|

Capillary pressuRE BASICS

Capillary pressuRE BASICS

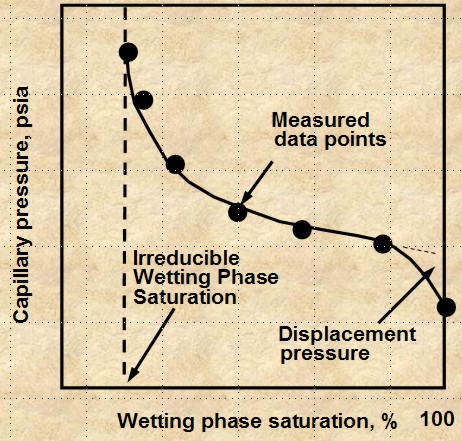

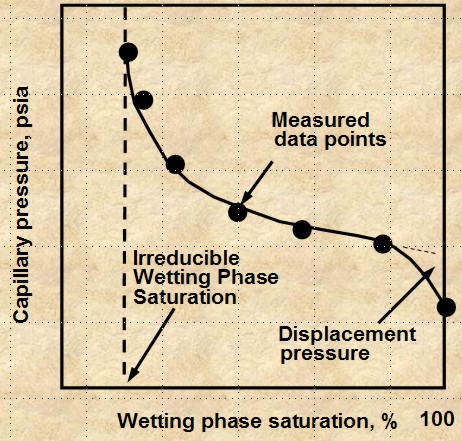

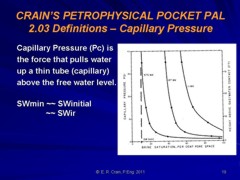

Capillary

pressure is a measurement of the force that draws a liquid up a thin

tube, or capillary. Fluid saturation varies with the capillary

pressure, which in turn varies with the vertical height above the

free water level. Typically, laboratory measurements of capillary

pressure are plotted on linear X - Y coordinate graph paper, as

shown at the right.

Capillary pressure measured in the laboratory can be performed using

air-brine or mercury injection (MICP) methods. The later is usually

used in poorer quality reservoirs. The pressures involved are quite

different so the graphs from the two methods are difficult to

compare directly. By converting the pressure axis to height above

free water (described later on this page), comparisons can be made

quite easily.

Petrophysicists use cap

pressure water saturation, adjusted for height above the

free water level, and residual oil saturation (Sor) to help

calibrate log derived water saturation in oil and gas

reservoirs above the transition zone, and to help detect

depleted reservoirs. It will not help calibrate SW in

partially depleted zones.

The water saturations from capillary pressure measurements

should be considered as "what-if" values. The saturations

represent the value to expect IF the zone is hydrocarbon

bearing. Clearly a water zone is still 100% wet, regardless

of what the cap pressure SW appears to be.

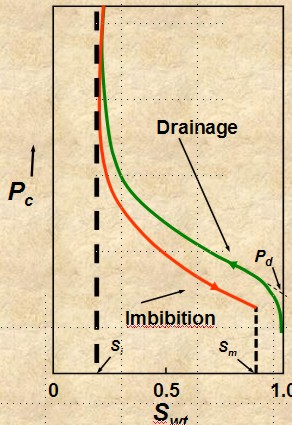

drainage and imbibition

drainage and imbibition

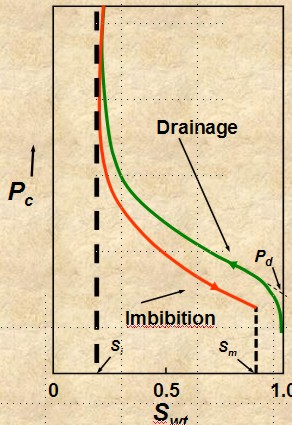

Accumulation of

hydrocarbon in a reservoir is a drainage process and

production by aquifer drive or waterflood is an

imbibition process. The capillary pressure curve is different for

these two processes, as shown in the illustration at the right. Most

capillary pressure graphs show only the drainage curve.

DRAINAGE

DRAINAGE

Fluid flow process in

which the saturation of the nonwetting phase increases.

Mobility of nonwetting fluid phase increases as nonwetting

phase saturation increases - upper curve on image at right.

IMBIBITION IMBIBITION

•Fluid flow

process in which the saturation of the wetting

phase increases. Mobility of

wetting phase increases

as wetting phase saturation increases

- lower curve on image at right.

THE PHYSICS OF

CAPILLARY

pressuRE

THE PHYSICS OF

CAPILLARY

pressuRE

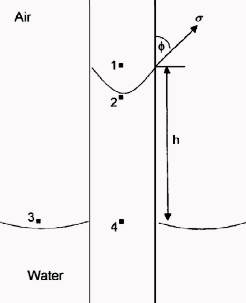

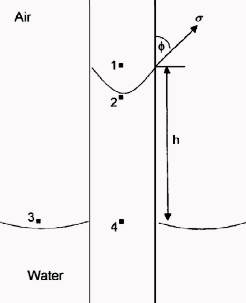

If

a glass capillary tube is placed in a large open vessel containing

water, the combination of surface tension and wettability of tube to

water will cause water to rise in the tube above the water level in

the container outside the tube. The water will rise in the tube

until the total force acting to pull the liquid upward is balanced

by the weight of the column of liquid being supported in the tube.

Assuming the radius of the capillary tube is R, the total upward

force Fup, which holds the liquid up, is equal to the force per unit

length of surface times the total length of surface: If

a glass capillary tube is placed in a large open vessel containing

water, the combination of surface tension and wettability of tube to

water will cause water to rise in the tube above the water level in

the container outside the tube. The water will rise in the tube

until the total force acting to pull the liquid upward is balanced

by the weight of the column of liquid being supported in the tube.

Assuming the radius of the capillary tube is R, the total upward

force Fup, which holds the liquid up, is equal to the force per unit

length of surface times the total length of surface:

1: Fup =

2 * PI * R * SIGgw * cos (THETA)

The upward force is counteracted by the weight of the water, which

is a downward force equal to mass times acceleration:

2: Fdown = PI * R^2 * H * (DENSwtr - DENSair) * G

Assume density of air is negligible and set Fup = Fdown, solve

for surface tension:

3: SIGgw = (R * H * DENSwtr * G) / (2 * cos

(THETA))

In the more general case of oil and water, the equation becomes:

4: SIGow = (R * H * (DENSwtr - DENSoil) * G) / (2

* cos(THETA))

Where:

PI = 3.1416.....

SIGgw = = surface tension between air and water (dynes/cm)

THETA = contact angle

R = capillary radius (cm)

H = height of water in capillary (cm)

DENSwtr = density of water (gm/cc)

DENSair = density of air (gm/cc)

G = acceleration of gravity = 980.7 (cm/sec^2)

Rearranging equation 5:

5: H = (SIGgw * 2 * cos (THETA)) / (R * DENSwtr *

G)

The

pressure difference across the interface between Points 1 and 2 is

the capillary pressure: The

pressure difference across the interface between Points 1 and 2 is

the capillary pressure:

6: P2 = P4 – G * H * DENSwtr

7: P1 = P3 – G * H * DENSair

8: Pc = P1 – P2

The pressure at Point 4 within the capillary tube is the same as

that at Point 3 outside the tube.

9: Pc = (P3 – G * H * DENSair) – (P4 – G * H *

DENSwtr)

10: Pc = G * H * (DENSwtr – DENSair)

11: Pc = G * H * ΔDENS

Where:

Pc = capillary pressure (dynes/cm2)

ΔDENS = density difference between the wetting and nonwetting

phase.(gn/cc)

Combining equations 5 and 11:

12: Pc = (SIGgw * 2 * cos (THETA)) /

R

To convert Pc in dynes/cm2 to psi, multiply by 1.45 * 10^-5.

Thus if Pc is measured in the lab and SIGMA is known, equation 12

can be rearranged to give pore throat radius R.

13: R = (SIGgw * 2 * cos (THETA)) /

Pc

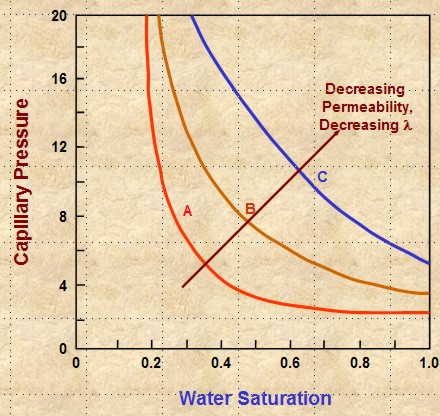

Examples of capillary pressure curves in good

quality rock (sample 1 – left) and poorer quality

rock

(sample 2 – right)

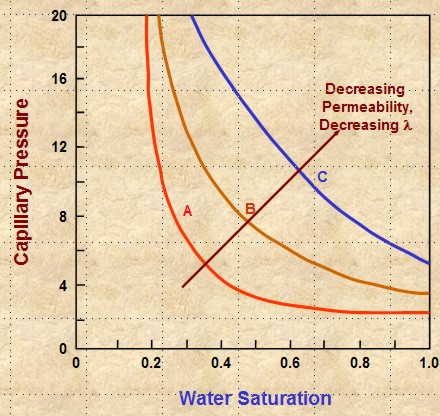

RESERVOIR QUALITY INDICATOR - LAMDA

RESERVOIR QUALITY INDICATOR - LAMDA

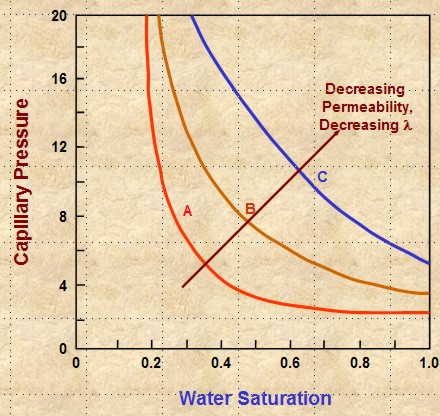

There are four key parameters that are related to a capillary

curve:

Si =

irreducible wetting phase saturation

Sm

= 1 - residual non-wetting phase

saturation

Pd

= displacement pressure, the pressure

required to force non-wetting fluid into largest pores

LAMBDA = pore size

distribution index; determines shape of capillary pressure

curve

Si is the

initial, or irreducible, water saturation in a

hydrocarbon-bearing, water-wet, reservoir at initial

pressure, prior to the start of production. It is termed SWir elsewhere in this Handbook.

(1 - Sm) is the residual oil saturation in a

fully depleted water-wet reservoir, called Sor elsewhere in this

Handbook.

(1 - SI) or (1 - SWir) is the non-wetting phase saturation

at initial conditions prior to production. In a water-wet

reservoir with a water drive, water saturation (Sw) increases

above Si as production proceeds. At any time, saturation of

the non-wetting phase (So) equals (1 - Sw). In a gas

expansion drive reservoir Sw = (1 - So) stays relatively

constant over time. Capillary pressure curves help to

explain the behaviour of water drive reservoirs but do

little for gas expansion or gas cap reservoirs with no water

drive.

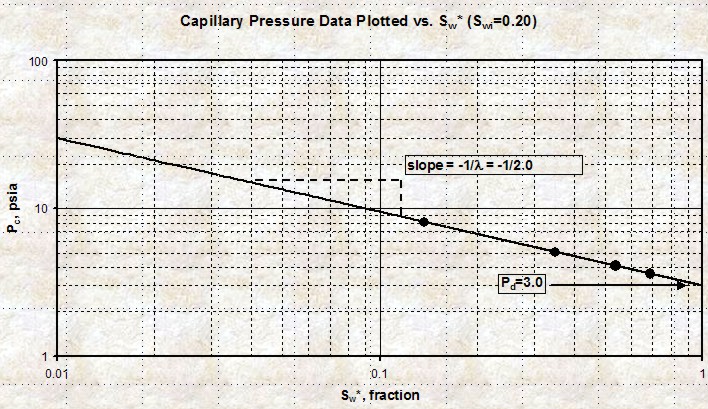

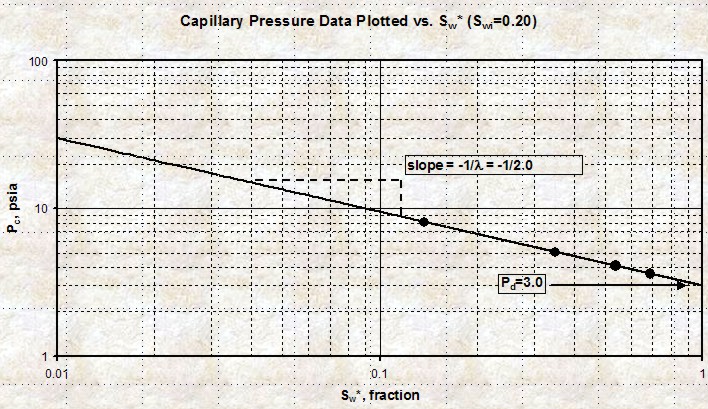

A

capillary pressure curve on Cartesian coordinates is

difficult to fit with simple equations. By transforming the

SW axis to Sw* and plotting Pc vs Sw* on log - log graph

paper, the curves become straight lines. A

capillary pressure curve on Cartesian coordinates is

difficult to fit with simple equations. By transforming the

SW axis to Sw* and plotting Pc vs Sw* on log - log graph

paper, the curves become straight lines.

14: Sw* = (Sw - SWir) / (1 - SWir - Sor)

15: Pc = Pd * (Sw*) ^ (1 / LAMBDA)

The slope of the line on the

log-log graph is

(-1 / LAMBDA) and the intercept at 100% Sw* is Pd. See

illustration below. SWir is

obtained from the Cartesian plot or on a saturation height

graph (see next section on this web page).

Steeper slope equals

higher (1 / LAMBDA), which means LAMBDA is lower. Lower

LAMBDA means poorer quality reseryoir rock.

LAMBDA decreases with decreasing permeability, poor grain

sorting, smaller grain size, and usually with lower porosity.

These effects shift the cap pressure curve upward and to the

right on Cartesian coordinate graphs, resulting in higher SWir values

(see graph at the right).

Plot of Pc versus Sw* on

log - log scale. The slope of the line is

(-1 / LAMBDA) and the intercept

at 100% Sw* is Pd.

The typical range

of (1 / LAMDA) is 0.5 for good quality sands to 4 or 8 for poor

quality sands and carbonates. Type curve

matching of Sw* can be used to assess cap pressure curves and

reservoir quality.

