|

PRODUCTION LOGGING BASICS

PRODUCTION LOGGING BASICS

The primary objective of production logging is reservoir

performance evaluation or flow profile evaluation.

Production logging is a complex downhole logging

technique designed to allow us to determine flowrate, fluid

types, and fluid flow distribution in production and

injection wells.

Secondary production logging objectives are lift (or

completion) performance evaluation and estimations of

factors affecting the reservoir performance (leaks and crossflows).

The best known production logging tool is the flowmeter log.

There are 3 flavours of flowmeter: continuous or fullbore,

diverting, and array spinner flowmeters.

Other measurements are usually

needed to aid analysis, including:.

Temperature log

Radioactive tracer log

Noise log

Focused gamma ray density log

Unfocused gamma ray density log

Fluid capacitance log

Fluid identification log (in high angle wells)

Gradiomanometer (fluid density) log

Pressure sensors for static, flowing, build-up, and draw-down pressures

Gamma ray and collar log for depth control

See links on right-hand navigation menu to access these tool

descriptions.

Modern toolstrings include up to one

hundred various sensors, and processing techniques utilize

probabilistic non-linear algorithms of multiphase flows. The

basics are still the same as 40- 50 years ago, but they

have been brought into the 21st century..

Production logging is sometimes combined with well

integrity logging (multiarm calipers, ultrasonic thickness devices,

or serve itself as an indicator with temperature, flowmeter or noise

logging sensors) and cased hole formation evaluation logging (multidetector neutron logs, dipole

shear sonic logs, pulsed neutron logs with spectrometry

capability, natural gamma ray spectrometry logs) in through tubing

applications.

Production logging is usually carried out by the cased

hole wireline crew of the service company. That is carried

on wells of different definitions: production wells (on

different stage of the field development), injection wells

(with water, gas or steam stimulation), exploration wells

and wildcats (in combination with conventional DST),

hydrology wells and steam energy (geothermal) wells. When

the well is producer the test is known as production logging

test, when the well is injector – the test is known as an

injection logging test.

The number and sequence of production logging tests

performed on a well-managed field is defined by the field

development team. A good practice is to run the Production

Logs at an early stage of the life of the well, in

order to establish baseline that will be used later when

things go wrong. Too often Production Logs are run when

something has gone wrong as the last resort (to design well

interventions and workovers or even to take decision to

abandon the well).

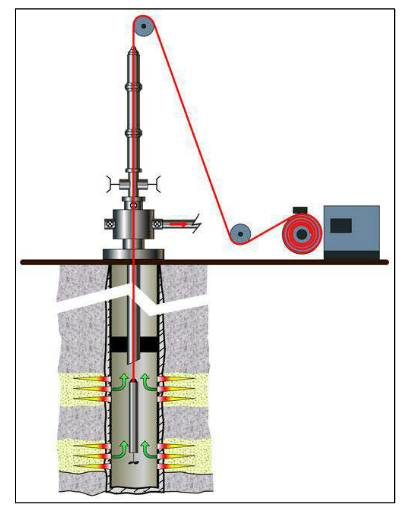

Schematics of Production Logging (KAPPA Eng. DDA handbook)

PLANNING A PRODUCTION LOGGING PROGRAM

PLANNING A PRODUCTION LOGGING PROGRAM

A production

logging job starts with PL Survey design. A great amount of data is

gathered and analyzed. As much data as possible should be taken

into account: openhole logs, well integrity logs (CBL’s, Multi-Finger

tools, etc), deviation surveys, completion sketches,

production (pressures, temperatures, rates), and well intervention

history (recent operations). Don't forget the overall geology of the

reservoir and detail petrophysical analysis of the porosity,

permeability, and saturation profiles relative to the existing

completion type and location.

Most modern PLT jobs are run using 2 or 3 different flow rates and

several shut-in so as to provide a complete picture of the well's

performance capabilities. The main idea is to design a safe,

economical,

and comprehensive Production Logging Test.

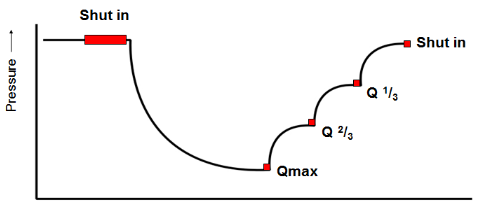

Typical PLT job sequence – flowing regimes and PLT

Surveys (marked with red dots). Well flowing rate regime is regulated by the

choke size (for natural flowing), gaslift injection rate (for

gaslift production), ESP power regulation (electric submersible pump

case – in this case special completion solution, known as Y-tool, is

required, otherwise logging below the pump is not possible) rod

pump power regulation (also special completion solution known as

“C-type” annulus is required for logging). For injectors, the

situation is the same.

The above example

illustrates 5 PLT surveys being performed (2 in shut in mode and 3

in flowing). Shut in survey (when the

well is closed at the surface) is used for downhole tool

calibration, pressure estimation, and possible crossflow evaluation.

In well-known fields, the

number of flowing regimes may be 2 with no shut in at all. However

in exploration wells (or wildcats), I have seen up to 7 flowing

regimes with direct and reverse measurements (increasing and

decreasing surface rate) and several shut in’s.

In some cases,

(low permeability rocks, shale gas formations, etc), the steady

state flow cannot be reached (or requires extremely long time for

well stabilizing). In this case, the advanced methods, known as

isochronal or optimized isochronal tests are being utilized.

PRODUCTION LOGGING RESULTS

PRODUCTION LOGGING RESULTS

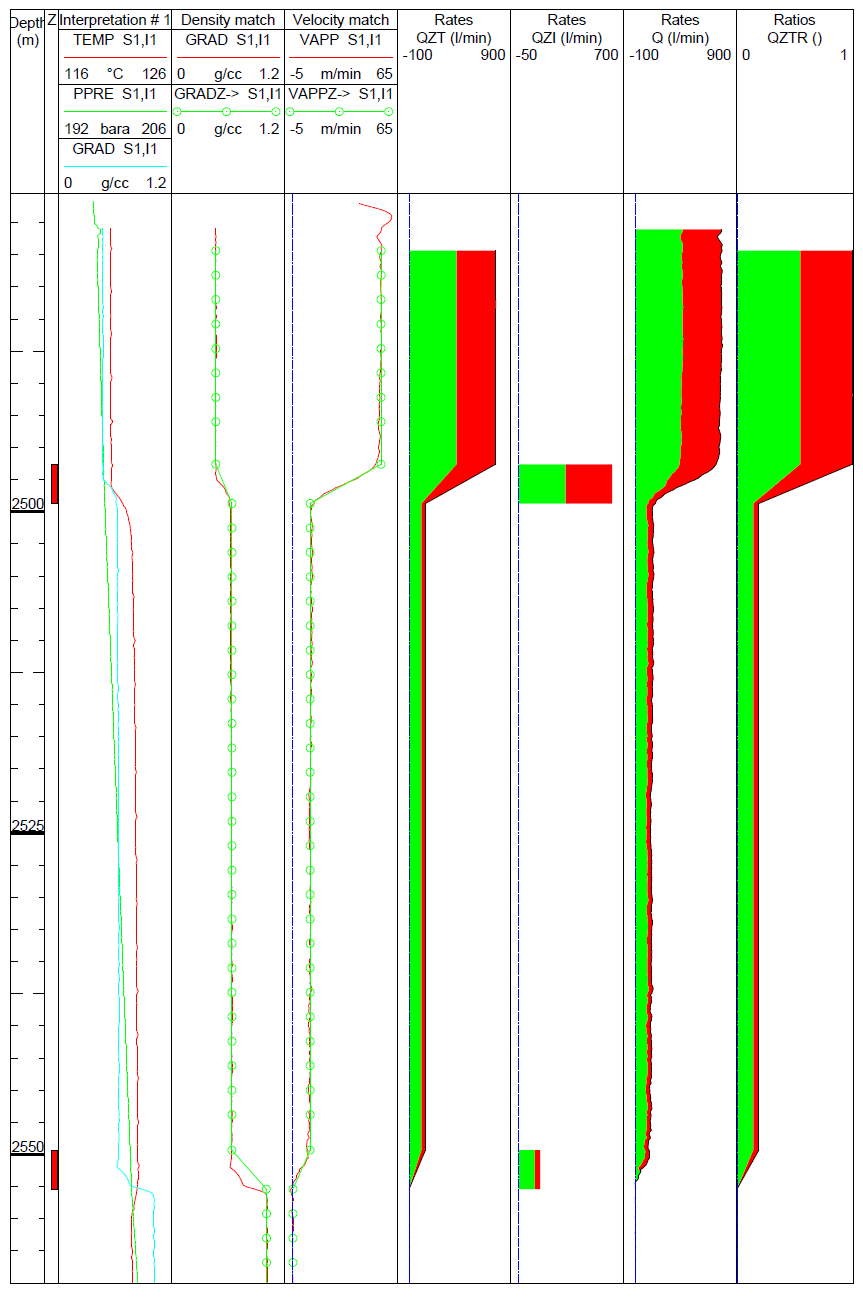

Data processing software takes all the production log sensor

information and creates a production profile based on borehole

geometry (vertical, deviated, or horizontal) and the fluid phase

rates (one, two, or three phases). The math for this is not covered

here..

The

processed results are the pay zone's phase rate profile (total QZT,

interval QZI, relative QZTR) and selective inflow performance SIP diagram.

Results presentation of the conventional PLT Survey (Processed

with Kappa Emeraude)

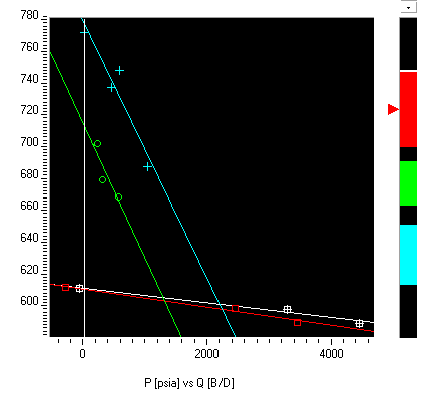

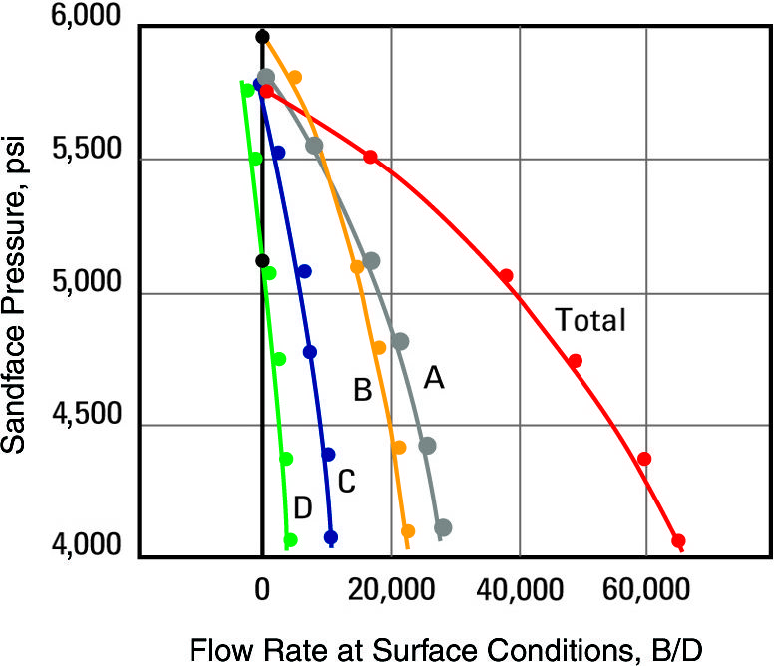

Selective Inflow performance (SIP) diagram refers

to the pay zone producibility index estimation.

The total Inflow Performance Relationship IPR diagram, which is a

part of well testing steady state flow data interpretation,

reflects the pressure (or dP) as a function of total surface rate.

In contrast, the

SIP is constructed for every particular pay zone and flowing phase

for downhole conditions. SIP may be approximated with linear

equation, Vogel, Fetkovich or other inflow relationship (like 2,3 –

phase or gas inflow cases). The major purpose of this technique is

to evaluate the zone rate with particular pressure difference under

several conditions.

SIP Diagrams (linear approximation for 3 water pay zones with total

IPR colored with white – left and Vogel model for 4 oil pay zones

below bubble point pressure with total IPR colored with red – right,

Kappa Engineering and PetroWiki SPE examples)

SIP is

extremely useful reservoir engineering tool that provides an

opportunity to estimate reservoir pressure, producibility index,

possible zone crossflow and depletion for every pay zone and for

various fluid phases. To construct the SIP several well flowing

regimes (at least two) are required. Well flowing regime means the

well is producing with constant (steady state) or close to

steady state at surface. During the PLT, the surface multi-phase rates

are measured as usual and are used later for matching with downhole

data and velocity (flowing) model

PERMEABILITY FROM FLOW RATE

PERMEABILITY FROM FLOW RATE

Once

actual flow rate at the formation is determined, reservoir

permeability can be calculated.

For linear horizontal flow, Darcy's fluid

flow equation relates flow rate to permeability as follows:

1: Q = 1.127 * A * (K / MU) * (P1 - P2) / L

Where:

Q = quantity of fluid (bbl/day)

A = area fluid flows through (sq feet)

K = permeability (Darcies)

MU = viscosity of fluid (centipoise)

P1 - P2 = pressure differential (psi)

L = length of flow path (feet)

For

oilfield work, fluid flow from a reservoir into a wellbore is not

linear but radial, so the equation becomes:

2: Q = 3.07 * H * (K / MU) * (Pr - Pb) / log(Rr/Rb)

Rearranging and solving for K:

3: K = Q * log(Rr/Rb) * MU / (3.07 * H * (Pr - Pb))

Where:

K = permeability (Darcies)

Q = quantity of fluid (bbl/day)

H = thickness of reservoir that fluid flows through (feet)

MU = viscosity of fluid (centipoise)

Pr - Pb = pressure differential from reservoir to wellbore (psi)

Rr = radius of reservoir = length of flow path (feet)

Rb = radius of wellbore (feet)

This

permeability

estimation should be calibrated with other data sources,

for

example pressure transient

analysis technique on pressure buildup or drawdown data, or the

geometric average of conventional core analysis data. Some skin-effect assumptions

may be

needed.

|