small, but

can be extremely high grade.

5. Tasmanite, named

from oil-shale deposits in Tasmania, is a brown to black oil

shale. The organic matter consists of telalginite derived

chiefly from unicellular algae of marine origin and lesser

amounts of vitrinite, lamalginite, and inertinite.

6. Kukersite, which

takes its name from Kukruse Manor near the town of Kohtla-Järve,

Estonia, is a light brown marine oil shale. Its principal

organic component is telalginite derived from green algae.

Kukersdite is the main type of oil shale in Estonia and westtern

Russiaa, and is burned instead of coal to generate

electricity in power plants.

OIL Shale IN CANADA

OIL Shale IN CANADA

Canada

produced some shale oil from deposits in New Brunswick in the

mid-1800's. The mineral was called

Albertite and was originally believed to be a form of coal. Canada

produced some shale oil from deposits in New Brunswick in the

mid-1800's. The mineral was called

Albertite and was originally believed to be a form of coal.

Albert Mines, New Brunswick, in 1850's Albert Mines, New Brunswick, in 1850's

Later, the nature of

the mineral and its relation to the surrounding oil shale was

described correctly. Abraham Gesner used Albertite in his early

experiments to distill liquid fuel from coal and solid bitumen.

He is credited with the invention of kerosene in 1846, and built

a significant commercial distillery to provide lighting oil to

replace whale oil in eastern Canada and USA. In the 1880's,

shale oil was abandoned as a source of kerosene in favour of

distillation from liquid petroleum.

Canada's oil-shale deposits range from

Ordovician to Cretaceous age and include deposits of lacustrine

and marine origin in at least 20 locations across the country.

During the 1980s, a number of the deposits were explored by core

drilling. The oil shales of the New Brunswick Albert Formation,

lamosites of Mississippian age, have the greatest potential for

development. The Albert oil shale averages 100 l/t of shale oil

and has potential for recovery of oil and may also be used for

co-combustion with coal for electric power generation.

Marinites, including the Devonian Kettle Point Formation and the

Ordovician Collingwood Shale of southern Ontario, yield

relatively small amounts of shale oil (about 40 l/t), but the

yield can be doubled by hydroretorting. The Cretaceous Boyne and

Favel marinites form large resources of low-grade oil shale in

the Prairie Provinces of Manitoba, Saskatchewan, and Alberta.

Upper Cretaceous oil shales on the Anderson Plain and the

Mackenzie Delta in the Northwest Territories have been little

explored, but may be of future economic interest.

Total Organic CARBON (TOC)

Total Organic CARBON (TOC)

Organic

content is usually associated with shales or silty shales, and

is an indicator of potential hydrocarbon source rocks. High

resistivity with some apparent porosity on a log analysis is a

good indicator of organic content. Kerogen is the main source of

TOC; kerogen is usually radioactive (uranium salts) but the

quantity of radioactivity is not a good predictor of the

quantity of organic matter.. Organic

content is usually associated with shales or silty shales, and

is an indicator of potential hydrocarbon source rocks. High

resistivity with some apparent porosity on a log analysis is a

good indicator of organic content. Kerogen is the main source of

TOC; kerogen is usually radioactive (uranium salts) but the

quantity of radioactivity is not a good predictor of the

quantity of organic matter..

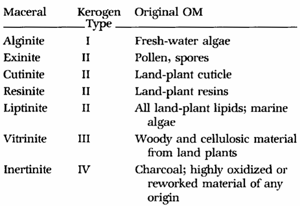

Oil

shales contain predominantly Type I kerogen, as opposed to coal and

coal bed methane reservoirs, which contain mostly Type III. Gas

shales contain mainly Type II kerogen.

Various

methods for quantifying organic content from well logs have been

published. The most useful approaches are based on density vs

resistivity and sonic vs resistivity crossplots. Other approaches

using core measured TOC versus log data, for example density or

sonic readings are also common. See TOC

Calculation for details.