SATURATION - HEIGHT CURVES

SATURATION - HEIGHT CURVES

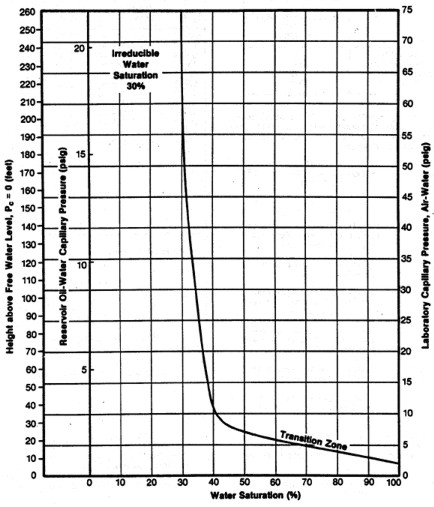

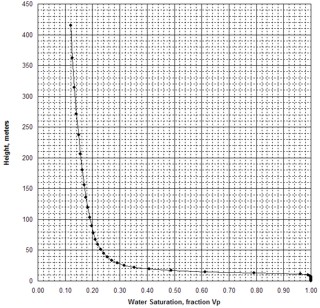

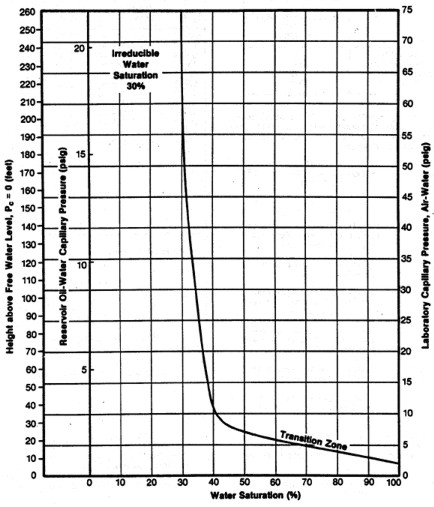

To convert from laboratory measurements to reservoir conditions, we need to use the

following relationship:

16: Pc_res = Pc_lab * (SIGow * cos (THETAow)) / (SIGgw

* cos (THETAgw))

Typical

values for air-brine conversion to oil-water are: Typical

values for air-brine conversion to oil-water are:

SIGow = 24 dynes/cm

THETAow = 30 deg

SIGgw = 72 dynes/cm

THETAgw = 0 deg

Giving: Pc_res = 0.289 * Pc_lab

Solving equation 11 for H, and using reservoir (oil-water) Pc

values:

17: H = KP15 * Pc_res / ΔDENS

Where:

Pc_res = capillary pressure at

reservoir (psi or KPa)

H = capillary rise (ft or meters)

ΔDENS = density difference (gm/cc)

KP15 = 2.308 (English units)

KP15 = 0.1064 (Metric units)

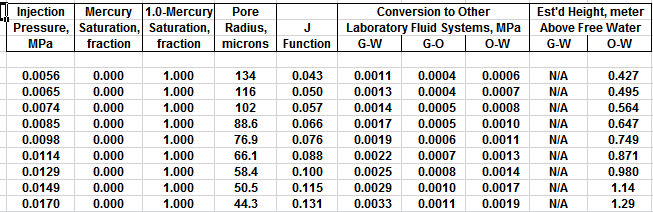

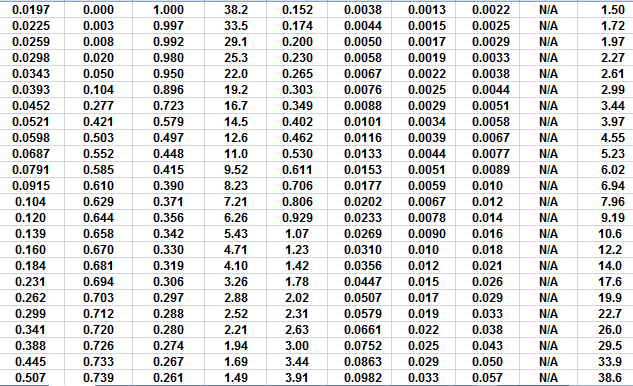

Tables and illustrations shown below in this Section were prepared

by Dorian Holgate of Aptian Technical Ltd.

|

Sw %

|

Pc_lab |

Pc_res |

H |

|

100 |

2 |

0.578 |

6.9 |

|

90 |

3 |

0.867 |

10.4 |

|

80 |

4 |

1.16 |

13.9 |

|

70 |

5 |

1.45 |

17.4 |

|

60 |

6 |

1.73 |

20.8 |

|

50 |

7 |

2.02 |

24.2 |

|

45 |

8 |

2.31 |

27.7 |

|

40 |

10 |

2.89 |

35 |

|

35 |

27 |

7.8 |

94 |

|

30 |

75 |

21.7 |

260 |

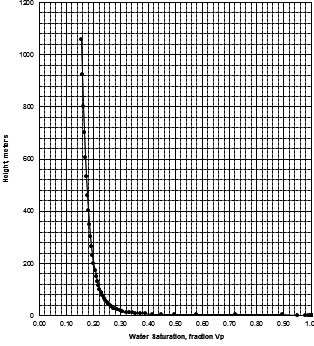

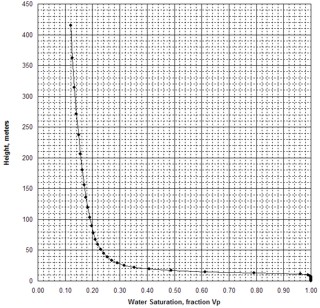

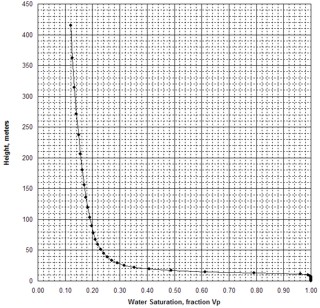

Example of conversion of lab air-brine capillary

pressure data to reservoir conditions, then into saturation-height

H; results plotted in graph above. Example of conversion of lab air-brine capillary

pressure data to reservoir conditions, then into saturation-height

H; results plotted in graph above.

All of the above assumes the lab data is an air-brine

measurement. For mercury injection capillary, pressure (MICP) measurements,

the density of the non-wetting phase (mercury) is 13.5 g/cc, so ΔDENS

is much larger than the air-water case. As a result, Pc values from

an MICP measurement are about 13.5 times higher than an air brine

measurement (for the same SW value in the same core plug). To

compare an air-brine cap pressure curve to an MICP curve, it is

merely necessary to change the Pc scale on one of the graphs by the

appropriate factor, or to convert both Pc scales to a

saturation-height scale.

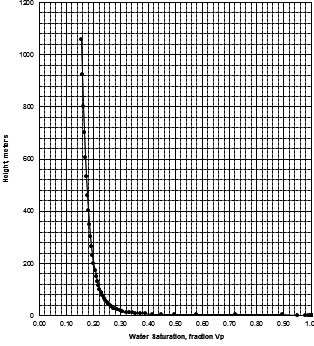

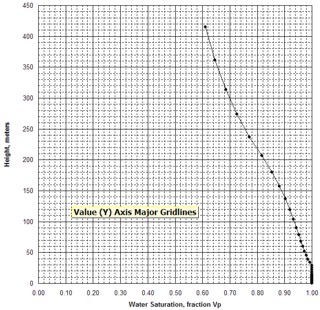

When H is calculated at a number of points on the Pc curve, the

resulting graph of H vs SW is known as a saturation-height curve and

can be plotted on a depth plot of log data or results by setting H =

0 at the base of transition zone on the logs. This assumes a uniform

porosity-permeability regime, which is seldom encountered in real

life, so more complicated methods are needed to superimpose the saturation

values from multiple Pc curves.

