|

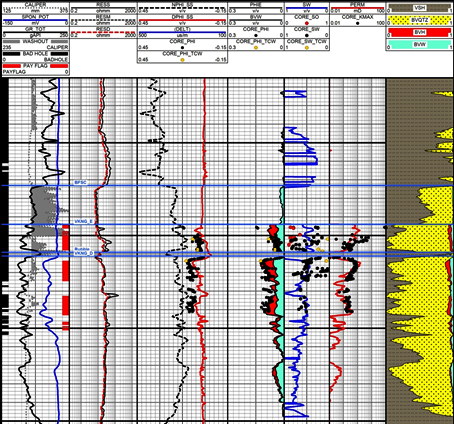

A three well minimum is

recommended for projects. Rarely will the subject well

have all data needed to complete a calibrated

petrophysical analysis. Offset wells should always

be reviewed and used to put together the best data set possible. The accuracy of the

petrophysical model improves with an increased number of wells

reviewed.

|

|||||||||||||||||||||||||||||||||||||||||||

|

Calibrate results

to known lithology from sample descriptions. Adjust trigger

levels to obtain a better match.

Read More about Lithology Triggers

Step 8: Calculate Total Porosity

Step 8: Calculate Total Porosity

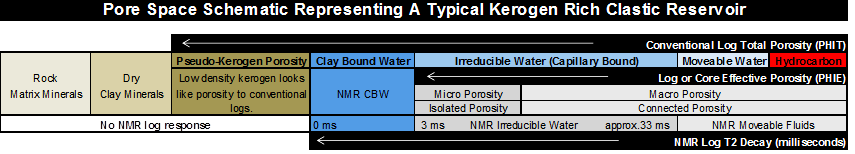

Total

porosity includes clay bound water (CBW). Kerogen will also look like porosity to conventional logs.

Porosity from the neutron

density complex lithology crossplot model is the preferred approach

and is relatively independent of grain density changes.

Other porosity models may also

be used; neutron sonic crossplot

(less sensitive to bad bore hole conditions), density only (very sensitive

to changes in grain density and bore hole conditions), sonic only (very sensitive

to changes in matrix travel time), neutron only (not

recommended, a last resort). NMR total porosity is unaffected by

kerogen and is independent of mineralogy. It is a good alternate

source of total porosity.

Calibrate results

to NMR total porosity or low temperature Dean-Stark core

analysis. Adjust parameters or select alternate porosity model

to obtain a better match.

Read More about Porosity

Step 9: Calculate Effective (Shale

and Kerogen Corrected) Porosity

Step 9: Calculate Effective (Shale

and Kerogen Corrected) Porosity

Effective porosity does not include kerogen effects (in kerogen rich reservoirs) or clay bound water. Shale and kerogen corrected versions of the total porosity models described in the previous section are used to calculate effective porosity.

Calibrate results to NMR effective porosity (3 ms cutoff) or high temperature Dean-Stark core analysis, drives off clay bound water, or conventional helium or Boyle's Law core analysis. Adjust parameters or select alternate porosity model to obtain a better match.

Read More about Porosity

Step 10: Calculate Lithology

Step 10: Calculate Lithology

The lithology model must match

the interval being evaluated, and is dependent on available

data. Three mineral models from PE,

neutron and density logs, or from

sonic density and PE logs are best. Two mineral models from sonic

or

density logs may also be useful. Multi-mineral models should be

used with care.

Mineral analysis from logs

is required to reconstruct logs for stimulation design.

Calibrate results

to XRD mineralogy assay, after converting lab data from mass

fraction to volume fraction. Adjust parameters or select

alternate lithology model or alternate mineral mixture to obtain

a better match.

Read More about Lithology

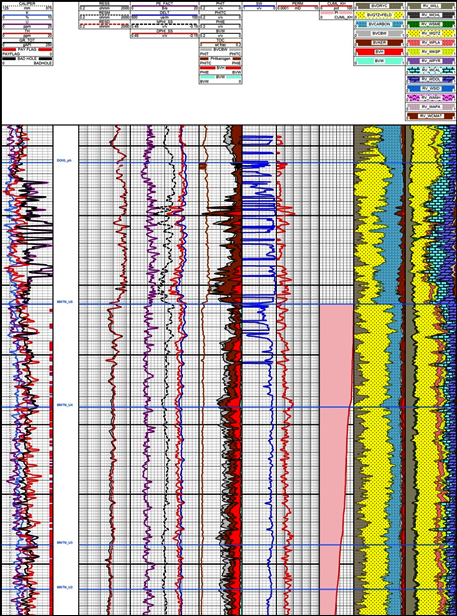

XRD data used to calibrate clay,

quart/feldspar, and carbonate volumes. Doig / Montney interval displaying

elemental capture spectroscopy (ECS) processed mineral volumes,

which were used for lithology model calibration

Step 11: Calculate Water

Step 11: Calculate Water

Saturation

The modified Simandoux equation

works well for most situations. It accounts for low resistivity

clay content and reduces to the Archie

equation when volume of shale equals zero. This model is better behaved in low

porosity than most other models

dual water models may also

work, but may give silly results when volume shale is high or

porosity is very low.

The tortuosity, cementation and saturation exponents (a, m and

n) are required inputs. In many cases electrical properties must

be varied from world averages to get SW to match lab data.

Recommended values are:

A = 1.0, M = N = 1.5 to 1.8. Lab measurement of electrical

properties is essential.

Water resistivity at reference temperature is required and must be corrected to formation temperature. A deep resistivity log reading and accurate shale and kerogen corrected effective porosity are also required.

