|

RADIOACTIVE

TRACER LOGGING BASICS

RADIOACTIVE

TRACER LOGGING BASICS

Tracer logs are used to monitor hydraulic

fracture placement in a reservoir and as

a method of determining injection flow

profiles.

Other

processes that can be tagged are gravel-pack

placement, squeeze cementing, acid treatments, and lost

circulation zones.

The most common radioactive tracers are the isotopes

110Ag (silver), 195Au (gold), 135I

(iodine), 192Ir (iridium), 124Sb

(antimony), and 46Sc (scandium).

MONITORING HYDRAULIC FRACTURE

PLACEMENT

MONITORING HYDRAULIC FRACTURE

PLACEMENT

In this case, a short-lived

radioactive element is added to the frac fluids or propping

material. Different elements may be introduced at different

times during the fracture placement so that fracture growth

can be assessed versus time. After placement, a gamma ray

log is run, starting some distance below to some distance

above the frac interval. If only one element was used, a

conventional gamma ray tool will suffice. For a

multi-element survey, a spectral gamma ray log is required.

The fracture height and position can be assessed by

observation of the gamma ray curves. The fracture may extend

above and below the perforated interval. Comparison of this

log with a competent petrophysical analysis will help

determine if the frac went up or down into unwanted

territory, for example a water zone below or a gas zone

above the desired oil zone.

Post-frac radioactive tracer log with natural gamma ray in

Track 1 recorded before stimulation. Tracer log in Tracks 2

and 3 shows some placement into both sets of perfs, but also

above upper perfs, possibly due to channel in cement behind

casing.

MONITORING FLUID FLOW

MONITORING FLUID FLOW

In this case, a specialized production

logging version of the gamma ray tool is used to

monitoring the reduction in tracer material as it moves down

the well. A slug of radioactive tracer is added to the

injection fluid. As the slug moves down the well, several

gamma ray logs are recorded at well defined time intervals.

The position of the slug is seen as a large gamma ray peak

whose size is proportional to the flow rate. A reduction in

the size of the peak indicates a loss of fluid into the

formation. Fluid velocity can be calculated from the time

interval and the distance the peak has moved.

Tracer-loss measurements produce a type of radioactive

tracer log used mainly to give a general idea of fluid flow

in low flow-rate wells. In very low flow-rates, an

alternative technique has been used in which the gamma ray

detector is held stationary at some depth until the slug has

passed. The detector is then moved down to another depth to

observe the slug again. With these data, it is possible to

make quantitative estimates of fluid flow.

The typical tool has a reservoir to hold radioactive

material and a pump section at the top

with two gamma ray detectors below. Once downhole, a slug of

tracer is ejected by the pump. The radioactivity of the slug

is much greater than the natural reservoir radioactivity.

The most commonly used tracer material is an aqueous

solution of sodium iodide, which contains the

isotope iodine 131 with a half-life of 8 days.

The following Sections are based on an article on

PetroWiki.com

TRACER SURVEYS IN INJECTION WELLS

TRACER SURVEYS IN INJECTION WELLS

By

tracking the progress of the slug down the wellbore, the

exits of injected flow from the wellbore can be determined,

as well as whether any of the injection, after exiting,

passes through a channel close to the pipe.

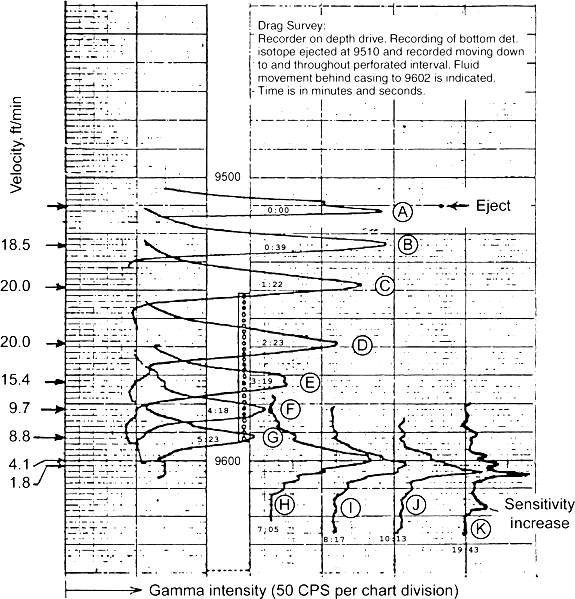

For slug tracking, the logging operator ejects a slug of

tracer from the tool at some distance above the

perforations. After ejection, the tool is run up and down

through the slug to ensure that the slug is uniformly mixed

across the wellbore cross section. Then the tool is lowered

quickly and an upward logging pass is made at constant

logging speed until the slug is detected. The time of

detection of the peak and the depth of the peak are

recorded. Then the tool is quickly lowered again, and

another upward logging pass is made at the constant logging

speed until the slug is detected and again the time

of detection of the peak and the depth of the peak are

recorded. This process is repeated several times, resulting

in a succession of detections of the same slug (see Fig. 1).

As long as the peak progresses downward, there is flow in or

near the wellbore. Once the peak stops, there is no flow in

or near the wellbore below the stopping depth.

For each detection, the area under the trace

and above the common baseline of the traces is proportional

to the percentage of injection still in or near the wellbore.

Generally, only one gamma-ray detector is used for

slug tracking. Slug tracking gives the best overview of where

injection leaves the wellbore and whether, after exiting, any

injection travels in a channel close to the pipe.

The vertical distance (ft) between two successive peaks in total

flow divided by the time (minutes) between detection of the peaks

provides an accurate estimate of the average flow velocity of total

injection.

Multi-pass radioactive tracer log

in 800 bwpd injection well showing slug moving downhole with

decreasing peak amplitude as slug begins to enter perforations.

VELOCITY SHOT

SURVEYS IN

INJECTION WELLS

VELOCITY SHOT

SURVEYS IN

INJECTION WELLS

A velocity shot survey is used in

intervals where greater vertical resolution is desired. With the

tool stationary, a slug of tracer is ejected into the injection

flow. As it passes downward, the slug is first detected by the top

detector and then by the bottom detector, resulting in two traces on

the log. The time interval between the two peaks (travel time) is

inversely related to the velocity of the injection flow.

The ratio of the travel time in total flow to the

travel time at a selected position is the fraction of injection

still in the wellbore at the selected position. However, dividing

the separation between the detectors (ft) by the travel time

(minutes) does not produce the average velocity of flow, as the slug

cannot be uniformly mixed in the flow before it passes the

detectors.

Two detectors are preferred for velocity shots. If

there is only a single detector, there can be timing errors between

initiating ejection of a slug and actual ejection downhole. These

timing errors contaminate the measured travel times.

TRACER SURVEYS IN PRODUCTION WELLS

TRACER SURVEYS IN PRODUCTION WELLS

Fewer applications of tracer logging occur in

production wells. In a true single-phase flow, a slug is tracked for

a while and then disappears uphole. Multiple slugs are used, one for

each producing interval under investigation. Usually, a well is

logged from a bottom, no-flow interval up to an interval of total

flow.

Because of the unusual circulation patterns that can occur in

multiphase flows, tracer results can be misleading

|