Petrophysical Training

Licenses

|

FLUID IDENTIFICATION LOGGING BASICS

FLUID IDENTIFICATION LOGGING BASICS

The flowmeter tells us how much fluid is

moving at any point in a production or injection well, but

it tells us nothing about which fluids are present or where

each came from. To resolve this, the logging industry has

come up with a number of solutions, described later on this

page.

Portions of this article are from the Schlumberger Glossary, with

minor edits and additions from other sources such as PetroWiki.

The term “holdup” appears often in fluid flow literature. It has

nothing to do with gun violence or the price of gasoline at the

service station. It really relates to the fraction of the total flow

contributed by each fluid phase, oil, gas, and water.

In multi-phase flow, “holdup” is the fraction of a particular fluid

present in an interval of pipe. Each fluid moves at a different

speed due to different gravitational forces (fluid density effect)

and other factors (viscosity

effect),

with the heavier phase moving slower, or being more “held up”, than

the lighter phase.

The sum of the fluid holdups of the fluids present is unity. The

“holdup ratio” is the ratio of the holdups of any two of the fluids.

For example, if the water holdup at a particular depth is 0.20, then

oil holdup is (1.00 – 0.20) = 0.80 and holdup ratio of oil to water

is 0.80 / 0.20 = 4.0.

The holdup of a particular fluid is not the same as the proportion

of the total flow rate due to that fluid, also known as its “cut”.

To determine in-situ flow rates, it is necessary to measure both

holdup and velocity of each fluid.

A “holdup” log is a record of the fractions of different fluids

present versus depth in the borehole. Various techniques are used to

measure these fractions. The earliest techniques measured the fluid

density, using a gradiomanometer, nuclear fluid density log, or the

dielectric properties as in the fluid capacitance log.

While these techniques were satisfactory in near-vertical wells with

two-phase flow, they were often found to be inadequate in highly

deviated and horizontal wells, where flow structures are complex.

More recent developments are based on the use of multiple local

probes (eg. array capacitance and array spinner imaging tools) to

detect bubbles of gas, oil, or water, and on a combination of

nuclear techniques usually known as three-phase holdup logs.

GRADIOMANOMETER

GRADIOMANOMETER

Introduced in the

late 1950s, the gradiomanometer measures the pressure difference

between two pressure sensors, placed approximately 2 feet (0.6 m)

apart. The pressure difference reflects the average fluid density

within that depth interval. The resolution is high, around 0.005

g/cc, but the accuracy can be affected by a friction effect, a

kinetic effect, and well deviation. The effect of deviation can be

corrected, but the sensitivity to holdup is reduced as the deviation

increases until it is zero in a horizontal well.

If we know or can estimate the density of the individual fluid

components (oil, gas, water), we can calculate the relative fraction

of each fluid present. This allows holdups to be determined,

directly in the case of two-phasic flow, and in combination with

other measurements for three-phasic flow.

The partitioning equation for a two-phase system is:

1: HoldUp1 = (DENS - DENS2) / (DENS1 - DENS2)

2: HoldUp2 = 1 - HoldUp1

Where:

HoldUp1 = fraction of fluid 1 at this depth

HoldUp2 = fraction of fluid 2 at this depth

DENS = density of fluid mixture (g/cc or kg/m3)

DENS1 = density of fluid 1 (g/cc or kg/m3)

DENS2 = density of fluid 2 (g/cc or kg/m3)

With the well shut in and if there is a sump below the perfs, it

often contains formation water so water density can be measured

directly by the log. Some distance above this, a direct measurement

of oil density can be made. Then during stable production, the

complete log for water holdup can be run.

Numerical Example

Assume

DENS1 = downhole water density = 1.110 g/cc

DENS2 = downhole oil density = 0.710 g/cc

Composite fluid density = 0.810 g/cc

Water Holdup = (0.810 - 0.710)/(1.110 - 0.710) = 0.100 / 0.400 =

0.25 (or 25%)

Oil Holdup = (1.0 - 0.25) = 0.75 (or 75%)

FLUID CAPACITANCE LOGS

FLUID CAPACITANCE LOGS

This log

provides a record of the capability of the fluid passing through a

sensor to store electrical charge. Since water has a high dielectric

constant, and hence capacitance, the log can distinguish water from

oil or gas. The fluid capacitance log can therefore identify water

and be scaled in terms of water holdup. However the relation between

capacitance and holdup depends strongly on whether the water is the

continuous phase, complicating quantitative evaluation.

The log was introduced in the 1960s as the so-called holdup meter.

It was mainly used in three-phase flow, or when fluid-density

measurements were insufficiently sensitive to water at low holdup,

or with heavy oils. Since the late 1980s, other holdup measurements

have been preferred.

NUCLEAR FLUID DENSITY LOG

NUCLEAR FLUID DENSITY LOG

Tool names used by the many service providers are

confusing or misleading. Focused gamma ray and unfocused gamma ray

logs, for example, do not record a gamma ray log, but they do use a

chemical gamma ray source to create a simple uncompensated density

log with a very small range of investigation.

These logs measure the density of fluids in a completed well, using

a radioactive source of gamma rays and a detector. A cesium 137 or

americium 241 source is used to induce Compton scattering, as in the

openhole density log, except that the device is unfocused. The count

rate at the detector depends primarily on the density of the fluids

in the well.

In unfocused devices, the source and detector are situated so that

the gamma rays pass outside the tool. The results reflect an average

density of all the fluids within the well at that depth. In smaller

casings, some formation signal may contaminate the measurement. This

type of density log has been used to assess the quality of gravel

pack completions.

On some devices, the fluids pass through an open space in the body

of the tool within which the measurement is made. The results

reflect the density of the fluids passing through the tool. Some

people call this type of tool a focused fluid density log since the

gamma rays are focused on the wellbore fluid and are not influenced

by anything outside the tool body.

Most fluid density logs are scaled in density units (g/cc) but some

may have a counts per second (cps) scale. Holdup is calculated as

explained for the gradiomanometer,

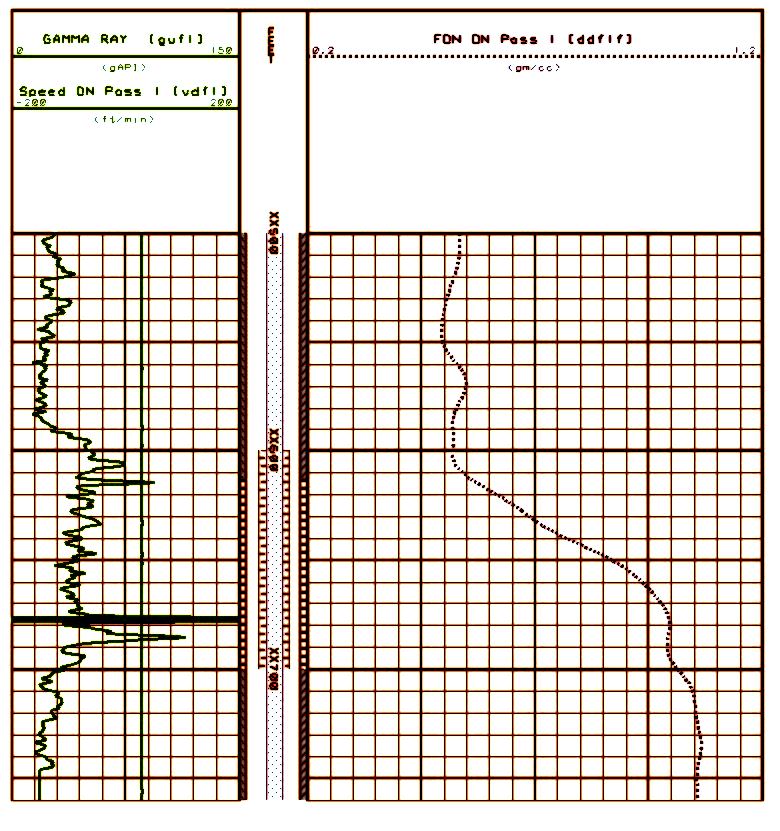

Example of a fluid density log using a chemical gamma ray source.

Density scale is 0.6 to 1.1 g/cc. Both water and oil densities can

be read directly from the log. A natural gamma ray log is in Track1

for correlation.

Compared with a gradiomanometer, the nuclear fluid density log is a

less direct measurement of density, and has a statistical

uncertainty and less resolution, but it is not affected by well

deviation, friction, or kinetic effects.

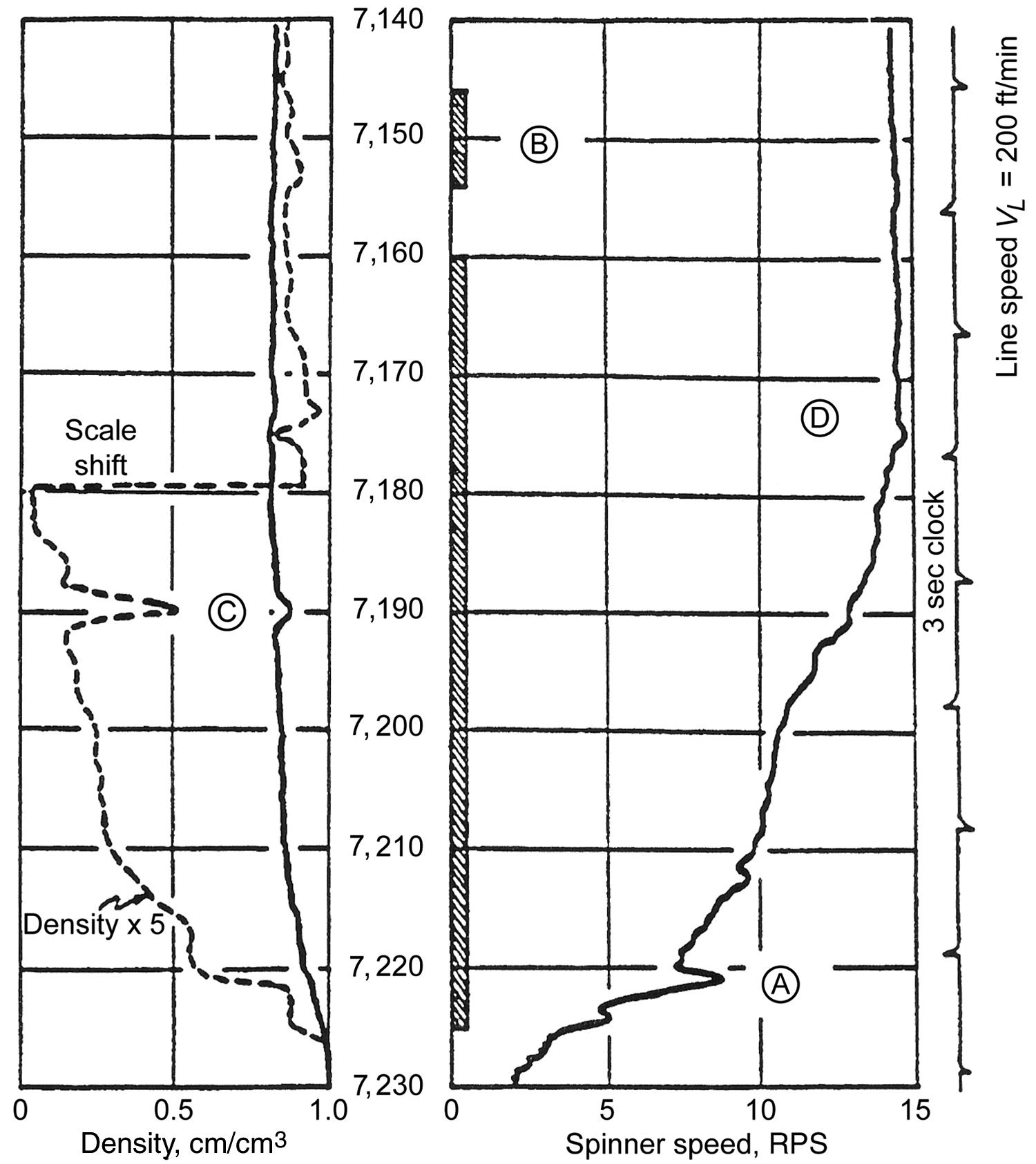

Fluid density (track 1) and spinner survey (tracks 2 and 3).

Well flowing 10,000 bpd. Density shows water density in sump

below perfs, oil density over perf interval. Spinner shows

increasing cumulative production over lower half of perfs.

The upper half of the perfs may have been ineffective or the

reservoir quality is so poor that no flow can be expected. A

competent forensic petrophysical analysis could answer

this question and a workover initiated if warranted.

Amplified fluid density curve shows slight decrease up to

7160 feet indicating some water in the oil below this depth

- this is the "water holdup".

|

|