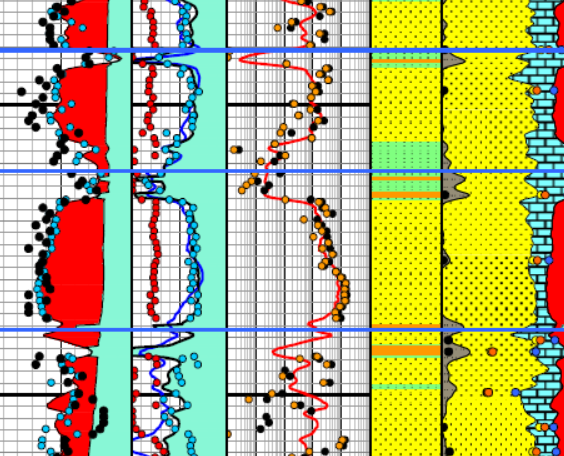

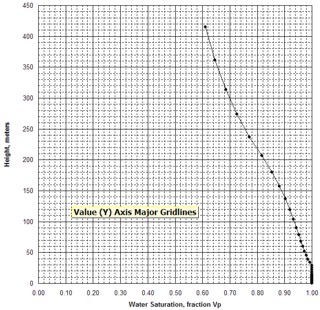

If cap pressure curves are available at various depths in the

reservoir, the pressure axis of each curve is converted to height

above free water. Then the saturation from each curve is selected

from the graph with respect to the sample's position above the water

contact. These saturations are then plotted with respect to the

sample depths onto the log analysis depth plot, as shown in the

example below.

The example below was prepared by Dorian Holgate during one of

our joint projects.

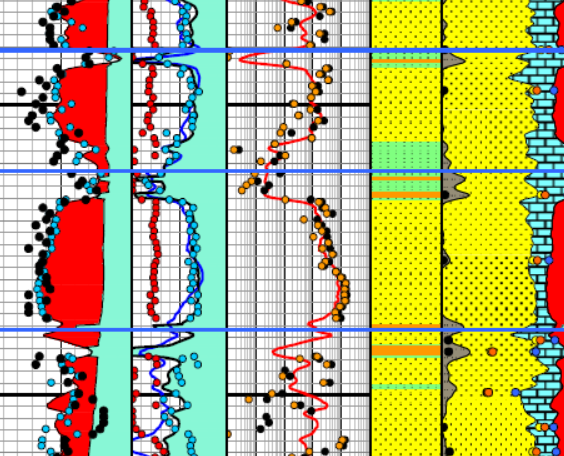

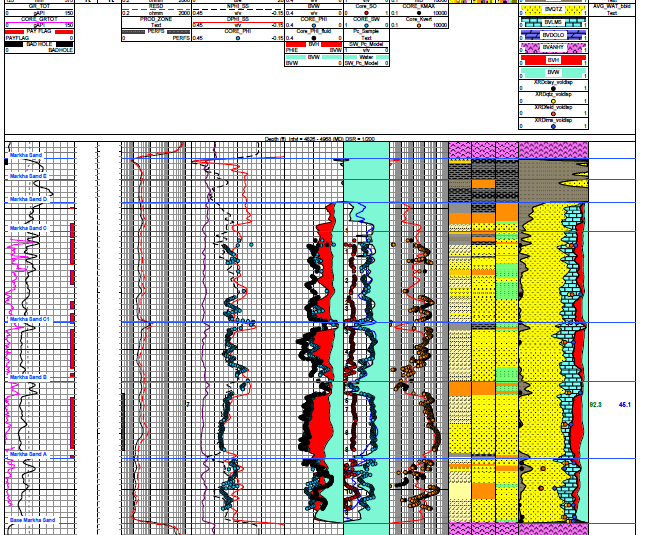

Enlarged image of log analysis depth plot showing porosity,

saturation, permeability, a

Enlarged image of log analysis depth plot showing porosity,

saturation, permeability, and lithology tracks over a conventional

oil-bearing sandstone. Black dots are conventional core porosity and

permeability. Pink dots show porosity of samples used for cap

pressure measurements and the water saturation for those samples,

chosen from their respective height above free water curve.

The pink dots match the log analysis water saturation (blue curve)

very closely everywhere.

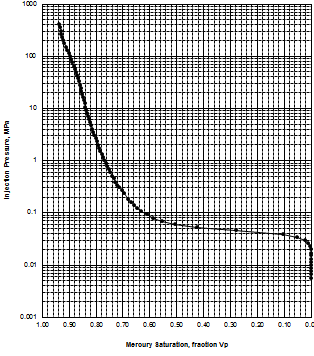

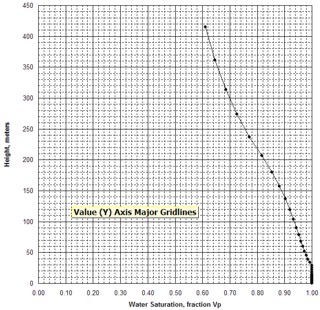

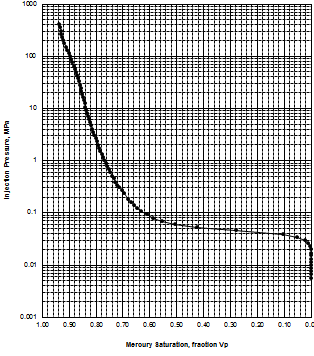

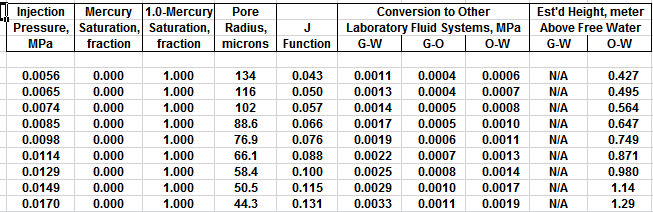

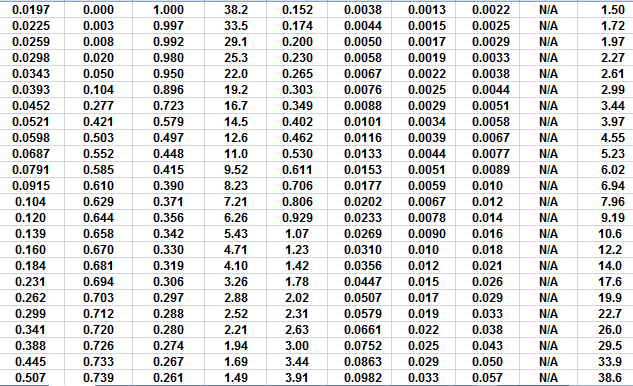

MICP capillary pressure curve (left) and equivalent height above

free water version (right) for the sample just above the oil water

contact on the above example. The reservoir is only 30 meters thick,

so we are only interested in a very small portion of these graphs,

near the bottom of each. The graph has no resolution at low height

values so it is easier to use the equivalent table of values, or

re-plot the data on a more appropriate scale.

The first Pc sample above the oil-water contact is at a height of

4.5 meters above the contact. The nearest height in the table is

4.55 meters (column 10) and the corresponding saturation (column 3)

is 0.497. Use interpolation or plot a detailed graph for better

accuracy. Repeat this for each sample and its respective data table.

