|

PROBLEMS WITH PERCEPTION

PROBLEMS WITH PERCEPTION

In many cases, horizontal wells

can overcome low productivity from vertical wells. An

extended reach well increases flow capacity by penetrating a

longer interval of reservoir rock, provided of course that

you stay inside the reservoir. If natural fractures are

present, aiming perpendicular to them will often improve

flow capacity, but not if the fractures also penetrate water

below the oil or gas above it. It's a 3-dimensional problem

and it needs to be understood before the well is planned in

detail. You ignore structure, stratigraphy, and fluid

contacts at your peril.

Petrophysical analysis can reduce

the risks of horizontal wells dramatically. Unfortunately, many such

analyses come too late and are merely post-mortem autopsies. I call

these projects forensic log analysis. a real whodunit detective

story usually unfolds.

In the three examples that follow,

the horizontal wells were planned because the vertical wells were

not producing as well as their neighbours. In all three cases, the

reservoir was thinner and lower structurally than those high

production neighbours. In all three cases, the horizontals were

economic failures and one was a complete write-off from the

beginning.

These projects date back about 30

years so the people and companies involved are long gone, so I

doubt anyone reading my commentary will be too embarrassed. The

wells shown are 0.5 to 1.0 mile apart.

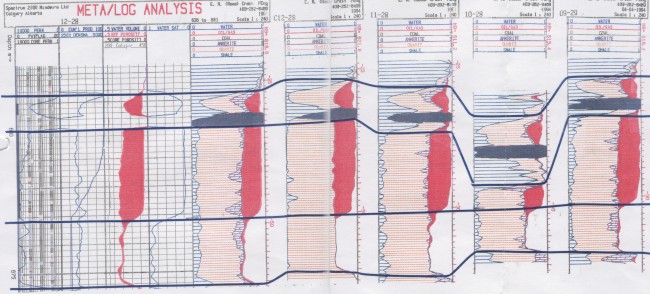

The operator of the well second from the right compared his well

performance with his luckier neighbours and came up short.

Stratigraphic correlation looks pretty good but his structural

position is terrible, due to differential salt solution during and

after deposition. That coal bed was horizontal once. The common oil

water contact in the channel sand confirms the current structural

levels. He decided to drill the horizontal well anyway and

penetrated only the upper poor quality sand and the coal, never

touching the better sand below

the coal. This reduced the risk of penetrating water but the result

was dry hole. This cross section was made after the fact, and the

operator appeared completely surprised by the structural situation.

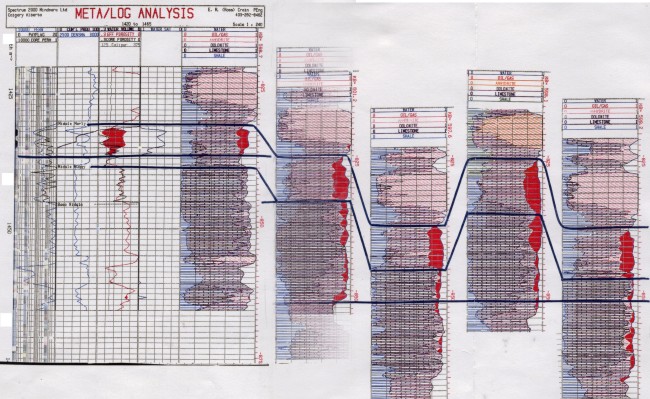

The complexity of carbonate lithology coupled with structural

concerns makes horizontal well planning a bit difficult. Same

operator, same problem as the previous example - his well at the

right is producing less than his neighbours, so let's do a

horizontal. It produced at a rate about the same as the original

vertical well and never made a positive cash flow. The zone is

thinner, lower porosity, and closer to the water, so it was a risk

at best, but fortunately not a total disaster. Note that the well at

far left is in a completely separate oil pool as the water contact is

quite different.

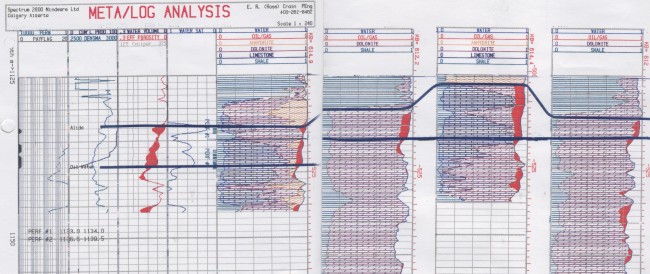

Yup. Same client, same problem, another post-mortem. His well is on

the right. You can write the prognosis yourself. The zone is thin

and low porosity, sitting on higher porosity water. What did you

expect to happen? Again, the well on the left is in a separate oil

pool.

|