|

SPINNER FLOWMETER BASICS

SPINNER FLOWMETER BASICS

Flowmeters use an impeller (spinner) driven by the movement

of borehole fluid. The data is recorded as revolutions per

second (rps) which, when properly calibrated, leads to the velocity of fluids in the tubing or

casing in a production or injection well. Knowing the pipe

size, we can calculate flow rate in barrels per day (bopd or

bwpd). A few other details are needed to handle gas rates.

On a fullbore flowmeter, the spinner assembly folds

into a diameter small enough to fit into the tubing, and

expands to a larger diameter for surveys in the casing below

the tubing. On a fullbore flowmeter, the spinner assembly folds

into a diameter small enough to fit into the tubing, and

expands to a larger diameter for surveys in the casing below

the tubing.

Continuous flowmeters do not fold and are best suited for

surveys in the tubing.

Both continuous and fullbore flowmeters can be logged

downward and upward to create continuous logs. Logging in

both directions at several different logging speeds is a

normal procedure to determine friction effects on the

spinner, giving a method for downhole calibration.

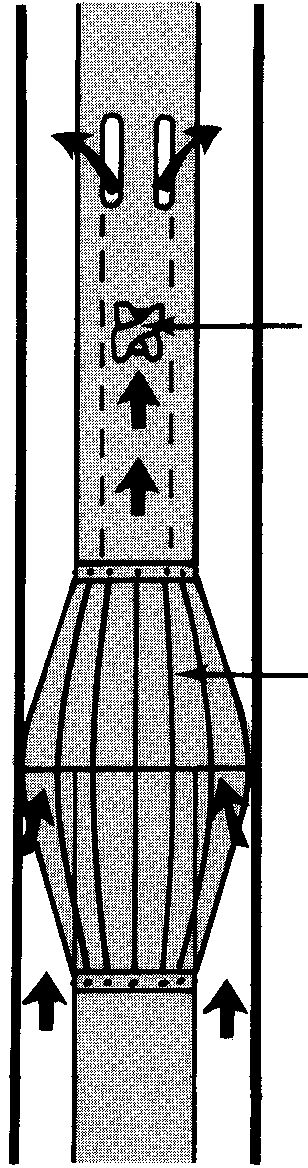

<== Diverting or basket flowmeter

Diverting flowmeters are the most accurate of

the spinner devices in low rate and multi-phase wells. The

flow is diverted through the tool barrel, which raises the

velocity of flow and increases the sensitivity so that they

can detect rates as low as 10 to 15 bpd. Diversion of fluid

into the tool barrel is accomplished by a skirt of fabric or

metal leaves that are deployed to contact the tubing or

casing wall. Often called basket flowmeters, the skirt

exhibits little leakage even below tubing.

Older tools used an inflatable packer to divert all flow

through the tool.

For multi-phase flow, additional tools are

necessary, such as the fluid capacitance or gradiomanometer

log to assess water or gas comingled with oil.

This tool takes its flow measurement while stationary with

the skirt in the open position. It can be pulled up to the

next station without closing the skirt. A log is created by

connecting the data points by straight lines.

A temperature sensor should always be included in the tool

string as it has better vertical resolution than the

spinner, so it can locate small inflows not seen on the

spinner log.

The multi-capacitance flowmeter measures the velocity of

fluid flow in a production or injection well by measuring

the transit time of a disturbance between two dielectric

sensors a fixed distance apart. The device is a type of

crosscorrelation flowmeter that uses several pairs of

capacitance, or dielectric, sensors held on an arm to span

the borehole.

An array

spinner with array capacitance is being developed, which

would be especially helpful in

highly deviated or horizontal wells.