Determining OIL YIELD (Grade) of

Oil Shale FROM ROCK SAMPLES

Determining OIL YIELD (Grade) of

Oil Shale FROM ROCK SAMPLES

The grade of oil shale has been determined by many

different methods with the results expressed in a variety of

units. The heating value of the oil shale may be determined

using a calorimeter. Values obtained by this method are reported

in English or metric units, such as British thermal units (Btu)

per pound of oil shale, calories per gram (cal/gm) of rock,

kilocalories per kilogram (kcal/kg) of rock, megajoules per

kilogram (MJ/kg) of rock, and other units.

The heating value is useful for determining the quality of an

oil shale that is burned directly in a power plant to produce

electricity. Although the heating value of a given oil shale is

a useful and fundamental property of the rock, it does not

provide information on the amounts of shale oil or combustible

gas that would be yielded by retorting (destructive

distillation).

The grade of oil shale can be determined by measuring the yield

of oil of a shale sample in a laboratory retort. The method

commonly used in Canada and United States is called the modified

Fischer assay, first developed in Germany, then adapted by the

U.S. Bureau of Mines. The technique was subsequently

standardized as the ASTM Method D-3904-80. Some laboratories

have further modified the Fischer assay method to better

evaluate different types of oil shale and different methods of

oil-shale processing.

The standardized Fischer assay consists of heating a 100-gram

sample crushed to –8 mesh (2.38-mm mesh) screen in a small

aluminum retort to 500ºC at a rate of 12ºC per minute and held

at that temperature for 40 minutes. The distilled vapors of oil,

gas, and water are passed through a condenser cooled with ice

water into a graduated centrifuge tube. The oil and water are

then separated by centrifuging. The quantities reported are the

weight percent of shale oil, water, shale residue, and “gas plus

loss” by difference. Some organic matter is turned to char and

reported as part of the shale residue. As a result, this assay

may understate the amount of oil that might be recovered in a

commercial scale retort that continuously mixes the feedstock.

Oil yield is usually converted from mass fraction into US or

Imperial gallons per ton (gpt or gal/t) of rock. So much for

going metric! In Canada, oil yields are quoted in liters per

metric ton of rock (l/t).

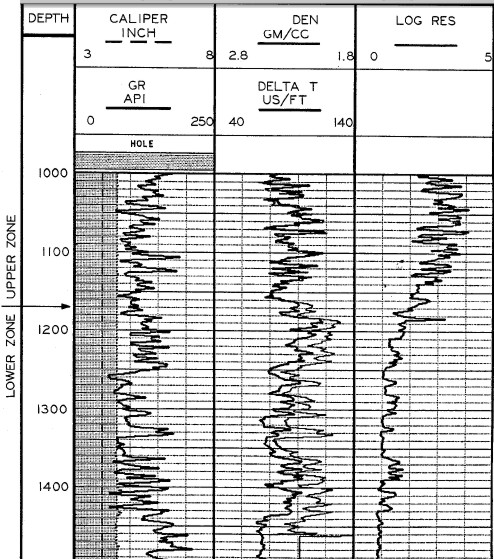

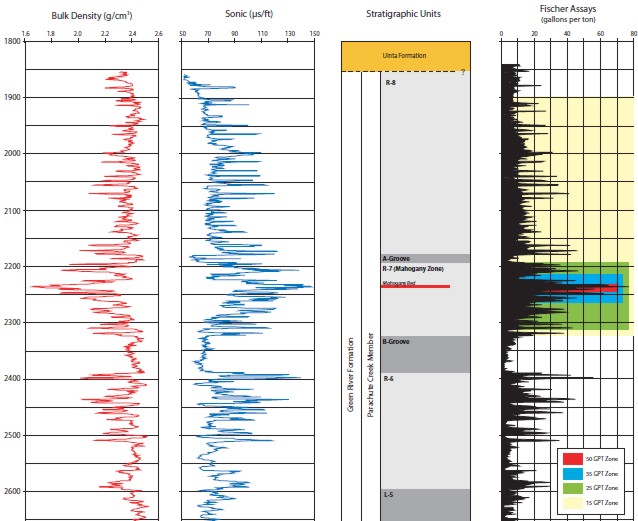

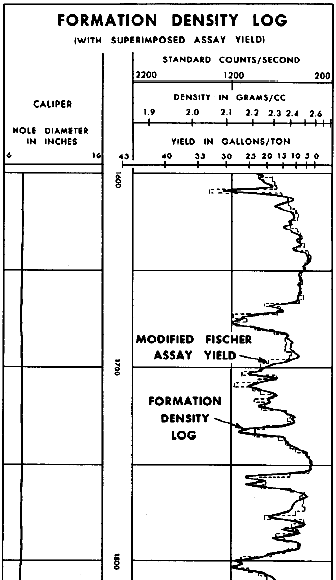

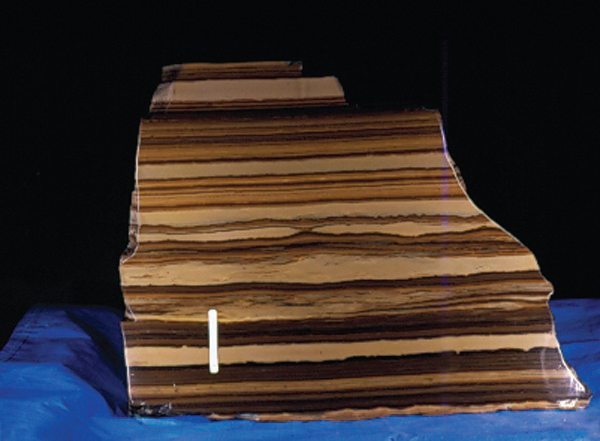

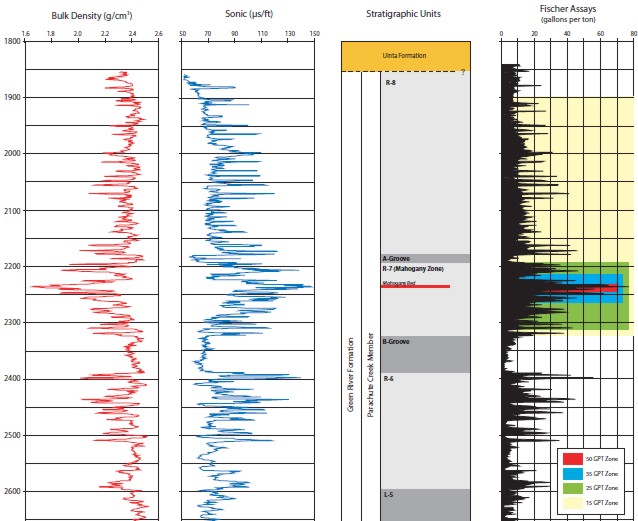

Oil shale example from Utah; density log (left), sonic (middle,

Fischer oil yield in gallons/ton (right). Note sonic scale is

reverse of conventional oilfield practice. Low density and high

sonic travel time correspond to high oil yield, analogous to

high porosity in conventional oilfield applications.

Determining OIL YIELD (Grade) of

Oil Shale FROM WELL LOGS

Determining OIL YIELD (Grade) of

Oil Shale FROM WELL LOGS

Traditional methods for log analysis of oil

shales, dating back to the early 1960's, are somewhat

over-simplified regression methods using sonic or density data.

See for example "Evaluating Oil Shales by Well Logs" by S. R.

Bardsley and S. T. Aigermissen, AIME, 1962.

By crossplotting Fischer assay oil yields with corresponding

log data, regression lines are generated that provide a decent

average oil yield from logs. Problems related to matrix density

or matrix travel time variations due to mineral variations with

depth are masked by this method. Separate transforms are usually

taken when mineralogy is known to change. Logs average about 3

feet (1 meter) of rock compared to much finer detail available

from the core assay, so crossplots tend to show considerable

scatter in laminated intervals, as shown in the examples

below..

