|

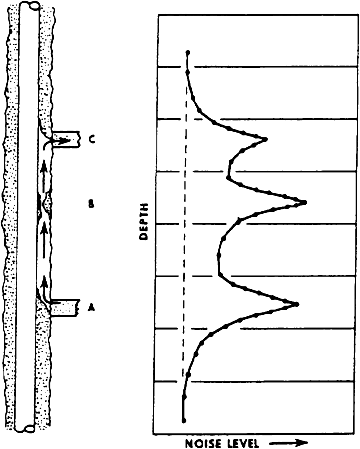

A noise log is a record of the sound measured at different positions in a borehole. Since fluid turbulence generates sound, high noise amplitudes indicate locations of greater turbulence, such as leaks, channels, and perforations. Noise logging is used primarily for channel detection, but has been used to measure flow rates, identify open perforations, detect sand production, locate casing and tubing leaks, and locate gas-liquid interfaces. Noise logs are used to identify unwanted flows behind casing, such as gas leaks to surface, crossflows between zones, coals dewatering into nearby sands, water or gas flows through bed cement into perforated intervals, and similar production problems. The log may be either a continuous record against depth or a series of stationary readings. The log may indicate the total signal over all frequencies, the signal at a single frequency, or consist of a set of log curves for different frequency ranges (spectral noise log). Different frequency ranges can be associated with different sources of noise or different flow regimes. The tool was first introduced around 1955, but the technique was not used commercially until after laboratory studies in the early 1970s. The noise logging tool is a passive device recording downhole noise using piezoelectric crystals (transducers) which convert the wellbore sound to a corresponding voltage. The voltage variations are passed through a number of high pass filters, usually 200, 600, 1,000, and 2,000 Hz, giving a spectral noise log. Low frequency sounds are associated with tool movement and ambient sounds carried by the pipe. Mid-range and higher frequency are interpreted as fluid flow through constrictions, with gas movement most likely at the highest range.

|

||

|

Page Views ---- Since 01 Aug 2020

Copyright 2023 by Accessible Petrophysics Ltd. CPH Logo, "CPH", "CPH Gold Member", "CPH Platinum Member", "Crain's Rules", "Meta/Log", "Computer-Ready-Math", "Petro/Fusion Scripts" are Trademarks of the Author |

||

|

||

| Site Navigation | PRODUCTION LOGGING NOISE LOGS | Quick Links |