|

INDUCTION LOG BASICS

INDUCTION LOG BASICS

This page describes induction logs

profiles, in the order of their appearance over the years.

This presentation style provides insights into tool

evolution, and a specific tool’s capabilities and

limitations. You will find most these tool types in your

well files – here’s your chance to learn more about them.

The induction log

was invented by Henry Doll of Schlumberger and described in 1947. It

was developed from electromagnetic research undertaken during World

War II on mine detectors. The first commercial success for the tool

began in 1956. Many evolutionary developments have occurred over the

last 50 years, providing better vertical resolution and deeper depth

of investigation.

Conventional

induction logs measure conductivity perpendicular to the axis of the

tool. In a vertical well, this is the horizontal direction. Vertical

conductivity may be quite different. Recent developments have

introduced a log that can measure vertically as well as

horizontally. It is in the commercialization phase of development,

and promises to be very useful in thin bedded and dipping reservoir

rocks.

The tool works in air, oil,

or mud filled open holes but salt muds give poor results, although

the array induction can handle saltier muds than earlier versions of

the tool. It does

not work in cased holes. A cased hole formation resistivity log is

available; it is a form of

laterlog.

Use the links in the right hand menu to skip the hairy technical

parts, although a little knowledge of electromagnetics, geometric

factors, and skin effect won't actually fry your brain.

References:

1. Introduction to

Induction Logging and Application to Logging of

Wells Drilled With Oil

Base Mud

H.G. Doll, AIME, 1949

2. Dual Induction-Laterolog: A New Tool for Resistivity Analysis

M.P. Tixier, R.P. Alger, W.P. Biggs, B.N. Carpenter, AIME,

1963

3. Introduction to the Phasor Dual Induction

Too

T.D.

Barber, JPT, Sept 1985

4. Using a Multiarray Induction Tool to Achieve Logs with Minimum

Environmental Effects

T.D.

Barber,, SPE paper 22725,,Oct 69, 1991

INDUCTION LOG THEORY -- CRAIN'S HIGHLY SIMPLIFIED VERSION

INDUCTION LOG THEORY -- CRAIN'S HIGHLY SIMPLIFIED VERSION

Induction logs are designed to measure the conductivity of rock

formations by using the electromagnetic principles outlined by

Faraday, Ampere, Gauss, Coulomb and unified in a single theory

by James Maxwell in 1864.

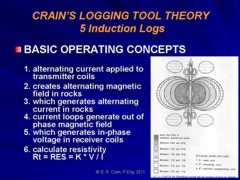

The process involves the interaction of magnetic and electric fields:

1. alternating

current applied to transmitter coils

2. creates alternating magnetic field in rocks

3. which generates alternating current in rocks (current loops, eddy

currents)

4. current loops generate out of phase magnetic field in rocks

5. which generates in-phase voltage in receiver coils

6. calculate resistivity Rt = RES = K * V / I

The basic

equations for a single transmitter – receiver coil pair, in

EXTREMELY simplified form, are shown below.

1: Bt = uo * dI/dt

magnetic field due to current “I” in transmitter coil

2 : I

= C * dBt/dt current in formation induced by magnetic field “Bt”

3: Br = uo * dI/dt

magnetic field due to current “I”

circulating in the rock

4: V = N * A * (dBr/dt) voltage induced in receiver coil by

magnetic field Br

Where;

Bt = the magnetic field strength in the formation created by an

induction log transmitter

uo = the magnetic permittivity

dI/dt = rate of change of the current in the transmitter coil

I

= current circulating in the rock

C =

conductivity of rock

dBt/dt

= rate of change of transmitted magnetic field

Br = out-of-phase magnetic field strength in the formation created

by the currents in the rock

dI/dt = rate of change of the current in the rock

V = voltage induced in an induction log receiver coil

N = number of turns on the coil

A = area of the coil

dBr/dt

= rate of change of the magnetic field created by the currents

circulating in the rock

The magnetic fields,

and currents in the rock and receiver-transmitter system are

vectors (amplitude and direction). The in-phase component measured

at the receiver coil is called the Real (or R) component. The signal

that is 90 degrees out of phase is called the Imaginary (or X)

component. Older tools could measure only the R component. Newer

tools measure both R and X components. The X component is used to

enhance bed resolution by use of proprietary algorithms.

If

you can handle advanced calculus and know what the “curl” operator

does, refer to “Basic Theory of Induction Logging” by J.H. Moran

and K.S. Kunz, SEG Oct 1959 for the real story on induction log

theory.

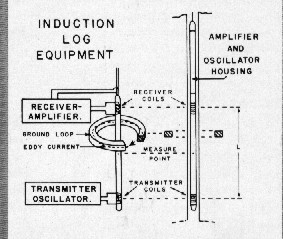

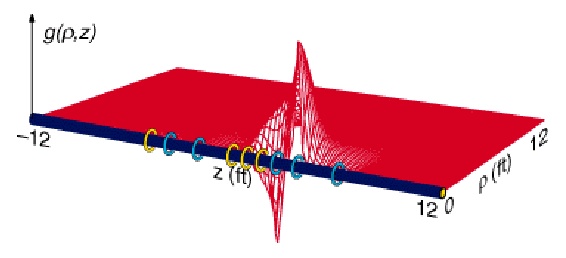

The

illustration at right shows a simple two coil induction log and a

single "ground loop" of current circulating in the rock around the

tool. An infinite number of ground loops exist, but only those near

the tool will generate a magnetic field strong enough to produce a

voltage in the receiver coil. The

illustration at right shows a simple two coil induction log and a

single "ground loop" of current circulating in the rock around the

tool. An infinite number of ground loops exist, but only those near

the tool will generate a magnetic field strong enough to produce a

voltage in the receiver coil.

Early induction logging tool consists of several

transmitter-receiver coil pairs within a logging tool housing. A

20,000 Hz regulated alternating current is produced in the

transmitter coils, which induces eddy currents by electromagnetic

induction into the rocks surrounding the coil system. The eddy

currents generate a magnetic field, which in turn induces voltages

in the receiver coils. By keeping the transmitter current constant,

the magnitude of the eddy currents are proportional to the

conductivity of the formation and 90 degrees out of phase with the

transmitter current. Voltages at the receiver coil induced by these

eddy currents are also proportional to the formation conductivity

and approximately in phase with the transmitter current. The

electronic circuitry of the receiver is designed to detect the

in-phase component of the receiver coil voltage and this serves as a

measure of the conductivity of the formation.

The eddy currents induced in a conductive formation

experience phase shift and attenuation. The loss due to attenuation

is known as skin effect (or propagation loss) and is corrected by

proprietary service company algorithms. Corrections fir the effect

of drilling fluid invasion may be required. Charts and computer code

are available for this purpose.

More modern induction tools use multiple frequencies and multiple coil spacings, along with measurements of both in-phase and quadrature

phase signal components. This allows numerical solutions for invaded

zone resistivity (Rxo) and true resistivity (Rt). These "answer"

curves are available to be presented along with the measured curves.

When Rt is provided, no further invasion corrections are required.

RADIAL and VERTICAL GEOMETRIC FACTORS

RADIAL and VERTICAL GEOMETRIC FACTORS

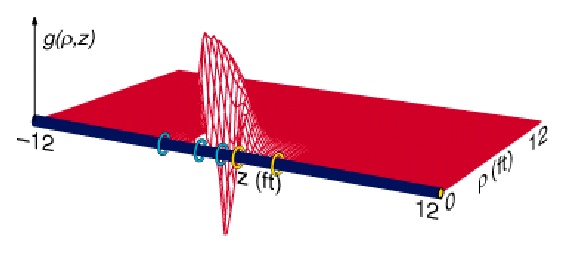

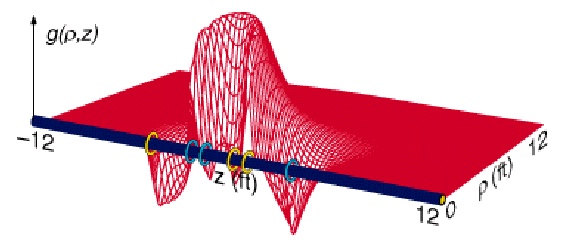

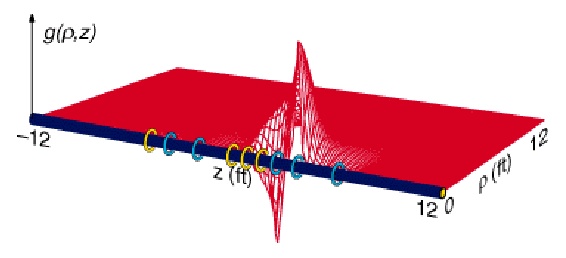

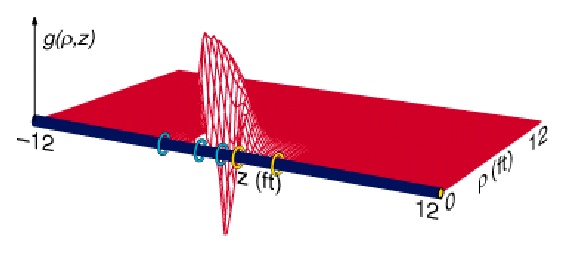

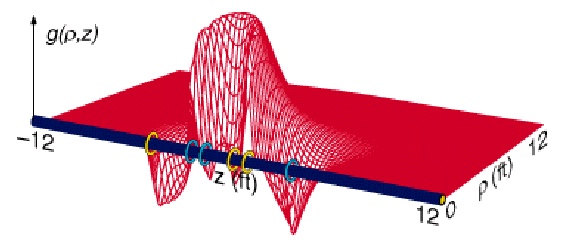

The voltage at the

receiver from a unit loop of radius, r, and altitude, z, with

respect to the center of the coil system is given by: Vr =

K * G * COND, where K is a function of the area of the transmitter

and receiver coils, distance between the coils, current in

the transmitter, and frequency of the transmitter current.

G is the geometric factor, which depends on the geometric position

of the unit loop as related to the transmitter and receiver

coils.

The radial geometric factor G considers

the formation as the combination of a large number of cylinders

coaxial with the borehole. The integrated radial geometric factor,

Gr, is the sum of all the G values for the total volume within

a cylinder of radius, r. This represents a thick homogeneous

formation invaded by mud filtrate where conductivity changes

radically, and includes a small portion of the borehole.

The signal measured by an Induction

log positioned opposite a thick formation usually reflects

the conductivity of that formation; however, in thin formations,

the signal is affected by the conductivities of the adjacent

formations. In a similar manner, the integrated vertical geometric

factor, Gv, becomes the sum of the G values for all of the

volume above (or below) a horizontal plane at a distance, z,

from the center of the coil span. The integrated vertical geometric

factor increases with the vertical distance, z, and must equal

unity for all space.

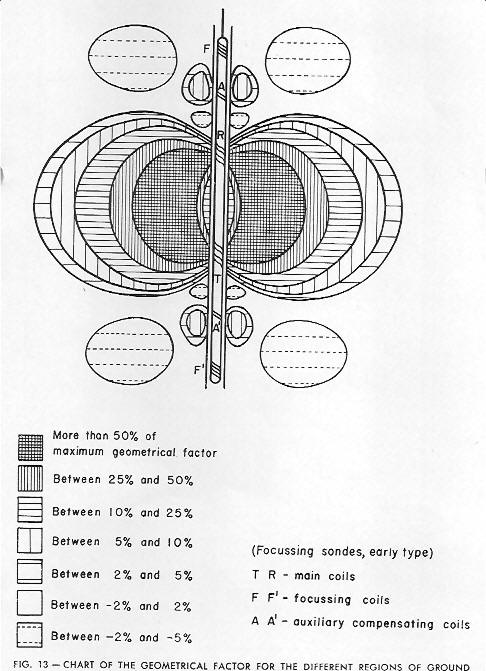

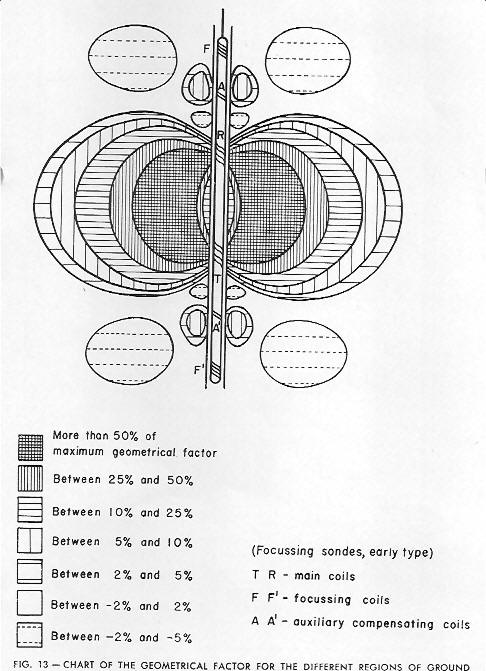

Development of the geometric factor

for a focused induction log can be accomplished by adding algebraically

all combinations of transmitter-receiver coil geometric factors

times each coil pair's contribution to the total instrument

response. This is done by computer modeling at the time the

tool is designed.

To illustrate the geometric factor

concept, assume borehole size = 8 in, invasion diameter = 40

in, Cm = 1000 mmho/m, Ci = 50 mmho/m, Cu = 100 mmho/m. For

a particular induction log, assume:

Gm = G8 = –0.001

Gi = G40 – G8 = 0.025 – (–0.001)

= 0.026

Gu = 1 - G40 = 1 – 0.025 = 0.975.

Where Cm, i, u = conductivity of the mud, invaded zone, and undisturbed zone

and Gm, i, u = radial geometric factor for the mud, invaded zone, and undisturbed

zone respectively.

1: CONDa

= Gm * Cm + Gi * Ci + Gu * Cu

= 1000

* (–0.001) + 50 * 0.026 + 100 *

0.975 = 97.8 mmho/m

The borehole and invasion create a

2.2 mmho/m error (100 – 97.8) in the measured value of

the un-invaded zone conductivity.

Illustration showing radial geometric factor for a 6

coil induction log

Bed thickness correction charts are

provided by service companies for their particular tools, based

on the vertical geometric factor concept. The following example

illustrates the geometric factor for thin bed response for

a typical logging tool:

Given:

Bed Thickness = 4 ft, CONDb = 100 mmho/m, CONDs = 1000 mmho/m,

Gb = 0.728,

Gs = 1 – 0.728 = 0.272,

where CONDb = conductivity of the bed of interest, and CONDs

= conductivity of the surrounding beds.

CONDa = 100 * 0.728 + 1000 * 0.272

= 345 mmho/m

The apparent conductivity is 3.45

times the actual conductivity of the zone (100 mmho/m), a 345%

error, illustrating the large error inherent in typical induction

log readings in thin beds. A resistive formation needs to be

at least 24 feet thick for the vertical geometric factor to

approach 1.0.

BED BOUNDARIES ON INDUCTION LOGS

BED BOUNDARIES ON INDUCTION LOGS

Bed boundaries on induction logs

should be picked on the conductivity curve halfway between the high

and low conductivity values, as shown below.

Depth of bed Boundary is chosen at mid-point of conductivity – not

the resistivity

Unfortunately, most modern induction logs display resistivity on a

logarithmic scale, not conductivity on a linear scale. As a result,

the mid-point rule is impossible to apply directly. You could do two

quick resistivity to conductivity conversions (COND = 1000 / RESD),

find the mid-point, and convert it back to resistivity (RESD = 1000

/ COND). This might be a bit onerous, so another rule is to pick the

resistivity inflection points, then move the top boundary of

resistive beds up 2 to 4 feet, and move the bottom down by

the same amount. Conductive beds get the same shift, but in the

opposite direction - make the bed thinner.

This

helps to compensate for the curve shape distortion caused by

transforming conductivity to resistivity. Newer induction logs have

better focusing and this stretch may not be needed - compare to core

or microlog or formation microscanner to see if a bed boundary shift

is needed. This shift is NOT required on Phasor or array induction logs.

The

illustration below shows the problem for a typical middle-aged

induction log (IES or DIL) These older logs were run for over 40

years so there are a lot of them in your well files.

Bed boundaries on induction log

INDUCTION ELECTRICAL SURVEY (IES) DETAILS

INDUCTION ELECTRICAL SURVEY (IES) DETAILS

This Section is based on a Schlumberger

document "Induction Response Theory

- the Basics". This may be part of "Induction Logging Manual", available

as a download from slb.com. Other service companies have provided

similar services to those described here. Images courtesy of

Schlumberger.

The

induction electrical log (IES) is well defined by its name; it

consists of a deep investigation conductivity measurement combine

with a shallow resistivity and SP curves from the older electrical

survey. The presentation was made as close as possible to the ES,

with linear resistivity in Track 2 and linear conductivity in Track

3, replacing the lateral curve on the ES. The

induction electrical log (IES) is well defined by its name; it

consists of a deep investigation conductivity measurement combine

with a shallow resistivity and SP curves from the older electrical

survey. The presentation was made as close as possible to the ES,

with linear resistivity in Track 2 and linear conductivity in Track

3, replacing the lateral curve on the ES.

THE 5FF27 and 5FF40 TOOLS

THE 5FF27 and 5FF40 TOOLS

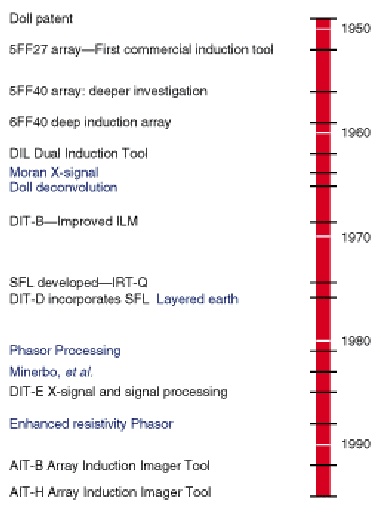

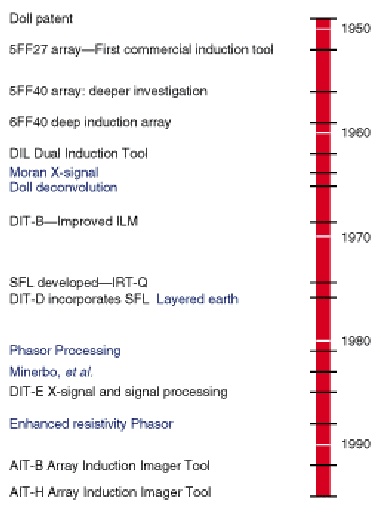

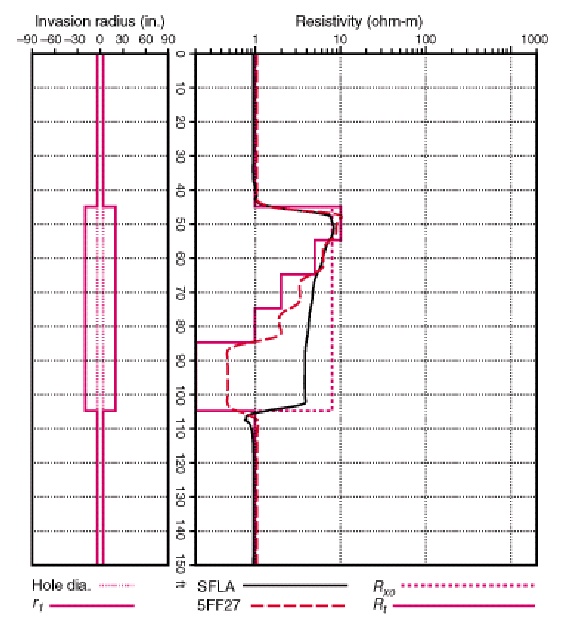

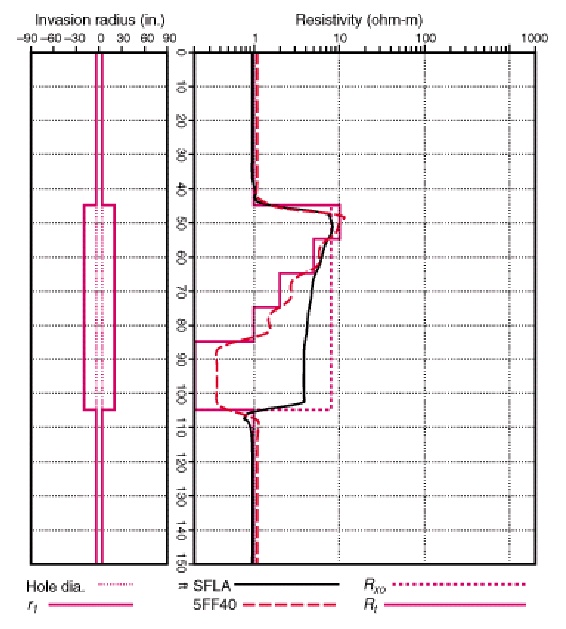

There were 3 flavours of IES over the years -- the original; 5FF27

(1952), the 5FF40 (1955), and the 6FF40 (1959), which became the

industry standard for more than 30 years. In the tool designation,

the first digit represented the number of coils, "FF" stood for

"fixed focus", and the last two digits represent the main coil-pair

spacing. The vertical resolution and depth of investigation were

about double that number in inches.

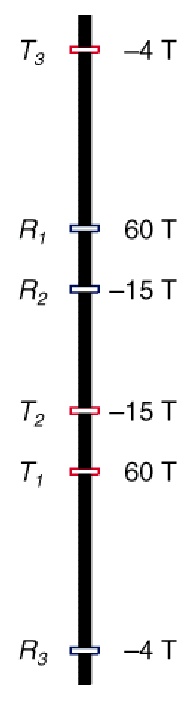

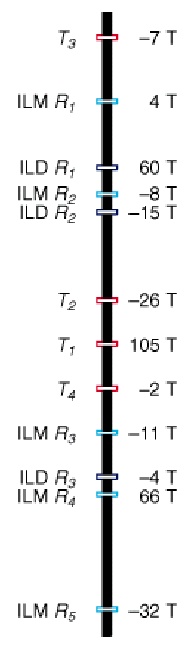

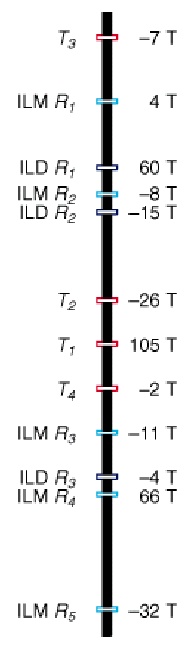

<== Timeline of induction log evolution

Induction logs need to "see" deep enough beyond the wellbore to read

reasonably accurate values for formation conductivity with a

minimum contribution from the borehole and invaded zone. They also

have to be focused well enough to avoid shoulder bed effects. This

is accomplished by using multiple coils to focus the measurement and

subtract borehole effects.

The first commercial induction tool was the 5FF27 array, which was

introduced in the Gulf of Mexico and Gulf Coast in 1952. Although it

had low skin effect (necessary in that high-conductivity

environment), its depth of investigation was insufficient.

5FF27 response was unsymmetrical and negative coils caused

overshoot and spikes at bed boundaries and in rough hole.

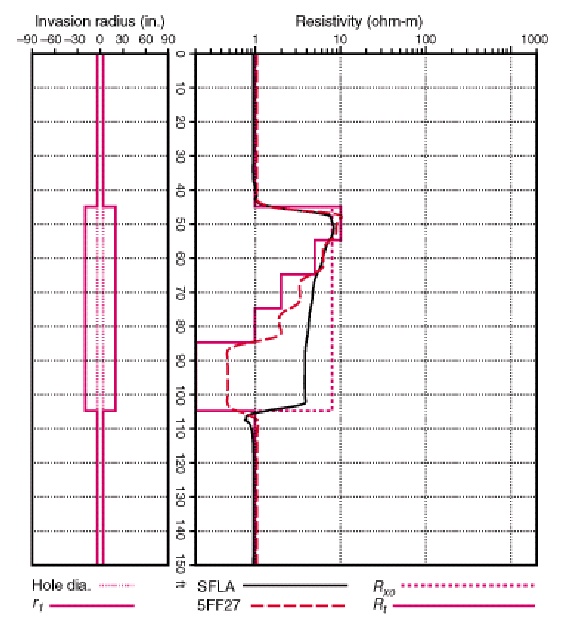

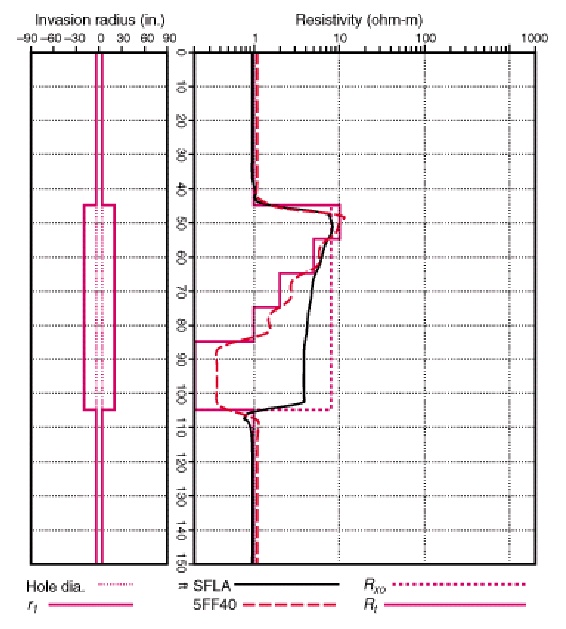

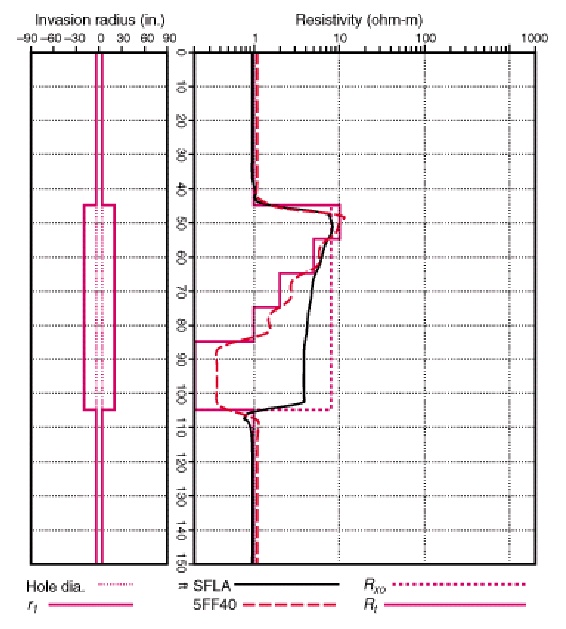

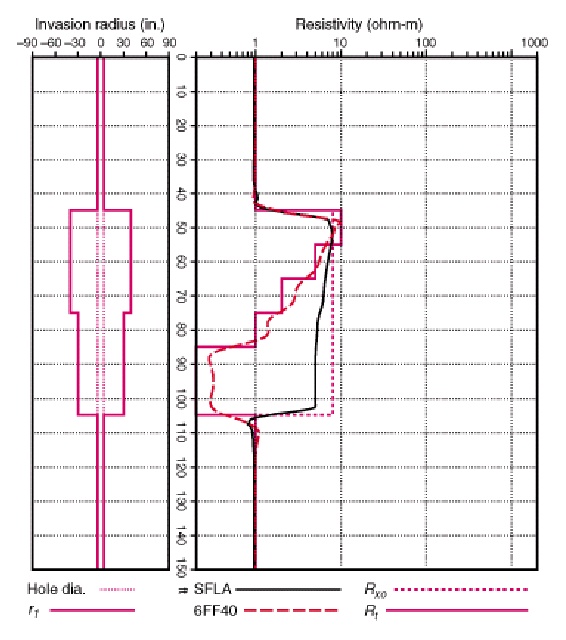

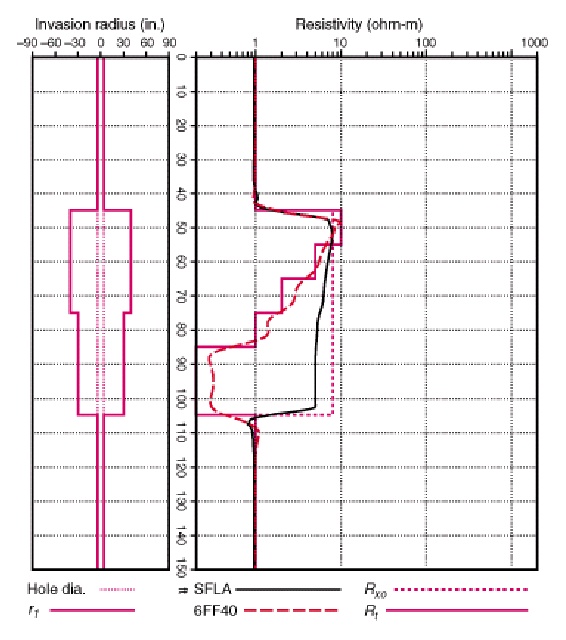

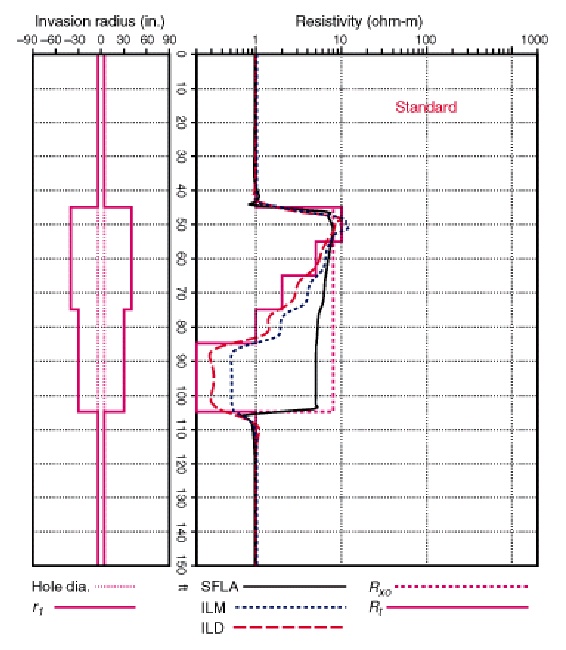

Calculated 5FF27 (left) and 5FF40 (right) responses for moderate

invasion compared to model. 5FF40 has better response un the higher

resistivity but bed boundaries are not as sharp. SFLA curve

represents a 16-jnch normal (shallow resistivity) curve which was

recorded on these logs, along with the SP curve.

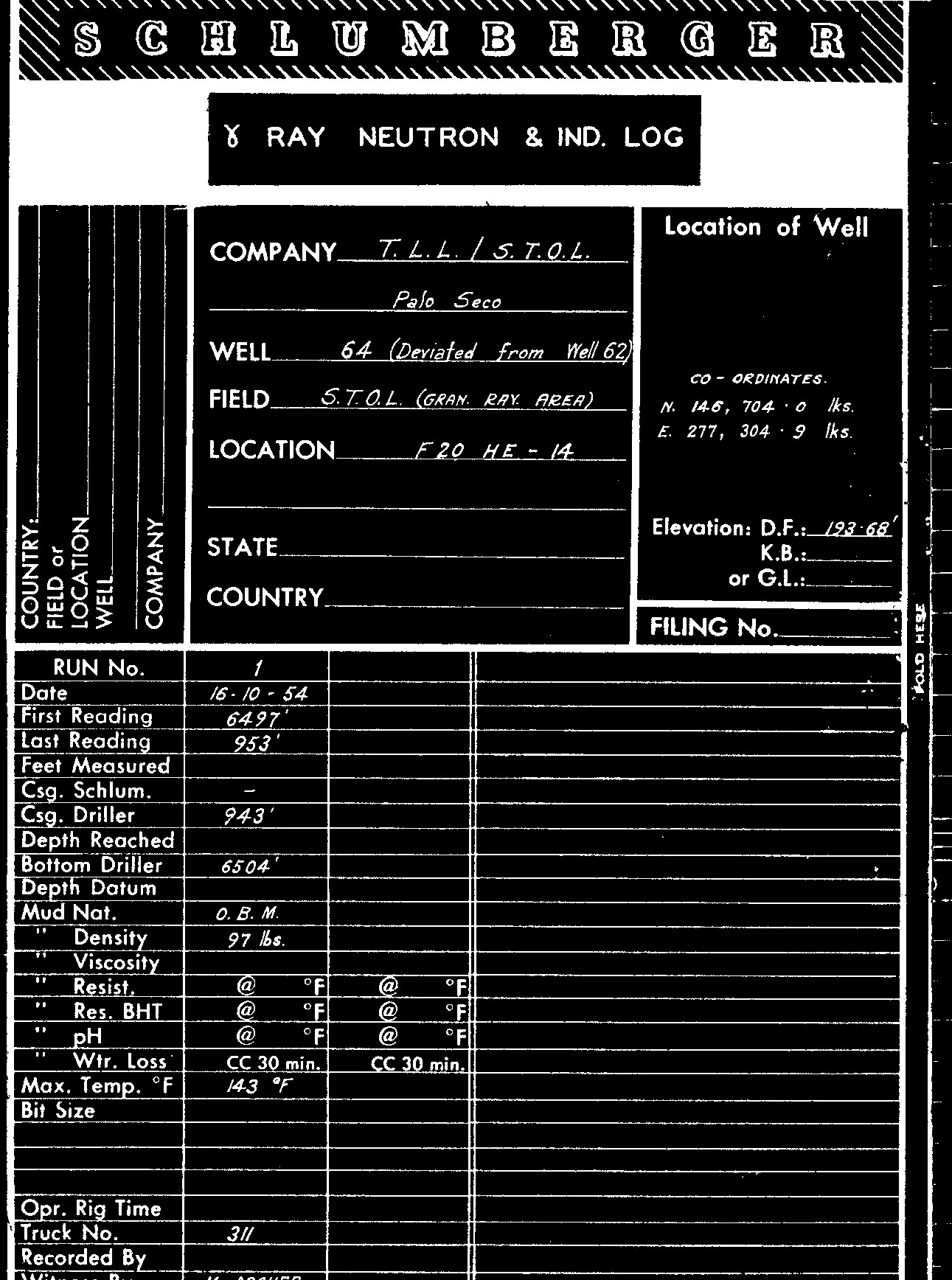

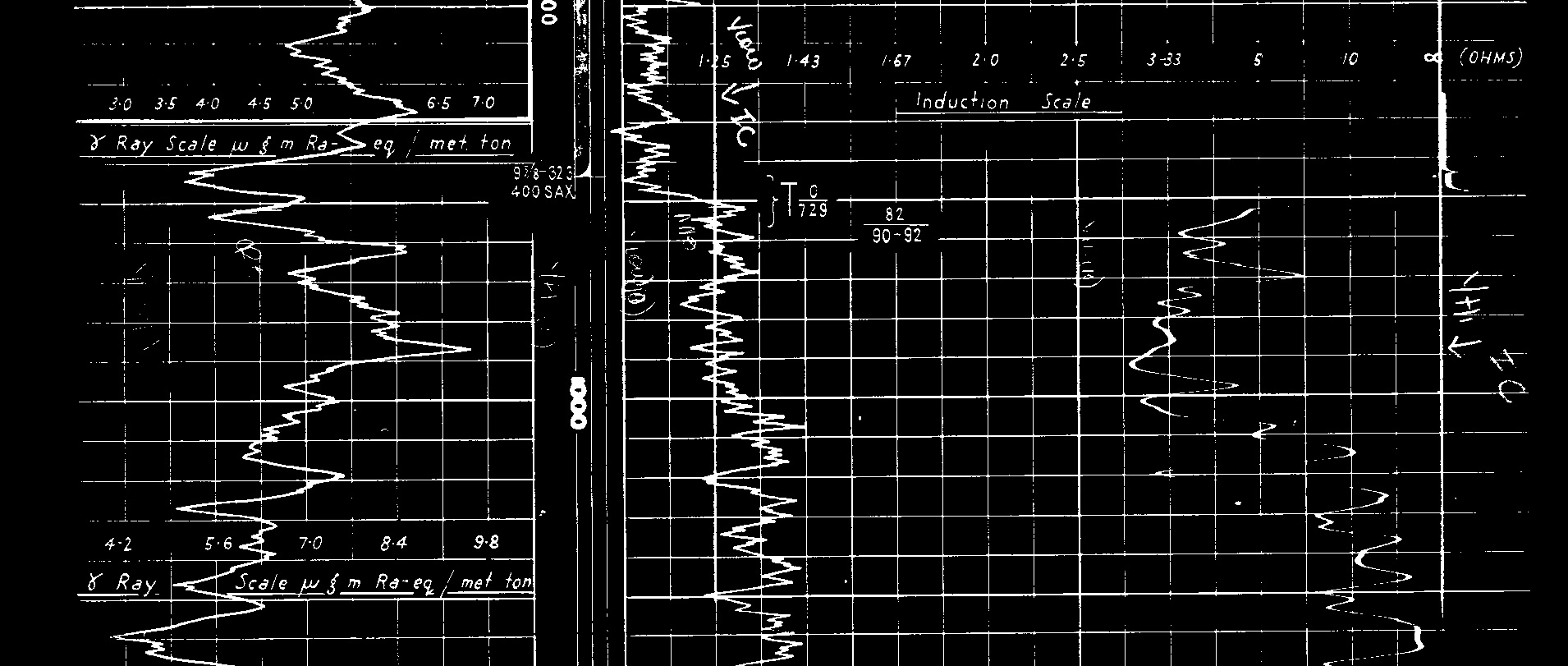

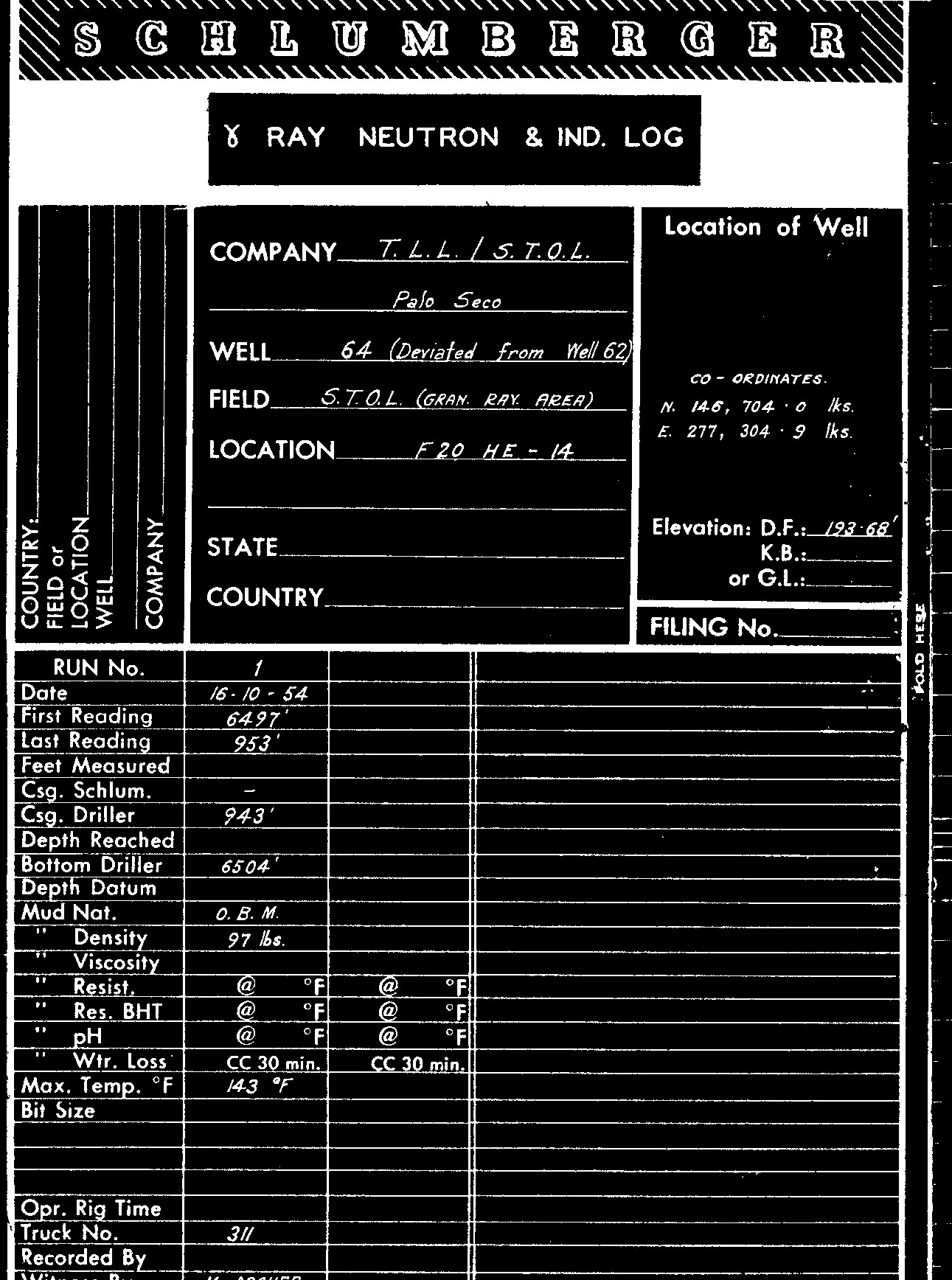

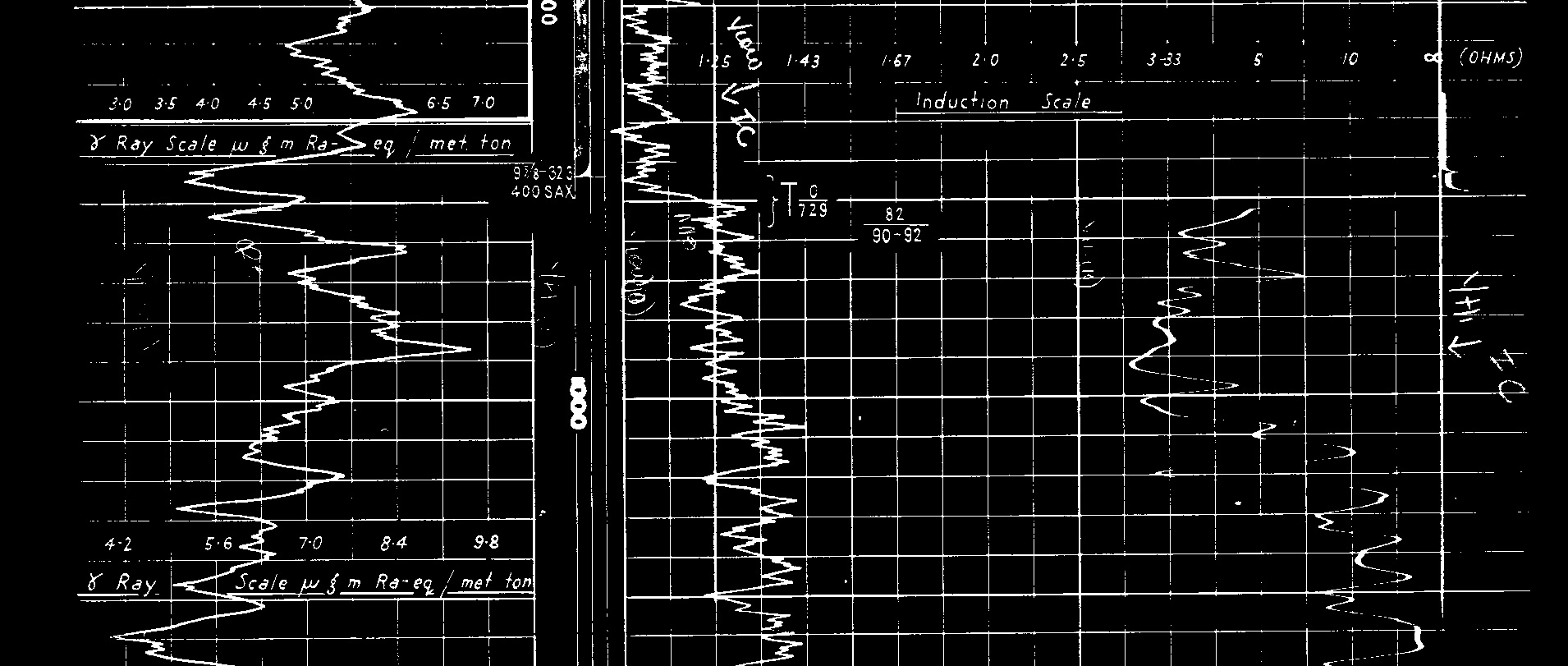

Heading and a portion of a very early induction conductivity log run

in 1954, with handwritten non-linear resistivity scale running from

1.0 ohm-m to infinity, derived from the conductivity curve

scale of 1000 to 0 mS/m (across the full width of the log).

The log appears to have been run simultaneously with the gamma ray

and neutron logs in Tracks 1 and 2.

THE 6FF40 TOOL

THE 6FF40 TOOL

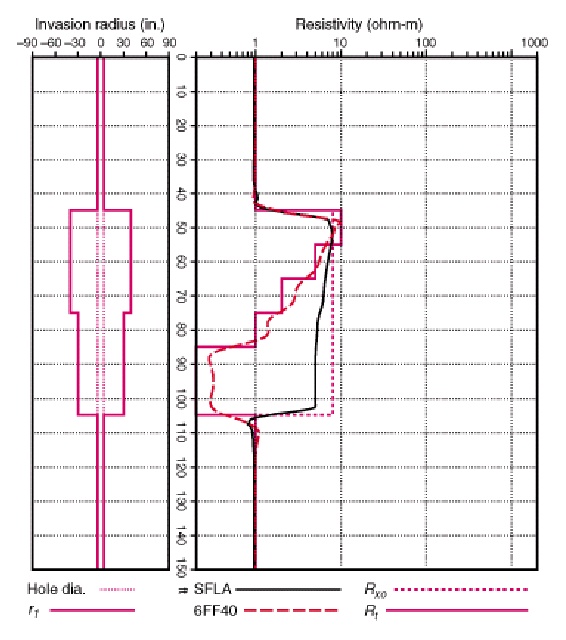

Schlumberger introduced what became the industry-standard induction

array, the 6FF40 array, in 1959. This array was licensed and

run, with minor variations, by almost all service companies. The

6FF40 array and its dual induction successor, the deep induction

array were the industry standard for 30 years. As was the case for

earlier tools, the signals from the coil sets were merged in analog

circuits in the tool body before being sent up hole.

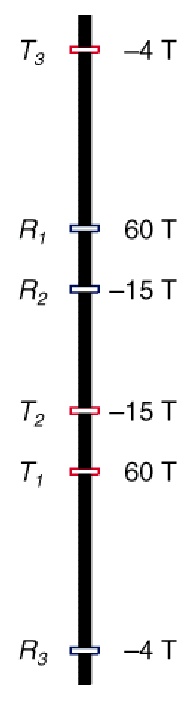

Coil arrangement on 6FF40 tool. Number and polarity of

coil windings shown on right side of image ==>

Response for 6FF40 tool is more symmetrical and sharper than for the

5FF40.

The effective length of the 6FF40 sonde is 61 inches, which is

significantly larger than the main-coil spacing of 40 inches. This

helps to explain why the sonde is unable to resolve beds thinner

than 5 feet and also why it reads much deeper than a 40-inche

two-coil sonde.

To add to the confusion,

the

standard resolution 6FF40 ILD logs has a resolution width of 8 feet.

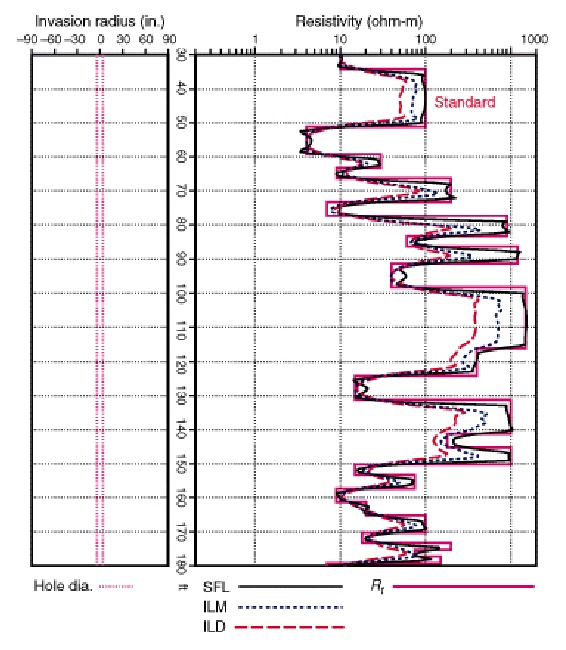

Comparison of 5FF40 (left) and 6FF40 (right) in the simulated rock

sequence. Depth of invasion (shown in Track 1) is much deeper on the

6FF40 model.

Because of the invasion, the logs are only qualitative as to Rt,

especially in the low resistivity zones.

DUAL

INDUCTION LOG (DIL) DETAILS

DUAL

INDUCTION LOG (DIL) DETAILS

This Section is based on a Schlumberger

document "Induction Response Theory

- the Basics". This may be part of "Induction Logging Manual", available

as a download from slb.com. Other service companies have provided

similar services to those described here. Images courtesy of

Schlumberger.

Dual

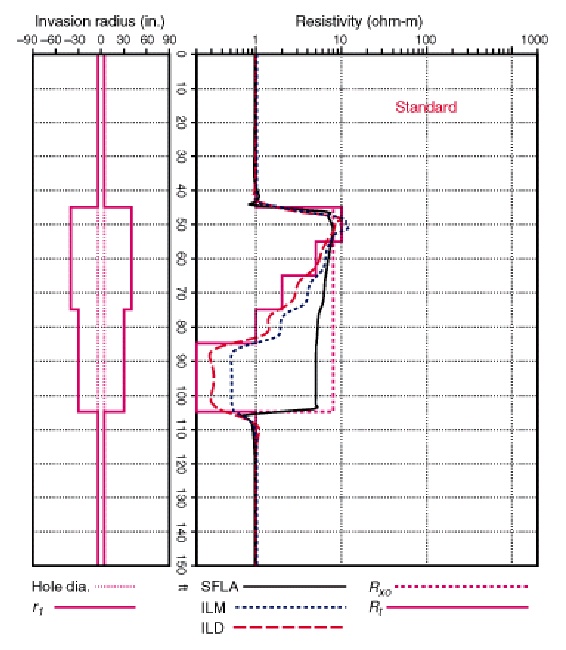

induction measurement was introduced in 1962 in an attempt to

quantify the effect of the invaded zone. The dual induction tool

kept the 6FF40 array as the deep measurement. The added shallower

induction measurement (medium induction) used the ILD

transmitter coils in combination with its own new receiver

configuration. This tool was referred to as the DIT-A.

Most of the ILM signal comes from within a radius of 60 inches,

whereas the ILD signal penetrates more than 100 inches. This was the

first log to provide linear and/or logarithmic resistivity scales on

the final log presentation. Dual

induction measurement was introduced in 1962 in an attempt to

quantify the effect of the invaded zone. The dual induction tool

kept the 6FF40 array as the deep measurement. The added shallower

induction measurement (medium induction) used the ILD

transmitter coils in combination with its own new receiver

configuration. This tool was referred to as the DIT-A.

Most of the ILM signal comes from within a radius of 60 inches,

whereas the ILD signal penetrates more than 100 inches. This was the

first log to provide linear and/or logarithmic resistivity scales on

the final log presentation.

In 1968, with the introduction of the second-generation DIT-B, an

additional small transmitter coil was added to both arrays to

improve the borehole response of the ILM. However, this coil does

not significantly affect the deeper ILD response, which remains

identical to 6FF40 log for all practical purposes.

Dual induction deep and medium coil arrays ==:

A shallow measurement provided by a laterolog tool is also included

when the dual induction tool is run. The LL8 tool was used on early

dual induction tools. It was replaced in the mid-1970s by the SFL

Spherically Focused Resistivity log, a laterolog tool with

considerably reduced borehole response.

The standard resolution ILD and ILM logs have resolution widths of 8

and 5 ft, respectively

ILM response. See previous Section for ILD (6FF40) response.

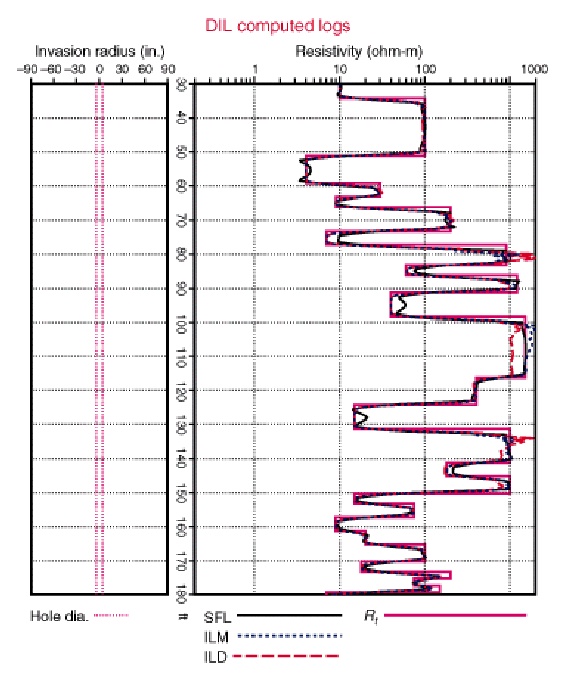

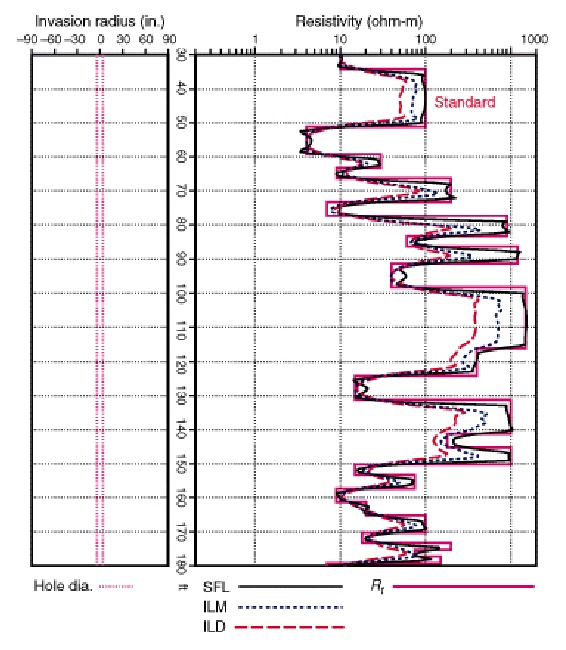

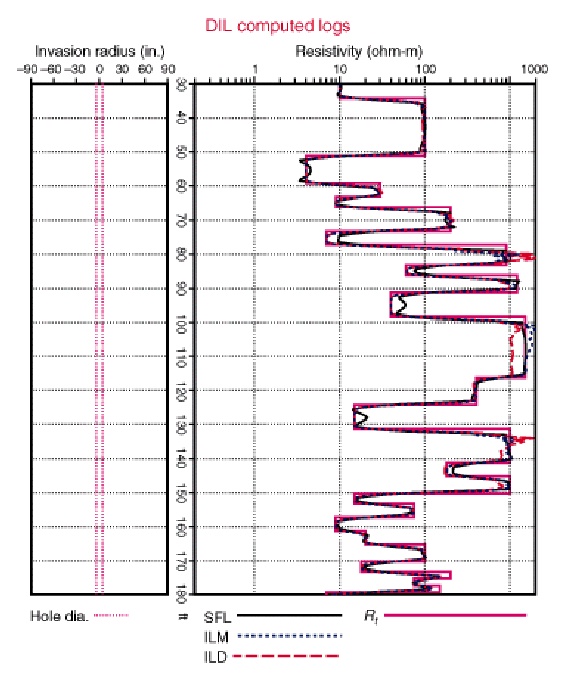

Comparison of 6FF40 (left) and DIL (right) in the simulated rock

sequence. Depth of invasion (shown in Track 1) is moderately

deep for both logs.

Because

the 6FF40 and ILD arrays survey a relatively large volume of the

formation, response to beds of interest can be affected by adjacent

beds, invasion of the drilling mud or even the presence of the

borehole itself. In addition, skin effect causes a significant

nonlinear decrease in signal, especially in conductive formations.

Over the years, a series of correction algorithms has been derived

to compensate for these parasitic effects. The traditional method

for using these algorithms is to apply them individually in an

empirically defined sequence. This methodology is not correct in

principle because of the interaction of the induction fields with

all the media they penetrate. However, it provided a reasonably

accurate stopgap means of obtaining an accurate estimation of Rt for

many years. Because

the 6FF40 and ILD arrays survey a relatively large volume of the

formation, response to beds of interest can be affected by adjacent

beds, invasion of the drilling mud or even the presence of the

borehole itself. In addition, skin effect causes a significant

nonlinear decrease in signal, especially in conductive formations.

Over the years, a series of correction algorithms has been derived

to compensate for these parasitic effects. The traditional method

for using these algorithms is to apply them individually in an

empirically defined sequence. This methodology is not correct in

principle because of the interaction of the induction fields with

all the media they penetrate. However, it provided a reasonably

accurate stopgap means of obtaining an accurate estimation of Rt for

many years.

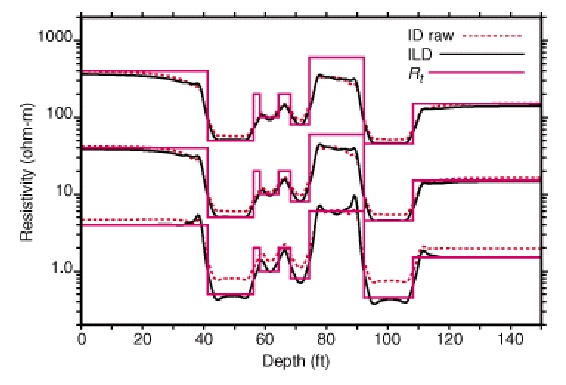

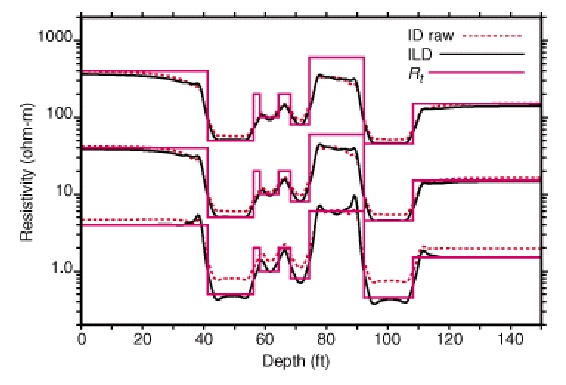

Example of conductivity boosting in three resistivity regimes. The

effect is only noticeable in low resistivity rocks ==>

For single and dual induction logs, charts were used to boost

conductivity and correct for invasion. Today this can be replaced by

stand-alone software. For Phasor and array induction tools, the work

is done in real-time as the logs are run and no further corrections

are needed.

PHASOR

INDUCTION LOG (IDPH) DETAILS

PHASOR

INDUCTION LOG (IDPH) DETAILS

This Section is based on a Schlumberger

document "Induction Response Theory

- the Basics". This may be part of "Induction Logging Manual", available

as a download from slb.com. Other service companies have provided

similar services to those described here. Images courtesy of

Schlumberger.

The Phasor induction tool is basically the same as a dual induction

with deep, medium, and SFL measurements. Coil arrays, windings, and

response maps for deep and medium measurements are unchanged. The

major difference is the real-time processing to enhance resolution.

Rxo and Rt are derived so no additional environmental

corrections are needed.

Starting in the mid-1980s, new developments in electronics

technology, new work on computing the response of the induction tool

in realistic formation models, and modern signal processing theory

were combined to overcome these limitations in the Phasor Induction-SFL

tool. Central to the development of the Phasor tool was a nonlinear

deconvolution technique that corrects the induction log in real time

for shoulder effect and improves the thin-bed resolution over the

full range of formation conductivities. This algorithm, called "Phasor

Processing" uses the induction quadrature signal, or X-signal, which

measures the nonlinearity directly. Phasor Processing corrects for

shoulder effect and provides thin-bed resolution down to 2 ft in

many cases.

To sharpen bed boundaries and reduce shoulder bed effects, an inverse filter

is used.

The filter is a set of weights, each of which is multiplied by the

corresponding log reading and then summed to produce a single depth

sample of the corrected log. Because the ILD measurement includes

information from formation layers within 50 ft, the filter includes

measurement data from 50 ft on either side of the current depth. The

resulting filter covers 100 ft of log to produce a single depth

sample. The result of the inverse filtering process is a log that

more closely resembles the formation conductivity profile.

A

transformation from the X-signal to match the skin effect signal

exactly was also developed, which when added to the inverse-filtered

R-signal, forms a linear log that does not change its

character at high formation conductivities.

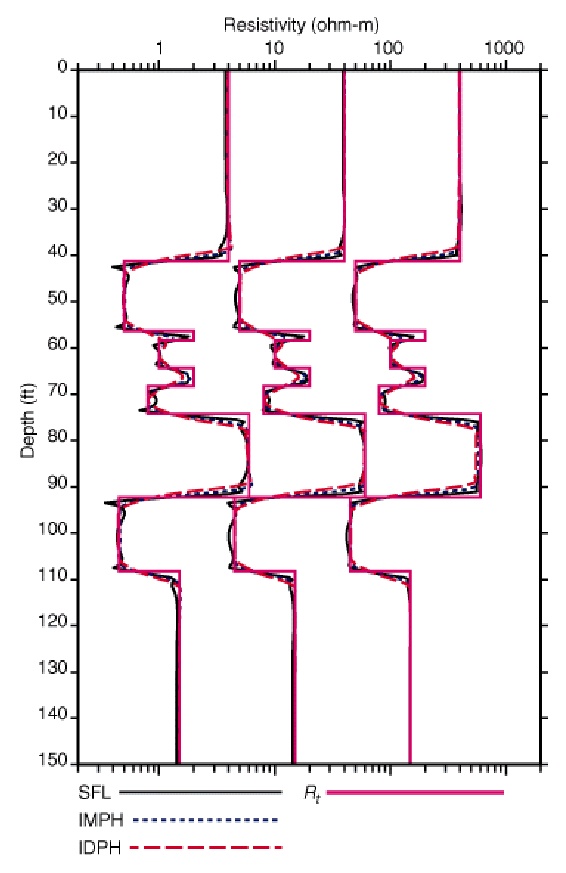

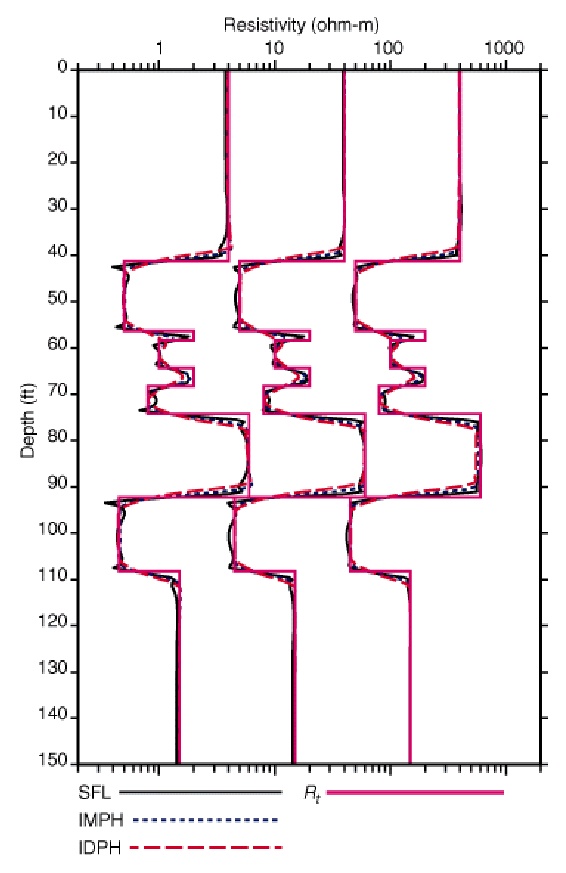

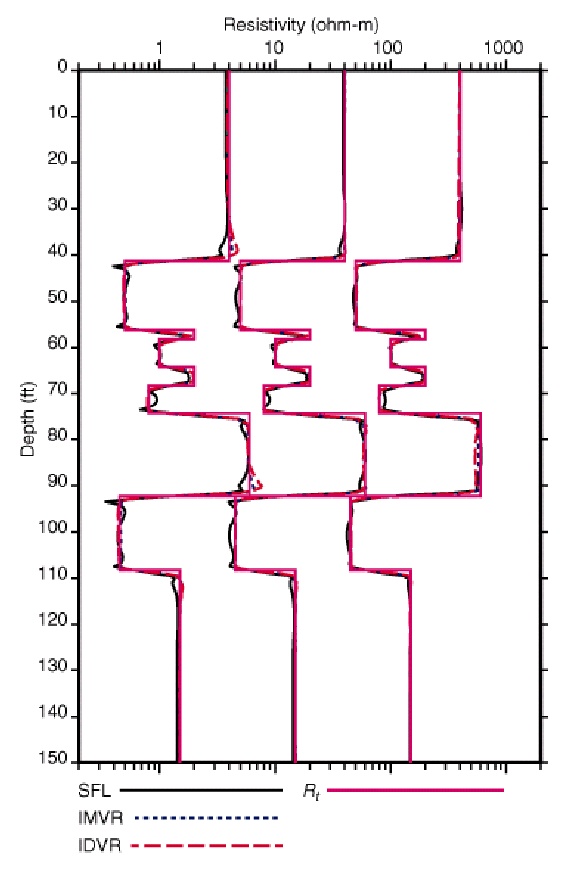

The standard- resolution IDPH and IMPH logs have resolution widths

of 8 and 5 ft, respectively, which are identical to the ILD and ILM

logs in resolution. The 3-ft resolution IDER and IMER logs are

matched in resolution. The 2-ft resolution logs are the IDVR and

IMVR logs. Not all wells can support high-resolution logs, due to

large borehole diameter.

Standard resolution Phasor induction (left), 2-foot resolution (right)

ARRAY

INDUCTION LOG (AIT) DETAILS

ARRAY

INDUCTION LOG (AIT) DETAILS

This Section is based on a Schlumberger

document "Induction Response Theory

- the Basics". This may be part of "Induction Logging Manual", available

as a download from slb.com. Other service companies have provided

similar services to those described here. Images courtesy of

Schlumberger.

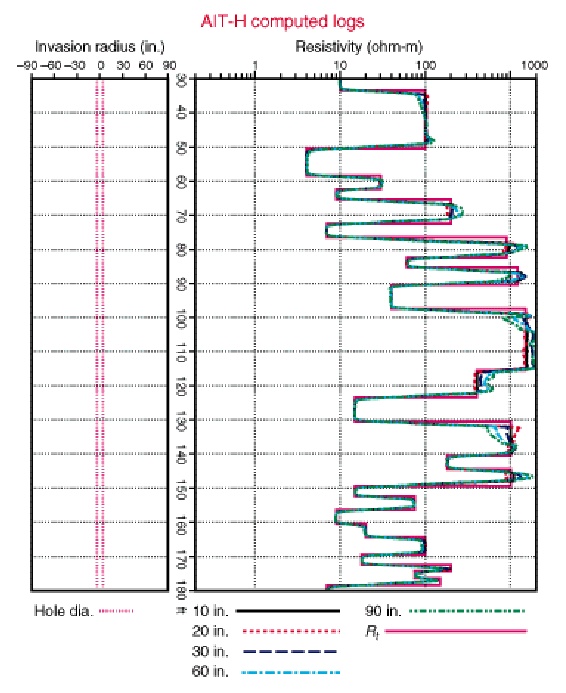

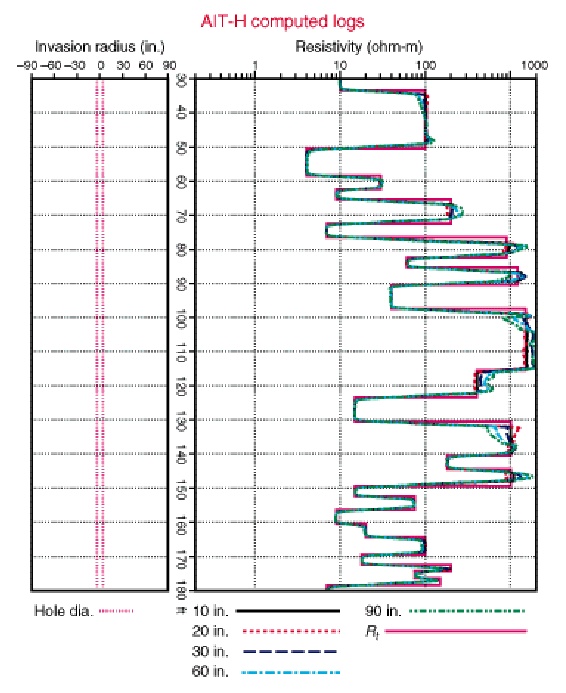

The

Phasor induction suffered in large boreholes and deep or complicated

invasion profiles. and was phased out in the mid to late 1990's. The

good ol' dual induction had been pushed to its technological limits

and could go no farther. The replacement was a totally new design --

the array induction tool (AIT). The log displays 5 resistivity

curves at depths of investigation ranging from 10 to 90 (or 120)

inches. Rxo and Rt are derived so no additional environmental corrections are

needed. Bed resolution can be computed to 1, 2, or 4 feet.

Resistivity and saturation images of the formation can be produced. The

Phasor induction suffered in large boreholes and deep or complicated

invasion profiles. and was phased out in the mid to late 1990's. The

good ol' dual induction had been pushed to its technological limits

and could go no farther. The replacement was a totally new design --

the array induction tool (AIT). The log displays 5 resistivity

curves at depths of investigation ranging from 10 to 90 (or 120)

inches. Rxo and Rt are derived so no additional environmental corrections are

needed. Bed resolution can be computed to 1, 2, or 4 feet.

Resistivity and saturation images of the formation can be produced.

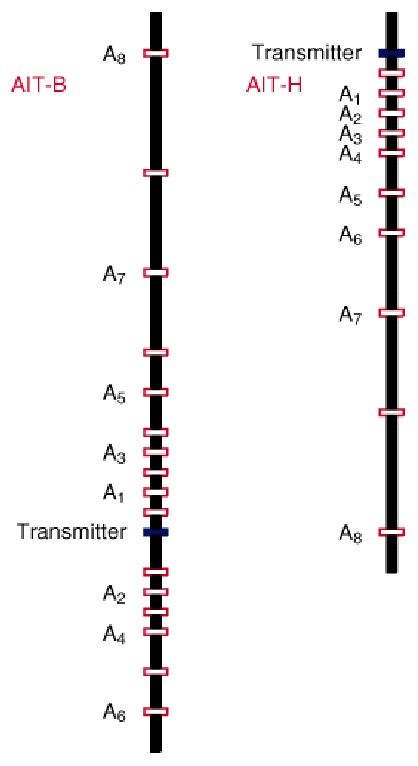

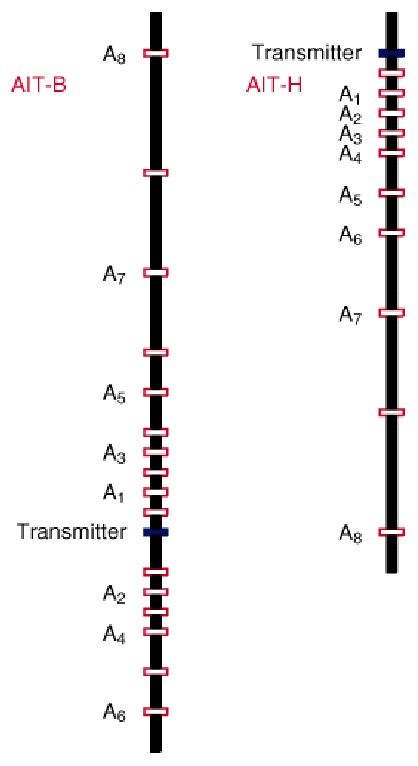

These tools abandon the concept of fixed-focus sensors and are

constructed of eight independent arrays with main coil spacings

ranging from 6 in. to 6 ft. Two AIT tools are presently in the

field: the AIT-B (standard AIT tool) and the shorter AIT-H (PLATFORM

EXPRESS AIT tool).

The AIT-B tool operates simultaneously at three frequencies;

in-phase and quadrature signals are acquired from every array at the

one or two frequencies suitable for that array length. The AIT-H

tool operates at a single frequency and measures the R- and

X-signals for each array. All these measurements, each with its

unique spatial response, are simultaneously acquired every 3 inches

of depth.

Exceptional stability is maintained over full temperature and

pressure ranges through the use of a patented metal mandrel and

ceramic coil forms; there are no fiberglass supporting structures in

the tool.

Each array consists of a single transmitter coil and two receivers.

In the AIT-H tool, some of the coils are co-wound.

Nonlinear processing methods have been developed that use each of

the measurements, combining them in such a way as to focus the log

response at a desired region in the formation that does not change

as formation conductivity changes. Several output logs can be

presented, each focused to a different distance into the formation.

Each of the new logs is a combination of several array measurements,

and all are interpretable as induction logs with full environmental

corrections. The logs are virtually free of cave effect and can

be used to provide Rt estimates with no built-in assumptions about

the invasion profile.

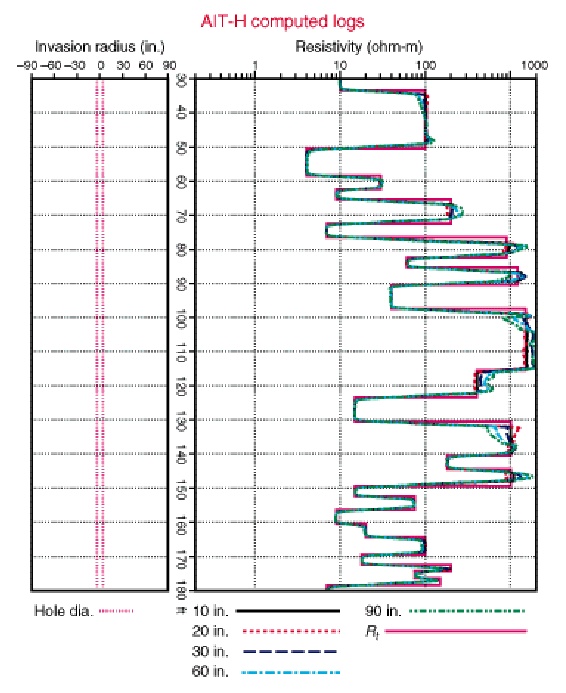

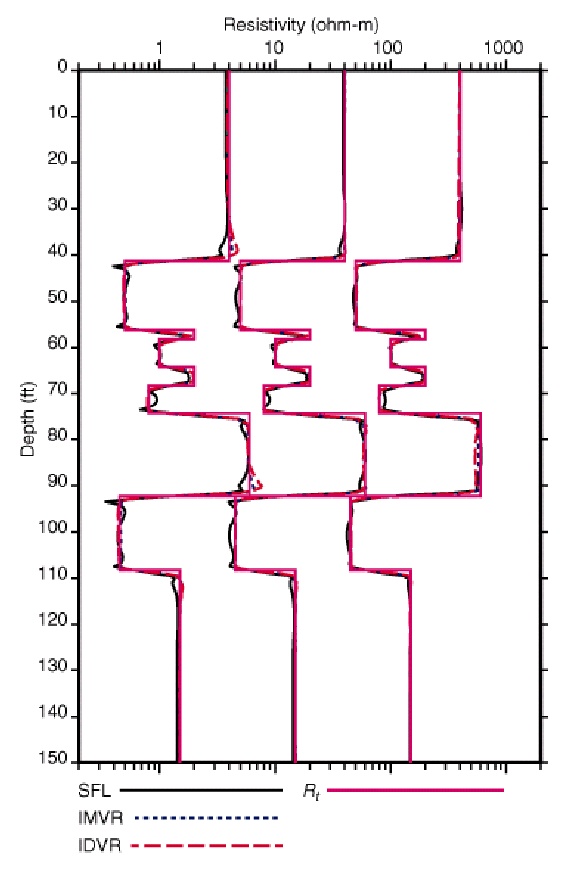

Computed DIL (left and AIT (right) shows effect of AIT's automatic

shoulder bed correction on high resistivity layers. AIT is 1-foot

resolution.

Computed Phasor induction 2-ft resolution (left and AIT 1-foot

resolution (right) shows AIT has better low resistivity results due

to automatic skin effect correction.

INDUCTION LOG CURVE NAMES

INDUCTION LOG CURVE NAMES

Notes: * = optional curve. Abbreviations varied

between service companies - common abbreviations are shown as well

as the generic abbreviation as used elsewhere in this Handbook.

Induction-Electrical

Survey (IES)

Induction-Electrical

Survey (IES)

|

Curves |

Units |

Abbreviations |

| 16"

normal |

ohm-m |

R16,

SN,

or RESS |

| induction

conductivity |

mS/m |

COND |

| induction

resistivity |

ohm-m |

RIL

or RESD |

| spontaneous

potential |

mv |

SP |

| *

gamma ray |

API |

GR |

Dual

Induction - LL8 or SFL (DIL or ISF)

Dual

Induction - LL8 or SFL (DIL or ISF)

|

Curves |

Units |

Abbreviations |

| deep

induction resistivity |

ohm-m |

ILD

or RESD |

| medium

induction resistivity |

ohm-m |

ILM

or RESM |

| shallow

resistivity |

ohm-m |

RLL8

or RSFL or RESS |

| spontaneous

potential |

mv |

SP |

| *

gamma ray |

API |

GR

|

| *

quick look ratio |

frac |

Rxo/Rt |

| *

apparent water resistivity |

ohm-m |

Rwa |

| *

formation factor ratio |

frac |

Fr/Fs |

| * sonic travel time |

usec/ft |

DELT or DTC |

| * density |

gm/cc |

RHOB or DENS |

Phasor Induction Log (DIT-E)

Phasor Induction Log (DIT-E)

|

Curves |

Units |

Abbreviations |

| deep

phasor resistivity |

ohm-m |

IDPH

or RESD |

| medium

phasor resistivity |

ohm-m |

IMPH

or RESM |

shallow

resistivity

*

deep enhanced phasor resistivity |

ohm-m

ohm-m

|

RSFL

or RESS

IDER

or RESD |

| *

medium enhanced phasor resistivity |

ohm-m |

IMER

or RESM |

| *

deep very enhanced phasor |

ohm-m |

IDVR

or RESD |

| *

medium very enhanced phasor |

ohm-m |

IMVR

or RESM |

* Rxo

* Rt |

ohm-m

ohm-m |

RXO or RESS

RT or RESD |

| spontaneous

potential |

mv |

SP |

| *

gamma ray |

API |

GR |

| *

quick look ratio |

frac |

Rxo/Rt |

| *

apparent water resistivity |

ohm-m |

Rwa |

| *

formation factor ratio |

frac |

Fr/Fs |

Array

Induction Log (AIT)

Array

Induction Log (AIT)

|

Curves |

Units |

Abbreviations |

| four

foot resistivity 10 inch depth |

ohm-m |

AF10,

AHF10, ASF10 (RESS) |

| four

foot resistivity 20 inch depth |

ohm-m |

AF20, AHF20, ASF20 |

| four

foot resistivity 30 inch depth |

ohm-m |

AF30,

AHF30, ASF30 (RESM) |

| four

foot resistivity 60 inch depth |

ohm-m |

AF60,

AHF60, ASF60 |

four

foot resistivity 90 inch depth

(see Special Features listed below) |

ohm-m

|

AF90,

AHF90, ASF90 (RESD) |

* Rxo

* Rt |

ohm-m

ohm-m |

RXO or RESS

RT or RESD |

| *

resistivity image |

Rwa,

or Sw |

image,

colour |

| *

spontaneous potential |

mv |

SP |

| *

mud resistivity |

ohm-m |

AHMF |

| *

gamma ray |

API |

GR |

| |

|

Note

1: Baker Atlas tool has 120 inch depth as well as

the 5 others, all with different mneumonics than Schlumberger. |

| |

|

|

|

Note

2: One foot and two foot curves may also be recorded

and displayed separately (AOxxx and ATxxx) as well as

environmentally corrected four foot resistivity (AExxx).

Some conductivity curves are also recorded but seldom

displayed. Extrapolated values for Rxo and Rt are also

generated for each of the 3 bed thickness resolutions. |

EXAMPLES OF INDUCTION LOGS

EXAMPLES OF INDUCTION LOGS

Sample log presentations are shown below. The shallow resistivity curve has evolved over time, from

the 16” normal in the 1960’s, laterolog-8 (LL8) in the 1970’s,

spherically focused log (SFL) in the 1980’s, to a shallow (10”)

induction curve on the current array induction log.

Induction log showing logarithmic scale (left)

and linear scale (upper left) with conductivity curve as well

as resistivity curves. Many varieties of Induction logs are

run today, some with interpretive images of resistivity profiles

or saturation. Combination log presentations with porosity

curves, such as sonic (right) or density are found in some

locations. The SP and/or gamma ray curve is in track one.

Logarithmic scales compress the resistivity range into a smaller

space, reducing the need for backup scales.

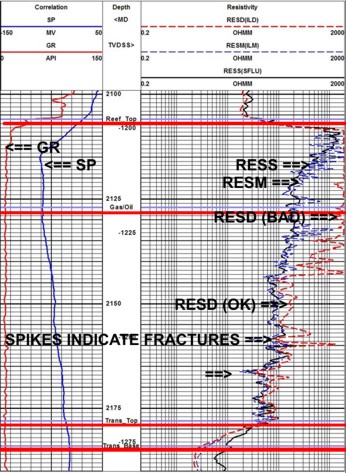

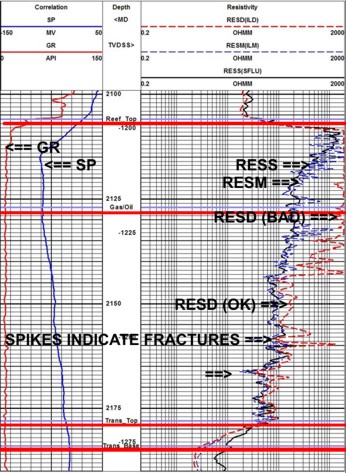

Typical layout of a dual induction log or equivalent, with GR

and SP in Track 1, and shallow, medium, and deep resistivity on

logarithmic scale in the wide track. Note bad deep induction log and

low resistivity spikes caused by fractures. There is a 6 meter

transition zone into the water zone at the bottom of the log.

The newest array induction logs use multi-coils combined with

higher transmitter currents, plus very intensive inverse

modeling to obtain conductivity focused to 1, 2, or 4 feet.

Commercial software is available to perform similar inverse

modeling on older logs, but the results will not be equal to a

modern array induction because the software has much less data to

work from. It is still worth doing, but don't expect miracles.

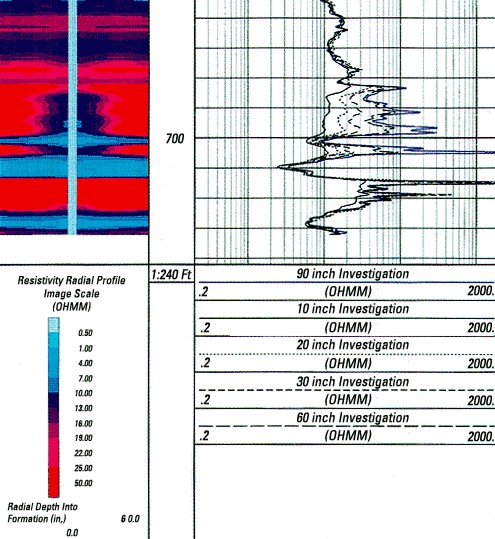

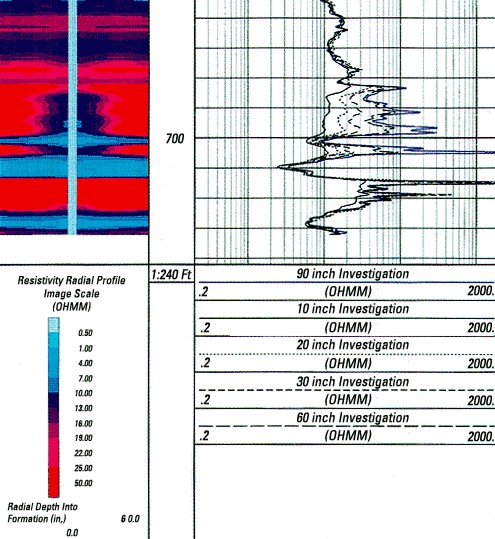

The standard presentation of an array induction log has 5 resistivity curves, with progressive depths of

investigation of 10, 20, 30, 60, and 90 inches. Some tools are

focused to reach 120 inches. A calculated value for Rxo and Rt are

often found in the digital data file. These are derived from the

inverse modeling of the inferred invasion profile using proprietary

algorithms. The invasion profile can be displayed as an image log.

|

The

induction electrical log (IES) is well defined by its name; it

consists of a deep investigation conductivity measurement combine

with a shallow resistivity and SP curves from the older electrical

survey. The presentation was made as close as possible to the ES,

with linear resistivity in Track 2 and linear conductivity in Track

3, replacing the lateral curve on the ES.

The

induction electrical log (IES) is well defined by its name; it

consists of a deep investigation conductivity measurement combine

with a shallow resistivity and SP curves from the older electrical

survey. The presentation was made as close as possible to the ES,

with linear resistivity in Track 2 and linear conductivity in Track

3, replacing the lateral curve on the ES.

Dual

induction measurement was introduced in 1962 in an attempt to

quantify the effect of the invaded zone. The dual induction tool

kept the 6FF40 array as the deep measurement. The added shallower

induction measurement (medium induction) used the ILD

transmitter coils in combination with its own new receiver

configuration. This tool was referred to as the DIT-A.

Dual

induction measurement was introduced in 1962 in an attempt to

quantify the effect of the invaded zone. The dual induction tool

kept the 6FF40 array as the deep measurement. The added shallower

induction measurement (medium induction) used the ILD

transmitter coils in combination with its own new receiver

configuration. This tool was referred to as the DIT-A.

Because

the 6FF40 and ILD arrays survey a relatively large volume of the

formation, response to beds of interest can be affected by adjacent

beds, invasion of the drilling mud or even the presence of the

borehole itself. In addition, skin effect causes a significant

nonlinear decrease in signal, especially in conductive formations.

Over the years, a series of correction algorithms has been derived

to compensate for these parasitic effects. The traditional method

for using these algorithms is to apply them individually in an

empirically defined sequence. This methodology is not correct in

principle because of the interaction of the induction fields with

all the media they penetrate. However, it provided a reasonably

accurate stopgap means of obtaining an accurate estimation of Rt for

many years.

Because

the 6FF40 and ILD arrays survey a relatively large volume of the

formation, response to beds of interest can be affected by adjacent

beds, invasion of the drilling mud or even the presence of the

borehole itself. In addition, skin effect causes a significant

nonlinear decrease in signal, especially in conductive formations.

Over the years, a series of correction algorithms has been derived

to compensate for these parasitic effects. The traditional method

for using these algorithms is to apply them individually in an

empirically defined sequence. This methodology is not correct in

principle because of the interaction of the induction fields with

all the media they penetrate. However, it provided a reasonably

accurate stopgap means of obtaining an accurate estimation of Rt for

many years.

The

Phasor induction suffered in large boreholes and deep or complicated

invasion profiles. and was phased out in the mid to late 1990's. The

good ol' dual induction had been pushed to its technological limits

and could go no farther. The replacement was a totally new design --

the array induction tool (AIT). The log displays 5 resistivity

curves at depths of investigation ranging from 10 to 90 (or 120)

inches. Rxo and Rt are derived so no additional environmental corrections are

needed. Bed resolution can be computed to 1, 2, or 4 feet.

The

Phasor induction suffered in large boreholes and deep or complicated

invasion profiles. and was phased out in the mid to late 1990's. The

good ol' dual induction had been pushed to its technological limits

and could go no farther. The replacement was a totally new design --

the array induction tool (AIT). The log displays 5 resistivity

curves at depths of investigation ranging from 10 to 90 (or 120)

inches. Rxo and Rt are derived so no additional environmental corrections are

needed. Bed resolution can be computed to 1, 2, or 4 feet.