FINDING IRREDUCIBLE WATER SATURATION

FINDING IRREDUCIBLE WATER SATURATION

It has been traditional to look at the minimum water saturation on a

cap pressure curve and to call it irreducible water saturation (SWir).

In the above example, we don't see the minimum until 600 to 800

meters above the oil -water contact, and this reservoir is only 30

meters thick. The true irreducible water saturation is much higher

than the minimum on the graph because we are so close to the

contact.

The true irreducible saturation is defined by the height versus SW

curve for each sample, and not by the minimum SW. If porosity,

permeability, pore geometry, grain size, sorting vary in a

reservoir, you need a height versus SW curve for each rock type, and

a reliable method for identifying those rock types by using a log

analysis algorithm or curve shape pattern.

Tables and illustrations shown below in this Section were

prepared by Dorian Holgate of Aptian Technical Ltd.

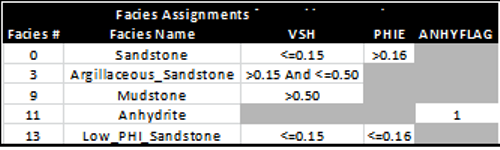

A typical method to differentiate rock types is to use raw log or

analysis results ranges to segregate rocks into various categories.

Then an appropriate cap pressure curve can be applied to each

rock type, where ever it occurs in the reservoir interval. An

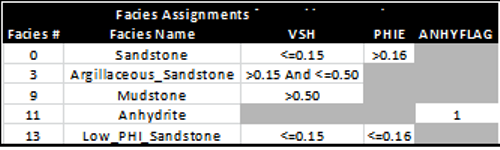

example is shown in the table below:

Example of facies assignments using cutoff ranges

based on analysis results. Note that only

facies 0, 3, and 13 are reservoir facies.

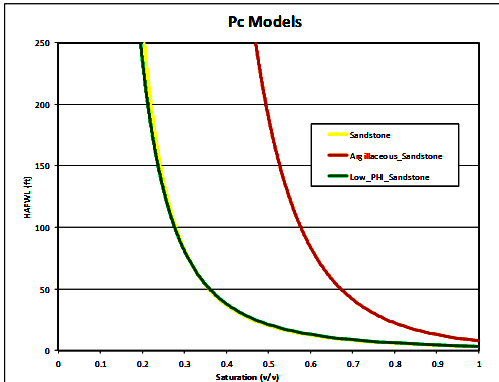

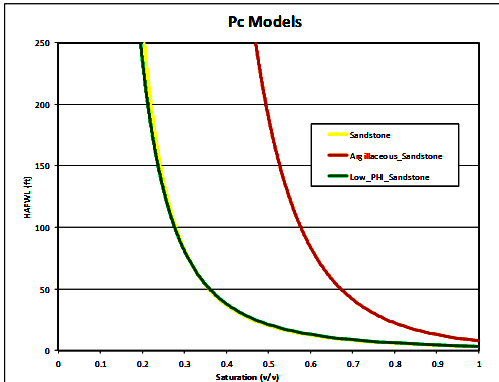

Once facies are assigned, the cap pressure curves are segregated

according to facies and converted to height above free water level

(HAFWL):

Height above free water level (HAFWL) curves for the 3 reservoir

facies. Note that the yellow (facies 0) and

green (facies 13) curves

are virtually identical, so there are in fact only two rock types.

The equation used to model water saturation from

capillary pressure is:

18: SWcp = A * ((Perm / PHIe)^0.5 * HAFWL)^B + C

Where:

Perm = permeability (mD)

PHIe = effective porosity (fractional)

HAFWL = height above free water level (meters)

A, B, C = regression coefficients

The coefficients can be obtained with Excel Solver or commercial Pc

software.

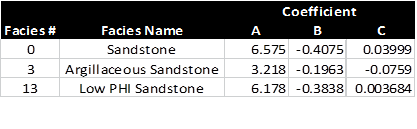

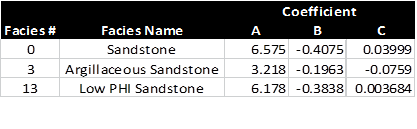

For the cap pressure curves shown

above, the coefficients A, B, and C are:

Regression coefficients for 3 cap pressure curves. Note that results

for facies 0 and 13 are virtually identical.

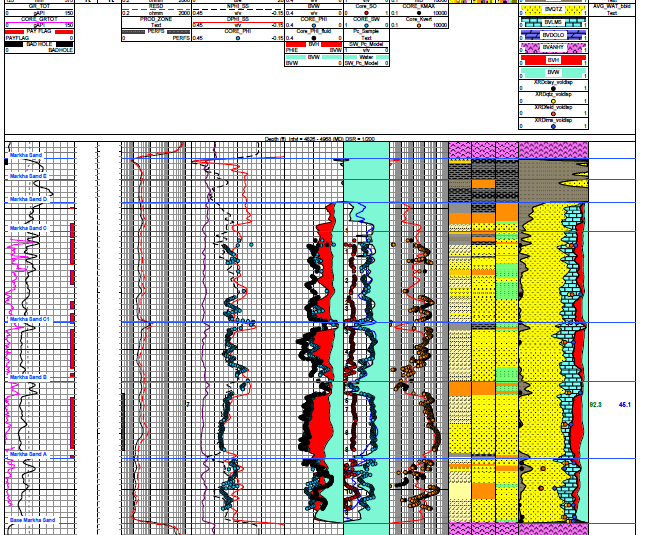

A comparison of the

capillary pressure derived water saturation and that from a

conventional Simandoux porosity-resistivity model is shown below.

Example showing SWpc (black), SWsimandoux

(blue), SWcore (black dots), and SOcore (red dots) in Track 5. Note

the near perfect match between log, core, and cap pressure

saturations. Log and core porosity are in Track 4 and permeability

is in Track 6. Unless porosity and permeability match core, it will

be impossible to match the saturations.

MEASURING

Capillary pressure

MEASURING

Capillary pressure

Capillary pressure can be measured in the

laboratory in four different ways:

Porous diaphragm

method

•

Mercury injection method

•

Centrifuge method

Dynamic

method

Detailed operation of the laboratory equipment is beyond the

scope of this Handbook. The illustrations are not fully

self-explanatory, but the general principles are relatively

visible.