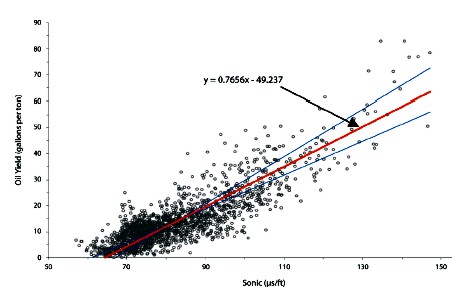

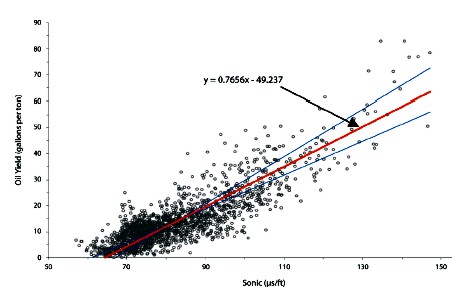

Sonic

log data versus oil yield from Utah example. Reduced major axis

best fit is the most appropriate regression method (red line).

Y-on-X and X-on-Y regression lines are also shown. Sonic is in

usec/foot, oil yield is in US gallons/ton (gpt or g/t)of rock. Sonic

log data versus oil yield from Utah example. Reduced major axis

best fit is the most appropriate regression method (red line).

Y-on-X and X-on-Y regression lines are also shown. Sonic is in

usec/foot, oil yield is in US gallons/ton (gpt or g/t)of rock.

Equation of the line is:

1: Y = 0.766 * DTC - 49.4

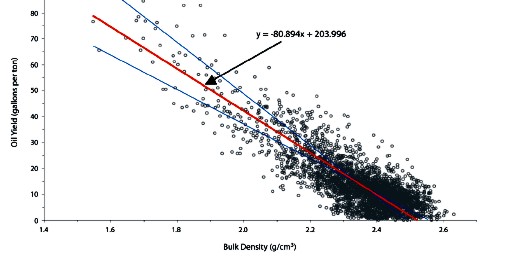

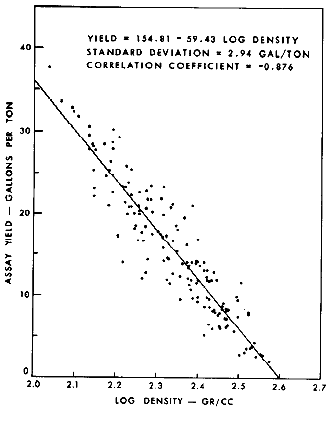

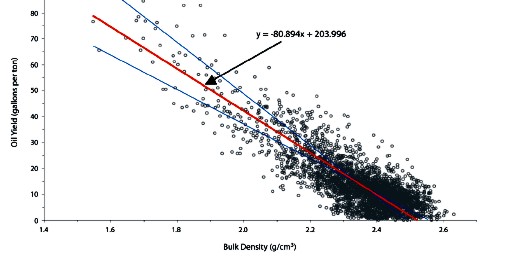

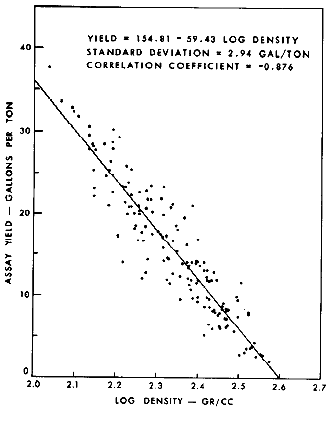

Density versus oil yield for

same data set. Density

is in grams/cc

Equation of the line is:

2: Y = - 80.3 * DENS - 204

Data is from "Basin-Wide

Evaluation of Uppermost Green River Oil Shale Resources, Uinta

Basin, Utah and Colorado" by M. D. Vanden Berg, Utah Geol

Survey, 2008.

Equations for each individual well were also presented,

showing considerable variation from well to well and zone to

zone.

