|

WIRELINE

FORMATION TESTING BASICS

WIRELINE

FORMATION TESTING BASICS

This page describes wireline formation

tester tools profiles, in the order of their appearance over

the years. This presentation style provides insights into

tool evolution, and a specific tool’s capabilities and

limitations. You will find most these tool types in your

well files – here’s your chance to learn more about them.

Formation testing on wireline was

developed in the mid 1950's to provide a faster, safer and

less expensive method of formation evaluation than

conventional drill stem testing (DST).

FORMATION TESTER (FT) TOOL

FORMATION TESTER (FT) TOOL

The earliest formation tester (FT)

used an electro-mechanical-hydraulic pad system to obtain

good contact with the borehole wall, then a 2 bullet

perforation charge was fired at a single depth point. This

created a pathway for fluids to flow from the reservoir into

a chamber at the base of the tool.

The first formation tester could only be operated in

uncased holes.

Hydrostatic, shut-in, and flowing

pressures were measured and recorded as the test proceeded. During

the flow period, formation fluids flowed into a collection chamber.

When the test was completed, the chamber was sealed at maximum

pressure and the tool brought back to the surface. Built-in

“Get-away” guns were fired in the case of differential sticking. The

recovered sample was analyzed in the lab to determine the fluid

properties. Shut-in pressures were plotted versus depth to determine

pressure gradients, gas-oil, gas-water, and oil-water contacts, as

well as the location of over- and under-pressured reservoirs.

Over the years, tools such as the

Formation Interval Tester (FIT), the Reservoir Description Tool (RDT)

and the Modular Formation Dynamics Tester (MDT) chart the evolution

of wireline formation testing. Each service company devised their

own tools and trade names. Tool development was driven by the need

to acquire single phase,

uncontaminated samples of reservoir fluid returned to surface. For

example, newer tools take multiple samples and allow the operator to

pump fluid from the reservoir instead of relying on natural flow

rates, permitting the tool to bypass the sample collection chamber

until a representative sample is obtained. This reduced the impact

of mud filtrate contamination on the final collected sample.

Along with pressure tests and

gradients, lab analyses of PVT relationships, GOR, viscosity, and

composition are the foundation for planning production and

processing facilities. The following overview of tools shows how

wireline testing has evolved to provide a clearer picture of

reservoir conditions.

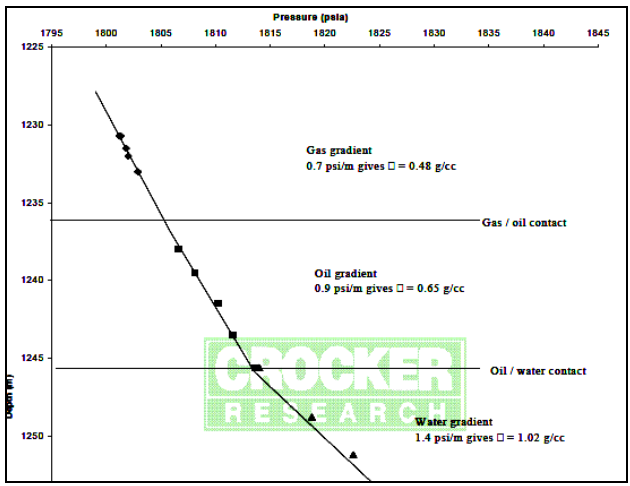

Graph of Shut-In Pressure versus Depth showing different pressure

gradients over the reservoir, indicating different fluid densities.

Gas-Oil and Oil-Water Contacts are marked at the changes in slope on

the gradient graph. It is sometimes difficult to see the change in

slope - try placing the graph horizontally at eye level and sighting

along the line. This is called the "Ant's-eye View". The bends in

the line are much more obvious.

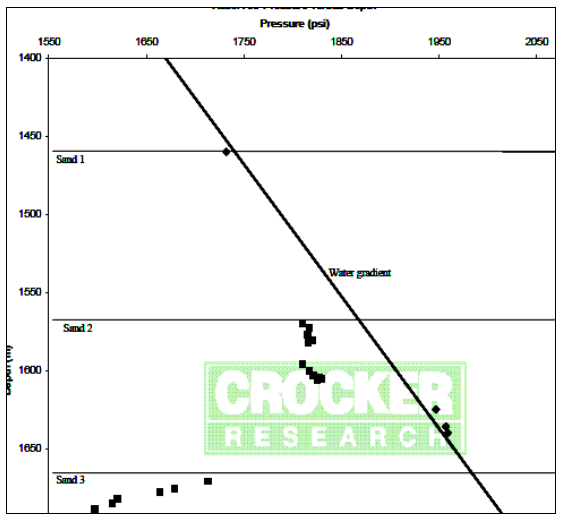

This graph shows partially depleted reservoir pressures, with some

pressure isolation between the upper and lower sands. A gamma ray or

image log on the graph would help to distinguish reservoir

boundaries and internal barriers.

(Illustrations courtesy Crocker Research)

REFERENCES:

REFERENCES:

A Method of Formation Testing on Logging Cable,

M. Lebourg, R.Q. Fields, C.A. Doh,

SPE-701-G, 1959.

Innovations in Wireline Fluid

Sampling,

Alastair Crumble et al

Oilfield Review, , Autumn 1998, pg. 26 – 41.

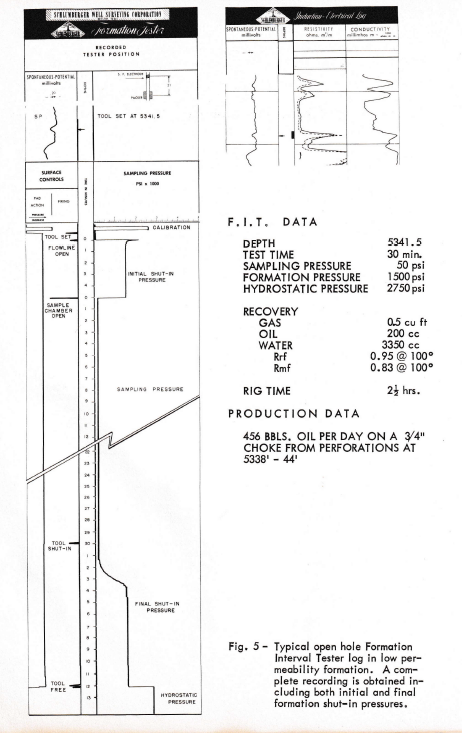

FORMATION

INTERVAL TESTER (FIT)

FORMATION

INTERVAL TESTER (FIT)

The first formation tester (FT) was developed to test

unconsolidated, soft rock in 7 7/8” open hole and claimed about a

50% success rate. The Formation Interval Tester (FIT) was developed

to test 5.5” cased hole completions, and to resolve poor sample

recoveries from hard, low-permeability formations.

