|

TEMPERATURE LOGGING BASICS

TEMPERATURE LOGGING BASICS

Temperature logging began around 1846

when William Thomson (Lord Kelvin) made measurements of

temperature in water wells in England. His first technical paper

on the subject was "Age of the Earth and its Limitations as

Determined by the Distribution and Measurement of Heat within

It". Kelvin's calculated age was 20 - 40 million years.

Since radioactivity had not

been discovered yet, Kelvin was unaware of the heat generated

internally from this source, so he can be excused for a

100-fold error in his estimate of the Earth's age. Controversy,

debate, and a slew of additional papers ensued for another 50

years. Temperature logging began around 1846

when William Thomson (Lord Kelvin) made measurements of

temperature in water wells in England. His first technical paper

on the subject was "Age of the Earth and its Limitations as

Determined by the Distribution and Measurement of Heat within

It". Kelvin's calculated age was 20 - 40 million years.

Since radioactivity had not

been discovered yet, Kelvin was unaware of the heat generated

internally from this source, so he can be excused for a

100-fold error in his estimate of the Earth's age. Controversy,

debate, and a slew of additional papers ensued for another 50

years.

The first wireline temperature log was run in 1933. Many

modern logging tools have a temperature sensor built-in, so

a separate device is not always needed. These are not highly

accurate but sufficient for most petrophysical analysis

models. High resolution and rapid response temperature logs

are needed for some reservoir engineering tasks, such as

gas leak and crossflow detection.

The

temperature sensor is

a thermistor exposed to the borehole fluid. A

platinum element is usually used, as the electrical

resistance varies linearly with temperature over a wide

range and is stable over time.

According to PetroWiki, "The

temperature tool is most effective when located at the

bottom of a tool string. In a production well, the tool

should always be logged downward so as to enter undisturbed

fluid. The log should be recorded at a constant logging

speed, not to exceed 30 ft/min."