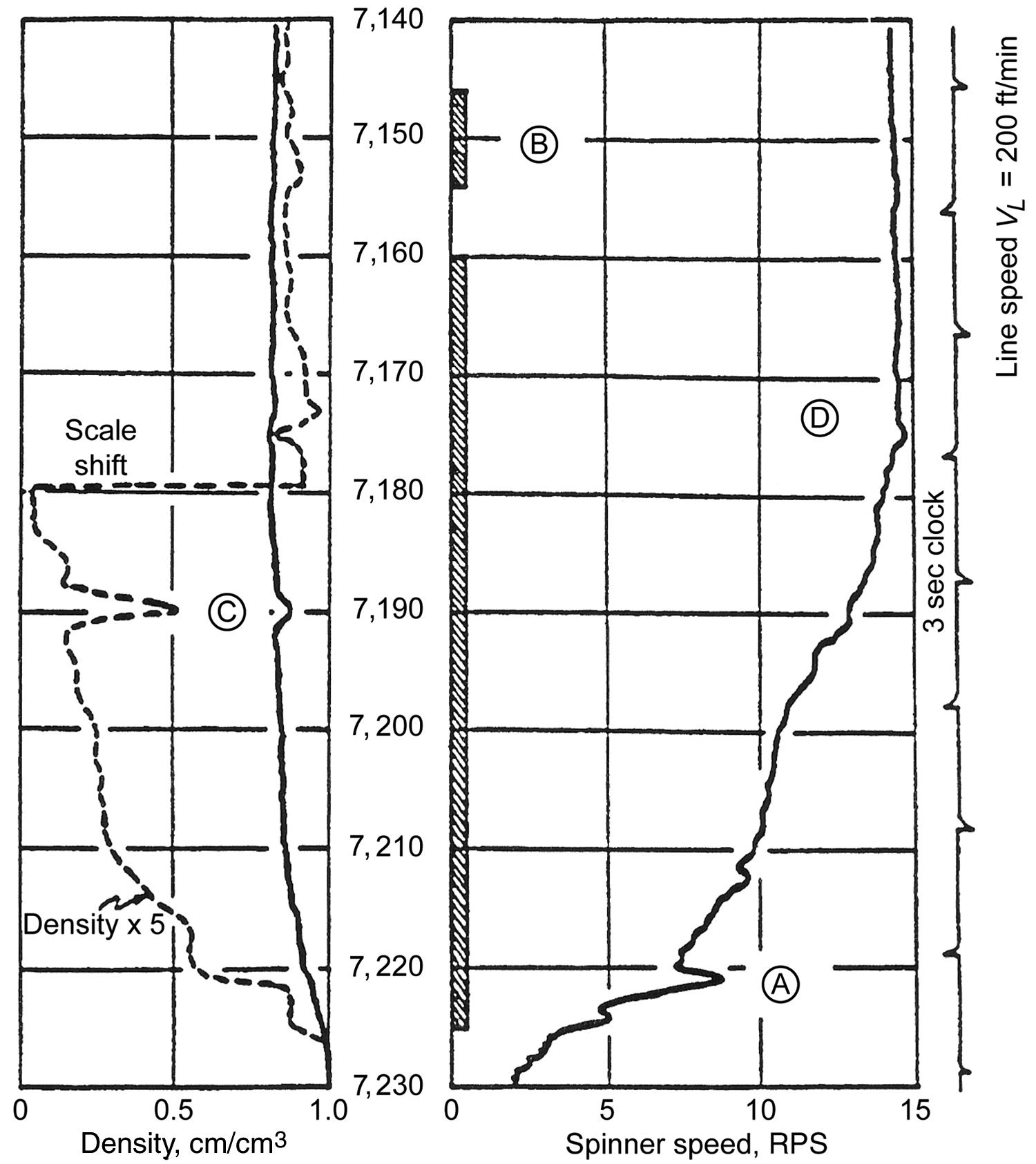

Fluid density (track 1) and spinner survey (tracks 2 and 3).

Well flowing 10,000 bpd. Density shows water density in sump

below perfs, oil density over perf interval. Spinner shows

increasing cumulative production over lower half of perfs.

The upper half of the perfs may have been ineffective or the

reservoir quality is so poor that no flow can be expected. A

competent forensic petrophysical analysis could answer

this question and a workover initiated if warranted.

Amplified fluid density curve shows slight decrease up to

7160 feet indicating some water in the oil below this depth

- this is the "water holdup".

MODERN INTEGRATED PRODUCTION / FLOWMETER LOGS

MODERN INTEGRATED PRODUCTION / FLOWMETER LOGS

Numerous service providers have offered flowmeters in

combination with fluid density, temperature, pressure, natural gamma

ray, and tracer logs for many years. In two-phase flow, these logs

are quite adequate in many cases, even in some horizontal wells in

which the flow regime is reasonably well behaved.

However, understanding horizontal flow can be quite challenging and

more sophisticated tools may be helpful. These include all the usual

sensors as well as some new ones, with some arranged in fixed arrays

to show horizontal flow and three-phase flow in considerable detail.

Layered flow often occurs in high angle wells, with a

water layer in the lower part of the wellbore cross-section, an oil

layer above the water, and a gas layer at the upper part of the

cross-section. One objective of the integrated tools is to create an

image of the actual flow regime.

The following tool description is based on

the Schlumberger Floview Plus tool introduced in the mid 1990s. The

description is condensed from PetroWiki and the examples are from

Schlumberger.

There are three key components to the tool. First is a

full-bore spinner. This item gives information about composite fluid

velocity.

The second component is called Floview Plus. The main results from

this tool are eight-electrode measurements of water holdup to

provide an approximate image of how the fluids are segregated in the

cross section of the casing. The fluid image greatly aids in the

interpretation of the spinner response.

The tool uses matchstick-sized electrical probes to measure the

resistivity of the wellbore fluid, high for hydrocarbons and low for

water. The probes are located inside the tool’s four centralizer

blades to protect them from damage. Opening of the blades positions

each probe at midradius in the casing. In some flow regimes, both

water holdup and bubble-count measurements may be obtained from the

output of the probe.

Local water holdup is equated to the fraction of the time that the

probe is conductive, whereas bubble count comes from the average

frequency of the output. The local water holdup from each of the

eight probes is used to generate the water/hydrocarbon distribution

in the well’s cross section.

The third component is the Reservoir Saturation Tool, often run in

conventional cased hole logging programs to assess the current state

of the reservoir. This tool is a pulsed-neutron log that can be

operated in nuetron-lifetime mode or spectral carbon/oxygen mode.

Its main applications are for estimation of oil, gas, and water

holdups and determination of water-phase velocity by oxygen

activation.

From a combination of the holdups, the cross-sectional area of the

wellbore, and the fluid velocities, the rates of the individual

phases are estimated as a function of position along the wellbore’s

axis.

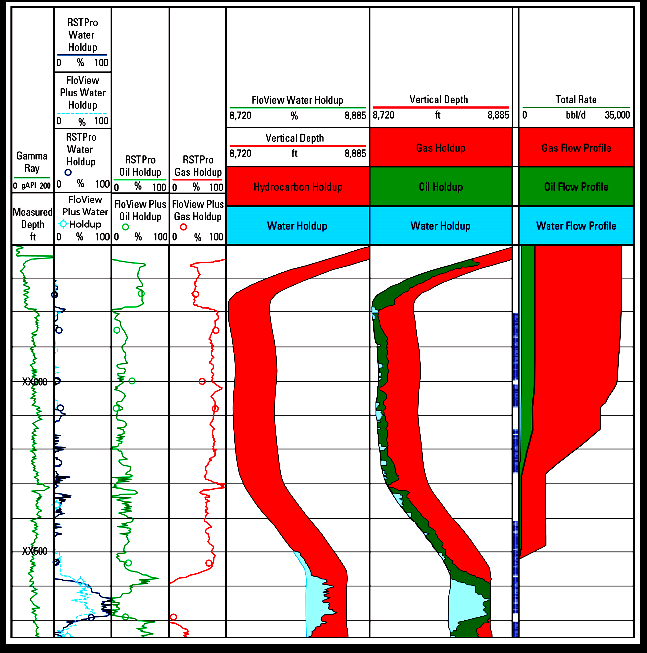

On

the right of the gamma ray and depth track, Track 2 displays water

holdup from the FloView Plus tool and three phase holdup log (TPHL).

Stationary measurements and continuous logging results are plotted

from both. Tracks 3 and 4 are TPHL log oil and gas holdup data.

Track 4 is the FloView Plus two-phase measurement plotted along the

trajectory of the horizontal section of the wellbore. Track 6 is a

similar plot of TPHL log holdup data for all three phases along the

wellbore trajectory. Track 7 is a flow rate profile computed from

TPHL log holdup data and the FloView Plus tool's velocity

measurements. The perforated interval is indicated between Tracks 6

and 7.

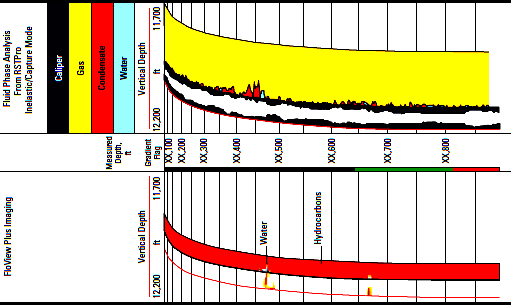

The water holdup plots of the TPHL log and FloView Plus tool's data

agree well over most of the interval. Above XX,500 feet, however, the FloView Plus tool is unable to measure the small water flow values

because of high water velocity and low holdup. The highest point in

the horizontal section of the well occurs at approximately XX,560

feet. Little fluid is produced from below that point, resulting in

high water holdup in the bottom of the well. From XX,560 to XX,800

feet, where the fluids are flowing downward, oil and water travel

faster than gas and, consequently, have lower relative holdup rates.

The insensitivity of the TPHL log's measurement to fluid velocity or

droplet size makes it possible to detect condensate in mist flow or,

as in this case, high-velocity water flow at low holdup. Above

XX,800 feet, the well becomes more vertical, slowing the oil flow and

increasing its holdup.

SYNTHETIC FLOWMETER LOGS

SYNTHETIC FLOWMETER LOGS

Optimizing perforation interval or horizontal well placement

can be aided by creating a cumulative flow capacity curve,

based on the permeability derived from the petrophysical

analysis of the prospective pay zone.

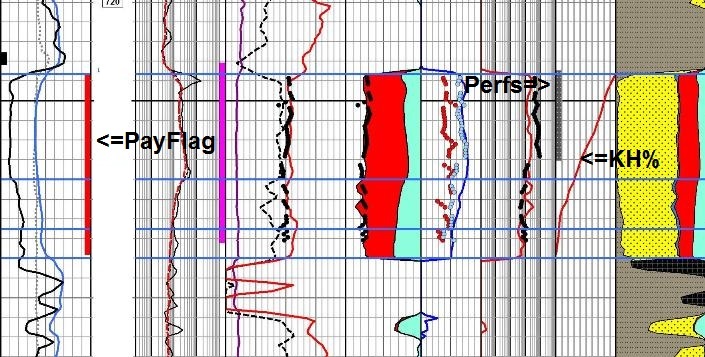

The KH% curve is presented with 0% at the left and 100% on

the right. This will match the shape of a spinner flowmeter

survey, with zero flow capacity at base of

pay and 100% at top of pay.

Intervals with the steepest slope on the KH% curve are the most productive

and should be perforated if not too close to water or gas.

Where the KH% curve is near vertical, no perfs are required.

Place horizontal well at or slightly below midpoint of the

steepest slope of the KH% curve. This may vary depending on

frac design and rock mechanical properties.

Permeability does not have to be well-calibrated to use this

technique since the KH% curve is normalized between 0 and

100%.

Grid lines are 1 meter spacing. Tracks 1, 2,

3 show GR, SP, PayFlag, resistivity, PE, neutron, and density

porosity.

Calculated and core porosity in Track 4 with saturations in Track 5,

calculated and core permeability in Track 6. Note excellent match to

core data (coloured dots). Higher SW in lower zone

is due to finer grained sand, not transition to water. KH% in Track

7 starts at base of PayFlag and runs up to top of PayFlag. Arrow

shows base of perforations. KH% curve shows 40% of possible flow

capacity has not been perforated. Since this is a gas expansion

drive reservoir, the perforations should be extended 2.2 meters to

capture at least 30% more flow capacity.

|