The FIT simultaneously detonated two

perforations at an 8.5” spacing, testing a 1 foot interval of

formation rather than a single depth point. The 4.4” slim tool was

rated to penetrate ~3” of steel while the regular tool, with it’s

larger charge size, was able to penetrate over 4” of casing, or up

to 12” of formation. Dual packers sealed the FIT to the formation

wall, plus an automatic seal valve closed the sample chamber in the

event of seal failure. Like the FT, several chamber sizes were

available: 1, 2 ľ or 5 ˝ gallon. The deeper penetration, plus

better sealing function increased the chance of recovering fluids in

low permeability, hard formations and opened up formation testing

for use in cased holes. The FIT was not recommended for use in

unconsolidated formations.

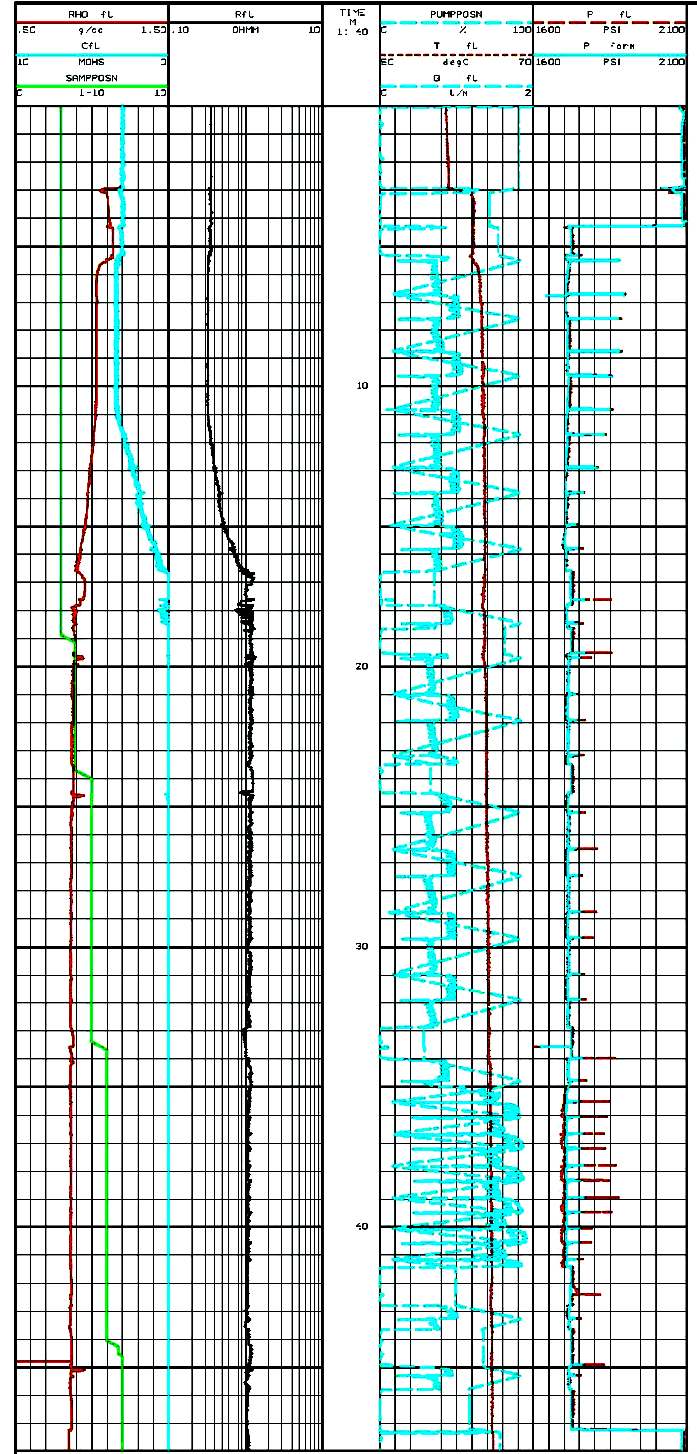

Plot from FIT showing recorded tester position calibrated to SP,

with Surface Control display marking the tool operations and

Sampling Pressures showing initial and final formation shut-in

pressures.

FORMATION

EVALUATION TOOL (FET)

FORMATION

EVALUATION TOOL (FET)

The Formation Evaluation Tool (FET) was developed by Crocker

Research in Australia in the late 1980’s and is widely used by other

service companies under license. Its foremost feature is its ability

to pump from the formation until a representative sample is present,

that is until the characteristics of oil, gas, or water are

exhibited in the resistivity, conductivity, and density sensors of

the FET. Once a representative sample is flowing through the tool

the FET has the ability to capture a predefined volume of this

sample. This predefined volume is based on the multisampler

configuration which is set prior to down-hole operation.

In addition the FET contains two

Quartz Pressure Gauges which have an accuracy of 0.01 psi. This in

conjunction with the tools pumping ability allows for accurate

shut-in pressures (SIPs) to be obtained with controlled draw downs.

The FET pump can be manually controlled enabling any user defined

draw down volume to be acquired, lowest being 1cc. In addition the

FET has the ability to reverse pump, that is pump fluids from the

borehole into the formation.

The proven benefit of reverse pumping

is the tool’s ability to “pump off” the formation, beneficial for

situations where the tool has been set for long periods of time. The

FET has been designed such that if there is a loss of tool power for

whatever reason the tool will automatically retract (unset itself

from the formation) enabling it to be retrieved via the wireline

cable.

During the operation of the tool, the

operator is able to give the following information to the client:

For Pretests;

·

Draw Down Pressure (DDP) in PSIA,

·

Draw Down Volume in cc,

·

Shut In Pressure (SIP) in PSIA,

·

Fluid temperature in °C,

For Constant Flow Tests (for every

litre pumped);

·

Resistivity in ohm/m, Conductivity in mho/m,

·

Density in g/cc,

·

Temperature in °C,

·

Reservoir pressure in PSIA,

·

Flow rate in L/min,

·

and Permeability in mDarcy.

For each sample taken;

·

Resistivity in Ohm/m,

·

Conductivity in mho/m,

·

Density in g/cc,

·

Temperature in °C,

·

Reservoir pressure in PSIA,

·

Flow rate in Litres/min,

·

Permeability in mDarcy,

·

Pressure at surface in PSIA,

·

and Volume captured at surface in cc.

The primary purpose of a constant flow

test is to ensure that an uncontaminated sample of the Reservoir

fluid or gas is flowing through the tool. During a constant flow

test, for every litre pumped the resistivity, conductivity and

density of the hydrocarbon or water is monitored in search for a

“breakthrough”. Meaning, when all the mud filtrate has been pumped

from the reservoir and the actual uncontaminated hydrocarbon or

water is present. When this occurs there is a noticeable difference

in the FET’s sensor readings which corresponds to the properties of

the hydrocarbon or water expected. It is at this stage that a sample

is taken upon the client’s request. Therefore, a constant flow test

must be performed before a sample is taken to ensure a

representative (uncontaminated) sample is taken.

Secondarily, a constant flow test may

be performed to gather the properties of the hydrocarbon or water

present after breakthrough in terms of resistivity, conductivity and

density. This may be used to confirm the depth pressure gradients as

well as reservoir contact depths.

In addition to this, a constant flow

test also results in the flow rate and permeability of the fluid to

be determined.

Reservoir fluid samples are captured

within the multisampler component of the FET. The configuration of

the multisampler depicts the quantity and volume of samples

captured.

The FET has the capability of

attaching a PVT sampling assembly to the bottom of the tool to

capture 2 x 524.4cc formation fluid samples per run.

Before any pretests are performed the

tool packer must be set at the correct depth. This is achieved via a

gamma ray plot. A gamma ray plot is printed and correlated with an

existing gamma ray plot and the packer depth adjusted accordingly.

The requirement for the gamma ray correlation is that the FET

Software must be connected to the logging unit’s depth system. The

FET Software can connect to the logging unit’s depth system via an

RS-232 serial port.

Once the down-hole job is completed,

the end result in the FET Software is a graphical log illustrating

all sensor measurements over time for pretests, constant flow tests,

and samples captured. The client receives a hardcopy and a data file

in LAS format. Examples are shown at the end of this webpage.

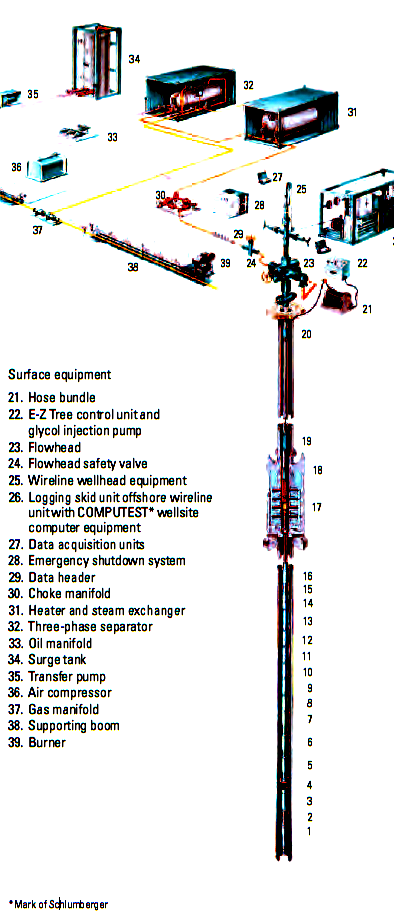

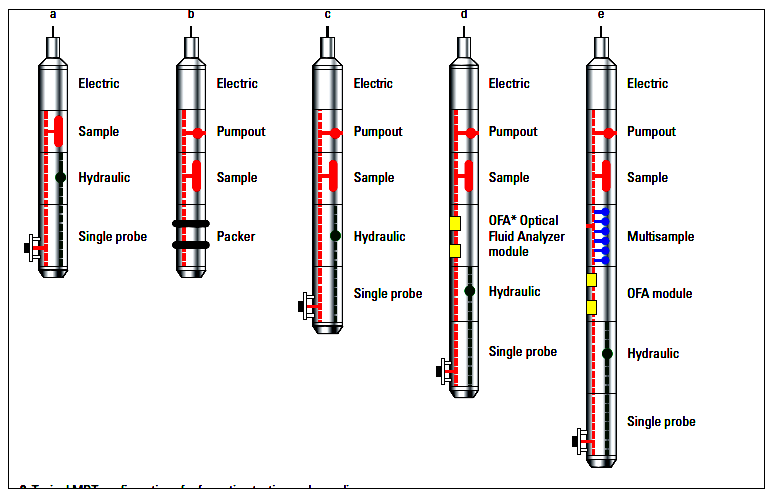

Diagram of a Schlumberger MDT formation tester.

MODULAR DYNAMIC

FORMATION TESTER (MDT)

MODULAR DYNAMIC

FORMATION TESTER (MDT)

Schlumberger’s Modular Dynamic Formation Tester tool (MDT)

exemplifies a modular approach to suit different reservoir types and

to ensure recovery of monophasic samples. The MDT is powered by an

electronic power cartridge which converts AC from surface to DC to

power all modules. An hydraulic power module sets/retracts probes

and is used to prevent differential sticking. A dual-purpose

pump-out module removes unwanted filtrate before sampling and

inflates packers.

Today’s formation testers can be configured in various ways to suit

the test requirements. (illustration courtesy Schlumberger)

The operator can choose a Single or

Dual-probe module depending upon the answers required. A basic

configuration for pressure, vertical permeability and sampling,

could combine several Single-probe assemblies with six sample

chambers set at the base of the tool. The Single-probe module

consists of packer and telescoping backup pistons, pressure gauges,

sensors for fluid resistivity and temperature plus a 20 cc pretest

chamber. The module has a strain gauge and a CQG (Crystal Quartz

Gauge) that allows monitoring of drawdown from surface.

When used in tandem with the

Dual-probe module, pressures are measured by both the Single and the

Dual-probe, the latter featuring two probes mounted back to back on

the same block, at 180 degrees, giving horizontal permeability. The

multi-probe configuration provides data for near wellbore

permeability anisotropy, or running interference testing to assess

communication between adjacent horizons.

The Probe/Dual-Packer Module, with two

inflatable packers isolating an interval of 3-11’, ensures that

fluid can be withdrawn at a greater rate without dropping below the

bubble point. The larger interval results in a radius of

investigation up to 10 feet into the reservoir for better

permeability estimates. The Flow Control Module allows formation

fluid to flow into a 1 liter pretest chamber, useful for tests which

require a controlled flow rate.

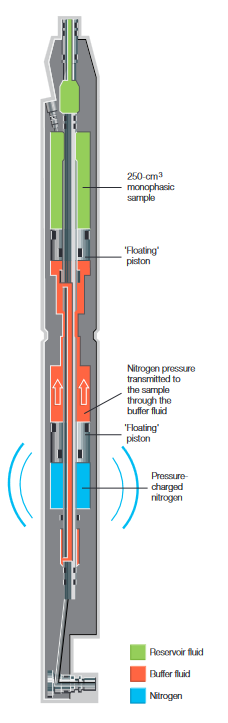

A Single-Phase Multisample Chamber

used with the Multi-Sample Module enables monophasic fluid

collection for PVT analysis. The sample is pressurized by Nitrogen,

to stop phase alterations due to temperature induced pressure drop

as the chamber is returned to surface.

Multisample Chamber showing Nitrogen Pressure component which allows

the sample to be pressurized but not contaminated by the element.

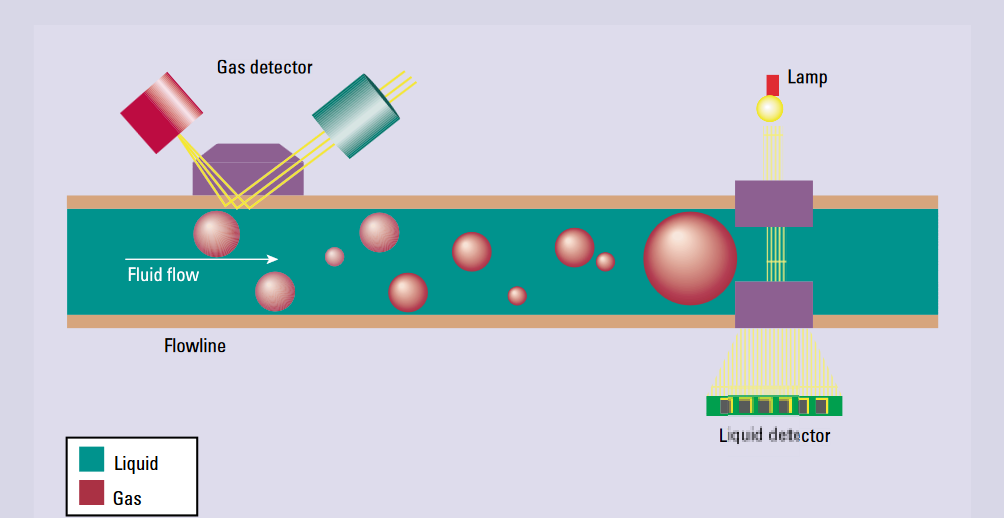

Possibly the most innovative module is

the Live Fluid Analyzer, used to pinpoint when the fluid becomes

least contaminated by filtrate, particularly that of Oil Based Muds

(OBM), or in cases of deep invasion. Using a near-infrared

spectrometer, the LFA (or Optical Fluid Analyzer - OFA) measures

optical properties of the fluid in the flowline. Gas is detected by

measuring polarized light reflection. When optical readings indicate

that the amount of mud filtrate has stabilized at a low value, the

sample is taken. The tool also discriminates between oil and water,

and crude oil versus OBM.

As oil exploration requires ever

greater finesse, tools such as MDT Forte and MDT Forte-HT have been

developed for use in rugged and high temperature environments.

Rugose/unstable boreholes, thinly laminated formations and sampling

low mobility/heavy fluids can be tested using the Saturn 3D Radial

Probe system. With multiple self-sealing ports, this tool provides

temporary mechanical stabilization of the reservoir walls and a

pressure differential great enough to mobilize heavy oil.

Diagram of Schlumberger LFA module gas detector and spectrometer.

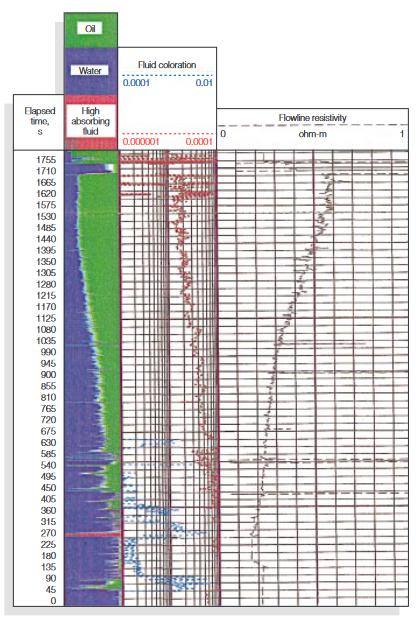

wing elapsed time (track 1) seal failures (exemplified by red spike

on track 2 at 270 seconds, – high absorbing fluid), and a

stabilizing of ratio between oil and water at 1440 seconds, with

corresponding decrease in coloration (track 3) and increase in

flowline resistivity (track 4). Sample was taken at 1440 seconds

and confirmed a 30% water cut.

FORMATION TESTER

EXAMPLES

FORMATION TESTER

EXAMPLES

The following examples of FET log presentations is courtesy of

Crocker Research.

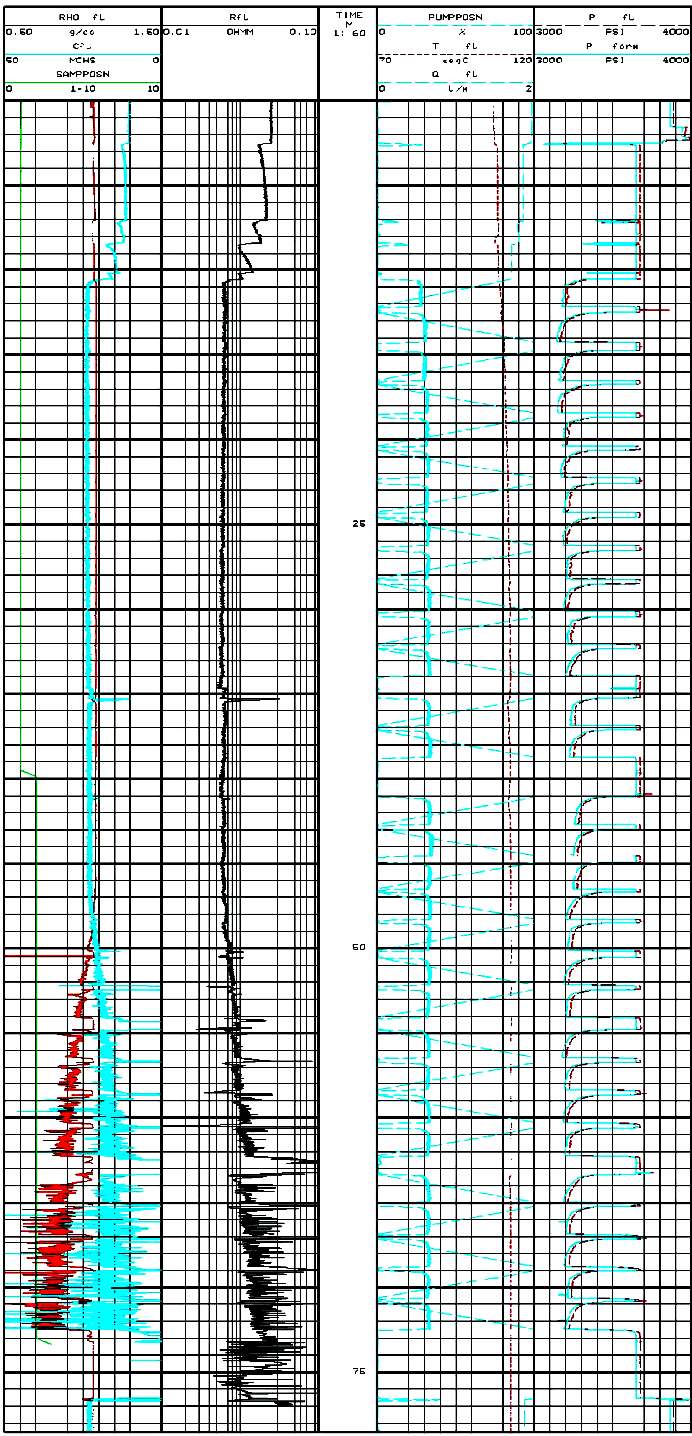

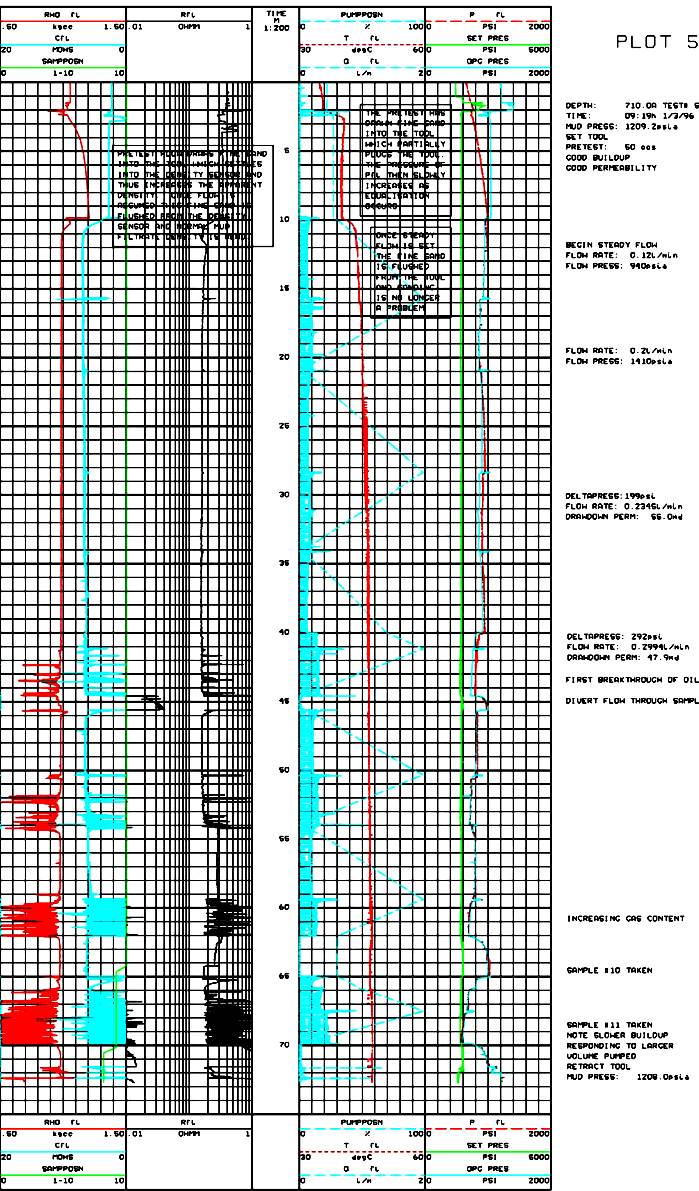

EXAMPLE

1:

High permeability sand with light oil.

EXAMPLE

1:

High permeability sand with light oil.

This is probably the easiest test. Oil breakthrough occurred only

six minutes after steady state flow began. Multi rate testing was

done which allows a plot of flowrate Q versus pressure drawdown.

Four samples were taken, all contained light oil.

EXAMPLE 2:

Low permeability sand with low viscosity oil.

EXAMPLE 2:

Low permeability sand with low viscosity oil.

Large pressure drawdown was required to obtain 630 ml/min flow rate.

Oil breakthrough occurred after thirty-seven minutes of steady flow

(from the commencement of pumping). One filtrate and one oil sample

were taken. Permeability can be calculated from the pressure

drawdown or buildup curves. Note the marked difference between the

pretest buildup and the drawdown curves.

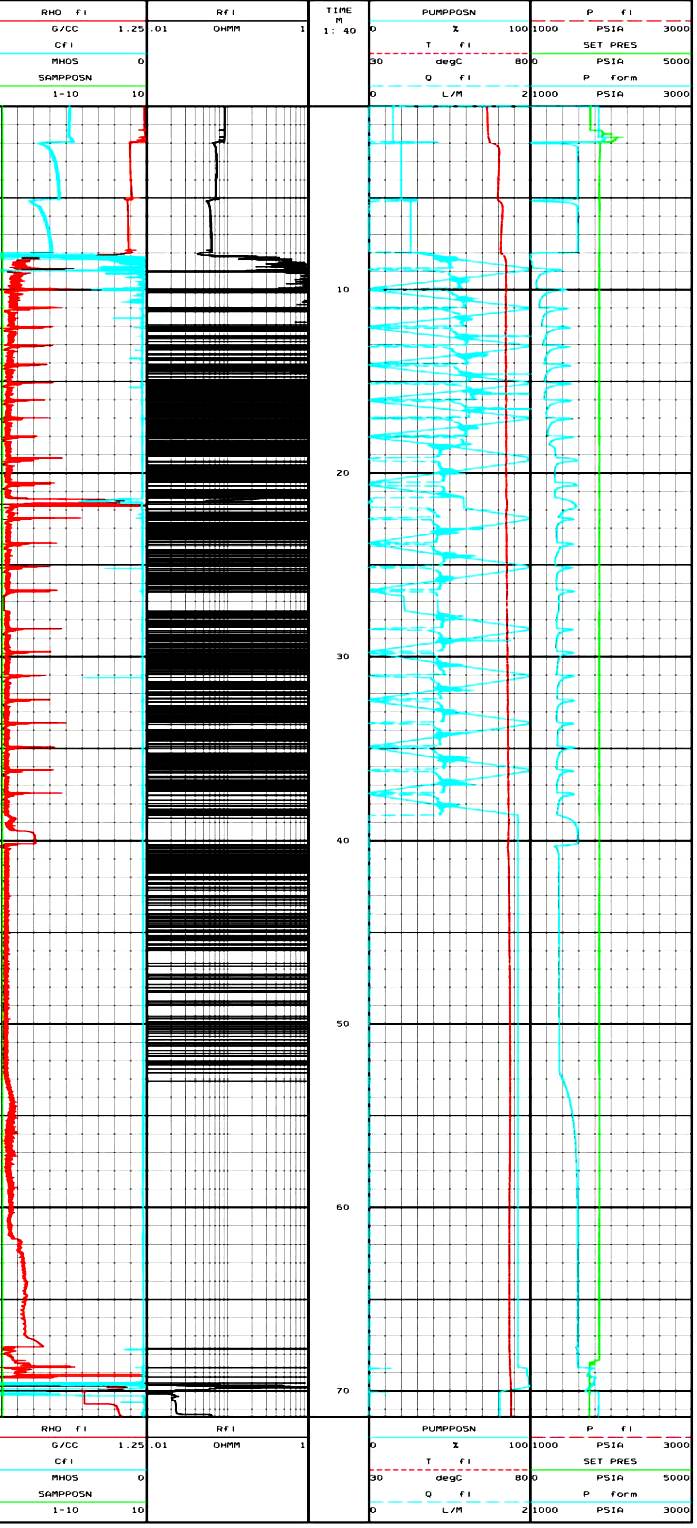

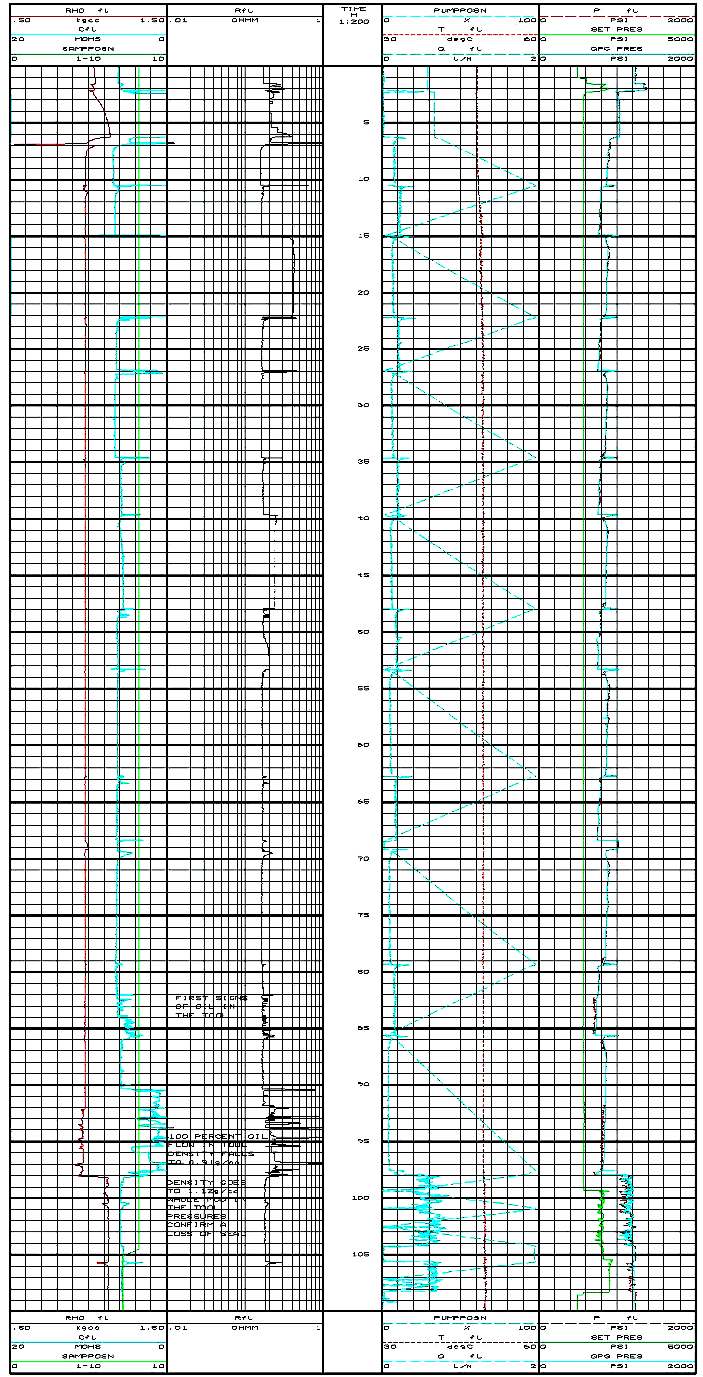

EXAMPLE 3:

High permeability loose sand with viscous oil.

EXAMPLE 3:

High permeability loose sand with viscous oil.

This is most interesting. All previous attempts in these

unconsolidated sands with other wireline test tools had failed

because of lost seals. We were asked if the FET could sample with a

minimum flowrate even if several hours of testing were required.

This test was done with only 14 psi drawdown and a flow rate of only

33ml/min. After some seven hours we had only taken 13 litres of

formation fluids. Oil breakthrough occurred after some 80 minutes of

steady flow (from the commencement of pumping). Slug flow occurred

resulting in the spiky resistivity, conductivity and density logs.

Despite the sanding problems the tool moved the formation fluids

steadily until after some five hours, sanding effects show steps on

the pump motion. Nine samples were taken and heavy oil and some

filtrate was recovered. Despite the long test the tool came free

with only a minimum overpull. Conventional large cylindrical sample

chambers present a large area for differential sticking. The FET

involves no such chambers and thus is unlikely to be differentially

stuck. Moreover, the tool is pumped off the wall once the tool is

retracted.

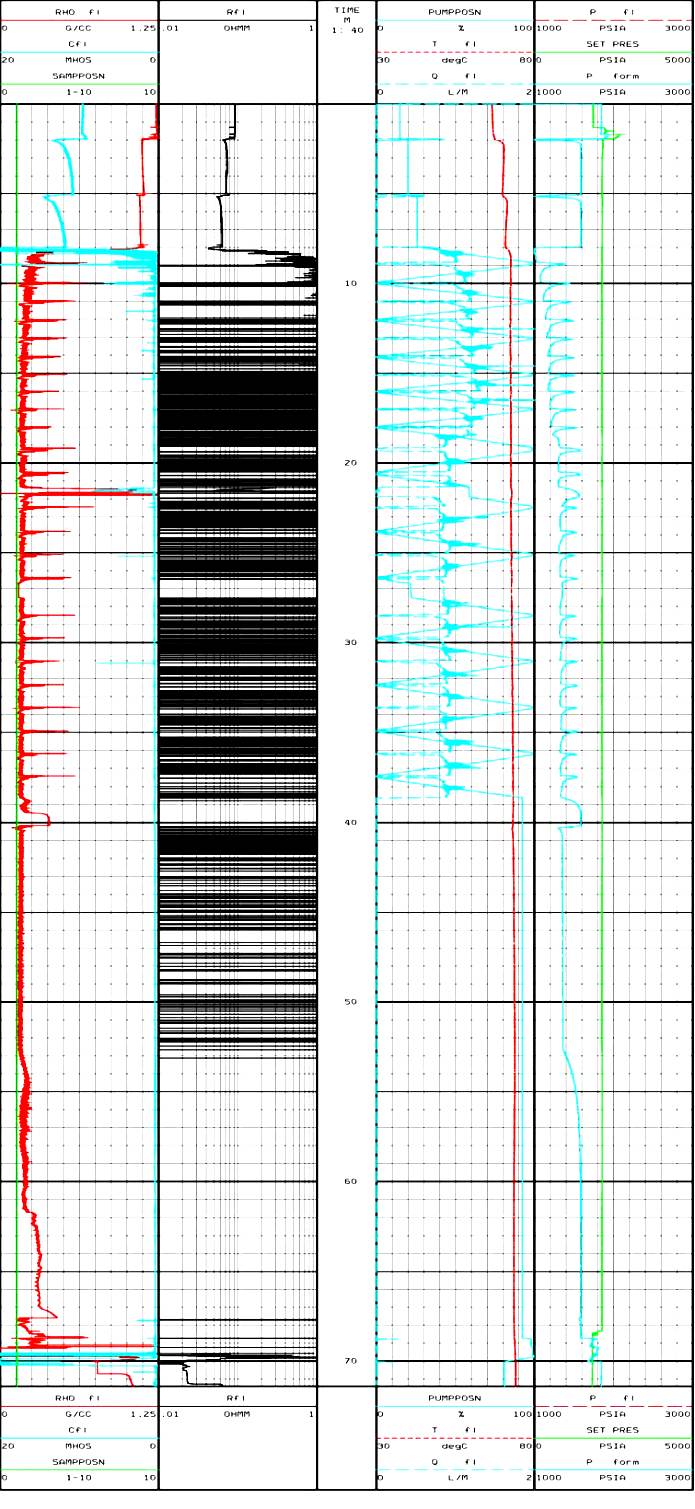

EXAMPLE 4:

Moderate permeability sand with viscous oil.

EXAMPLE 4:

Moderate permeability sand with viscous oil.

The

fourth possibility. Oil breakthrough occurred after about

thirty-five minutes of steady flow. Pressure drawdown was 107 psi at

a flowrate of 880 ml/min, which equates to a drawdown permeability

of 380 mD. After oil breakthrough the pressure drawdown increased to

486 psi at 720 ml/min. Assuming no relative permeability change

(which may not be valid) and a water viscosity 0.5 centipoise then

the oil viscosity is 2.75 centipoise. Please note that the oil

density is shown as 0.96 g/cc which checks well with the known

density. Four oil samples were taken. The

fourth possibility. Oil breakthrough occurred after about

thirty-five minutes of steady flow. Pressure drawdown was 107 psi at

a flowrate of 880 ml/min, which equates to a drawdown permeability

of 380 mD. After oil breakthrough the pressure drawdown increased to

486 psi at 720 ml/min. Assuming no relative permeability change

(which may not be valid) and a water viscosity 0.5 centipoise then

the oil viscosity is 2.75 centipoise. Please note that the oil

density is shown as 0.96 g/cc which checks well with the known

density. Four oil samples were taken.

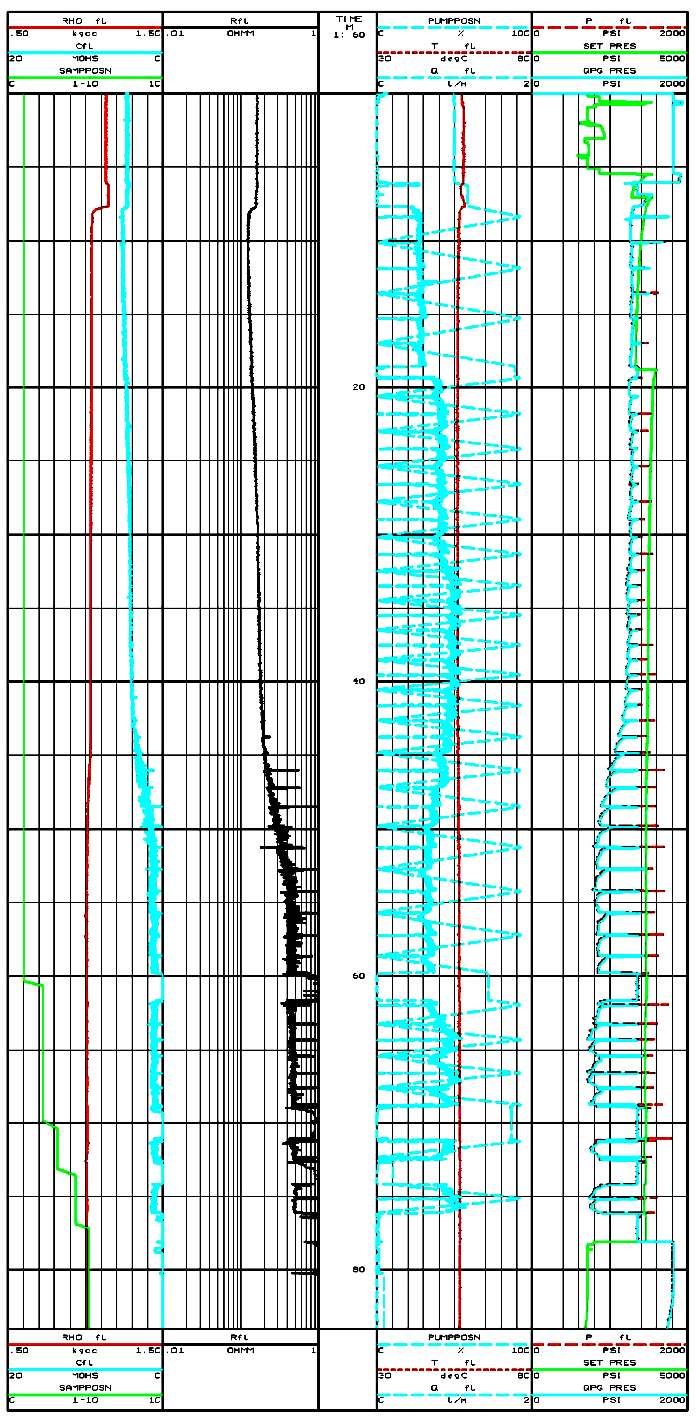

EXAMPLE 5:

Gas sampling.

EXAMPLE 5:

Gas sampling.

Care is taken to pump as little gas into the borehole as possible.

Although we have often sampled gas; no problem has ever been had

when circulating after testing. Gas breakthrough occurred after

thirty minutes of steady flow. Thereafter gas increased with time

but, curiously not at low flow rates. Two gas samples were taken.

The down-stroke of the pump (0.3 l/min) was at a higher rate than

the upstroke (0.2 l/min). It is clear that at 0.2 l/min flow rate

the filtrate supply from vertical flow in the formation is enough to

meet the FET flow rate and no gas enters the tool. At 0.3 l/min the

vertical flow rate of filtrate is not enough to meet the FET flow

rate and thus gas enters the tool. The final pump stroke is at 0.45

l/min and the highest gas flow rate occurs. Clearly the gas fraction

of flow is rate sensitive.

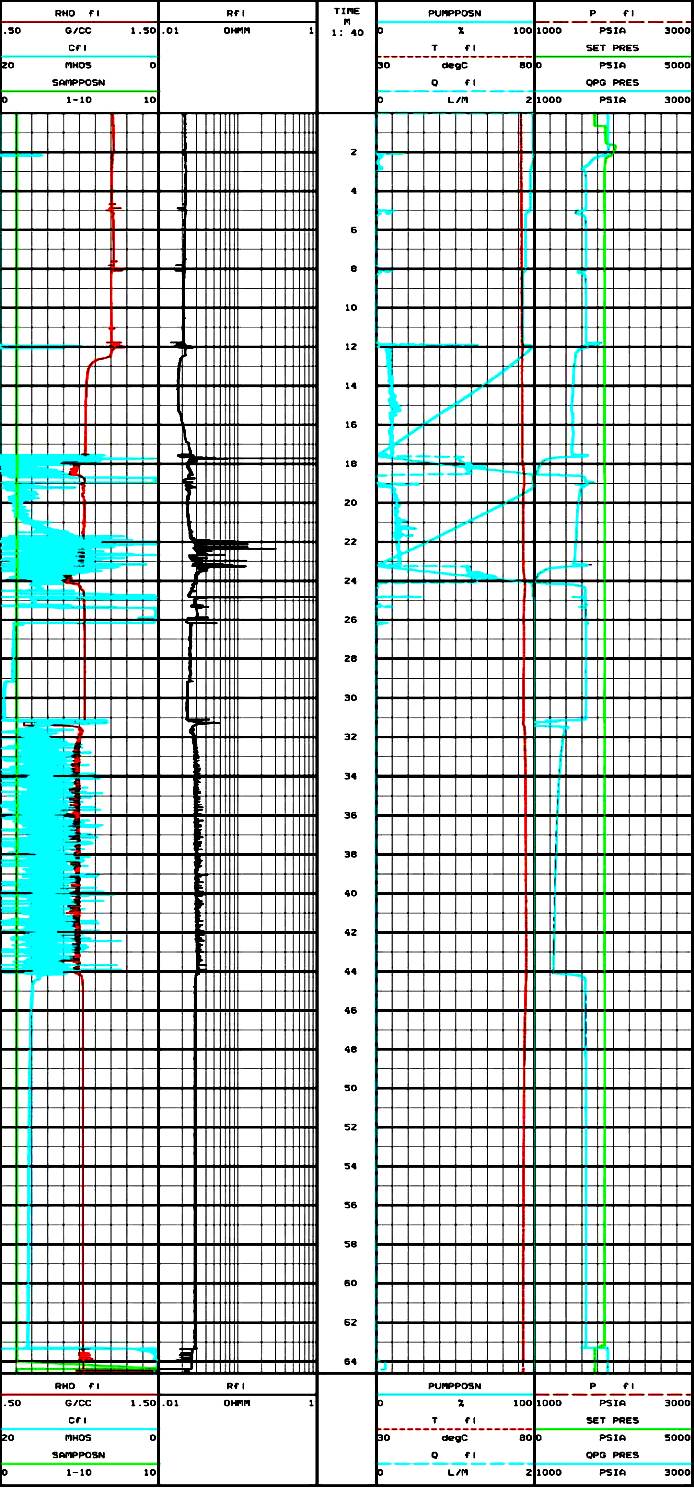

EXAMPLE 6:

Gas/Oil contact definition.

EXAMPLE 6:

Gas/Oil contact definition.

This test was taken three metres below Example 5. Oil breakthrough

occurred after eighty minutes of steady flow.

Oil density was 0.98 g/cc and contrasts strongly with the gas of

Example 5. This oil is heavily biodegraded, the light ends have been

removed by bacteria. Thus the oil is very under-saturated. This is

curious since the gas is in contact with the oil. It seems likely

that two stages of hydrocarbon migration have occurred, one of oil

and a later one of gas.

EXAMPLE 7:

Halliburton SFT with FET, Gas sampling.

EXAMPLE 7:

Halliburton SFT with FET, Gas sampling.

This test was the first commercial use of the SFT chambers in

conjunction with the FET. 25 litres pumped in 31 minutes before

diversion into SFT chamber. Flowing pressure ~200 psi below shut in

pressure. Chamber filled in ~12 minutes. Note the slow pressure

build-up when chamber fills. This is consistent with a compressible

fluid in the tool. Minimal filtrate in sample at surface. High

quality sample produced. Normal operation of the SFT is to open the

Chamber after pretest. The advantage of the FET is the ability to

removed an unlimited amount of fluid before sampling commences.

EXAMPLE 8:

Halliburton SFT with FET - Water sampling

EXAMPLE 8:

Halliburton SFT with FET - Water sampling

This test was the second commercial use of the SFT chambers in

conjunction with the FET. 4 litres pumped in 12 minutes before

diversion into SFT chamber. Flowing pressure is ~400 psi below shut

in pressure. Chamber filled in ~12 minutes. Note the rapid pressure

build-up when chamber fills. This is consistent with a

noncompressible fluid, water, in the tool.

|