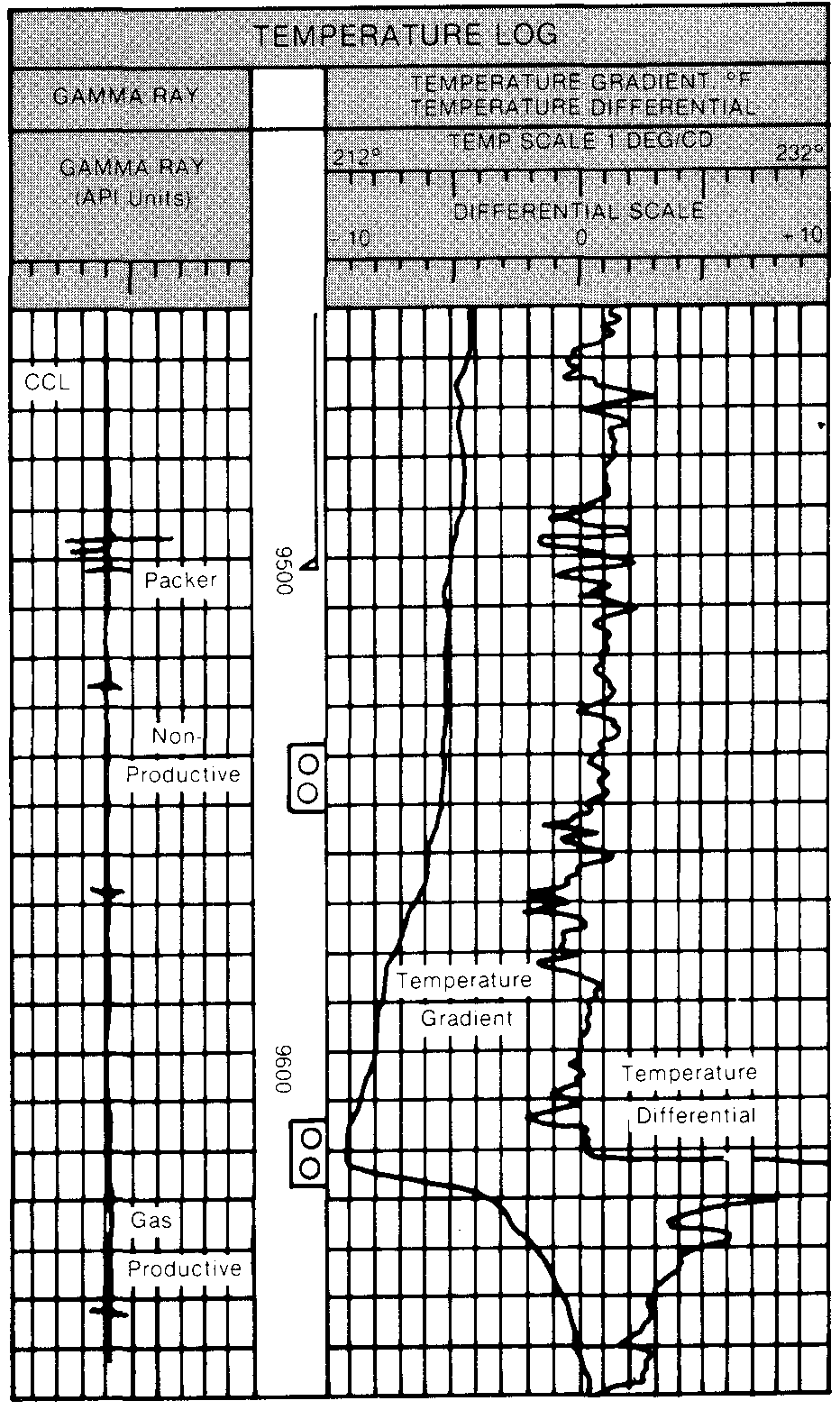

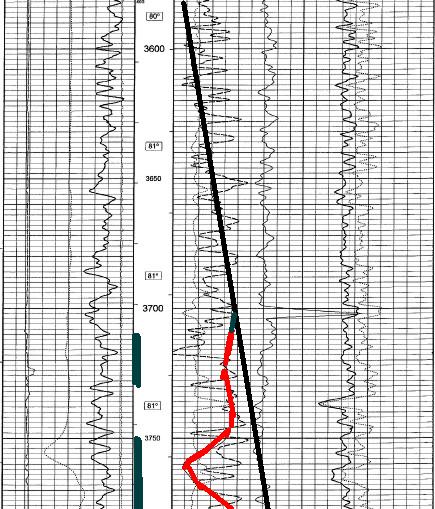

Typical temperature log in a flowing gas well shows

cooling at the perforations due to gas expansion into the

casing, and a very slight warming as the gas enters the

tubing. The log returns to geothermal gradient below the

perfs. A derivative curve helps locate small changes in

temperature. A casing collar locator (CCL) is shown in Track

1 for depth control - a gamma ray curve is often displayed

as well.

APPLICATIONS OF TEMPERATURE LOGS

APPLICATIONS OF TEMPERATURE LOGS

Temperature logs are used to establish local and regional

formation temperature, temperature gradients in oil, gas,

and geothermal wells, and gas inflow in open and cased hole,

Other applications are (or were) location of cement top

after setting casing, assessment of perforation efficiency

in production and injection wells, as well as detection of

crossflows and gas flows behind casing.

The temperature log is an integral part of all production

logging operations as it is essential in assessing

multi-phase flow rates, especially in deviated and

horizontal wells.

They have been widely used to assess completions

in producing and injection wells. Here are two examples.

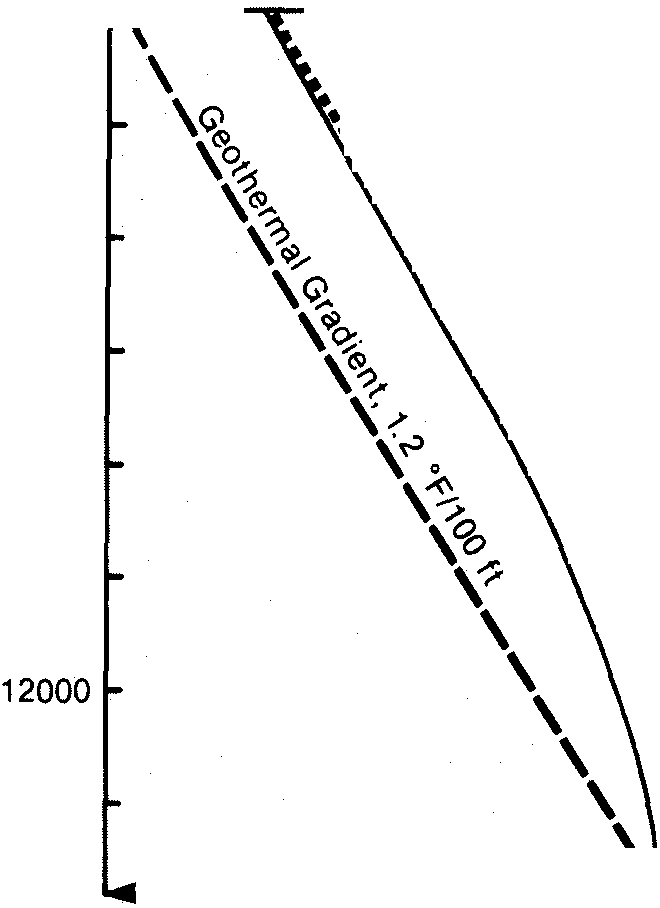

Temperature logs in oil production well (left) and water

injection well (right). Production carries heat uphole so log

is above but parallel to geothermal gradient curve.

Injection carries cooler temperatures downhole so log is

below geothermal gradient curve. The amount of heating or

cooling depends on flow rate and specific heat of the

produced or injected fluid. In both cases, the log merges

with the geothermal gradient curve below the perfs. If a

well is shut in, it gradually returns to the local formation

temperature. (Images courtesy Western Atlas)

The

"forgotten" log, the temperature survey in

open hole, might be

useful if some gas has evolved into the wellbore

prior to logging. There is a temperature sensor on

most modern logging tool strings - just ask for it to be

displayed.

<== Temperature log recorded with density neutron log. ln open hole over a gas shale shows cooling (highlighted in

red) due to gas

inflow. Vertical black bar indicates interval to be

completed.

Temperature

logs in geothermal wells are essential for both exploration and

development. Temperature

logs in geothermal wells are essential for both exploration and

development.

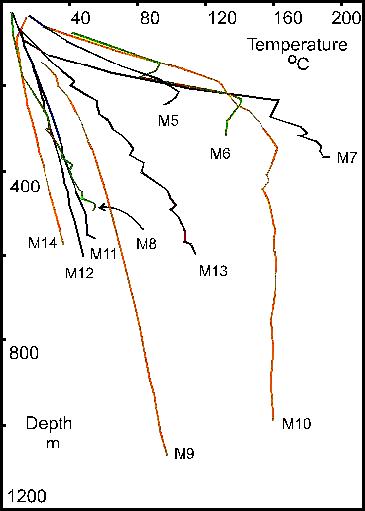

Temperature logs from a Canadian geothermal prospect in the Rocky

Mountains of BC show that some exploration wells do not reach

geothermal criteria. (GSC image) ==>

Back

in

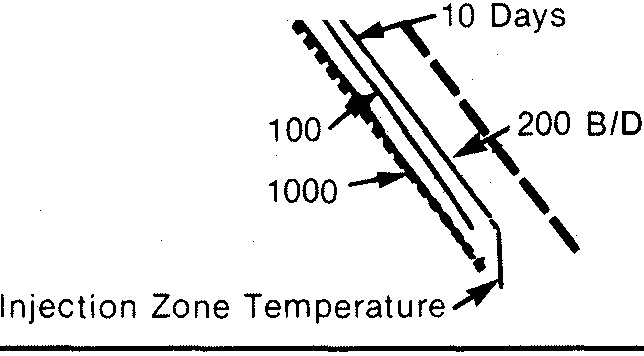

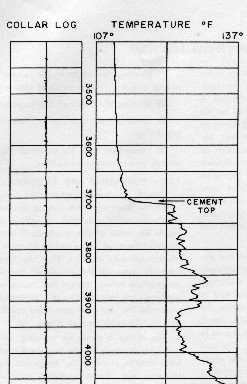

the “good old days” before the invention of sonic

logs, there was no genuine cement integrity log. However, the

location of the cement top was often required, either to satisfy

regulations or for general knowledge. Since cement gives off heat

as it cures, the temperature log was used to provide evidence

that the well was actually cemented to a level that met expectations. Back

in

the “good old days” before the invention of sonic

logs, there was no genuine cement integrity log. However, the

location of the cement top was often required, either to satisfy

regulations or for general knowledge. Since cement gives off heat

as it cures, the temperature log was used to provide evidence

that the well was actually cemented to a level that met expectations.

<== In this example, the top of cement is located

where the temperature returns to geothermal gradient. The log

must be run during the cement curing period as the temperature

anomaly will fade with time.

|