|

RESISTIVITY IMAGE LOGS

RESISTIVITY IMAGE LOGS

This page describes resistivity image

logs profiles, in the order of their appearance over the

years. This presentation style provides insights into tool

evolution, and a specific tool’s capabilities and

limitations. You will find most these tool types in your

well files – here’s your chance to learn more about them.

In

1986, the "ultimate" dipmeter was developed by

Schlumberger, called

the formation microscanner (FMS). Later versions were called

formation micro-imager (FMI). There are now similar services

available from other suppliers. The tool is generically known as

a resistivity image log.

Using an additional 27 electrodes

on each of two dipmeter pads of the dipmeter; each pad records 27 microresistivity

curves spaced 1/10 inch apart on the borehole surface. Each pad

covers a 2.8 inch wide portion of the circumference of the well

bore. Several passes over the interval will often provide virtually

complete coverage of the rock face.

The

resistivity traces are translated into images based on their relative

resistivity values, in either black and white or colour. The

resistivity data provided by this tool are of very high resolution,

in the order of a few millimeters. Thus, a substantially large

data array must be handled, and it is an obvious challenge to

process and display this information in a way which facilitates

its interpretation. This is resolved through a point to point

mapping of the resistivity traces into a spatial image, each

pixel in the image display having a gray scale or colour value

associated with a particular resistivity level. Subsequent

interpretation benefits from the close relationship between this

image and core photography.

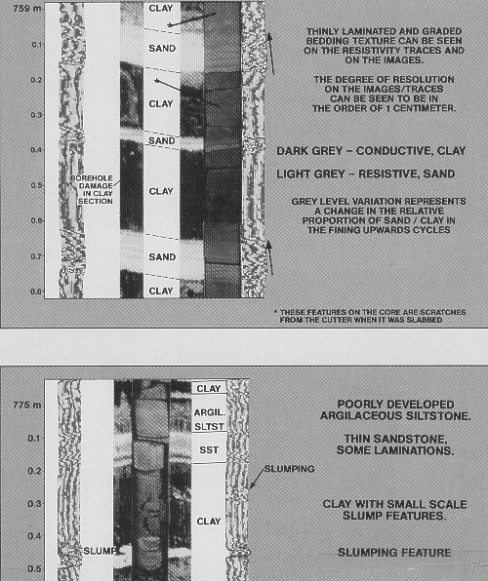

The gray

scale or colour spectrum can be stretched or squeezed in the computer

to enhance certain features, such as porosity, fractures, or shale

laminations. Images can be plotted at the same scale as the core

photographs for comparison.

It is traditional to show low resistivity (shales and open

fractures) as black, shading to white for high resistivity

(tight streaks and healed fractures). Porous sands and shaly

sands will be grey or a mix of yellow-brown with darker colour

suggesting higher resistivity and possibly lower porosity. In

rare cases, such as tar sands and oil shale, the colours may be

reversed to make hydrocarbon layers black and shales lighter

colours.

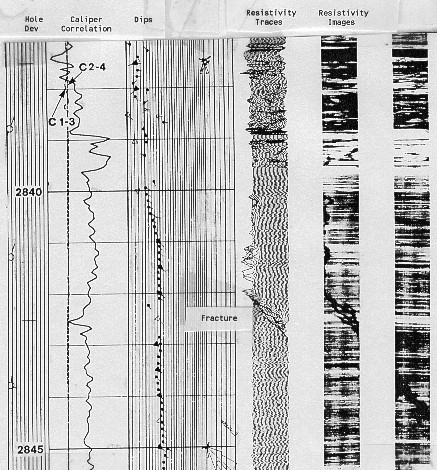

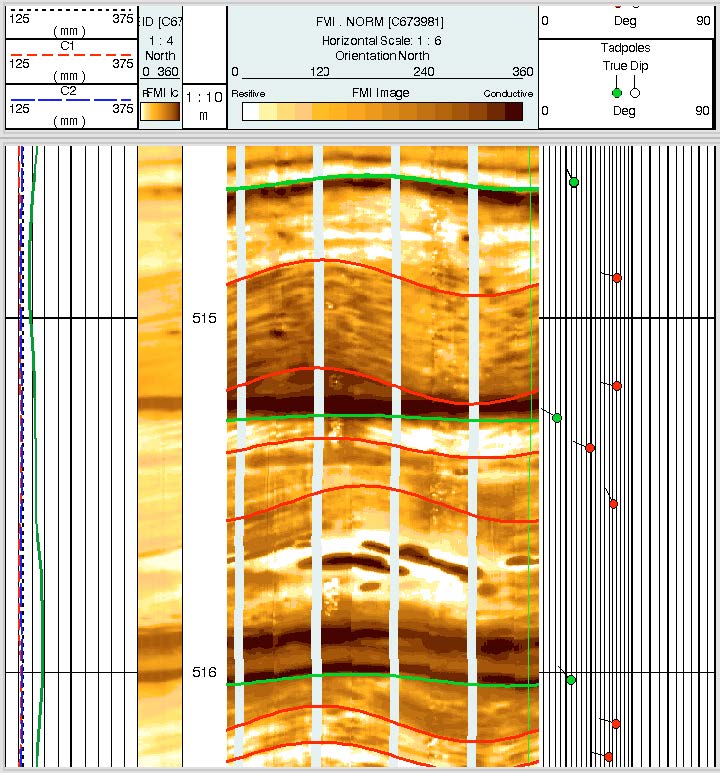

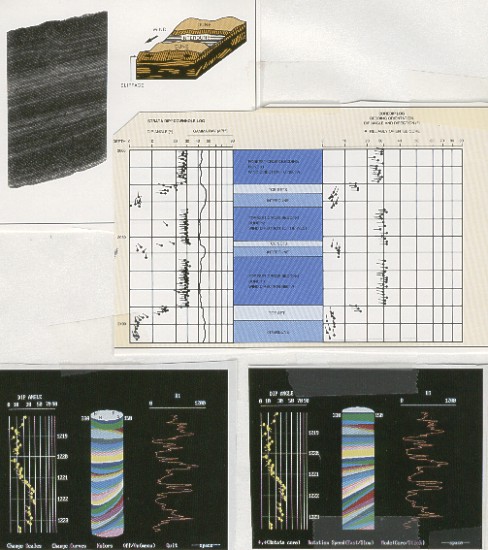

Resistivity image log showing calculates dips, raw curves, and

image log from a two pad FMS device.

A

resistivity image logging tool with fewer (sixteen) electrodes per pad, but

with four or eight imaging pads, is now available, and provides

better coverage of the wellbore wall than the two pad version.

The electrodes are smaller, allowing for higher vertical resolution, but

are spaced to provide the same wall face coverage, about 2.5 inches

per pad. In an 8 inch diameter hole, electrode coverage is about

80% and in a 6 inch hole is greater than 100%. This overcomes

one of the major complaints about the FMS, namely the number of

passes needed to obtain a complete image of the well bore. An

example is shown below.

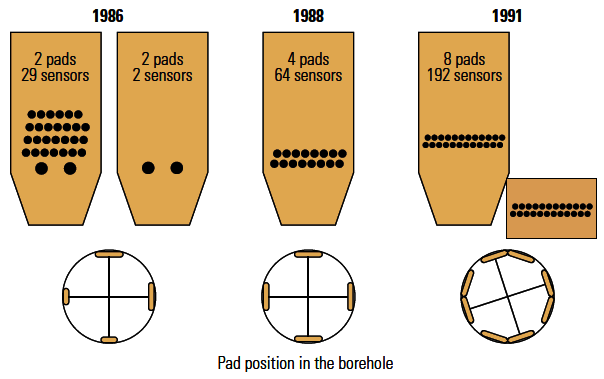

Evolution of the Schlumberger resistivity image

log pad design, starting with the original two pad FMS (located on 2

of the 4 pads of the SHDT dipmeter), the four pad FMI (which could

be twinned with another tool at 45 degree offset for better borehole

coverage), and the eight pad FMI-HD tool (which gives about 98%

coverage in an 8" boreho;e).

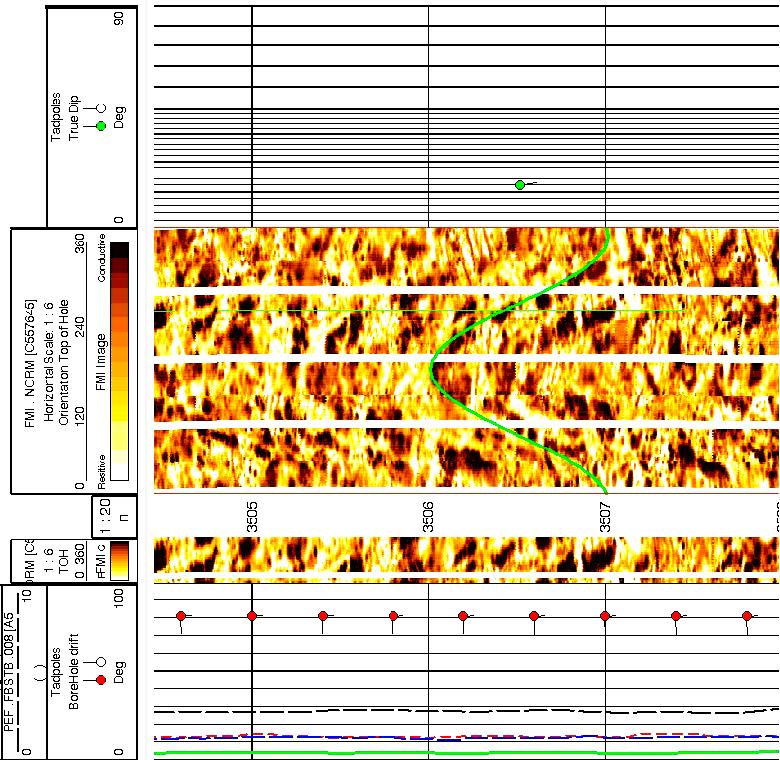

Four pad FMI log in fractured granite reservoir showing

computed dip angle and direction. North is at centerline of

image.

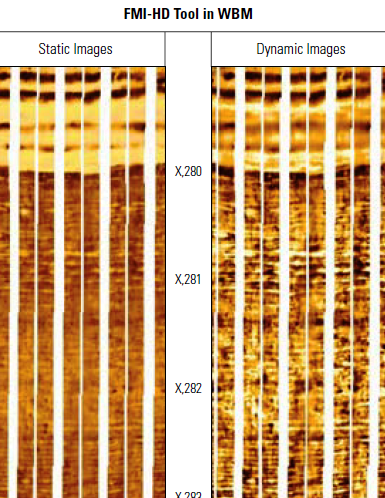

An 8-pad FMI-HD log in a gas shale. Left track is static (fixed

colour scale) image. Right track is dynamic image, in which a

running average type of colour scaling is used to amplify

resistivity contrasts, making easier to see stratigraphic features,

faults, and fractures.

The

primary use of the tool is definition of bedding plane dips, for identification of irregular features,

such as vugs and fractures, for accurate sand counts in thin bedded

zones, and for identifying stratigraphic features. If sufficient

rock face is imaged, dips can be found by digitizing the bedding

planes visible on the microscanner image, or by automatic computation

using all valid image traces.

The dips found by FMI dip processing

are superior to CSB or LOC dips because a larger number of resistivity

traces can be used in the calculation. They can be computed automatically

and displayed on the FMS image. In addition, calculated dips can

be edited or removed, and new bed boundary correlations picked

with a mouse on an interactive CRT image. Thus dips that pass

or fail preconceived processing criteria can be deleted or added

as the analyst desires. Dip tadpoles can be coded by colour to

indicate bedding, cross bedding, fractures, or faults.

RESISTIVITY IMAGE LOG EXAMPLES

RESISTIVITY IMAGE LOG EXAMPLES

Images

courtesy of Schlumberger

Left track is caliper, right track is formation dips. Dip in

the cross beds indicate paleocurrents to the WNW direction. This

is confirmed by the imbricated shale clasts.

Channel orientation is ESE to WNW

Resistivity images are best dislayed horizontally for

horizontal wells-- toe of the well is on the right. Top track is

formation or fracture dips, bottom track is borehole deviation.

Images illustrate fenestral porosity within a carbonate unit

intersected by a horizontal well. Actual well productivity with

this type of reservoir is higher than convention open hole logs

would indicate.

The slimhole FMS* provides imaging capabilities in boreholes

as small a 114mm (4.5 in). This Image reveals a normal fault and

fractures in a horizontal well. Fault block downthrown to the

N45E direction with 63' dip.

Expanded colour scale image of tight streak (light

brown) on resistivity image shows detail of porosity laminations

- light colour is tight, darker colours are more porous, black is

shale.

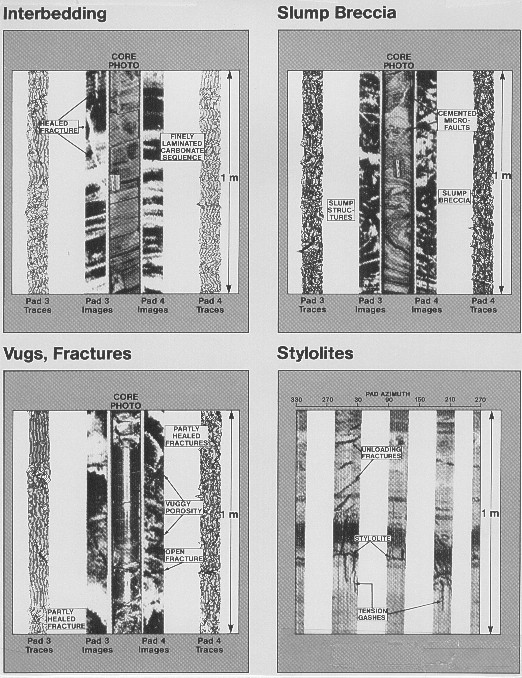

Formation microscanner images in various environments

Formation microscanner images in various environments

RESISTIVITY IMAGE LOGS IN OIL-BASE MUD (OBM) SYSTEMS

RESISTIVITY IMAGE LOGS IN OIL-BASE MUD (OBM) SYSTEMS

Material in this section is based on "Imaging - Getting the Picture

Downhole" edited by Tony Smithson, Schlumberger Oilfield Review,

Sept 2015.

Conventional resistivity image logs require a conductive mud system

to operate. In oil based (nonconductive) mud, a knife blade

electrode, or "scratcher pad", version of the resistivity image log

was available from several suppliers in the later 1980's. The

scratcher systems worked reasonably well for bedding dips and sand

counts, but could not see fractures very well, because they filled

with nonconductive mud.

Schlumberger

introduced a new typw of oil-based mud imaging log (OBMI) for use in nonconductive

mud systems in 1988. It uses micro induction resistivity

measurements instead of the usual electrical resistivity pads. It

had 4 pads with 2 rows of 4 electrodes on each pad, operating in the

10 to 20 kiloHertz range. A second tool could be added at 45 degree

offset to increase borehole coverage. Resolution vertically and

horizontally was about 1 cm, much coarser than the conventional

tools (FMS, FMI). It was not very effective in fractures and there

were other artifacts that caused shadow events, making the image

difficult to interpret in some cases.

The micro-induction technique of

older OBM imagers and scratchers of even older dipmeters have been

replace by Schlumberger's Quanta Geo tool. It makes a

capacitive measurement at two frequencies in the megaHertz range

(instead of the kiloHertz range used in conventional tools) and then

derives the best image from the optimal frequency. The tool has 8

pads so the coverage is good compared to other OBM tools. The

electrodes are surrounded by guard electrodes that focus current

through the mud and mudcale into the formation.

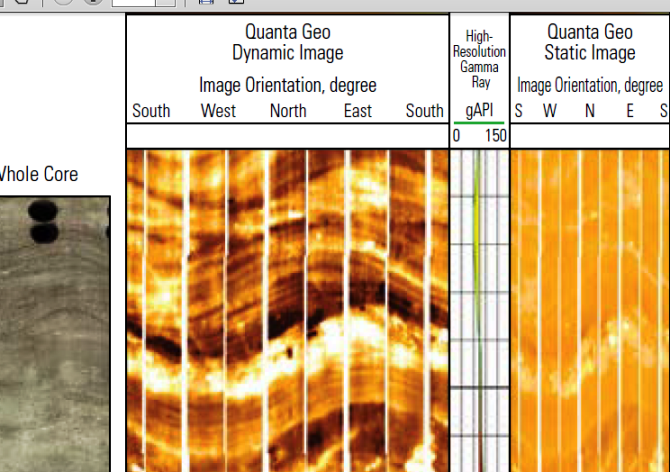

Core image (left), static and dynamic images from Quanta Geo

image log

The capacitive measurement allows

the processing to determine the amplitude of the current / voltage

ratio and the phase shift between the two measurements. The ratio

gives the electrical impedance of the rocks. At the frequencies

used, the impedance is not directly proportional to resistivity, but

the images produced have the same general appearance as conventional

image logs. Vertical resolution is 6 mm and horizontal resolution is

3 mm, comparable to the FNI-HD in water based mud. Both open and

healed fractures are quite evident on the Quanta Geo output as high

resistivity (white) sinusoids. An acoustic image log uld be used to

distinguish open from healed.

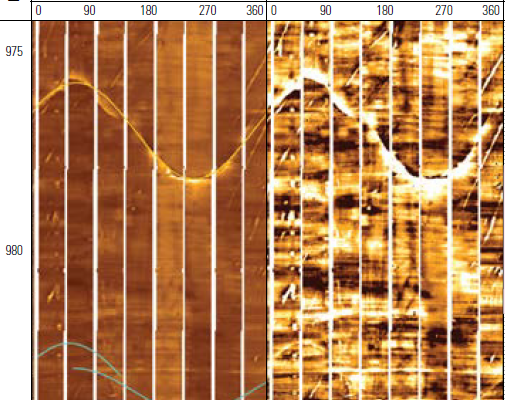

Fractures (white sinusoids) in oil base mud using Quanta Geo image

log. Open fractures cannot be distinguished from healed as both are

resistive in OBM.

LOGGING

WHILE DRILLING IMAGE LOGS

LOGGING

WHILE DRILLING IMAGE LOGS

Measuring

resistivity at the drill bit is part of a normal logging while

drilling operation. Three resistivity curves sampling different

depths of investigation are sent uuole in real-time, along with any

other logs in the tool string. Since the tools are rotating while

drilling, the deep resistivity scans the entire wellbore as the tool

moves slowly down hole. The scanned data is too much to send uphole

in real-time and is recorded, then recovered at the surface

when the drill string is tripped for a bit change. Some newer RAB

tools can transmit sufficient dats to create an image uphole for

near real-time display. Once all the image data is assembled, it can

be processed to obtain dip indoemation i a manor similar to wirekine

image logs.

Since the density log

is also a directionally focused tool that rotates, it too can give

an image, although with less contrast than resistivity.

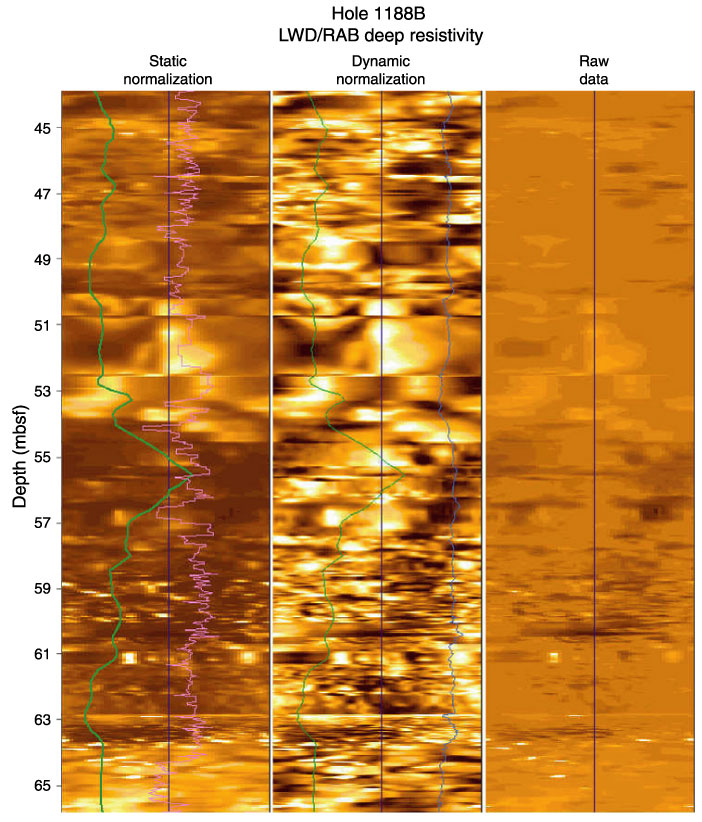

Deep resistivity image from a logging while drilling tool called

Resistivity at Bit (RAB). As for all image logs, black represents

low resistivity, white is high resistivity. North is at centerline

of each image. Since this is a deep resistivity, light colours could

mean hydrocarbons or low porosity. Comparison to an open hole FMI or

an LWD density image log could resolve the ambiguity.

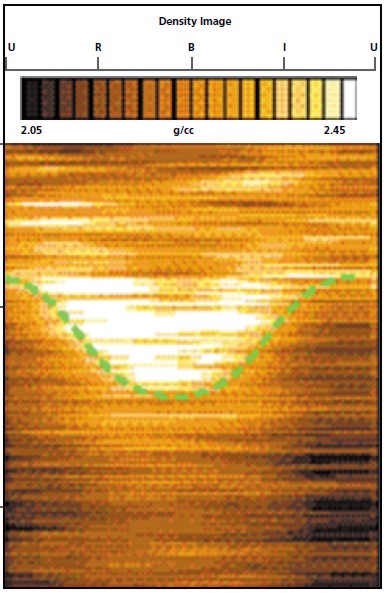

LWD density image log, black is low density (shale or porous),

white is high density (tight). Comparison to RAB

can identify

hydrocarbons: light colour on RAB + dark colour on density image =

hydrocarbon. This image is from a

horizontal well; bottom side of

hole is at the centerline of the image.

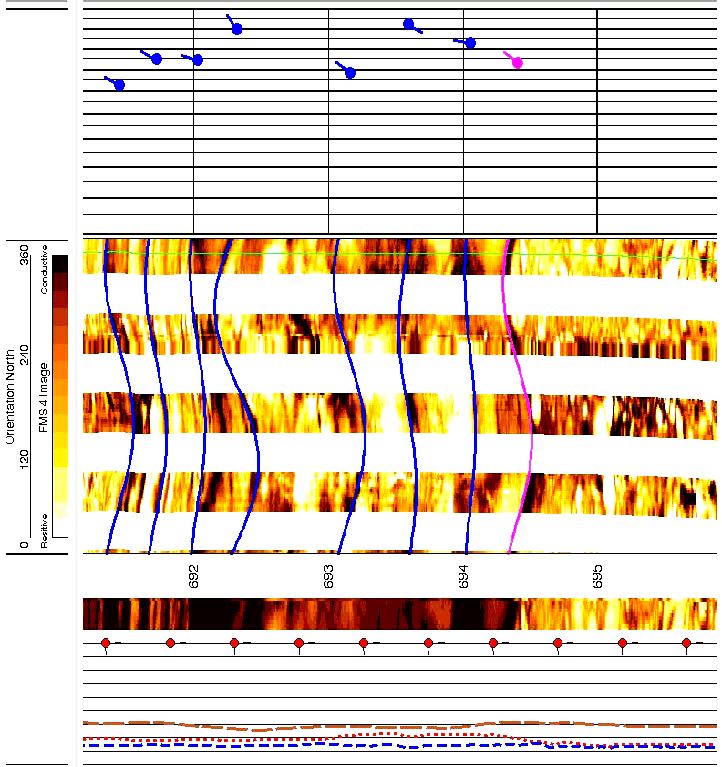

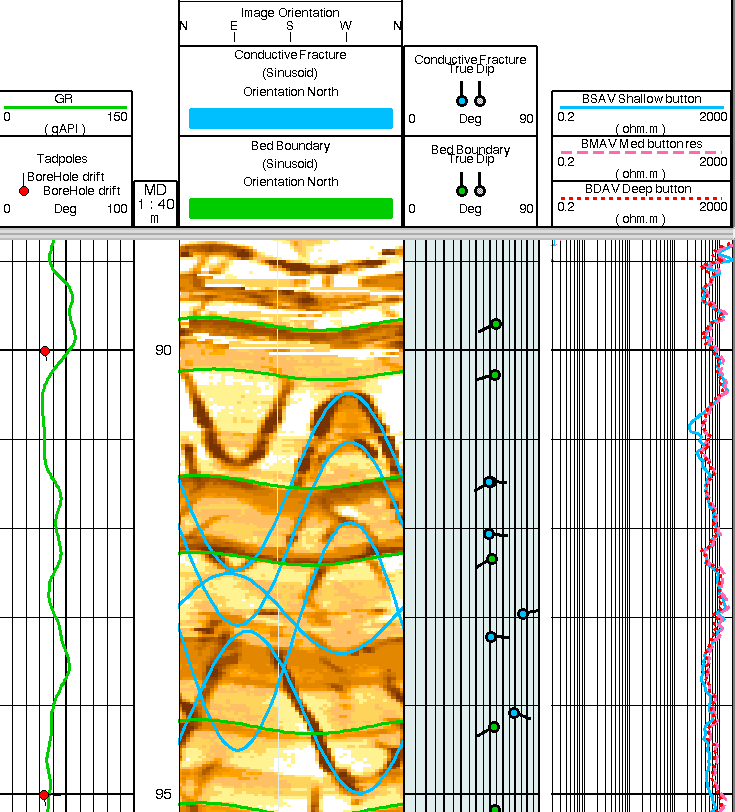

Typical Resistivity-At-Bit (RAB) image log shows gamma ray at

left, resistivity image, dip tadpoles, and 3 resistivity curves

on the right. This image illustrate open fractures (with blue

traces) cross-cutting bedding (in green).

IMAGE LOGS FROM DIPMETERS

IMAGE LOGS FROM DIPMETERS

Dipmeters and image logs are an essential for assessing structure

and stratigraphy of reservoir rocks and for Identification of

fracture intensity and fracture porosity. Tool design has improved

considerably since its introduction in 1986.

A

resistivity image log has about 10 times the spatial resolution of an

acoustic image log

and 500 times the amplitude resolution, due to the difference

in contrast between the resistivity and acoustic impedance ranges

measured by the respective tools.

The

standard tool works only in conductive mud in open hole, and a

specialized tool is available for non-conductive mud. It does not

work in cased holes.

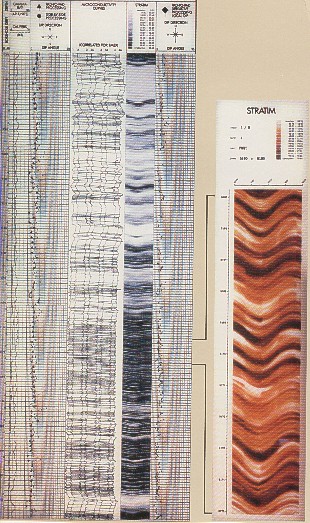

An extension of the

stratigraphic high resolution dipmeter (SHDT) processing provides a core-like image

of the borehole, using the LOC dip correlations and the measured

resistivity curves. The program is called STRATIM (Schlumberger

trademark). This image predates the resistivity image log by a

few years.

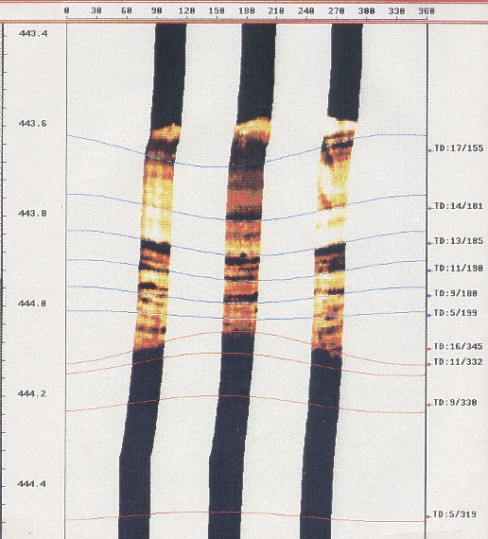

An

example is given on the left. The program produces a 360 degree

image of the borehole wall by interpolating between the eight

resistivity measurements from the eight electrodes on the SHDT

pads. Images can be coded in gray scale or colour. Dark gray or

dark colour usually represents conductive, often tight shale,

beds and light colour resistive, often porous sand, beds. If shales

are more resistive than sands (or carbonates), the colour scheme

can be reversed to keep shales looking dark.

The dipmeter curves are rotated to their true azimuth but are

not adjusted to true dip. The dips seen on the image are as they

would appear on the surface of a conventional core. The trace

of a plane dipping bed forms a sinusoidal curve when the image

of the borehole wall is unwrapped and laid flat, as they are in

these images. Bed boundaries, dipping beds, slump features, and

fractures are easily seen, if present. Images can be enhanced

as in Formation Microscanner processing, but processing is cheaper

because much less data is manipulated.

A

similar program, called DIPVUE is available from Western Atlas,

illustrated below. Here the 3-D image can be rotated in real

time to view the artificial "core" from any direction. In addition, most core service companies

can provide core photographs and dip logs from core data for comparison

with log derived borehole images.

The

colour convention is to show low resistivity in black and high

resistivity in white (or yellow). This makes shale beds black and

clean sands white, with shades of grey or brown representing shaly

sands. In carbonates, the same rules are used, but white may now

mean tight streaks with grey representing porosity. The colour scale

can be stretched and squeezed to enhance the image for a particular

situation.

Note

that a planar, dipping, bedding plane will trace a sine wave on a

circumferential image, such as those shown above

DIPVUE image created from dipmeter data

RESISTIVITY IMAGES FROM

MODERN LATEROLOGS

RESISTIVITY IMAGES FROM

MODERN LATEROLOGS

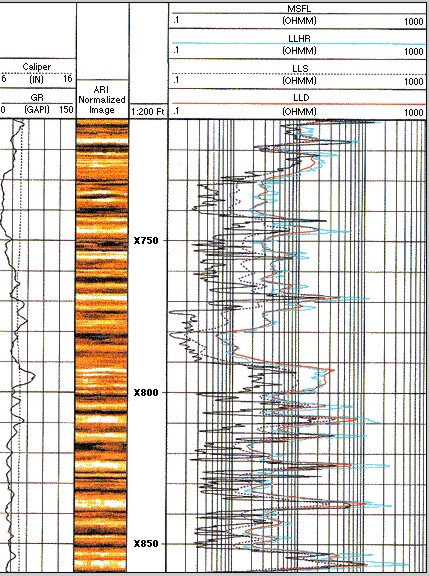

Azimuthal resistivity image logs

(a form of laterolog) and high resolution laterologs can be

displayed as images as well as resistivity curves.

Below is a sample of an array induction (AIT) log and an azimuthal

resistivity (AIR) log, the latter showing the azimuthal image log

presentation.

Comparison of array induction log (left) and azimuthal resistivity laterolog (right). Curve complement and

presentations vary considerable with age and contractor. The image

log on the azimuthal resistivity presentation is "poor man's"

resistivity microscanner log, giving a reasonable sand count

regional dip, and some fracture information. A real microscanner

image is shown for comparison (left image).

High resolution laterolog showing deep invasion and high

resolution image.

All curves are focused to

about 8 inches. This tool is not azimuthal so image shows flat-lying

beds even when dip is present.fs

|