Calibrate with core

SW or capillary pressure data. Adjust RW, A, M, N to obtain

better match. Both core SW or capillary pressure data pose problems in

unconventional reservoirs, especially reservoirs with thin

porosity laminations. Common sense may have to

prevail over “facts”.

Read More about Water Saturation

Step 12: Calculate Permeability

Index

Step 12: Calculate Permeability

Index

The Wylie-Rose equation works

well in low porosity reservoirs. Calibration constant can

range between 100,000 to 150,000 and beyond. Generally assume

that the

calculated SW is also the irreducible SW.

This assumption may not

always be correct.

An exponential equation derived from regression of core permeability against core porosity may also work well. High perm data caused by micro or macro fractures should be eliminated before performing the regression.

Permeability from Wyllie-Rose

Permeability from Regression

Other permeability models are

often used. Any model that can be calibrated to core and uses

log derived properties will do the job. Most models match conventional

core permeability quite well, but will not match permeability

derived from crushed samples using the GRI protocol.

Permeability index from log or core analysis must be

corrected to in-situ conditions before use in flow capacity or

productivity calculations. Log analysis permeability does not

include permeability from micro or macro fractures so flow

capacity from logs may not match KH from pressure transient

analysis. Log perm is usually considered to be matrix

permeability.

Calibrate with

core permeability, excluding fractured samples. Adjust

parameters to obtain a better match.

Read More about Permeability

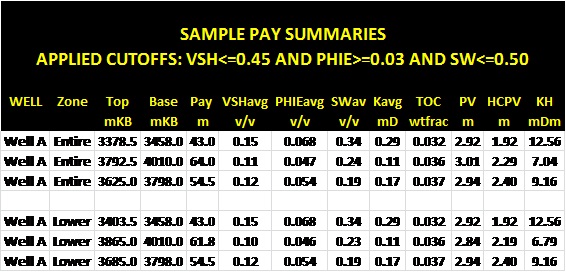

Step 13: Net Reservoir and Net Pay

Step 13: Net Reservoir and Net Pay

Net pay, pore volume, hydrocarbon

pore volume and flow capacity are the final result of most

petrophysical well log analyses. These are called mappable

properties and lead directly to oil and gas in place

calculations.

In many shale gas and some shale

oil plays, typical porosity cutoffs for net reservoir are very

low, 2 or 3% for those with an

optimistic view, 4

or 5% for the pessimistic view.

The water saturation cutoff for

net pay is quite variable. Some unconventional

reservoirs have very little water in the free porosity so the SW

cutoff is not too important. Others have higher apparent

water saturation than might be expected for a productive

reservoir. However, they do produce, so the SW cutoff must be

quite liberal. SW

cutoffs between 50 and 80% are common.

Shale volume cutoffs are usually

quite liberal for unconventional reservoirs, and are usually set

above the 50% mark.

Multiple cutoff sets help

assess the sensitivity to arbitrary choices and gives an indication of the risk or variability in OGIP or OOIP.

Calibration is

not usually possible until years after the field has begun production.

May be possible in flowing wells using flowmeter logs.

Read More about Net Pay and Cutoffs

Step 14: Free Gas or Oil in Place

Step 14: Free Gas or Oil in Place

It is easier to compare zones or wells on the basis of OOIP or OGIP instead of average porosity, net pay, or gross thickness. If area = 640 acres and zone thickness is in feet, then OGIP = Bcf/Section (= Bcf/sq.mile) and OOIP is in barrels per square mile. These units of volume are commonly used to compare zones, wells, or different unconventional plays.

Bg = (Ps * (Tf + KT2)) / (Pf * (Ts + KT2)) * ZF

OGIPfree = KV4 * PHIe * (1 - Sw) * THICK * AREA / Bg

OOIP = KV3 * PHIe * (1 - Sw) * THICK * AREA / Bo

This step is often done by a reservoir engineer on the

evaluation team, based on the petrophysical results developed in

Steps 1 through 13.

Read More about

Gas and Oil in Place.

Step 15: Adsorbed Gas In Place For

Kerogen Rich Reservoirs

Step 15: Adsorbed Gas In Place For

Kerogen Rich Reservoirs

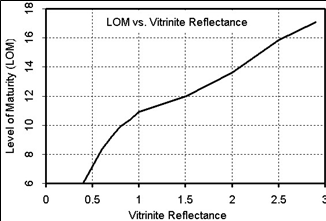

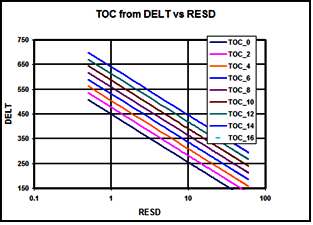

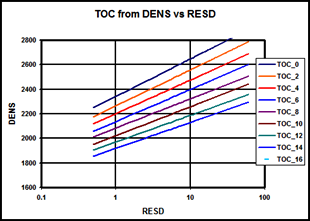

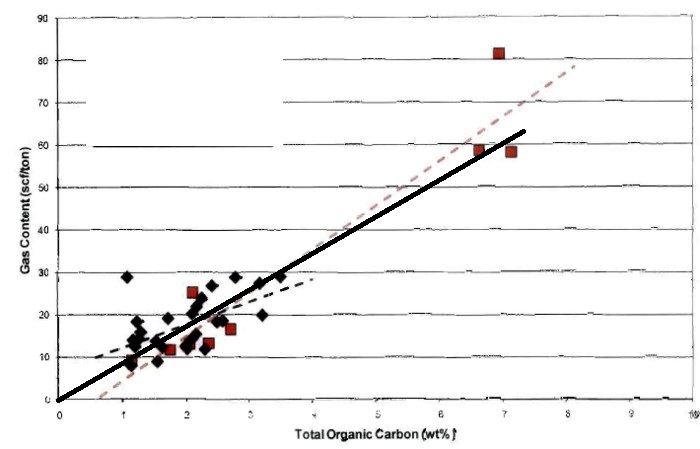

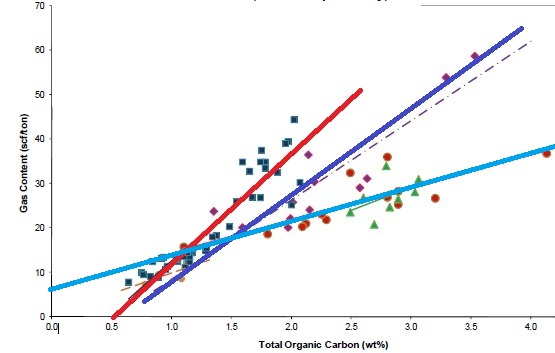

TOC is widely used as a guide to

the quality of shale gas plays. Some deep hot shale gas

plays have little adsorbed gas even though they have moderate

TOC content. Using correlations of lab

measured TOC and gas content (Gc), we can use log derived TOC

values to predict Gc. Gc can then be summed over

the interval and converted to adsorbed gas in place, again

measured in Bcf/section to make it easy to compare projects.

Adsorbed gas in place

Gc = KG11 * TOC%

OGIPadsorb = KG6 * Gc * DENS * THICK * AREA

Crossplots of TOC versus Gc for

Tight Gas / Shale Gas examples. Note the large variation in Gc

versus TOC for different rocks, and that the correlations are not

always very strong. These data sets are from core samples; cuttings

give much worse correlations. The fact that some best fit lines do

not pass through the origin suggests systematic errors in

measurement or recovery and preservation techniques, and erroneous

lost gas estimates.

This step is often done by a reservoir engineer on the evaluation team.

Read More about Adsorbed Gas

Step 16: Reconstruct Sonic and

Density Log Curves

Step 16: Reconstruct Sonic and

Density Log Curves

For stimulation design

modeling, the logs need to represent a water filled

reservoir conditions. Since logs read the invaded zone,

light hydrocarbons (light oil or gas) make the density log

read too low and the sonic log read too high compared to the

water filled case. Rock mechanical properties are calculated

based on reconstructed logs derived from the petrophysical

analysis. The reconstructed logs eliminate gas effect (if

any) and low quality data caused by rough borehole.

Calibrate

by comparing Vp/Vs ratio (DTS/DTC ratio) with known values for

lithology as computed from petrophysical analysis.

Read More about

Log Reconstruction

Read More about

Log Reconstruction

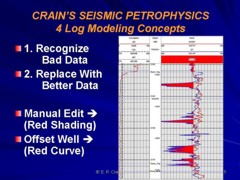

Using

bad sonic data results in erroneous elastic properties ![]()

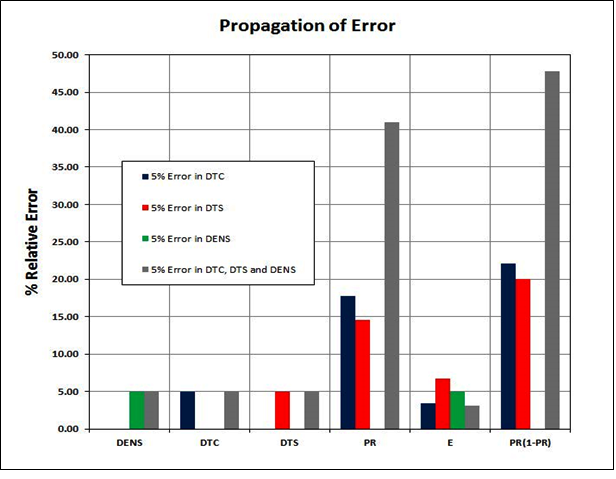

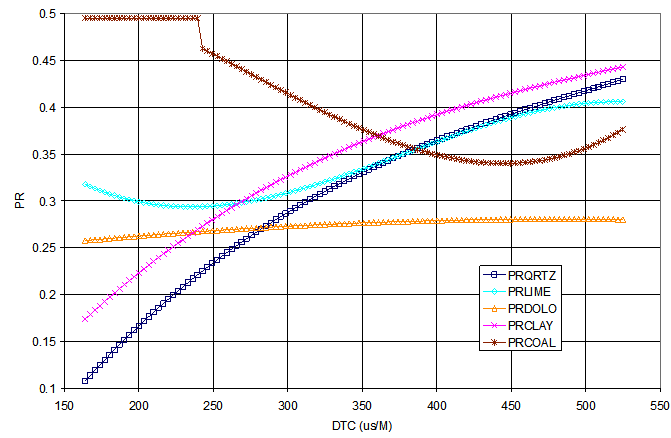

![]() Effect of porosity and gas on Poisson’s

Ratio. PR will be too low for frac design

purposes unless the water filled case is created by log

reconstruction.

Effect of porosity and gas on Poisson’s

Ratio. PR will be too low for frac design

purposes unless the water filled case is created by log

reconstruction.

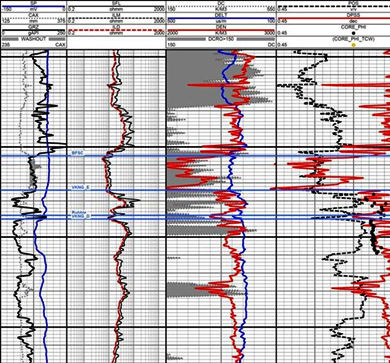

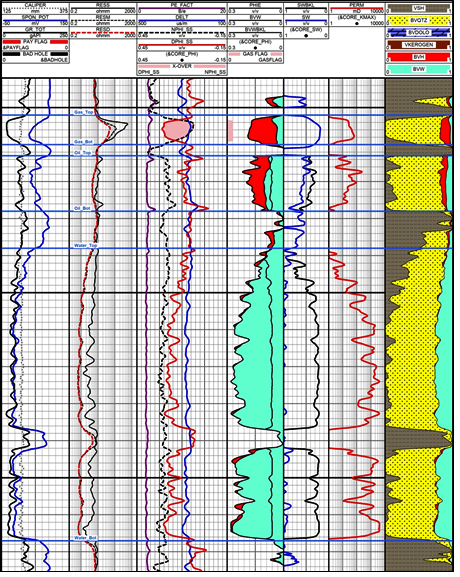

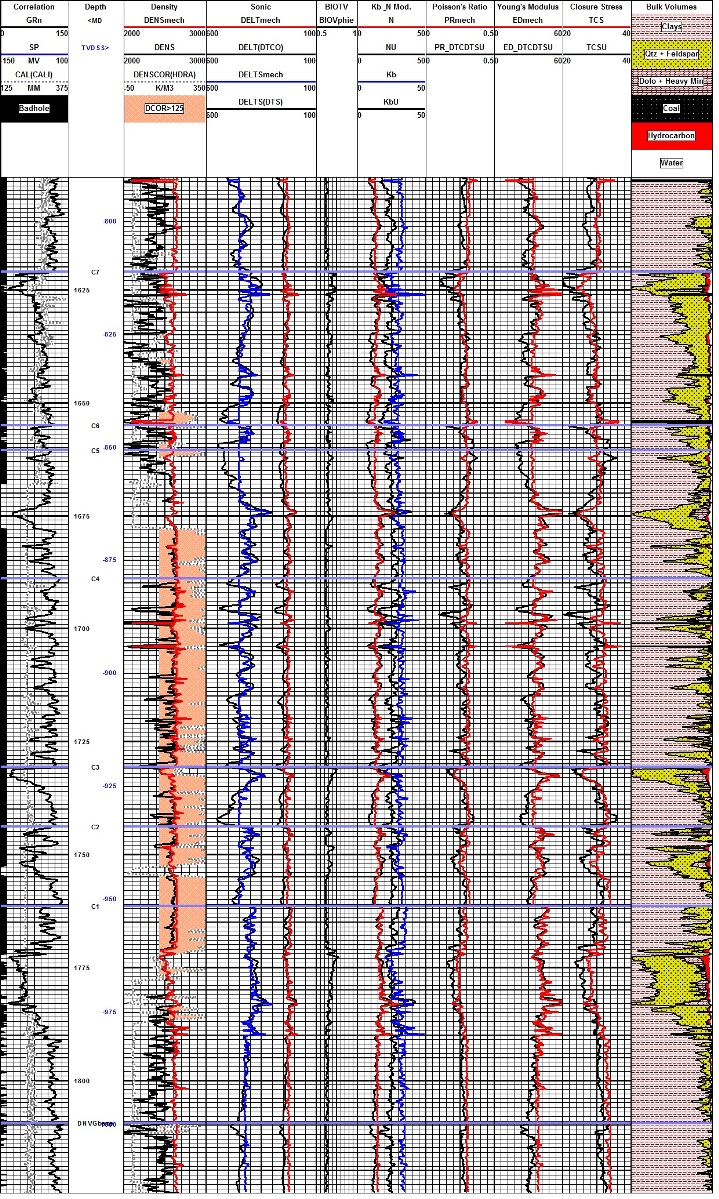

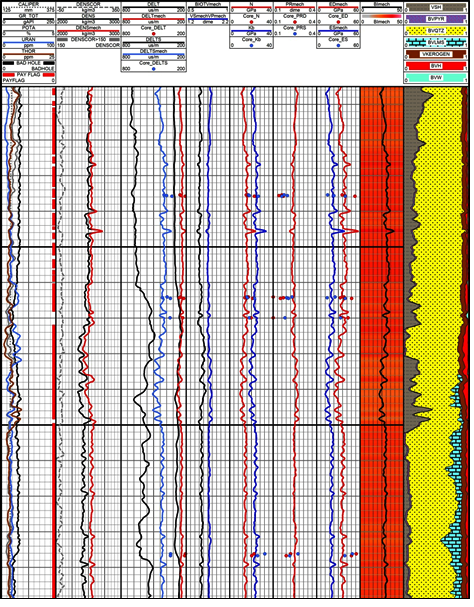

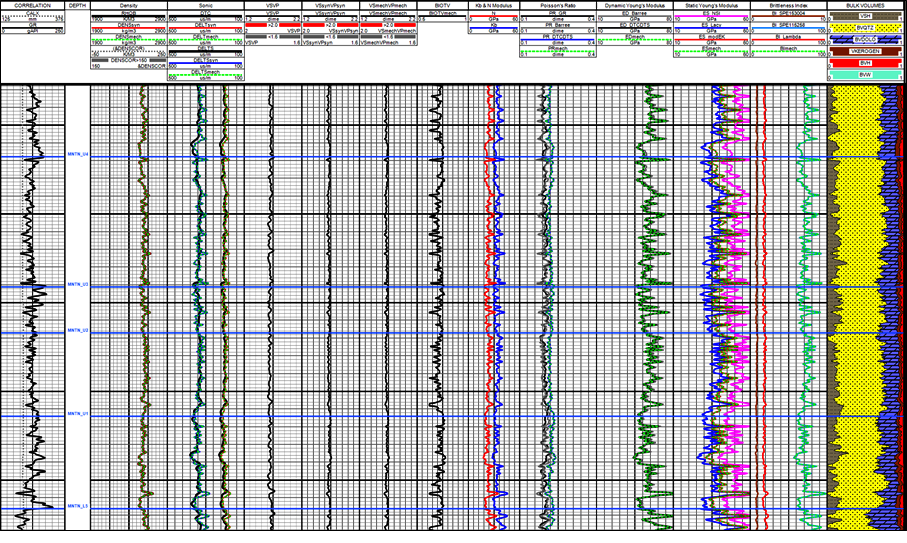

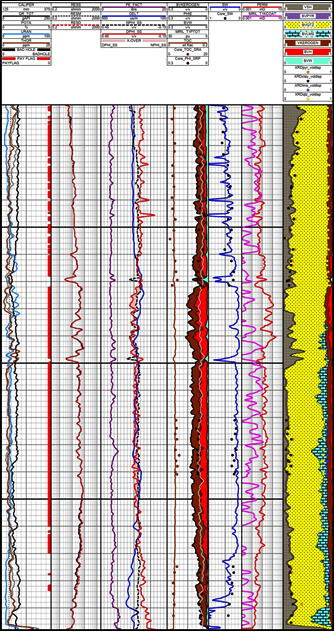

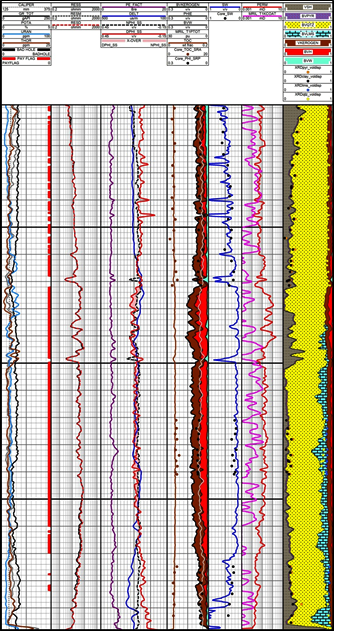

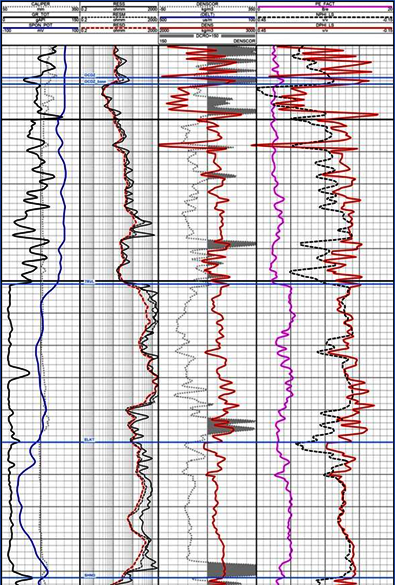

Example of log reconstruction in a shaly sand sequence (Dunvegan).

The 3 tracks on the left show the measured gamma ray, caliper,

density, and compressional sonic. Original density and sonic are

shown in black, modeled logs are in colour. Shear sonic is the model

result as none was recorded in this well. Computed elastic

properties are shown in the right hand tracks. Results from the

original unedited curves are shown in black, those after log editing

are in colour. Note that the small differences in the modeled logs

compared to the original curves propagate into larger differences in

the results, especially Poisson's Ratio (PR), Young's Modulus (ED),

and total closure stress (TCS).

Step 17: Calculate Dynamic

Step 17: Calculate Dynamic

Mechanical Properties

The reconstructed density and sonic logs are used to calculate:

• Poisson’s ratio

R = DTS / DTC

PR = (0.5 * R^2 - 1) / (R^2 - 1)

•

Shear modulus

N = KS5 * DENS / (DTS ^ 2)

• Young’s dynamic modulus

Y = 2 * N * (1 + PR)

•

Bulk modulus

Kb = KS5 * DENS * (1 / (DTC^2) - 4/3

* (1 / (DTS^2)))

• Mullin's brittleness index

Y1 = ((Yst - 1)

/ (8 - 1) * 100)

PR1 = ((PR - 0.40) / (0.15 - 0.40)) * 100

BI = (Y1 + PR1) / 2

The equations used to generate these

values have been used for many years with well log data as

input. The results are usually called dynamic rock properties

because the sonic log is an impulse (moderately high frequency)

measurement. Dynamic measurements can also be made in the lab

using a sparker type device. Static measurements are also made

in the lab, using pressure sleeves; the process is considered to

be a zero frequency or static measurement. Unfortunately, the

dynamic and static results do not agree with each other.

Calibrate to dynamic lab data.

Read More about Dynamic Rock

Properties

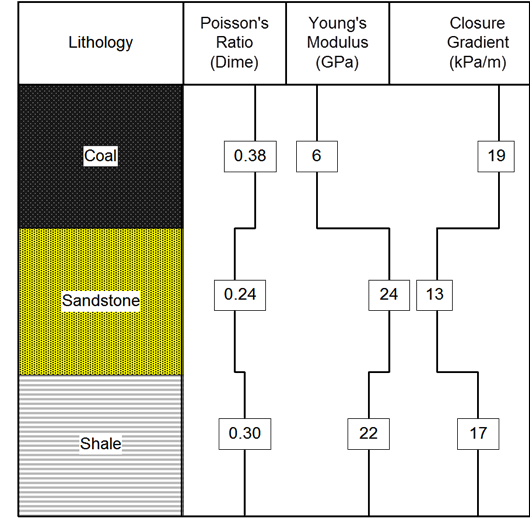

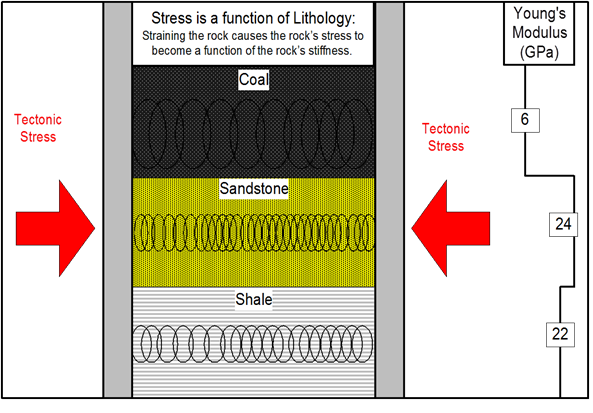

Step 18: Compare Mechanical

Properties to Other Models

Step 18: Compare Mechanical

Properties to Other Models

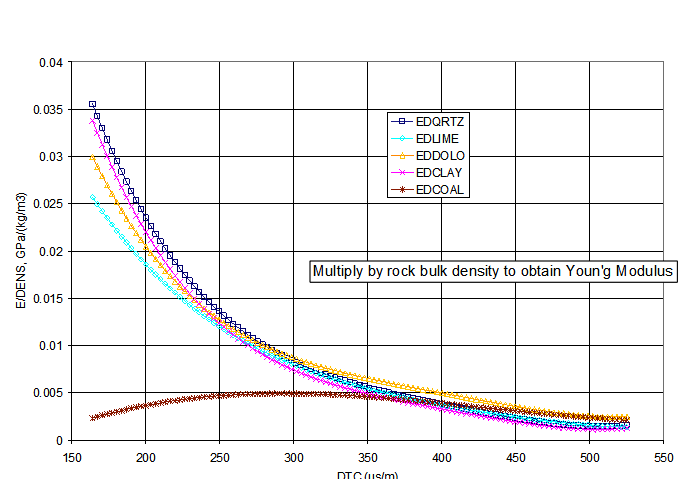

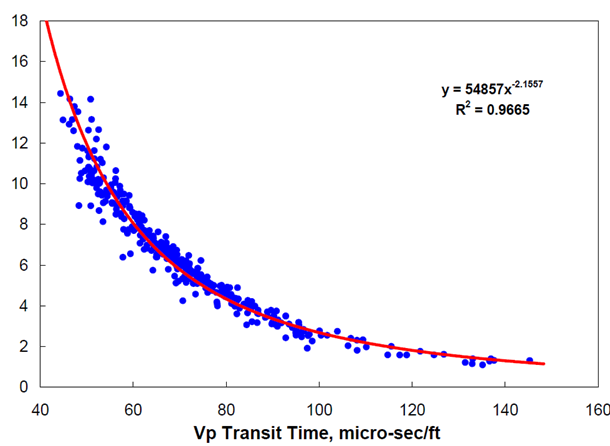

Simple linear

relationships may work well in clastic intervals, usually

relating the parameter to shale volume and mineralogy. Neural

network models may also work with corrected log data. The

results from the mechanical properties analysis should be

compared to the following graphs, based on the lithology and the

compressional sonic log values. Data that falls off trend is

probably suspect, suggesting that further log editing or

adjustments to the analysis parameters are needed.

Young's Modulus versus compressional travel

time (DTS)

Poisson's Ratio versus compressional travel time (DTS)

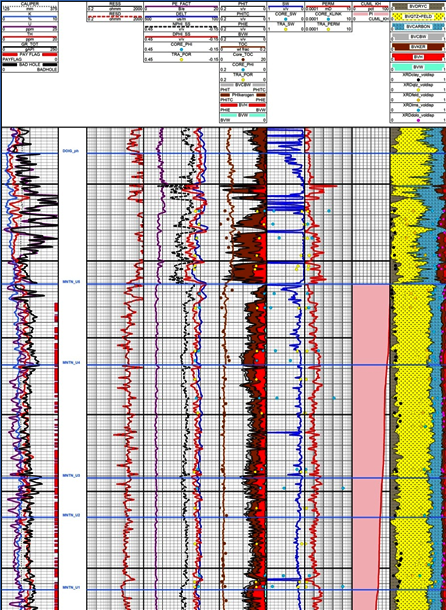

Sample of a mechanical properties log analysis. Left hand tracks show original and reconstructed logs. All results are shown in that right hand tracks. At far right is the lithology / porosity track for correlation.

Step 19: Estimate Static Mechanical

Properties

Step 19: Estimate Static Mechanical

Properties

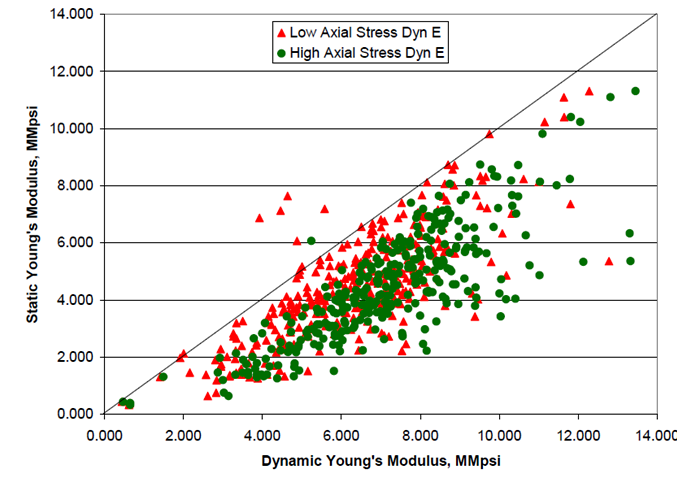

Static values differ from dynamic values because strain and strain rate are dependent on the measurement method.

• dynamic: acoustic wave propagation is a phenomenon of small strain at a large strain rate

• static (triaxial): large strain at small strain rate

Rocks appear stiffer in response

to an elastic wave, compared to a rock mechanics laboratory (triaxial)

test. The weaker the rock, the

larger the difference. This accounts for the difference

between dynamic and static Young’s moduli. The difference between dynamic

and static Poisson’s ratio is very small, and is generally not

considered.

Static mechanical rock properties are needed as input for

hydraulic fracture simulation work because static values more closely

represent the strain and strain rate created during hydraulic frac stimulation treatments.

Many transforms have been

published.

Calibrate to static lab data.

Read More about

Static Rock Properties

Step 20: Calculate

Closure Stress

Step 20: Calculate

Closure Stress

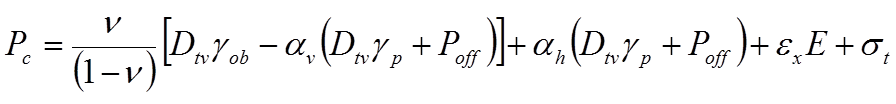

Closure stress is calculated using GOHFER’S Total Stress equation and must be calibrated to local field conditions with a strain or stress correction factor. In tectonically active areas, the closure stress calculated from logs will be too low and will need to be increased. Generally, the strain offset approach is favoured.

Pc = closure pressure, kPa

ν = Poisson’s Ratio

Dtv = true vertical depth, m

γob = overburden stress gradient, kPa/m

γp = pore fluid gradient, kPa/m

αv = vertical Biot’s poroelastic constant

αh = horizontal Biot’s poroelastic constant

Poff = pore pressure offset, kPa

εx = regional horizontal strain, microstrains

E = Young’s Modulus, GPa

σt = regional horizontal tectonic stress, kPa

Overburden

Pressure:

Overburden

Pressure:

The density log is used to

calculate overburden stress. The easiest way to calculate

overburden stress is by determining the average bulk density

above treatment depth. Bad density data are first eliminated by

running a discriminator, using caliper and density correction

logs. With the discriminator

applied, the average bulk density is calculated and then used to

calculate overburden stress.

The more complicated approach

requires integration of the bulk density log. This approach requires a

synthetic density log to be created. The synthetic log is then

integrated from treatment depth to shallowest log reading.

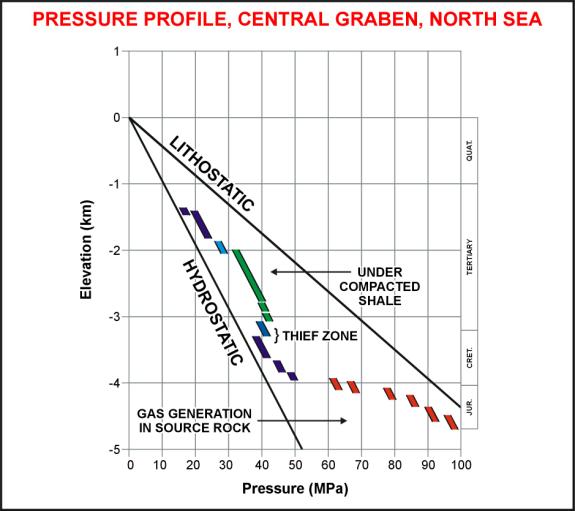

Pore Pressure:

Field measured

data should be used to assign pore pressure. Pore fluid

supports part of the total stress. Pore pressure

depletion increases net stress and leads to compaction. Pore pressure

depletion decreases total (fracture closure) stress.

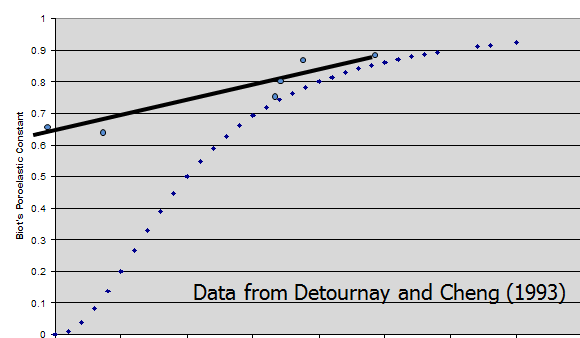

Biot’s

constant:

Biot’s

constant:

Barree defines Biot’s poro-elastic

constant as the efficiency with which internal pore pressure

offsets the externally applied vertical total stress. As Biot decreases, net (intergranular)

stress increases and pore pressure variations have less impact

on net stress.

Calibrate to mini-frac or field data.

The best way to calibrate closure

stress is to review previous fracturing work in nearby wells, or

to perform a mini-frac. If possible, this step should be

completed by the completion engineer (the person running the

hydraulic frac simulation software).

Read More about Closure Stress

STRAIN OFFSET

Calibration eXAMPLE

STRAIN OFFSET

Calibration eXAMPLE

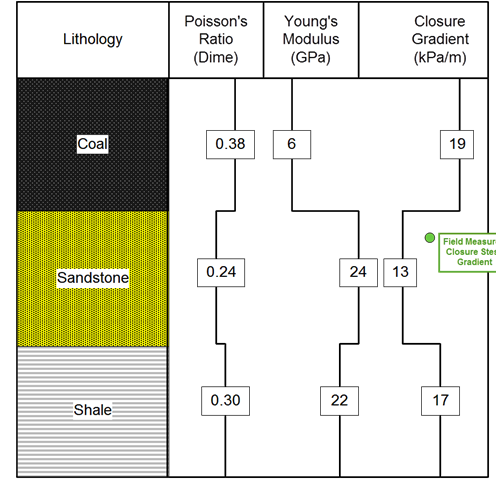

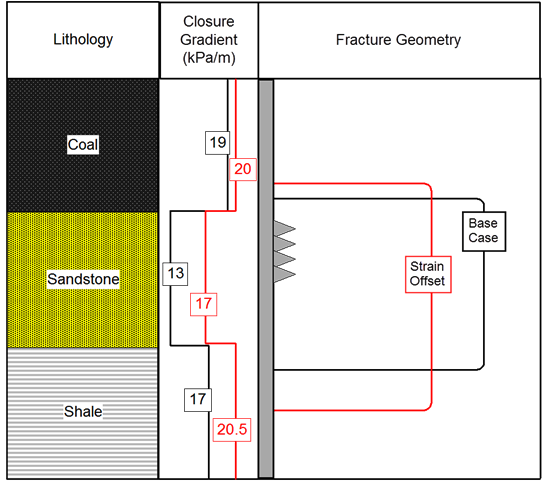

The following schematic examples,

prepared by Dorian Holgate, illustrate computed mechanical

properties and closure stress, and how they change with

different reservoir conditions.

Base Case: No stress offset, no

strain offset

Regional tectonic stress added --- closure stress increases

Mini-frac closure stress does not match base case

Strain offset added to calibrate to field data

Applying a strain offset can decrease the stress difference between the reservoir and non-reservoir intervals - fracture geometry will be affected compared to base case.

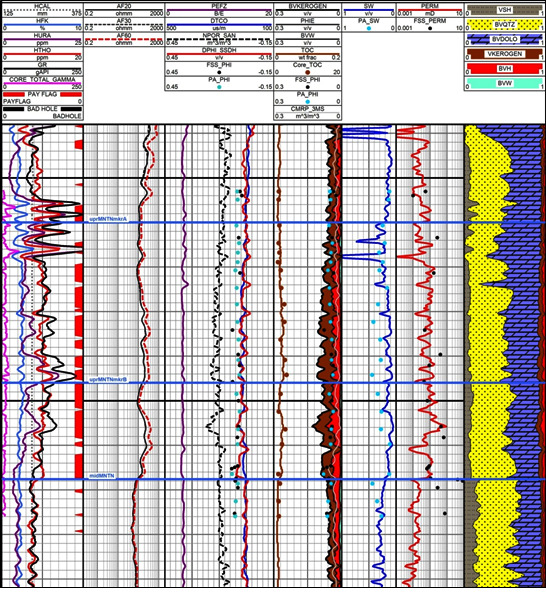

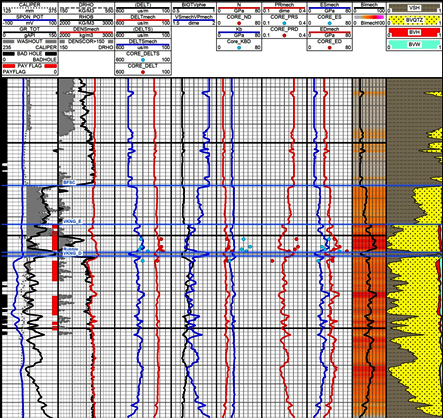

Unconventional shale gas example. Results from the custom

calculation sequence match SCAL data very well. Next, results

were used as input to reconstruct the density and sonic logs.

The reconstructed logs were then used to calculate mechanical

rock properties.

Clastic Example with Rough Bore Hole.

The reconstructed density and sonic logs were

used to calculate mechanical rock properties.

Copyright 2023 by Accessible Petrophysics Ltd.

CPH Logo, "CPH", "CPH Gold Member", "CPH Platinum Member", "Crain's Rules", "Meta/Log", "Computer-Ready-Math", "Petro/Fusion Scripts" are Trademarks of the Author

Logs required are a full suite with resistivity, compressional

and shear sonic, density, neutron, nuclear magnetic, spectral

gamma ray, and caliper logs. LAS (Log ASCII Standard) files

must be reviewed for curve availability. A text editor (Notepad,

Wordpad) can be used to open LAS files to review curve data and

borehole parameters. Measured depth logs should always be

loaded, along with a deviation survey allows reference between

MD, TVD, and TVDSS.

Logs required are a full suite with resistivity, compressional

and shear sonic, density, neutron, nuclear magnetic, spectral

gamma ray, and caliper logs. LAS (Log ASCII Standard) files

must be reviewed for curve availability. A text editor (Notepad,

Wordpad) can be used to open LAS files to review curve data and

borehole parameters. Measured depth logs should always be

loaded, along with a deviation survey allows reference between

MD, TVD, and TVDSS.