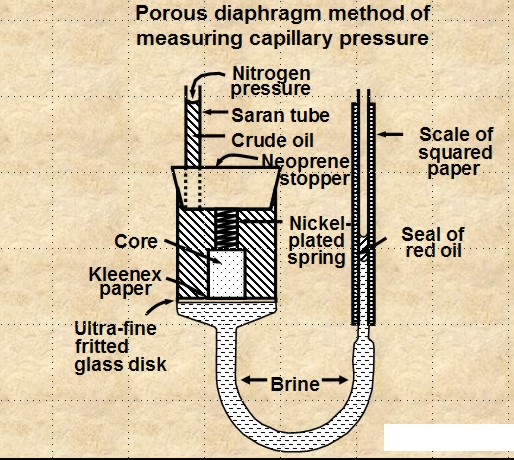

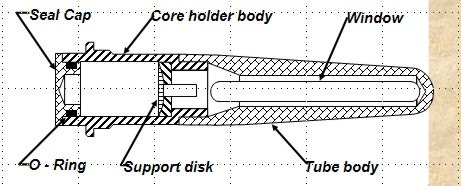

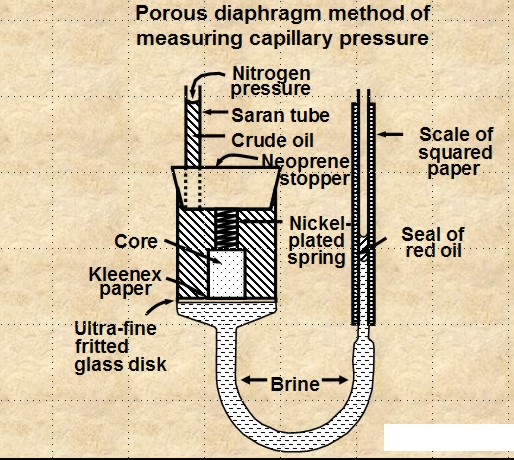

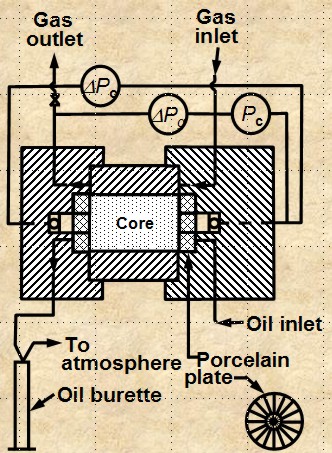

POROUS DIAPHRAGM METHOD

POROUS DIAPHRAGM METHOD

The apparatus and sample data set are shown

below. The method is very accurate but it can take days to

months to get a complete cap pressure curve.

Porous Diaphragm apparatus and results

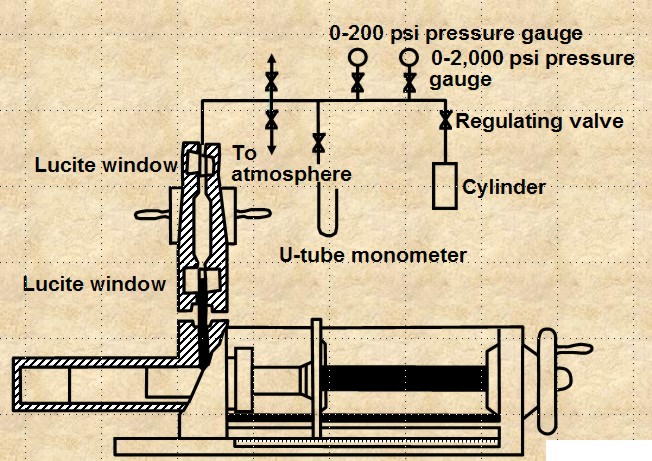

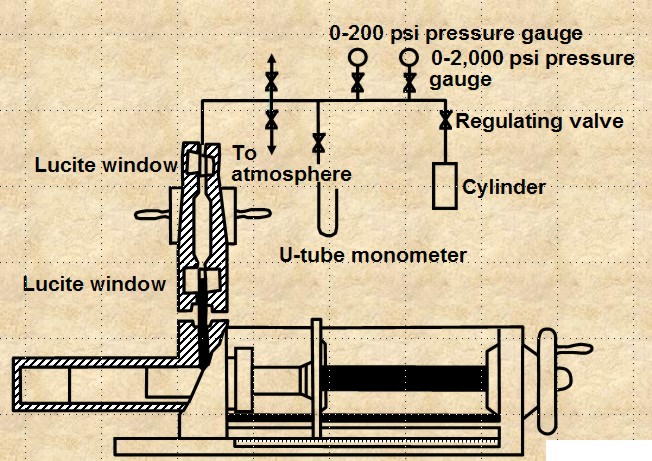

MERCURY INJECTION METHOD

MERCURY INJECTION METHOD

The apparatus is shown at right. The method is

reasonably accurate and takes minutes to hours to get a complete

cap pressure curve. The core sample cannot be re-used for any

purpose and require special disposal procedures due to the

mercury. A conversion factor is needed to get an equivalent

air-brine capillary pressure, comparable to that from a porous

plate method.

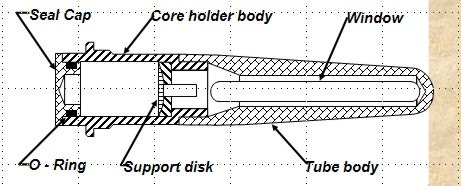

CENTRIFUGAL METHOD

CENTRIFUGAL METHOD

The apparatus is shown below. The method is

reasonably accurate and takes hours to days to get a complete

cap pressure curve. Data analysis is complicated and can lead to

errors.

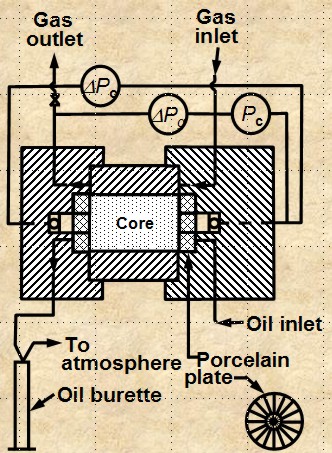

DYNAMIC METHOD

DYNAMIC METHOD

The apparatus is shown at right. The method is

reasonably accurate and simulates actual reservoir flow when

whole core is used. It can take weeks or months to complete a

full cap pressure curve.

AVERAGING

Capillary pressure

AVERAGING

Capillary pressure

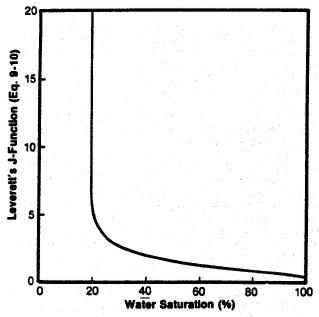

-- Leverett J-FUNCTION

The Leverett J-function was

originally an attempt to convert all capillary pressure data

to a universal curve.

•A universal

capillary pressure curve does not exist because the rock

properties affecting capillary pressures in reservoir have

extreme variation with lithology (rock type).•

But, Leverett’s J-function has proven valuable for

correlating capillary pressure data within a lithologic rock

type.The

Leverett J-Function is described by

21: Jsw = C * Pc * ((K / PHIe)^0.5)

/ (SIGwo * Cos (THETA))

The square root of (K / PHIe) is a function of pore throat

radius. The constant C is a units conversion factor to make

Jsw unitless.

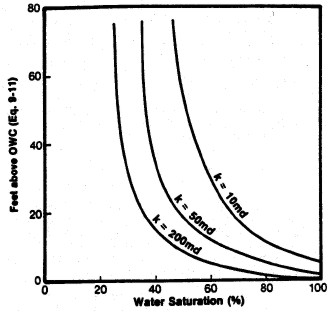

By substitution and

rearrangement:

22: H = Jsw * SIGwo * cos (THETA) / ((K / PHIe)^0.5)

/ ΔDENS

All parameters are adjusted to represent reservoir

conditions. When Pc is in psi and ΔDENS is in psi/ft,

then H is in feet.

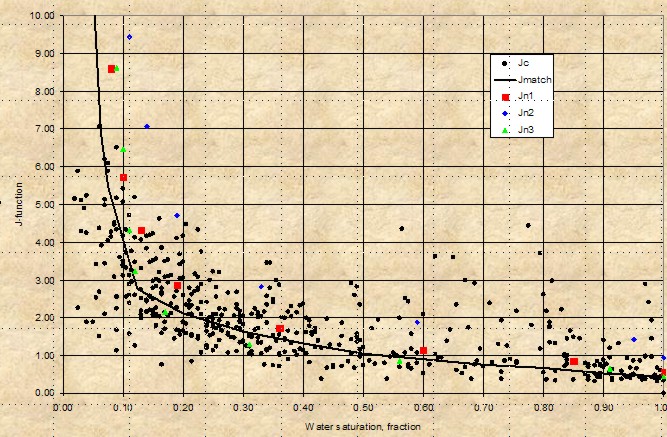

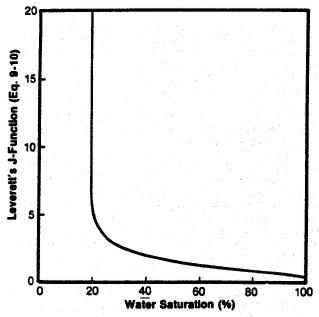

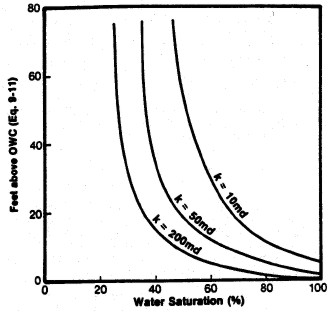

Left: Smoothed Jsw curve versus Sw; Right: Derived

saturation-height curves for various permeability values

(porosity held constant) using equation 22.

•J-function is

useful for averaging capillary pressure data from a

given rock type from a given reservoir and

•can

sometimes

be extended to different reservoirs having the same

lithology.

Use extreme

caution in assuming this can be done. J-function is usually not an accurate

correlation for different lithologies. If J-functions are not successful

in reducing the scatter in a given set of data, then

this suggests that we are dealing with variation in

rock type.

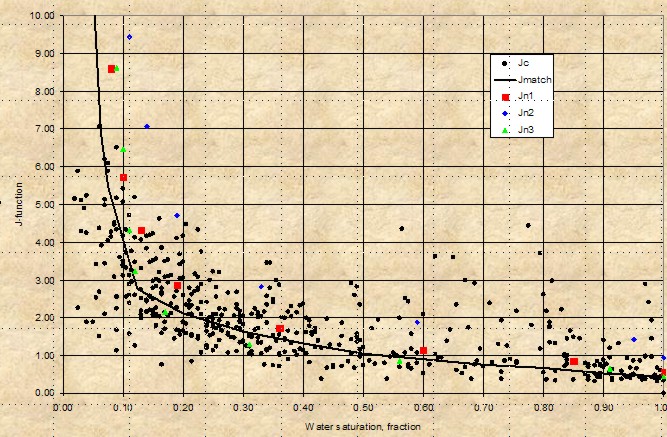

Leverett J-Function versus water saturation for

West Texas Carbonates showing moderate

spread of saturation data - rock type is not really

very uniform (varying pore geometry). However, the

J-function curve may be suitable for reservoir

simulation purposes

CAP PRESSURE EXAMPLE - Sand and Silt Reservoir

CAP PRESSURE EXAMPLE - Sand and Silt Reservoir

A

capillary pressure (Pc) data set, along with some

calculated parameters, is summarized in the table

below.

|

CAPILLARY PRESSURE

SUMMARY |

|

Sample |

Depth |

Perm |

PHIe |

SWir |

SWir |

PHI*SW |

PHI*SW |

sqrt/PHIe) |

Pore Throat |

|

|

m |

mD |

|

425m |

100m |

425m |

100m |

|

Radius um |

|

Bakken |

|

|

|

|

|

|

|

|

|

|

1 |

x03.5 |

2.40 |

0.118 |

0.12 |

0.19 |

0.014 |

0.022 |

4.51 |

1.358 |

|

2 |

x04.3 |

0.24 |

0.137 |

0.62 |

0.94 |

0.085 |

0.129 |

1.32 |

0.036 |

|

3 |

x04.5 |

0.32 |

0.139 |

0.39 |

0.64 |

0.054 |

0.089 |

1.52 |

0.100 |

|

4 |

x05.2 |

0.77 |

0.149 |

0.31 |

0.62 |

0.046 |

0.092 |

2.27 |

0.113 |

|

Average |

x04.4 |

0.93 |

0.136 |

0.36 |

0.60 |

0.050 |

0.083 |

2.41 |

0.402 |

|

|

|

|

|

|

|

|

|

|

|

|

Torquay |

|

|

|

|

|

|

|

|

|

|

5 |

x16.8 |

0.05 |

0.163 |

1.00 |

1.00 |

0.163 |

0.163 |

0.55 |

0.008 |

|

6 |

x20.4 |

0.07 |

0.145 |

0.59 |

0.97 |

0.086 |

0.141 |

0.69 |

0.038 |

|

7 |

x21.8 |

0.09 |

0.174 |

0.79 |

0.96 |

0.137 |

0.167 |

0.72 |

0.019 |

|

8 |

x23.8 |

0.03 |

0.157 |

1.00 |

1.00 |

0.157 |

0.157 |

0.44 |

0.009 |

|

9 |

x31.4 |

0.07 |

0.138 |

0.83 |

0.98 |

0.115 |

0.135 |

0.71 |

0.017 |

|

Average |

x24.4 |

0.07 |

0.154 |

0.80 |

0.98 |

0.124 |

0.150 |

0.64 |

0.021 |

In

higher permeability rock, the cap pressure curve

quickly reaches an asymptote and the minimum

saturation usually represents the actual water

saturation in an undepleted hydrocarbon reservoir

above the transition zone. In tight rock, the

asymptote is seldom reached, so we pick saturation

values from the cap pressure curves at two heights

(or equivalent) Pc values to represent two extremes

of reservoir condition. In

higher permeability rock, the cap pressure curve

quickly reaches an asymptote and the minimum

saturation usually represents the actual water

saturation in an undepleted hydrocarbon reservoir

above the transition zone. In tight rock, the

asymptote is seldom reached, so we pick saturation

values from the cap pressure curves at two heights

(or equivalent) Pc values to represent two extremes

of reservoir condition.

Only

sample 1 in the above table behaves close to

asymptotically, as in curve A in the schematic

illustration at the right. All other samples behave

like curves B and C (or worse). The real cap

pressure curves for samples 1 and 2 are shown below.

Examples of capillary pressure curves in good

quality rock (sample 1 – left) and poorer quality

rock

(sample 2 – right)

The

summary table shows wetting phase saturation

selected by observation of the cap pressure

graphs at two different heights above free water,

namely 100 meters and 425 meters in this example. In

this case, the 100 meter data gives water

saturations that we commonly see in petrophysical

analysis of well logs in hydrocarbon bearing Bakken

reservoirs in Saskatchewan. This is a pragmatic way

to indicate the water saturation to be expected when

a Bakken reservoir is at or near irreducible water

saturation. The data for the 450 meter case is

considerably lower and probably does not represent

reservoir conditions in this region of the Williston

Basin.

Two other columns

in the table are calculated from the primary

measurements.

The

first is the product of porosity times saturation,

PHI*SW, often called Buckle’s Number. It is

considered to be a measure of pore geometry or grain

size. Higher values are finer grained rocks. These

values vary considerably in the Bakken, between low

and medium values, indicating the laminated nature

of the silt / sand reservoir. The values in the

Torquay are uniformly high, indicating that the

reservoir is poor quality in all samples.

The

second is the square root of permeability divided by

porosity, sqrt(Kmax/PHIe), which is another measure

of reservoir quality, directly proportional to pore

throat radius and Pc. High numbers represent good

connectivity and low values show poor connectivity.

Again, the Bakken shows the variations due to

laminations, and the Torquay shows low values and

unattractive reservoir quality.

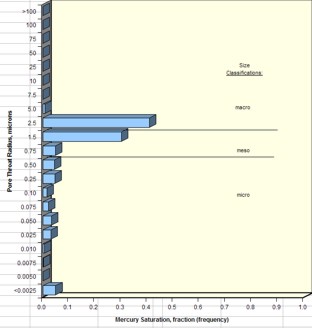

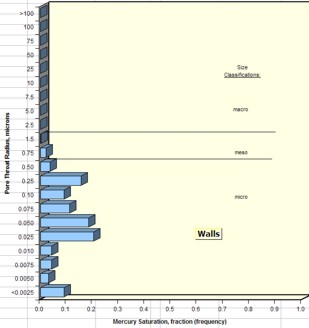

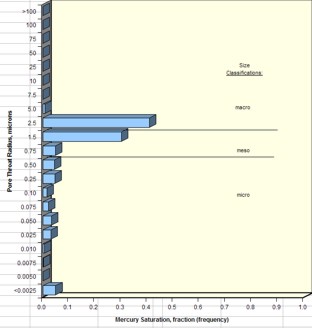

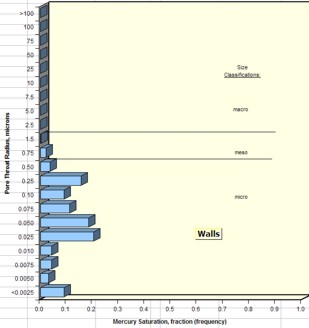

Average pore throat radius and detailed pore throat

distribution data are now routinely available in the capillary

pressure spreadsheet provided by the core analysis

laboratory.

Examples are shown below.

Examples of pore throat

radius distribution in good quality rock (sample 1 –

left) and poorer quality rock (sample 2 – right)

By

comparing cap pressure and pore throat distribution

graphs from each sample with the quality indicator

values in the summary table, it becomes more evident

as to which parameters in a petrophysical analysis

might be the best indicator of reservoir quality.

Since both Buckle’s Number and the Kmax/PHIe

parameter can be determined from logs, it has been

relatively common to assess reservoir quality from

these parameters as a proxy for capillary pressure

and pore throat measurements.

However, in thinly laminated reservoirs like the

Bakken, this is not always possible since the

logging tools average 1 meter of rock. This means we

cannot see the internal variations of rock quality

evident in the core data.

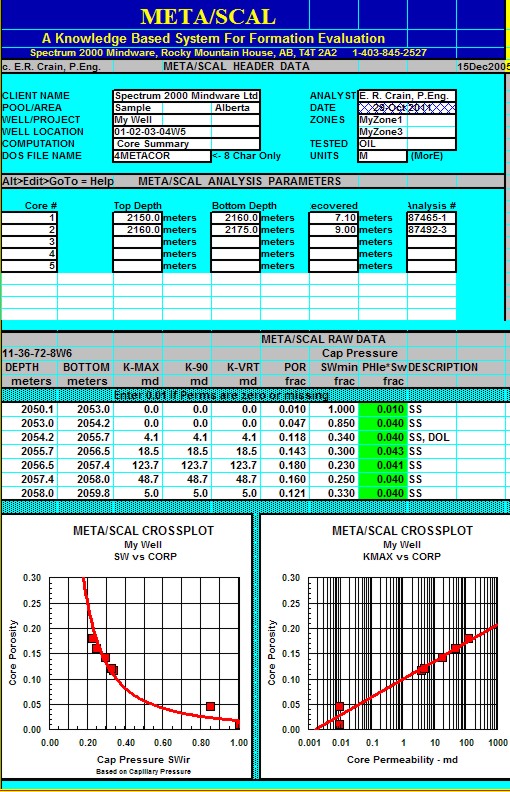

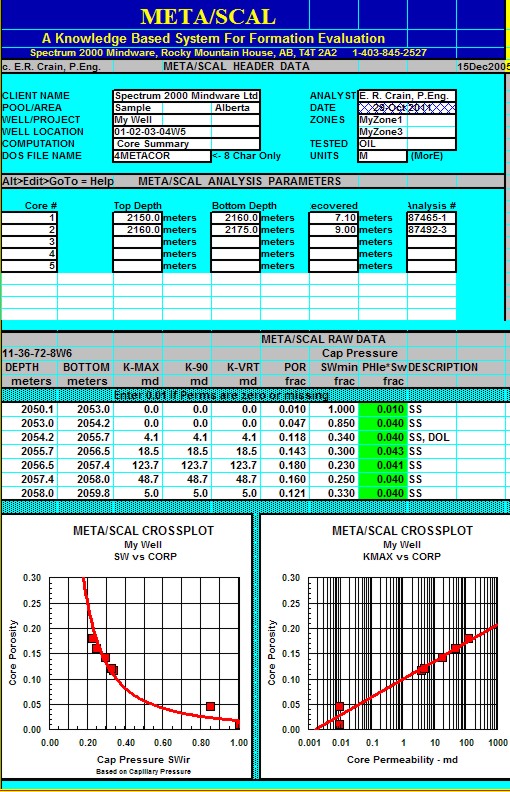

"META/SCAL" Spreadsheet -- Capillary Pressure Summary

"META/SCAL" Spreadsheet -- Capillary Pressure Summary

This spreadsheet is used to

summarize Capillary Pressure data,

with crossplot to find SWir.

Download this spreadsheet:

SPR-11 META/LOG PC-SPECIAL CORE ANALYSIS (SCAL) CALCULATOR

Calculate irreducible water saturation SWir

from capillary pressure data,

crossplots.

Sample of "META/SCAL" spreadsheet for summarizing

capillary pressure data.

|

If

a glass capillary tube is placed in a large open vessel containing

water, the combination of surface tension and wettability of tube to

water will cause water to rise in the tube above the water level in

the container outside the tube. The water will rise in the tube

until the total force acting to pull the liquid upward is balanced

by the weight of the column of liquid being supported in the tube.

Assuming the radius of the capillary tube is R, the total upward

force Fup, which holds the liquid up, is equal to the force per unit

length of surface times the total length of surface:

If

a glass capillary tube is placed in a large open vessel containing

water, the combination of surface tension and wettability of tube to

water will cause water to rise in the tube above the water level in

the container outside the tube. The water will rise in the tube

until the total force acting to pull the liquid upward is balanced

by the weight of the column of liquid being supported in the tube.

Assuming the radius of the capillary tube is R, the total upward

force Fup, which holds the liquid up, is equal to the force per unit

length of surface times the total length of surface: The

pressure difference across the interface between Points 1 and 2 is

the capillary pressure:

The

pressure difference across the interface between Points 1 and 2 is

the capillary pressure:

A

capillary pressure curve on Cartesian coordinates is

difficult to fit with simple equations. By transforming the

SW axis to Sw* and plotting Pc vs Sw* on log - log graph

paper, the curves become straight lines.

A

capillary pressure curve on Cartesian coordinates is

difficult to fit with simple equations. By transforming the

SW axis to Sw* and plotting Pc vs Sw* on log - log graph

paper, the curves become straight lines.

Typical

values for air-brine conversion to oil-water are:

Typical

values for air-brine conversion to oil-water are: