|

QUICKLOOK WELL LOG OVERLAYS

QUICKLOOK WELL LOG OVERLAYS

Most people

working in the oil industry just want to "look" at a log and

understand what the reservoir is all about. Even after years of

experience, this is difficult, especially when working on new or

unfamiliar areas. That's why specialists use fancy software and

take hours or days to generate results for the rest of the team.

However, there are things you can

do using your eyes and your logical brain power to gain some

understanding without the calculator or the chartbook.

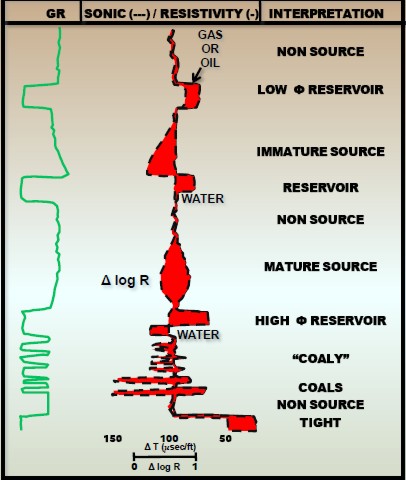

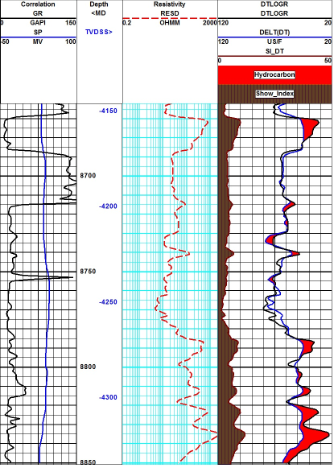

Lets

start with just 3 curves - the gamma ray (GR), resistivity, and

a porosity indicating log (a sonic log in this case) as shown in

the image below. The GR is

at the far left and the sonic is the left edge of the red

shading. The resistivity and sonic have been overlaid to make it

easier to see the shape of the two curves relative to each

other.

Basic Rule

"A": When GR (or SP) deflect to the left the zone is clean and

might be a reservoir quality rock. When GR deflects to the

right, the zone is usually shale (not a reservoir quality rock).

There are exceptions to this rule, of course.

Basic Rule "B": Porosity logs are

scaled to show higher porosity to the left and lower porosity to

the right. Clean and porous is good, so compare the GR to the

porosity log and mark clean+porous zones.

Basic Rule "C": Resistivity logs

are scaled to show higher resistivity toward the right. Higher

resistivities mean hydrocarbons or low porosity. Low resistivity

means shale or water zones. So clean+porous+high resistivity are

good. There are exceptions to this rule too.

Schematic drawing of a

resistivity-porosity overlay, showing the variety of rocks that

can show separation between the porosity and resistivity. Note

that the two curves "track" each other in water and non-source

shales.

The exceptions are what makes the

job interesting. There are low resistivity pay zones,

radioactive (high GR) pay zones, gas shales, oil shales, coal

bed methane, and low porosity zones that produce for years. Some

of these are shown in the illustration. See if you can figure

out the

logic behind each of the interpretations shown here before you

move on to the more formal rules.

The technique is called the

resistivity-porosity overlay. It has been in use since about

1962 when the first sonic logs showed up, concurrent with the

beginning of the logarithmic scale for resistivity log displays.

The overlay is created by tracing

or "overlaying" the deep resistivity curve (on a logarithmic

scale) on top of a porosity log (sonic, density, or neutron),

and shifting the resistivity log sideways until it lines up with

the porosity curve in an "obvious" water zone. That means that

the lowest resistivity values sit on top of the porosity curve

and higher resistivity values fall to the right of the porosity

curve. We then colour in the separation between the curves with

a red pencil, and perforate the zone for production.

If there is no obvious water

zone, we do the overlay using a nearby (non-source rock) shale

bed instead - less accurate but it works often enough. The

concept is widely used to identify source rocks. Some of these

are completed as unconventional reservoirs such as the Barnett

Shale (resistive shales).

SOME OVERLAY EXAMPLES

SOME OVERLAY EXAMPLES

Most overlays also show the SP and GR logs to aid

in correlation and to recognize cleaner rocks form shalier rocks.

Here are some examples.

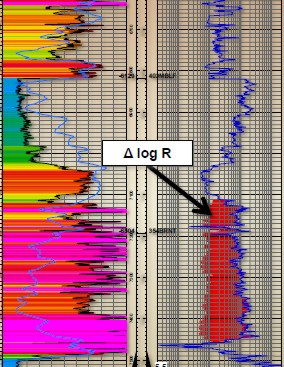

Sonic resistivity overlay showing separation in Barnett Shale, Texas,

labeled "ΔlogR" and shaded red. The high

resistivity interval is about 50% clay and 50% silt with 4 to 5%

porosity, with free gas and adsorbed gas. There is kerogen, as well

as gas, contributing to the high resistivity. The zone is also quite

radioactive , some of it due to clay but most of it due to uranium

carried by the kerogen.

Sonic resistivity overlay showing separation in Barnett Shale, Texas,

labeled "ΔlogR" and shaded red. The high

resistivity interval is about 50% clay and 50% silt with 4 to 5%

porosity, with free gas and adsorbed gas. There is kerogen, as well

as gas, contributing to the high resistivity. The zone is also quite

radioactive , some of it due to clay but most of it due to uranium

carried by the kerogen.

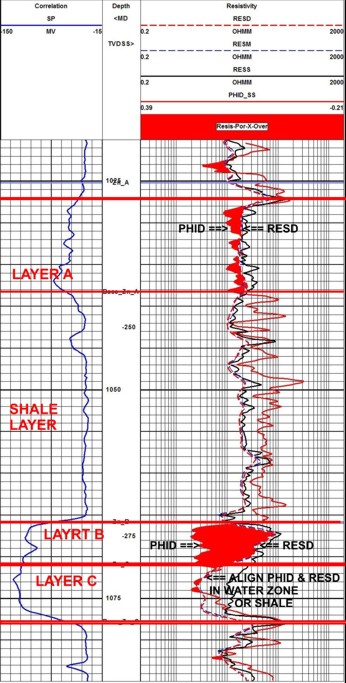

Raw logs showing resistivity porosity overlay. Red

shading indicates possible hydrocarbon zones. The density or

density porosity (solid red curve) is placed on top of the deep

resistivity curve (dashed red curve) Line up the two curves so

that they lie on top of each other in obvious water zones. If

there are no obvious water zones, line them up in the shale

zones. If the porosity curve falls to the LEFT of the

resistivity curve, as in Layers A and B, hydrocarbons are

probably present.

Because of poorly chosen shift

criteria, it is possible to create too much or too little

separation between the resistivity and porosity curves. This is

where the logic comes into play. If the two cureves are

"tracking" each other, then the zone is wet. Tracking means the

two curves roughly parallel each other, like railroad tracks. If

the two curves are roughly a mirror image of each other, then

they are not tracking, and separation is expected. Adjust the

shift to make this happen. The quantity of the separation is a

measure of the quality of the hydrocarbon show.

QUANTIFYING THE OVERLAY CONCEPT

QUANTIFYING THE OVERLAY CONCEPT

The

resistivity porosity overlay was, and still can be, made by

tracing one curve on the other, or by using a film copy of one

curve laid on the paper copy of the other. Back in the day, we

used light tables or windows so we could see through the paper.

When I traveled to the Arctic, I built a page sized light table

in my brief case. The remaining space held pencils, straight

edge, calculator, QC and analysis forms, spare socks, and

underwear. The

resistivity porosity overlay was, and still can be, made by

tracing one curve on the other, or by using a film copy of one

curve laid on the paper copy of the other. Back in the day, we

used light tables or windows so we could see through the paper.

When I traveled to the Arctic, I built a page sized light table

in my brief case. The remaining space held pencils, straight

edge, calculator, QC and analysis forms, spare socks, and

underwear.

Today, we can make these overlays

on most professional petrophysical software packages or even

with a spreadsheet program.

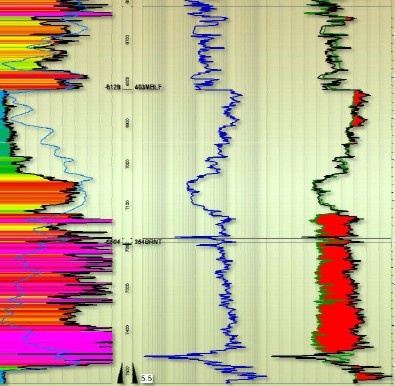

Original sonic

log (black curve) and calculated resistivity curve (shaded red)

showing potential source rock or, as

in this case, a gas shale (Barnett)

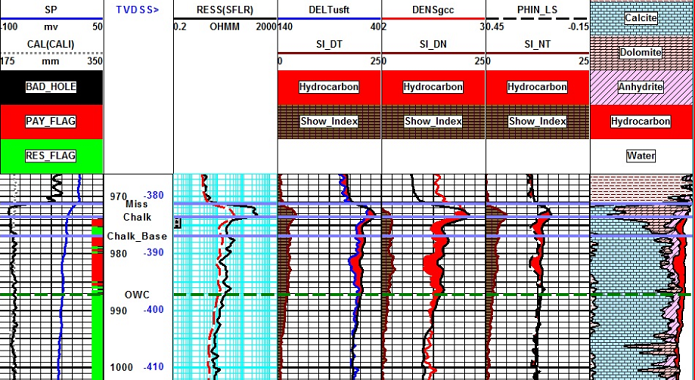

Example of a resistivity

porosity overlay looking for bypassed pay in a limestone. The

resistivity has been transformed into a sonic log by appropriate

scaling (see below). Red shading indicates possible

hydrocarbons. The brown shaded curve is a "Show Index" - higher

values are good news.. Example of a resistivity

porosity overlay looking for bypassed pay in a limestone. The

resistivity has been transformed into a sonic log by appropriate

scaling (see below). Red shading indicates possible

hydrocarbons. The brown shaded curve is a "Show Index" - higher

values are good news..

Resistivity porosity overlay

for sonic, density, and neutron (shaded red) and Show Index for

each (shaded brown) The full blown lithology porosity track on

the right shows a typical computerized analysis. More detailed

porosity, water saturation, and permeability curves would

normally be presented. Here, the objective is to locate the oil

water contact in a low permeability regime with residual oil

below the contact. The transformed resistivity sits on the

porosity curve at the base of each track (water zone) and also

in the shale zone above the oil (on sonic and neutron only).

QUANTIFYING THE OVERLAY

QUANTIFYING THE OVERLAY

The

illustrations in the previous Section were generated by

appropriate mathematical transforms that convert the resistivity

log into sonic, density, and neutron values. This is easily done

on most petrophysical software by adjusting the horizontal scale

of the resistivity log and placing the curve in the porosity

track or vice versa. A more useful approach is to code a few

custom equations into the User Defined Equation module of your

software. This allows you to run several dozen wells in a day to

see which ones might have bypassed pay. The equations you need

are:

1: DTlogR = DT1 -- DT2 * log(RESD)

2: SI_DT = 5 * (log(RESD / RSH) + 0.02 * (DTC --

DTCSH)

3: DNlogR= DN1 -- DN2 * log(RESD)

4: SI_DN = 5 * (log(RESD / RSH) - 2.5 * (DENS --

DENSSH))

5: NTlogR = NT1 -- NT2 * log(RESD)

6: SI_NT = 5 * (log(RESD / RSH) + 4.0 * (PHIN --

PHINSH))

Where:

XXlogR = resistivity log scaled into compatible porosity log units

SI_XX = show index based on the separation between the porosity log curve

and the transformed resistivity

Default Values for Carbonates:

RSH = 4.0, DTCSH = 60, DENSSH = 2.47, PHINSH = 0.15

DT1 = 82, DT2 = 22, DN1 = 2.10, DN2 = --0.45, NT1 = 0.22, NT2 =

0.09

The

parameters assume DTC is in usec/ft, DENS is in g/cc, and PHIN

is decimal fraction porosity.

Shale base lines need to be adjusted so that the Show Index is

near zero in water or shale zones.

DT1, DN1, NT1

are adjusted so that the resistivity porosity separation is near

zero in shale or water zones.

DT2, DN2, NT2 are amplitude scale factors and seldom need to be

changed.

Default shale base lines for sand

shale sequences will be considerably higher.

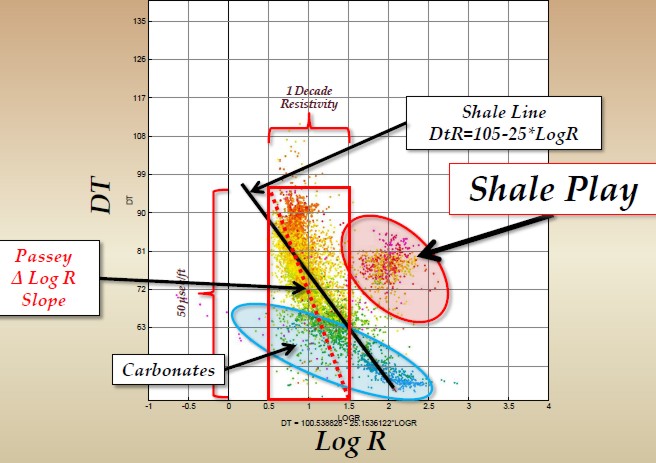

The best way to find the

parameters for scaling resistivity into porosity units is to

crossplot logarithm of resistivity on the horizontal axis and

the porosity indicating log values on the vertical axis. You

need to include enough interval to see non-source rick "normal"

shales and some of the potential reservoir intervals. The data

points along the southwest edge of the data show the normal

trendline. Data points for reservoir or source rock peel off

toward the northeast of the plot area.

Sonic versus logarithm of resistivity (DTlogR) Crossplot showing

non-source rock trend line and reservoir or source rock clusters of data. The

equation of the non-source rock line is DTlogR = 105 - 25 log(RESD) for

this Barnett Shale example (DT1 = 105 and DT2 = 25). Similar plots

can be made with density or neutron data on the vertical axis..

|