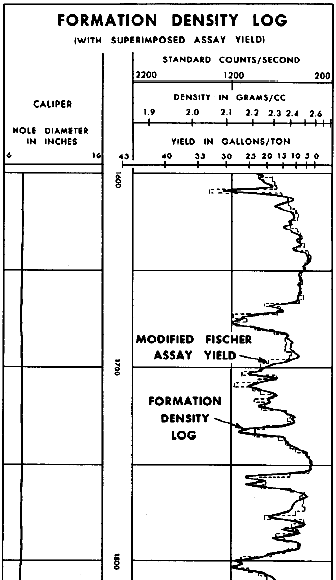

Portuib of debsity log with Fischer core assay (dashed

line) and crossplat of density and oil yield, from "Log

Evaluation of

Non-Metallic Minerals" SWSC, by M,P, Tixier and R.P/ Alger

A

literature search quoted by R. M. Habiger and R. H. Robinson in

1985 gives the following equations for estimating oil yield: A

literature search quoted by R. M. Habiger and R. H. Robinson in

1985 gives the following equations for estimating oil yield:

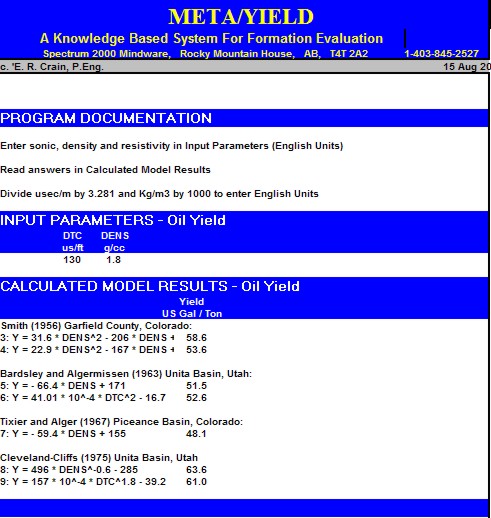

Smith (1956) Garfield County, Colorado:

3: Y = 31.6 * DENS^2 - 206 * DENS + 327

4: Y = 22.9 * DENS^2 - 167 * DENS + 280

Bardsley and Algermissen (1963) Unita Basin, Utah:

5: Y = - 66.4 * DENS + 171

6: Y = 41.01x10^-4 = DTC^2 - 16.7

Tixier and Alger (1967) Piceance Basin, Colorado:

7: Y = - 59.4 * DENS + 155

Cleveland-Cliffs (1975) Uinta Basin, Utah

8: Y = 496 * DENS^-0.6 - 285

9: Y = 157 * 10^-4 * DTC^1.8 - 39.2

I have reduced all equations to 3 significant digits, which

is all that log analysis can support. The reader should refer to

the appropriate technical papers to see the data spread and

regional environment before using any of the above equations.

NUMERICAL EXAMPLE

DENS 2.2 1.8 g/cc

DTC 100 130 usec/ft

Smith

3: 26.7 58.6 US gal/ton

4: 23.4 53.6

Bardsley and Algermissen

5: 24.9 51.5

6: 24.3 52.6

Tixier and Alger

7: 24.3 48.1

Cleveland-Cliffs

8: 24.0 63.6

9: - 23.3 61.0

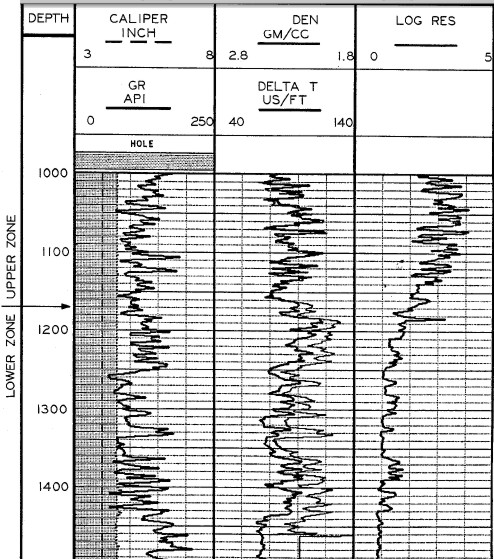

MULTIPLE REGRESSION (PHILLIPS) METHOD

MULTIPLE REGRESSION (PHILLIPS) METHOD

A more sophisticated method was proposed by R. M. Habiger and R.

H. Robinson in 1985, using multiple linear regression of sonic,

density, and resistivity versus oil yield. The method was

patented by the authors on behalf of Phillips Petroleum (US

Patent #4548071), even though the method is strictly

mathematical and no "invention" was involved. The patent

actually claims to protect every individual step of the math,

including taking the logarithm of resistivity. Since

mathematical solutions and computer code cannot be patented,

infringement is moot. Both sonic and density crossplots of the

type shown above are included in the patent and in their 1985 SPWLA paper.

They were also faced with very poor quality density log data

from poorly calibrated slim hole, non-contact tools. As a

result, they had to normalize the density logs using histograms

and correlated density "variation" (DV) to oil yield instead of

raw density. DV was calculated from:

10: DV = DENSlog - DENSmean

This also had the effect of handling some of the matrix

density variations between wells, but not from layer to layer

within each interval in a single well.

A clay index was generated by regression:

11: CI = DTC + 127.31 * DV - 84.84

Their regression line is quoted as:

Upper zone:

12: Y = - 74.37 * DV + 7.86 * (log RESD) +

0.5 * CI - 9.65

Lower Zone

13: Y = - 81.58 * DV + 4.70 * (log RESD) + 9.36

Where"

DENSlog = actual log reading (gm/cc)

DENSmean = average density log readings over the analyzed interval

(gm/cc)

DV = density variation (gm/cc)

DTC = compressional sonic travel time (usec/ft)

CI = clay index (percent)

RESD = deep resistivity reading (ohm-m)

Y = oil yield (gallons per ton of rock).

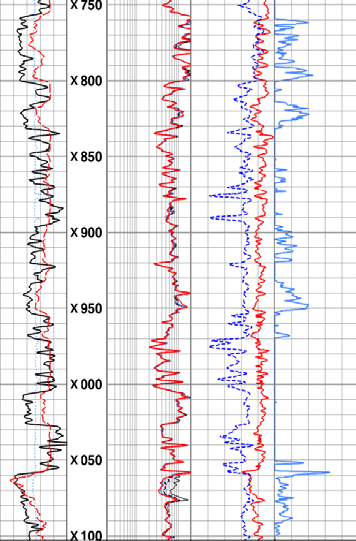

This is the log data from the paper and patent application.

Unfortunately neither

document contains an answer plot or Fischer assay data plotted

versus depth. Note that

both density and sonic scales are

reversed compared to normal oilfield practice.

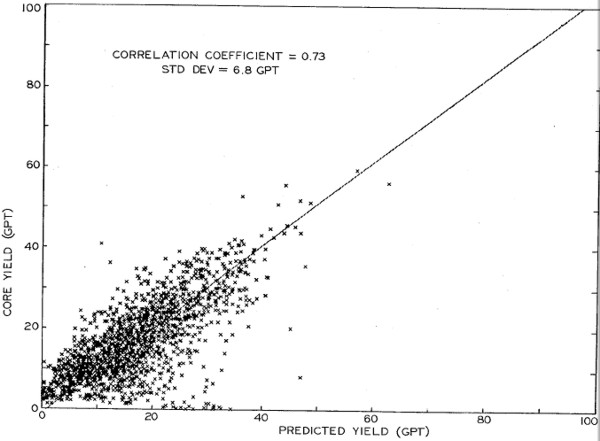

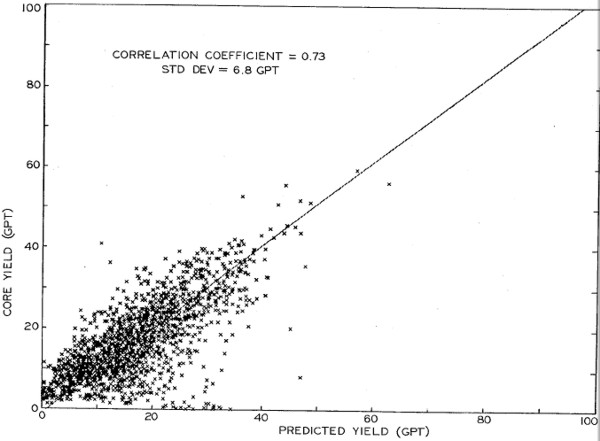

Comparison of Fischer assay oil yield versus yield

predicted from multiple regression.

Multi-mineral models for

IMMATURE OIL SHALE evaluation

Multi-mineral models for

IMMATURE OIL SHALE evaluation

There are no good reasons to avoid

standard multi-mineral methods such as simultaneous equations,

principal components, or other statistical methods for oil

shales. Simultaneous equation solutions are widely used in

mineral evaluation from logs and are covered elsewhere in this

Handbook. A typical equation set for an oil shale would be:

14: DENS = 2.35 * Vshl + 2.65 * Vqtz + 2.74 * Vlim + 2.87 * Vdol

+ 0.95 * Vker

15: DTC = 120 * Vshl + 55 * Vqtz + 47 * Vlim + 44 *

Vdol + 200 * Vker

16: PHIN = 0.30 * Vshl - 0.05 * Vqtz + 0.00 * Vlim + 0.04 * Vdol

+ 0.95 * Vker

17: PE = 3.45 * Vshl + 1.85 * Vqtz + 5.10 * Vlim + 3.10 *

Vdol + 0.95 * Vker

18: 1.00 = Vshl + Vqtz + Vlim + Vdol + Vker

This equation set is inverted by

Cramer's Rule or with spreadsheet functions to obtain the

unknown volumes. Parameters must be adjusted to suit local

conditions. Minerals chosen must be guided by local knowledge,

based on petrography or XRD results. If a log curve is

unavailable or faulty due to bad hole conditions, the data can

be synthesized or the equation set reduced to eliminate that

curve, with the loss of one of the minerals in the answer set.

The volumetric results must then be converted

to mass fraction, as is done for tar sands, potash, and coal

analysis:

19: WTshl = Vshl * 2.35

20: WTqtz = Vqtz * 2.65

21: WTlim = Vlim * 2.71

22: WTdol = Vdol * 2.87

23: WTker = Vker * 0.95

24: WTrock = = WTshl + WTqtz + WTlms + WTdol + WTker

Mass fraction

25: Wker = WTker / WTrock

26: WT%ker = 100 * Wker

Where:

Vxxx = volume fraction of components

WTxxx = weight of components

Wxxx = mass fraction of components

WT%xxx = weight percent of components

Density parameters must match those used in the original simultaneous

equation set.

Kerogen mass fraction should be close to Oil Yield mass fraction from Fischer

analysis, or a simple linear conversion to account for "gas plus

loss". If Fischer analysis is given in US gal / ton or liters /

ton, suitable conversion factors must be used to obtain mass

fraction (ton / ton) for comparison to the log analysis results.

Calibration to Fischer assay data would permit adjustment of

parameters to produce a better match to core than is usual from

single or multiple regression. The core data should be averaged

over a 3 foot running average so that comparison to logs can be

more meaningful.

I have had no chance to test simultaneous or PCA approach

on oil shale, but have used it successfully in potash and

conventional multi-mineral oil reservoirs.

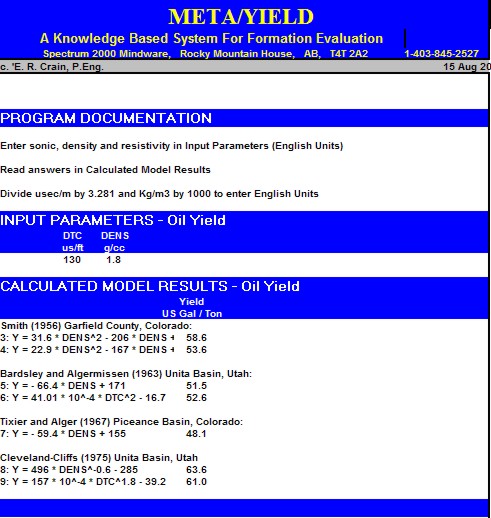

META/LOG

"YIELD"

SPREADSHEET -- IMMATURE OIL SHALE ASSAY FROM LOG ANALYSIS META/LOG

"YIELD"

SPREADSHEET -- IMMATURE OIL SHALE ASSAY FROM LOG ANALYSIS

This

spreadsheet calculates an Oil Shale Assay that can be used to evaluate

oil shale quality and provides a comparison with Fischer core analysis

data.

SPR-17 META/-LOG SHALE OIL YIELD CALCULATOR

Calculate oil yield

in immature oil shale,

6 methods.

Sample output from "META/YIELD" spreadsheet for oil

shale qusality analysis.

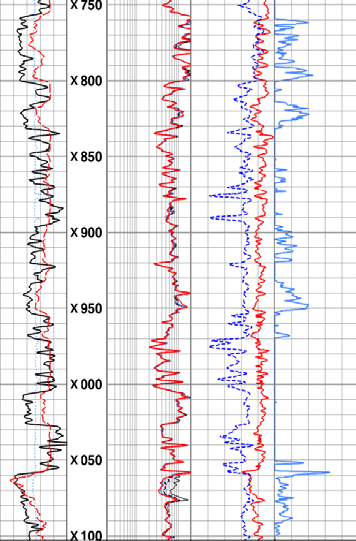

OIL SHALE EXAMPLE

OIL SHALE EXAMPLE

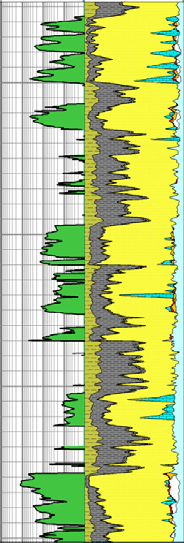

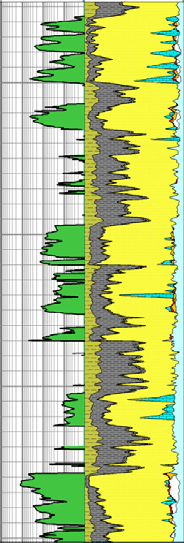

Raw data and computed results in an oil shale. Calculated oil

yield is in 2nd track from the right on a logarithmic scale of

1000 to 1.0 US gal/ton.

|

Canada

produced some shale oil from deposits in New Brunswick in the

mid-1800's. The mineral was called

Albertite and was originally believed to be a form of coal.

Canada

produced some shale oil from deposits in New Brunswick in the

mid-1800's. The mineral was called

Albertite and was originally believed to be a form of coal.  Organic

content is usually associated with shales or silty shales, and

is an indicator of potential hydrocarbon source rocks. High

resistivity with some apparent porosity on a log analysis is a

good indicator of organic content. Kerogen is the main source of

TOC; kerogen is usually radioactive (uranium salts) but the

quantity of radioactivity is not a good predictor of the

quantity of organic matter..

Organic

content is usually associated with shales or silty shales, and

is an indicator of potential hydrocarbon source rocks. High

resistivity with some apparent porosity on a log analysis is a

good indicator of organic content. Kerogen is the main source of

TOC; kerogen is usually radioactive (uranium salts) but the

quantity of radioactivity is not a good predictor of the

quantity of organic matter..

A

literature search quoted by R. M. Habiger and R. H. Robinson in

1985 gives the following equations for estimating oil yield:

A

literature search quoted by R. M. Habiger and R. H. Robinson in

1985 gives the following equations for estimating oil yield: