|

ELECTRICAL

PROPERTIES BASICS

ELECTRICAL

PROPERTIES BASICS

Studies of electrical

properties in rocks have been performed as functions of frequency,

temperature, applied field, pressure, oxygen fugacity, water

content, and other variables. In the context of this Handbook, we

are concerned only with those properties that affect the water

saturation calculation as proposed by Archie and others, and their

shale corrected derivatives.

Most water saturation models rely on work originally done by Gus

Archie in 1940-41. He found from laboratory studies that, in a

shale free, water filled rock, the Formation Factor (F) was a

constant defined by:

1: F = R0 / Rw

He also found that F varied with porosity:

2: F = A / (PHIt

^ M)

For a tank of water, R0 = Rw. Therefore F = 1.

Since PHIt = 1, then A must also be 1.0 and M can have any

value. If porosity is zero, F is infinite and both A and M can

have any value. However, for real rocks, both A and M vary with

grain size, sorting, and rock texture. The normal range for A is

0.5 to 1.5 and for M is 1.7 to about 3.2. Archie used A = 1 and

M = 2. In fine vuggy rock, M can be as high as 7.0 with a

correspondingly low value for A. In fractures, M can be as low

as 1.1. Note that R0 is also spelled Ro in the literature. In

some carbonates, M seems to vary with porosity.

For rocks with both hydrocarbon and

water in the pores, he also defined the term Formation

Resistivity Index (

I

) as:

3: I

= Rt / R0

4: Sw = ( 1 /

I

) ^ (1 / N)

The value for R0 is measured in the laboratory

using either a two or four electrode resistivity apparatus, with

the sample 100% saturated with water of resistivity Rw. The

porosity is also measured.

The core sample is then partially saturated by

extraction of water with a centrifuge. The water extracted is

measured to determine water saturation and resistivity Rt is

measured. This step is repeated for several saturations.

Results of these tests are shown in the

next twp Sections.

Electrical properties can be measured at

the same time on the same core plugs as used for capillary pressure

measurements. Since both measurements strongly affect the results of

reservoir assessment and reservoir simulation projects, it would

seem prudent to evaluate both properties in the lab before spending

a lot of money on reservoir development.

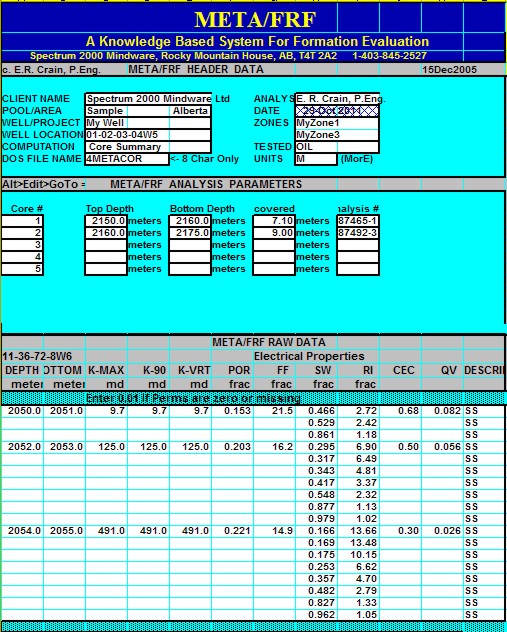

Combined

resistivity index and cap pressure report. Combined

resistivity index and cap pressure report.

Most modern rock laboratories

can perform these so-called "special core analysis" procedures.

Unfortunately, many operators fail to have this work done, which is

a great shame, as the data can change the calculated water

saturation values quite dramatically compared to using

"world-average" numbers.

Values of A, M, or N that are lower than

the world-average values will increase calculated oil or gas in

place.

An outline of the laboratory

procedure is listed below.

COMBINED

ELECTRICAL PROPERTIES AND POROUS PLATE CAPILLARY PRESSURE TEST

COMBINED

ELECTRICAL PROPERTIES AND POROUS PLATE CAPILLARY PRESSURE TEST

1.

Obtain 1-1/2 inch diameter

by maximum length cylinders from core material.

2.

Perform BaCl Cation Exchange Capacity measurement on sample end

pieces.

3.

Package with Teflon tape

and stainless steel end screens if unconsolidated.

4. Extract

core fluids using low temperature solvent extraction.

5. Dry

samples in humidity controlled oven.

6. Determine

Boyles’ Law porosity, grain density and nitrogen permeability at

reservoir stress.

7. Vacuum

saturate with synthetic reservoir brine.

8. Mount

samples at reservoir stress and temperature (optional) in electrical

conductivity/porous plate capillary pressure apparatus with water

wet porous plate end piece.

9. Flush

with synthetic brine at backpressure and monitor for 100% brine

saturation and electrical stability.

10. Determine

Formation and Cementation factor. FRw= Ro/Rw

m=log FRw/log porosity

11. De-saturate

using humidified nitrogen or oil in appropriate pressure steps to

describe a full capillary pressure curve.

12. Monitor

resistance and production volume on a daily basis at each pressure

step.

13.

Dean Stark extract for final water saturation verification

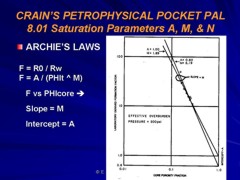

Cementation Exponent (M) from Special Core Data

Cementation Exponent (M) from Special Core Data

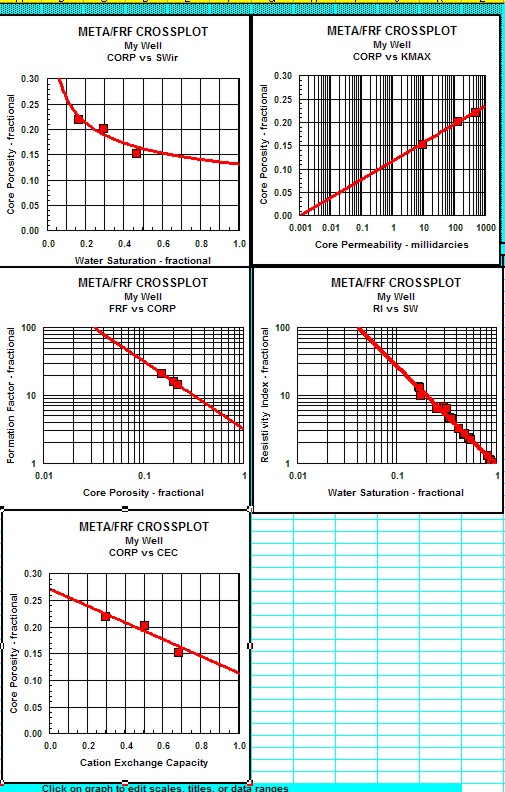

Measure

R0 and PHI on several core samples, preferably samples with a

range of porosity values, and calculate formation factor F. Plot

porosity vs lab measured formation factor on log-log axes. Fit

regression or eyeball line to data. Slope of line is M. Intercept

at PHIe = 1 is A. The line force-fitted through F = PHIe = 1.0

is called a "pinned" line. Some people prefer the pinned line but

most data sets do not support this approach. Strictly speaking,

the line must pass through F = 1 = PHIe, so the line must be non-linear

approaching this point on the graph. An example is shown below.

Find A and M from special core data (electrical properties

data) - M is slope of best fit line

(pinned or free regression - your choice), A is intercept at

PHIe = 1.0. Multiple samples with a range of porosity are best

for regression, but a single sample with the line pinned at PHIe

= 1.0 can also be used.

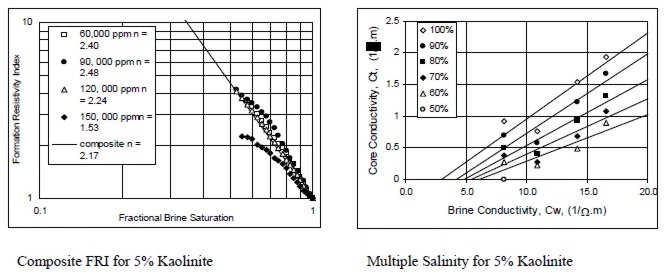

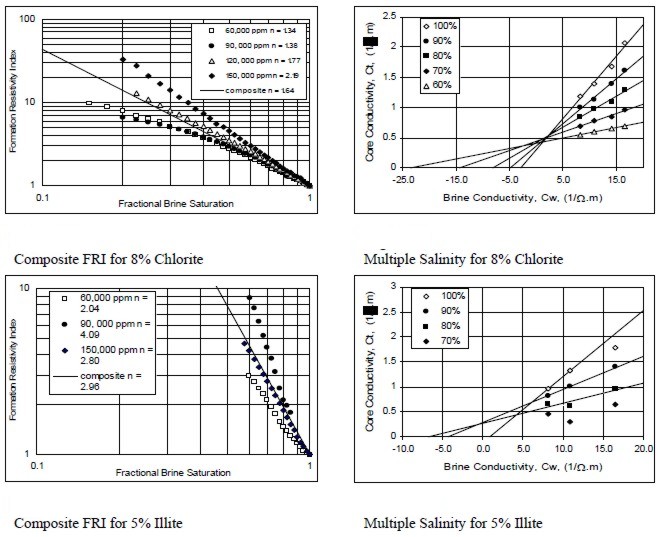

saturation exponent (N) from Special Core Data saturation exponent (N) from Special Core Data

Measure Rt

and calculate water saturation and resistivity index of a

core plug at various water saturations. Plot

saturation versus formation resistivity index on log-log axes. Draw line through the data

to intercept at SW = 1.0. The slope of this line

is N. Data from several wells may have to be combined to get a

reasonable fit, although the values from a single core plug may

suffice.

Find N from special core data (electrical properties

data). Slope is N and line must pass

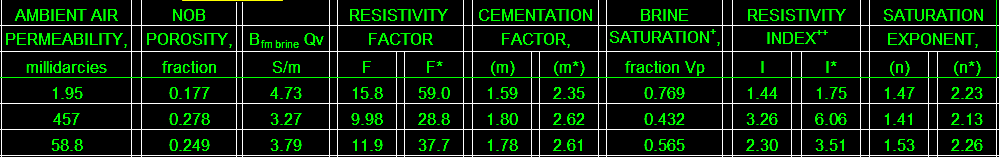

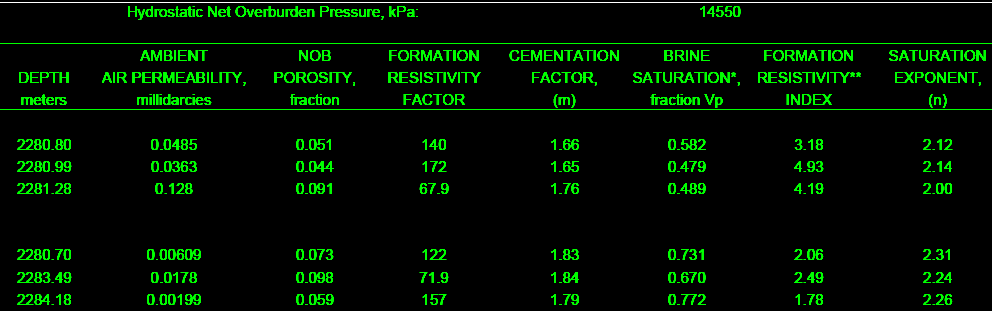

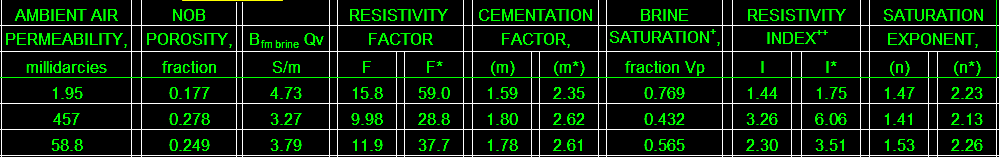

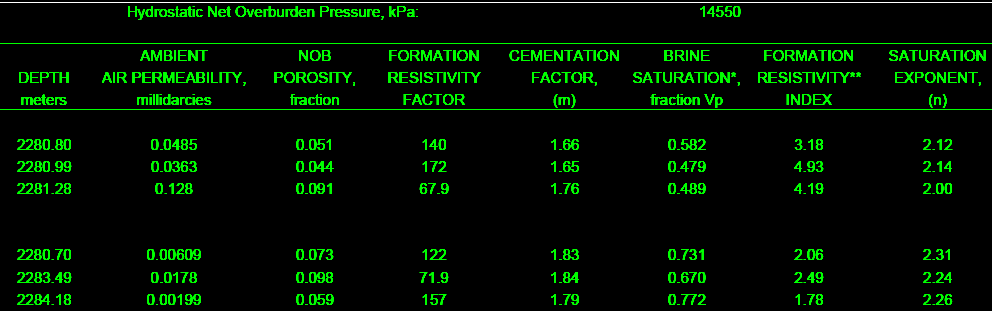

The final product: a table of F, M, RI, and N for use in the

appropriate water saturation equations. This example is from a

clean, moderately tight, dolomitic sandstone.

through Sw = 1.0 at RI = 1.0..

TYPICAL A, M, N

PARAMETERS:

TYPICAL A, M, N

PARAMETERS:

for

carbonates A = 1.00

M = 2.00

N = 2.00 (Archie Equation as first published)

for sandstone A = 0.62

M = 2.15

N = 2.00 (Humble Equation)

A = 0.81 M = 2.00 N = 2.00 (Tixier Equation -

simplified version of Humble Equation)

NOTE:

N is often lower than 2.0

For

quick analysis use carbonate values. Values for local situations

should be developed from special core data. Results will always

be better if good local data is used instead of traditional values,

such as those given above.

Asquith (1980 page 67) quoted other authors, giving values for A

and M, with N = 2.0, showing the wide range of possible values:

Average sands A = 1.45 M = 1.54

Shaly sands

A = 1.65 M = 1.33

Calcareous sands

A = 1.45 M = 1.70

Carbonates

A = 0.85 M = 2.14

Pliocene sands S.Cal. A = 2.45 M = 1.08

Miocene LA/TX

A = 1.97 M = 1.29

Clean granular

A = 1.00 M = 2.05 - PHIe

CATION EXCHANGE CAPACITY (CEC)

CATION EXCHANGE CAPACITY (CEC)

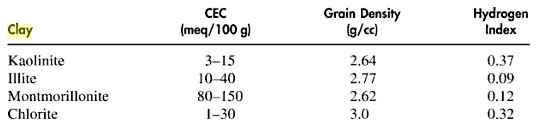

CEC is the quantity of positively charged ions (cations) that a

clay mineral or similar material can accommodate on its

negatively charged surface, expressed as milli-ion equivalent

per 100 g, or more commonly as milliequivalent (meq) per 100 g.

Clays are aluminosilicates in which some of the aluminum and

silicon ions have been replaced by elements with different

valence, or charge. For example, aluminum (Al+++) may be

replaced by iron (Fe++) or magnesium (Mg++), leading to a net

negative charge. This charge attracts cations when the clay is

immersed in an electrolyte such as salty water and causes an

electrical double layer.

The cation-exchange capacity (CEC) is

often expressed in terms of its contribution per unit pore

volume, Qv.

nbsp;

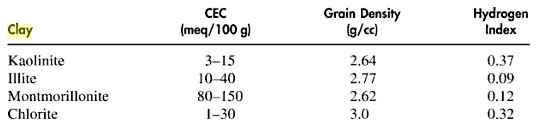

Typical range of CEC values for various clay

minerals

In formation evaluation, it is the

contribution of cation-exchange sites to the formation electrical

properties that is important. Various techniques are used to measure

CEC in the laboratory, such as wet chemistry, multiple salinity, and

membrane potential. Wet chemistry methods, such as conductometric

titration, usually involve destruction or alteration of a portion of the

core sample.

The multiple salinity and membrane

potential methods are more direct measurements of the effect of CEC

on formation resistivity and spontaneous potential.

Conductometric titration is a

technique for estimating the cation-exchange capacity of a sample by

measuring the conductivity of the sample during titration. The

technique includes crushing the end pieces of a core sample and

mixing it for some time in a solution like barium acetate, during

which all the cation-exchange sites are replaced by barium (Ba++)

ions. The solution is then titrated with another solution, such as

MgSO4, while observing the change in conductivity as the magnesium

(Mg++) ions replace the Ba++ ions.

For several reasons, but mainly

because the sample must be crushed, the measured cation-exchange

capacity may differ from that which affects the in situ electrical

properties of the rock.

ELECTRICAL PROPERTIES FROM MULTIPLE SALINITY or C0/Cw METHOD

ELECTRICAL PROPERTIES FROM MULTIPLE SALINITY or C0/Cw METHOD

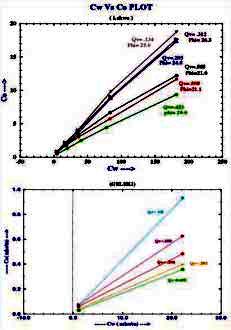

The C0/Cw, or multiple salinity

method, is

another technique used for the determination of the electrical

properties of a shaly core sample. The sample is flushed with brines

of different salinities, and the conductivity determined after each

flush. A plot of the conductivity of the sample (C0) versus the

conductivity of the brine (Cw) gives the excess conductivity caused

by clays and other surface conductors. Then, using a suitable model

(Waxman-Smits, dual water) it is possible to determine the intrinsic

formation factor F* and porosity exponent M*, and the cation-exchange

capacity.

In conventional core analysis for

porosity, the primary measurements are bulk density (DENS or RHOB)

and grain density (DENSMA or RHOG), which give:

5: PHIcore = 1.0 - (DENS - 1.0) / (DENSMA - 1.0)

Where:

PHIcore = porosity from conventional core analysis (fractional)

DENS = bulk density from core analysis (gm/cc)

DENSMA = grain density from core analysis (gm/cc)

Most literature claims that this porosity is the total porosity PHIt.

However, both DENS and DENSMA contain a contribution from clay bound

water, the resulting porosity is closer to effective porosity PHIe

than total porosity PHIt. If a Dean-Stark analysis is used, clay

bound water is driven off and core porosity is closer to total

porosity PHIt. So depending on the source of PHIcore, you may

actually be using PHIe or PHIt or something in between. PHIe is used

in the balance of this webpage.

The excess conductivity

caused by the clay is termed (B*Qv).

Qv is a function of CEC and B is related to the mobility of the clay

cations, and that is a function of the salinity of the water in the

pores (and thus a function of water resistivity): The excess conductivity

caused by the clay is termed (B*Qv).

Qv is a function of CEC and B is related to the mobility of the clay

cations, and that is a function of the salinity of the water in the

pores (and thus a function of water resistivity):

6:

B = 4.6 * (1 - 0.6 * exp (-0.77 / RW@25C))

7: Qv = 0.01 * CEC * DENS / PHIe

OR

7A: Qv = 0.01 * CEC * (1 - PHIe) * DENSMA / PHIe

Example crossplot of Qv versus

porosity

nbsp;

Where:

B = equivalent conductance of clay exchange cations at room temperature

(mS/meq)

Qv = cation exchange capacity per unit pore volume (meq/cc)

CEC = cation exchange capacity (meq/100gm)

RW@25C = formation water resistivity

converted to 77 degrees F or 25 degrees C

In producible shaly oil sands, Qv ranges up to about

1.0 meq/cc. Shaly sands with Qv > 1.0 are generally too tight to

produce. When porosity approaches 0.00, set Qv = 0.0.

Using the basic Archie definition

of formation factor F = R0 / Rw = Cw / C0, then

C0 = (1 / F) * Cw. Correcting this equation for the excess

conductivity (B*Qv), we get: Using the basic Archie definition

of formation factor F = R0 / Rw = Cw / C0, then

C0 = (1 / F) * Cw. Correcting this equation for the excess

conductivity (B*Qv), we get:

8: C0 = (1 / F*) * (B * Qv + Cw)

Rearranging eqn 8:

9: F* = (B * Qv + Cw) / C0

10: M* = -log(F*) / log(PHIe)

Example crossplot of M* versus Qv

Using the standard Archie model for resistivity index RI = Rt / Rw =

Cw / Ct and correcting for excess conductivity, we get:

11; RI* = C0 / (B * Qv + Ct)

12: N* = -log(RI*) / log(Sw)

Where:

C0: Conductivity of rock fully saturated with brine solution (mS/m)

Cw = conductivity of the brine (mS/m)

Ct = conductivity of the partially saturated rock (mS/m)

F* = formation factor for shaly sandstone

RI* = resistivity index for shaly sandstone

M* = cementation exponent

N* = saturation exponent

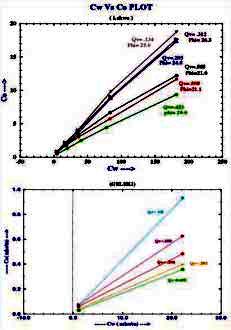

In the lab, the values of C0 and Cw are crossplotted as shown below.

The formation factors F* of the shaly sand is calculated as the

reciprocal of the slope of the linear best-fit regression

line through the higher salinity data points. The excess conductivity term B*Qv is equal to the value of Cw when C0 is zero.

At salinities below 10,000 ppm, the data may depart from the linear

best-fit line. which complicates the use of this method in fresh

water shaly oil sands in various parts of the world. SPE paper 29272

has a good explanation and possible solutions.

A standard log-log plot of formation factor F* versus porosity is

then made to illustrate the variations in M* (not shown).

Data may not fit a straight line as predicted by

the Archie model, and at low salinity the line will have a

distinctive curve to the left.

Example crossplots of multiple salinity C0 versus Cw lab results

for shaly sand samples

from "Validation of Shaly Sand Model using Electrical Core

Measurements in Low Resistive Reservoirs of Upper Assam" by I.K.Rai,

L.Yadav, B.S. Haldiya

nbsp;

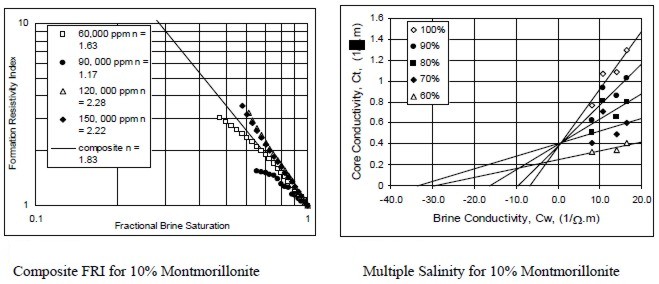

A crossplot of Ct versus C0 is also

made with data at various water saturations, as shown (below right).

The resistivity ratio RI* for each data point is then replotted on a

conventional RI vs Sw crossplot (below left), with the data grouped

by salinity. Because conductance of clay exchange cations B varies

with RW as in equation 6, the RI* varies with salinity and so does

N*.

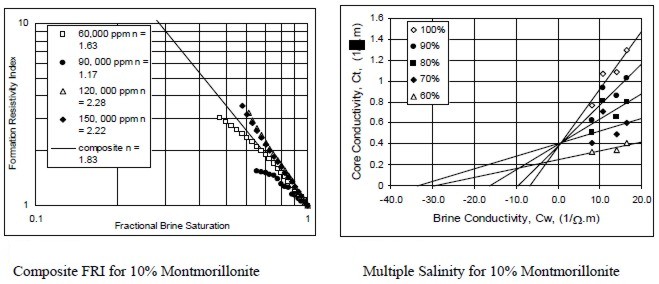

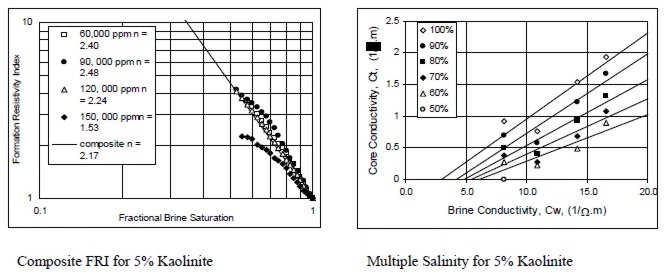

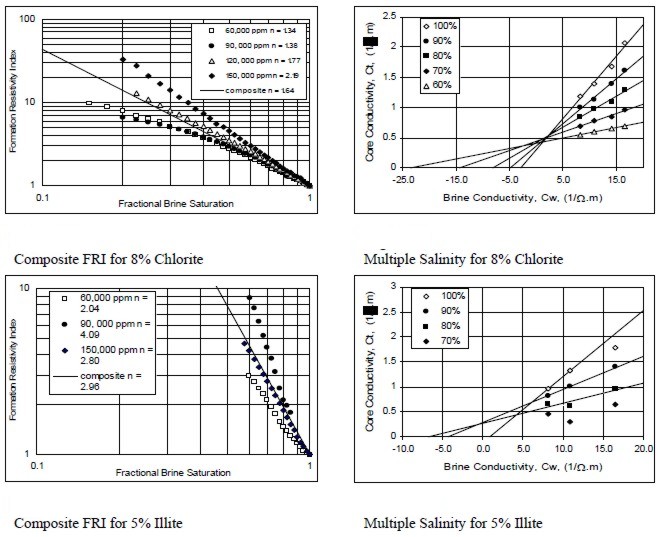

Examples of multiple salinity tests showing variations in

resistivity index (left) and Ct/Cw (right) for four common clay

types. Only the 100% Sw line (open diamonds) is a C0/Cw line.

The final product: a table of BQv, F, F*, M, M*, RI, RI*, N, and

N* for use in the appropriate water saturation equations.This

example is from a Cretaceous shaly sand in southern Alberta.

|

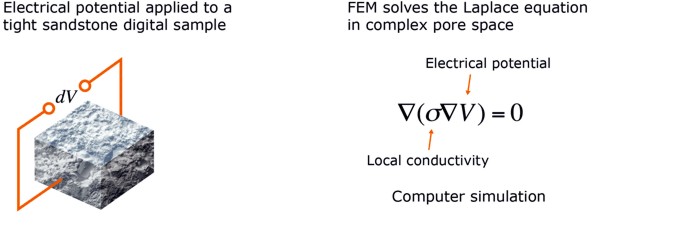

With

a micro CT scan image of pore size

distribution, software is employed using the finite element method (FEM) to

solve the Laplace equation for the

electric potential field inside a

digital sample for a specified potential

difference at the boundaries. The

electrical current field in the pores is

computed and then summed-up to obtain

the total current through the sample.

The effective conductivity of the sample

is simply the ratio of this current to

the potential drop per unit length.

Formation factor is then calculated as

the ratio of brine conductivity to the

calculated conductivity of the rock

sample. Source:

www.ingrainrocks.com.

With

a micro CT scan image of pore size

distribution, software is employed using the finite element method (FEM) to

solve the Laplace equation for the

electric potential field inside a

digital sample for a specified potential

difference at the boundaries. The

electrical current field in the pores is

computed and then summed-up to obtain

the total current through the sample.

The effective conductivity of the sample

is simply the ratio of this current to

the potential drop per unit length.

Formation factor is then calculated as

the ratio of brine conductivity to the

calculated conductivity of the rock

sample. Source:

www.ingrainrocks.com.

The excess conductivity

caused by the clay is termed (B*Qv).

Qv is a function of CEC and B is related to the mobility of the clay

cations, and that is a function of the salinity of the water in the

pores (and thus a function of water resistivity):

The excess conductivity

caused by the clay is termed (B*Qv).

Qv is a function of CEC and B is related to the mobility of the clay

cations, and that is a function of the salinity of the water in the

pores (and thus a function of water resistivity):  Using the basic Archie definition

of formation factor F = R0 / Rw = Cw / C0, then

C0 = (1 / F) * Cw. Correcting this equation for the excess

conductivity (B*Qv), we get:

Using the basic Archie definition

of formation factor F = R0 / Rw = Cw / C0, then

C0 = (1 / F) * Cw. Correcting this equation for the excess

conductivity (B*Qv), we get: