Petrophysical Training

Licenses

|

HOW TO GET STARTED

HOW TO GET STARTED

The 20 or so articles in this Chapter comprise a “Reader’s

Digest” version of Crain's Petrophysical Handbook, specially

designed for Newbies to the Science of Petrophysics in the

petroleum and mining industries. Because many professional

and technical people grow-up in diverse career paths,

Newbies could be anyone: a CEO, CFO, geoscientist, engineer,

geotech, student or instructor looking to understand what

petrophysics can do for their company or career.

Petrophysics, literally the Physics of Rocks, is the

foundation of geology, geophysics, and petroleum / mining

engineering. We all rely on the Shared Earth Model, which is

described by the integration of petrophysics with all these

other disciplines. In fact, any resource exploration or

development project that ignores petrophysics is destined to

be inefficient, or worse, doomed to failure.

If you might be displaced by the

energy transition, or are looking for a long-term career

path, or a university specialty that could lead to an

interesting and rewarding life, petrophysics in its broadest

sense may suit you.

Let's start with the basics of oil and gas and later we'll

do the same for the mining industry.

SOME PETROLEUM BASICS

SOME PETROLEUM BASICS

Petrophysics is mainly used in petroleum exploitation, but also

in defining mining and ground water resources.

To understand petrophysics, you need to understand rocks and the

fluids they contain, how the earth's surface and subsurface

change shape, and how pressure, temperature, and chemical

reactions change rocks and fluids over eons of time. That's a

tall order.

Rocks

are formed in several ways, but usually end up as moderately flat

layers, at least initially (mountain building comes later). As

successive layers are laid on top of each other, the Earth

builds a sequence of rocks with varying physical properties.

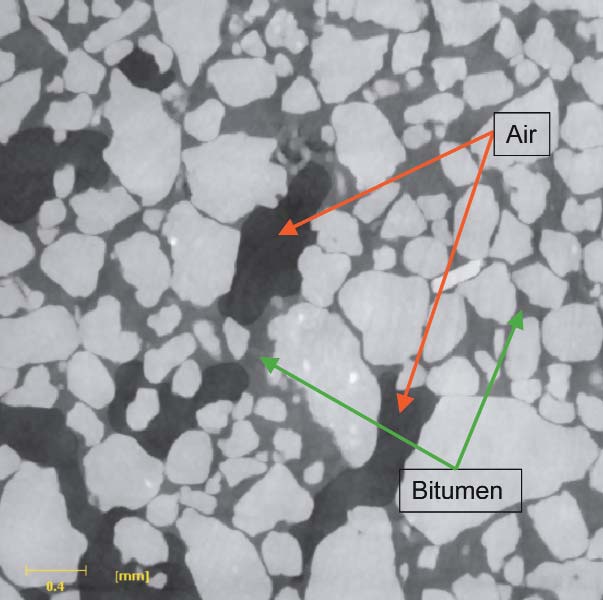

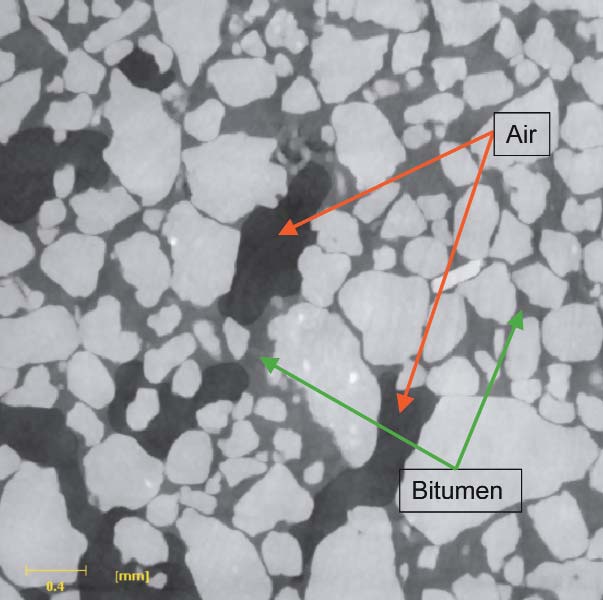

Some layers will have open spaces, called pores or porosity,

that contain fluids (water, oil, or gas). A rock on Earth with

porosity cannot be "empty" -- they must contain something, even

if it is only air. Rocks

are formed in several ways, but usually end up as moderately flat

layers, at least initially (mountain building comes later). As

successive layers are laid on top of each other, the Earth

builds a sequence of rocks with varying physical properties.

Some layers will have open spaces, called pores or porosity,

that contain fluids (water, oil, or gas). A rock on Earth with

porosity cannot be "empty" -- they must contain something, even

if it is only air.

Microphotograph of a rock -- dark blue colour is the porosity

where Microphotograph of a rock -- dark blue colour is the porosity

where

oil, gas, and water can be held inside the rock.

Think of a porous rock as similar to a

huge sponge full of holes that can soak up fluids. Although we

often talk about "oil pools", these are not tanks of oil

underground -- they are porous rocks. The porosity, or quantity

of open space relative to the total rock volume, can range from

near zero to as much as 40%. Obviously, higher values of this

physical property of a rock are good news.

Some

rocks have very little porosity and do not hold much in the way

of fluids. These are often called "tight" rocks. Both tight and

porous rocks can contain animal and plant residue that are

ultimately transformed into hydrocarbons such as coal, oil, or

natural gas that we can extract and use to power vehicles and

heat our homes. As the plant and animal residues mature into oil

or gas, they may migrate through porosity or natural fractures

in the rock until trapped by a non-porous rock structure.

Sometimes a rock only sources itself or an adjacent porous rock,

so little migration occurs. Some

rocks have very little porosity and do not hold much in the way

of fluids. These are often called "tight" rocks. Both tight and

porous rocks can contain animal and plant residue that are

ultimately transformed into hydrocarbons such as coal, oil, or

natural gas that we can extract and use to power vehicles and

heat our homes. As the plant and animal residues mature into oil

or gas, they may migrate through porosity or natural fractures

in the rock until trapped by a non-porous rock structure.

Sometimes a rock only sources itself or an adjacent porous rock,

so little migration occurs.

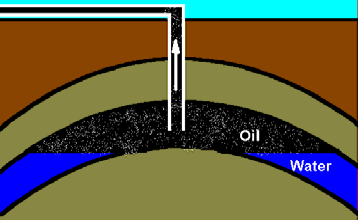

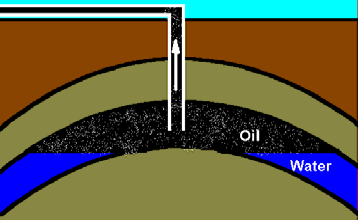

An anticline, the simplest form of petroleum trap

Rocks that are capable of holding hydrocarbons in economic

quantities are called reservoir rocks. Rocks in which the plant

and animal residue has not been fully converted to useful

hydrocarbons are called source rocks. Some rocks are both source

and reservoir; others are barren of hydrocarbons, and some

others may act as the trapping mechanism that keeps hydrocarbons

from migrating to the surface and escaping.

A trap is what keeps oil and gas in the rocks until we drill

wells to extract the hydrocarbons. Coal, being a solid, doesn't

need a trap to be kept in place.

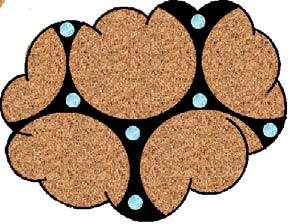

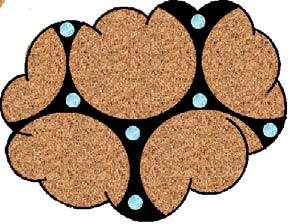

Reservoirs

that contain oil or gas also contain water. The quantity of

water relative to the porosity is called the water saturation.

In the illustrations, the brown colour is solid rock grains and

the space around the grains is the porosity. The black colour is

the hydrocarbon and the white is the water, which forms a thin

film coating the surfaces of each rock grain. This is a

water-wet reservoir (left). In an oil-wet reservoir, the black

and white colours are reversed (right). Reservoirs

that contain oil or gas also contain water. The quantity of

water relative to the porosity is called the water saturation.

In the illustrations, the brown colour is solid rock grains and

the space around the grains is the porosity. The black colour is

the hydrocarbon and the white is the water, which forms a thin

film coating the surfaces of each rock grain. This is a

water-wet reservoir (left). In an oil-wet reservoir, the black

and white colours are reversed (right).

Finding and evaluating the economics of such reservoirs is the

job of teams of geoscientists and engineers in petroleum and

mining companies. A petrophysicist, or someone playing this

role, will be part of that team.

Once a useful accumulation has been found, drilling, completion,

and production engineers take over to put wells on stream. Oil

production may initially flow to surface due to the pressure in

the reservoir. Some oil pools do not have enough pressure to do

this and need to be pumped. Depending on the reservoir drive

mechanism, some wells that start flowing will later need to be

pumped. Water may be produced with the oil. It is separated and

disposed of by re-injection into a nearby unproductive reservoir

layer. You can't just dump the water in the nearest swamp.

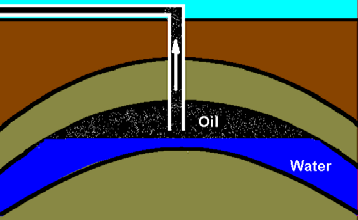

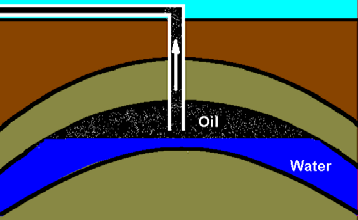

Aquifer Drive -- Before ... and After some production

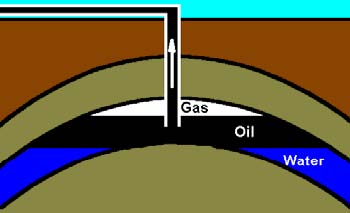

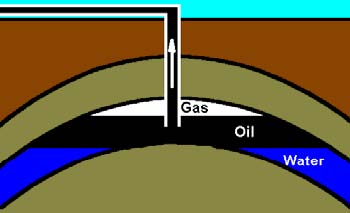

Gas Cap Drive

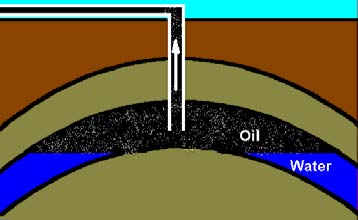

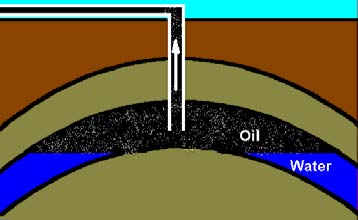

Gas Expansion Drive

An aquifer drive mechanism usually maintains the reservoir

pressure for some time but may drop off gradually. Recovery factors vary from 30 to 80% of the oil in place. The oil water

contact rises as production depletes the oil. A gas cap drive

pushes oil out as the gas expands. Recovery factor is similar to

aquifer drive. There may or may not be some aquifer support.

The gas oil contact drops as the oil is depleted. Gas expansion

reservoirs do not have aquifer or gas cap support. Gas dissolved

in the oil expels oil into the well bore because the pressure at

the well bore is below the reservoir pressure. Recovery factor is

awful - usually less than 10%, but this can be improved to maybe

20% by injecting water nearby to increase or maintain the

reservoir pressure. Water floods, carbon dioxide injection, and

re-injection of produced gas or water can be used in nearly any

reservoir to improve recovery efficiency.

Gas wells do not need pumps, but if they also produce water, a

special process called artificial lift is used to get the water

out. That water is also disposed of legally.

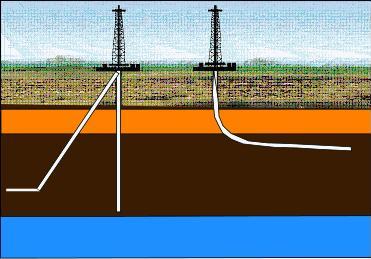

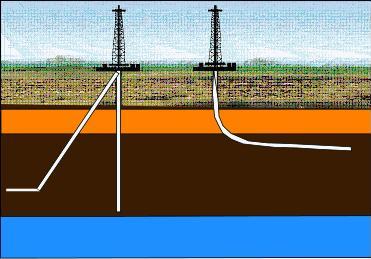

The

economics of a reservoir varies with improving technology.

Bypassed reservoirs, discovered and ignored years ago, are now

economic due to technical improvements in drilling practices and

reservoir stimulation techniques. Horizontal wells and deep

water drilling are now common. The use of heat or steam to assist

production of heavy oil or bitumen, and multi-stage hydraulic fracturing to

stimulate production in tighter reservoirs are relatively new

techniques and relatively economic today. Obviously the specific

price of oil or gas after delivery to the customer plays an

important role in how much effort can be expended to recover oil

and gas from underground. The

economics of a reservoir varies with improving technology.

Bypassed reservoirs, discovered and ignored years ago, are now

economic due to technical improvements in drilling practices and

reservoir stimulation techniques. Horizontal wells and deep

water drilling are now common. The use of heat or steam to assist

production of heavy oil or bitumen, and multi-stage hydraulic fracturing to

stimulate production in tighter reservoirs are relatively new

techniques and relatively economic today. Obviously the specific

price of oil or gas after delivery to the customer plays an

important role in how much effort can be expended to recover oil

and gas from underground.

The next section describes how the oil and gas industry will

handle the energy transition. Things will change, but the oil

and gas industry aren't going anywhere anytime soon. In 2023,

the Indian government ordered 500 new jumbo jetliners with a

lifespan of about 50 years. Somebody somewhere has to

supply the fuel.

FUTURE OF OIL AND GAS

FUTURE OF OIL AND GAS

Climate change is REAL and our use of oil and gas as a fuel needs to

change now to reduce CO2 emissions. Government

agencies have set aspirational goals to reduce emissions by some

arbitrary amount by some equally arbitrary date. But there is no

detailed roadmap to achieve the goals. How many electric

furnaces are needed to replace oil and gas home heating? Ditto

automobiles, delivery and transport trucks, tractors and

harvesters, ocean liners, container ships, ferries. Ditto trains, planes??? Ditto oil, gas, and coal fired power plants. Plus the

old infrastructure has to be maintained while the new is put into

place.

The quantities and costs are colossal for a world approaching 8

billion people.

However, oil and gas

will never disappear. Even if we electrify everything

possible, it still needs lubrication, paint, and insulated

wires. Solar panels are 50% plastic, so is your food packaging.

Except for cotton and wool, all your clothes are made from

petrochemicals. Most of your house is too: carpets, cupboards,

counter tops, siding, roofing, flooring, glue-lam beams, window frames, doors,

tubs and shower surrounds.... Don't forget computers, internet

servers, smartphones...tires for all those electric cars and trucks, and asphalt

pavement to run them on.

There are no economic alternatives unless you like living in

caves, so use of plastics and the oil and gas needed to make them have a long

life expectancy. We do need to stop burning them as fuels- there

are alternatives for that!!

So we just need to get smarter about extracting, refining, an

using oil and gas. Are you up to the challenge?

petrophysiCS and the Mining industry

petrophysiCS and the Mining industry

For this article, we are expanding the definition of

petrophysics to include the exploration methods performed on

or near the surface to locate potential ore bodies, using

all the physical principles we remember from our oil field

well logging experience. Another article covering borehole

logging in the mining environment is located

HERE.

But first, a little background to set the stage. A 2023

International Energy Agency (IEA), stated that “to reach

net-zero emissions by 2050, we need to be producing SIX

times the current global output of minerals just to build

the turbines, transmission lines, batteries, and other items

essential for low-carbon energy infrastructure. Instead, we

are mining less than we did in 2019. A 2020 Pan-Canadian

Geoscience Strategy report suggested that “a strategy was

needed to develop next generation geoscience knowledge and

tools to efficiently target higher-grade or deeper deposits,

with the ultimate goal being a mine of the future that

produces zero waste”.

Zero waste may be a bit of a stretch. Regardless, new mines

are urgently needed and we already have the tools, and the

petrophysicists and other geoscientists to use them. There

are a surprising number of tools and analysis techniques

available. No single one is a “magic-bullet, although some

combinations may come close.

The first Secret to Success is to choose the appropriate

tools and integrate the results to gain the best possible

understanding of the potential ore body. The second is to

combine the talents of both mining and

petroleum geoscientists to encourage collaborative and

innovative solutions to the search for critical minerals.

The “Petro” in Petrophysics means

“rock”, not “petroleum”! The right kind of rock is what

mining engineers, management, and shareholders are looking

for. It is time to integrate all our petrophysical /

geoscience skills to find those deeper prospects we know

must be out there. Our World depends on our success.

SOME

MINING BASICS

SOME

MINING BASICS

Many metals are found in the form of massive sulphide ore

bodies on or below the surface of the Earth. A massive

sulphide deposit is defined as an accumulation of sulphide

minerals which are normally composed of at least 40% to 100%

sulphide minerals, bounded on all sides by rock with little

or no sulphide minerals. Many deposits have a substantial

component of vein-like sulphide mineralization, called the

stringer zone, mainly in the footwall strata. A typical ore

body is 1 to 5 million tonnes of rock. Massive sulphides can

be hosted in volcanic or sedimentary rocks.

The main sulphide minerals are:

iron pyrite FeS2 (fool's gold),

pyrrhotite Fe(1-x)S (x=0 to 0.2),

troilite (magnetic pyrite) (Zn,Fe)S,

galena (PbS), and

chalcopyrite (Cu,Fe)S2.

Many mines produce more than one base metal and often one or

more precious metal, like silver and gold. Some more exotic

minerals can be found in the tailings of older mines.

A sulphide ore body may be found with multiple layers or

lenses, and are denser and more conductive than the

surrounding rock. These properties lead to numerous surface

and borehole geophysical techniques that can be used to

locate, and to some degree, quantify sulphide deposits. Core

assay data is the main measure of ore grade, and grade

thickness maps are the usual method of visualization; 3-D

display software is also common.

Many existing mines are shallow, and as these are depleted,

deeper exploration is now required. Some older mines can be

expanded to previously unknown deeper zones using modern

exploration methods. The Kidd Creek mine in Timmins, Ontario

is the largest massive sulphide deposit in the World, and

also the deepest at 2900+ m. produces zinc, copper, and

silver.

Gangue (pronounced “ɡćŋ” or “gang”) is the commercially

worthless material that surrounds, or is closely mixed with,

a wanted mineral in an ore deposit. It is distinct from

overburden (waste rock or soil) displaced during mining,

without being processed, and from tailings, which is rock

already stripped of valuable minerals by some form of ore

processing technique.

The separation of valuable minerals from gangue minerals is

known as mineral processing, mineral dressing, or ore

dressing. It is a necessary, and often significant, aspect

of mining. It can be a complicated process, depending on the

nature of the minerals involved.

borehole logging IN the Mining ENVIRONMENT

borehole logging IN the Mining ENVIRONMENT

For

clarity, we will refer to logs run for the mining industry as

“borehole logs” and those for the oil and gas industry as “oilfield

logs” or “well logs”, even though the guiding physical principles

are the same for both.

It is difficult to make direct comparisons between oilfield logging

tools and borehole tools. Many contractors developed their own

tools and probes are often customized to suit a particular

exploration challenge. The result is less standardization. Some

contractors offer a complete range of services from data acquisition

to mapping, while others specialize in smaller projects, by

supplying tool rentals. Happily, many of the borehole log names are

well-known to the oilfield log analyst, as the measurement

principles are the same. Acoustic, gamma ray, spectral gamma ray,

density, neutron and electrical logs are common to both industries.

In general, borehole tools are smaller and have reduced temperature

and pressure ratings (eg., 20 mPa and 80 degC) compared to oilfield

tools (100 mPa and 150 degC). However, many standard oilfield tools

are available in slim-hole versions and are quite suitable for

mineral borehole logging. A typical slim-hole gamma ray tool is just

42.9 mm (1-13/16 in) in diameter and approximately a meter long,

compared to a mineral service contractor’s GR tool at 38 mm diameter

and length of 0.63 meters.

There is a striking difference in scale between borehole logging

operations for mining, and that for petroleum. Mining drill-rigs

are typically portable (even heli-portable), and boreholes are

drilled to recover core or, in the case of reverse circulation (RC)

drilling, to recover samples. Boreholes can be blasted or drilled,

with logging equipment typically consisting of 3 components: a data

acquisition system to collect data from the downhole probe, a winch

to deploy the probe into the borehole, and the downhole probe

itself, which might be standalone or stackable.

borehole logging and coring Programs

borehole logging and coring Programs

The primary

logging measurements would be one or more of the following:

electrical conductivity (or resistivity), magnetic susceptibility,

natural gamma radiation (total and spectral), acoustic velocity (or

travel time), bulk density, and more recently, induced gamma ray

spectroscopy to identify particular metallic elements in the host

rock.

Specialty logs such as magnetic susceptibility, induced

polarization, or high resolution temperature logs may be used as

well.

Terraplus in Canada, offers auxiliary equipment such as video

inspection systems, borehole geophones, and hydrophone arrays, plus

ground penetrating radar antennas for single hole investigation and

cross-hole tomography. In the USA, Century Geophysical, among

others, provides a wide variety of tools for the mining industry.

The service providers are usually local contractors or the mining

company itself.

Geological Survey of

Canada and the US Geological Survey have

also developed their own logging tools, mostly used in mineral

reconnaissance surveys.

The mining

industry relies heavily on coring, core description, and lab work

for its geotechnical and geomechanical logs. Very detailed

lithology, stratigraphy, and structure are annotated on these logs,

as well as detailed notes on grain size, texture, and rock fabric.

This information is entered into 3-D modeling software. Rock

strength, discontinuities, faults, and fractures are carefully

mapped into the model. Borehole logs and core photos are added to

complete the 3-D display.

The model is constantly updated throughout the feasibility, design,

development, operational, and expansion phases of a mines long

lifetime. The integrity of the mine and the safety of the workers

depend on the accuracy of this model. No shortcuts allowed!

The coring and logging procedures described above are also used to

study geomechanical properties for dams, tunnels, highways,

foundations, and many other large construction projects.

BASIC PETROPHYSICS BASIC PETROPHYSICS

"Last week, I couldn't spell Petrophysicist. Now I are one."

That describes me in 1962 as I moved from Montreal to Red Deer,

Alberta to run well logs for a company called Schlumberger. The

word petrophysics had been coined 12 years earlier by a

geologist named Gus Archie and it wasn't used much back in the

day. Lately it has attained a certain cachet, denoting a professional

level career path.

What is a "well log" you ask. It is a record of measurements of

physical properties of rocks taken in a well bore, usually

drilled for oil or gas, but possibly for ground water or

minerals. Think of a ship's log. The first record of such a log

dates back to 1846 when Lord Kelvin measured temperature

versus depth in water wells in England, from which he deduced

that the Earth was 7000 years old. The fact that he was wrong is

not important. Log analysis is an imperfect science.

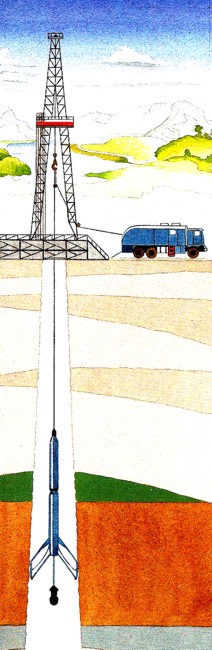

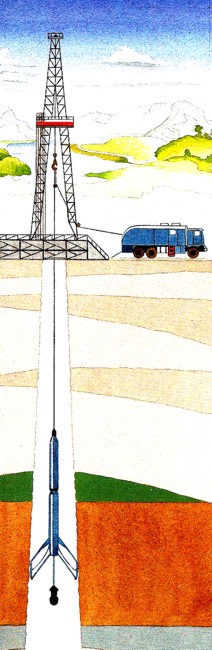

Illustration of a wireline logging job: logging truck with

computer cabin, cable and winch (right), cable strung from

winch into drilling rig derrick and lowered into bore hole, with

logging tool at the end of the cable. Logs are recording while

pulling the tool up the hole. Logs can also be run with special

tools located at the bottom of the drilling string, or

conventional tools can be conveyed on coiled tubing or drill

pipe

The first logs for oil field investigation were run by the

Schlumberger brothers, Marcel and Conrad, in 1928 in

Pechebron, France. Soon, the service migrated to North and South

America, Russia, and other locations in Asia. At that time, the

only measurement that could be made was of the electrical

resistivity of the rocks. High resistivity meant porous rock

with oil or gas, or porous rock with fresh water, or tight rock

with very low porosity. Low resistivity meant porous rock with

salty water or shale. Take your pick. Local knowledge helped.

One virtue of the well log was that the top

and bottom of each rock layer could be defined quite accurately.

When the log and depths were compared to the rock sample chips

created by the drilling process, a reasonable geological

interpretation might be possible, but was far from infallible.

By 1932, the spontaneous potential (SP) measurement was added.

The analysis rules expanded: low SP meant shale, or tight rock,

or fresh water. High values meant salt water with or without

oil or gas in a porous rock. The resistivity could then be used

to decide on water versus hydrocarbons. Perfect. Except there

were lots of shades of grey and the SP was not always capable of

defining anything.

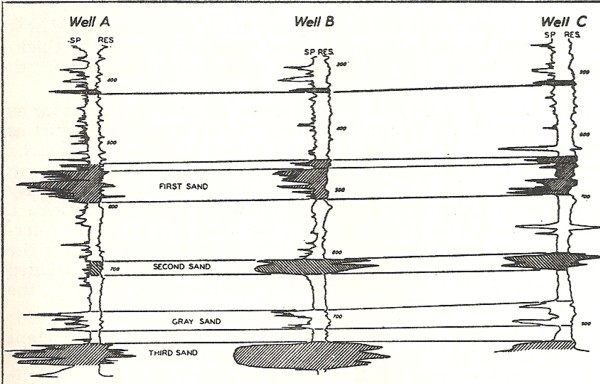

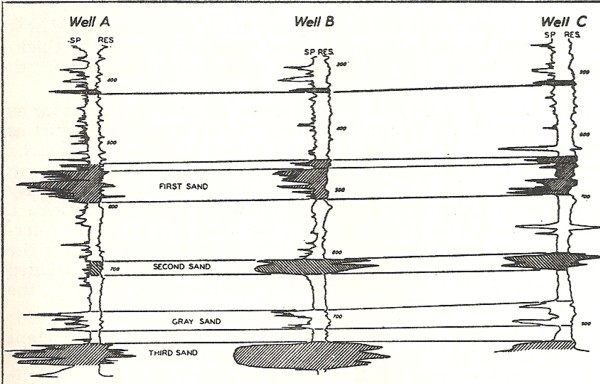

Logs from 1932 in Oil City-Titusville area, Pennsylvania, the

location of Edwin Drake's "First Oil Well" (in the USA - 6

other countries had oil wells predating this one). His well was only 69

feet deep, so it penetrated just to the top of these logs, which

found deeper and more prolific reservoirs.

Each pair of curves represents the measured data versus depth for

one well. The SP is the left hand curve of each pair; deflections to

the left (shaded) show porous rock. The resistivity is the curve on

the right of each pair. Deflections to the right (shaded) show high

resistivity, and when combined with a good SP deflection, indicate

oil zones. Some good quality rocks in this example do not have high

resistivity and are most likely water bearing.

The gamma ray log appeared in 1936. The rules

were easy: low value equaled porous reservoir or tight rocks.

High values were shale. It said nothing about fluid content.

By 1942, Gus Archie had defined a couple of quantitative methods

that turned analysis into a mathematical game, instead of just

some simple rules of thumb. His major work established a

relationship between resistivity, water saturation, and

porosity. If we knew porosity from rock samples measured in the

lab, and a few other parameters, we could calculate water

saturation from the resistivity log values. This was really new

news.

He even attempted to calculate porosity from the resistivity

log. This worked in high quality (high porosity) reservoirs but

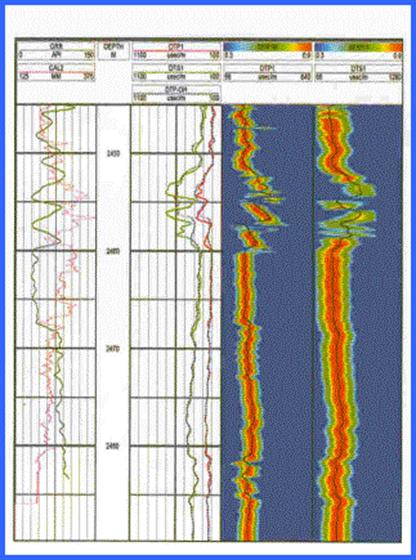

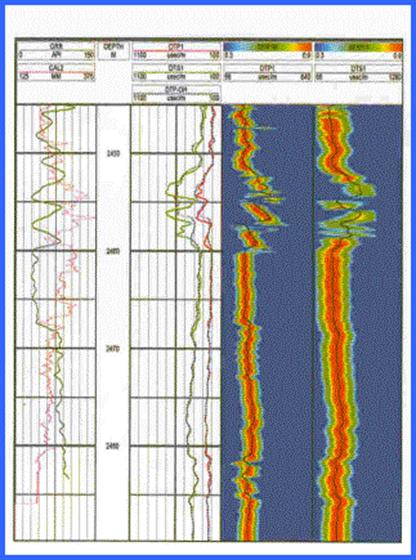

had problems in low quality rocks or heavy oil with gamma ray

and caliper curves (far left), shear and compressional sonic travel

time curves (middle) and sonic waveform image log (right).

Depths are shown in the narrow track next to the gamma ray

curve.

This is an example of a modern sonic log

This is an example of a modern sonic log

Just after 1945, a method that investigated the response of

rocks to neutron bombardment became available. The neutron log

was the first porosity indicating well log. High values meant

low porosity or high porosity with gas. Low values meant high

porosity with oil or water, or shale. Add the gamma ray log, SP,

and resistivity and again the world was perfect, except for all

those shades of grey. Calibrating the response to porosity

depended on a lot of well bore environmental parameters (hole

size, mud weight, temperature) so it was not terribly accurate.

It wasn't until 1958 that the measurement of the velocity (or

travel time) of sound through rocks in a well bore was achieved.

It turned out that the travel time was a linear function of

porosity and a few other factors.

Shortly after 1960, another

porosity indicating log appeared that measured the apparent

density of the rocks. Porosity was a linear function of density

-- higher density meant lower porosity.

Both sonic travel time

and density as measured by these logs could be transformed into

moderately accurate porosity values, using the gamma ray to

discount shale, and the resistivity to distinguish between

salty water and oil. Fresh water was still a problem and gas

zones could only be located if a neutron log was also run.

This was the state of petrophysics when I entered the scene in

1962. The rules were obvious, the

math was easy. And running the logging tools into the well bore

meant lots of travel. I loved the job. There were no computers

on every desk, calculators were bigger and heavier than

typewriters, so the quantitative work was done with pencil and

paper or sliderule. Anybody know what a sliderule is?

Later, with sidetracks into seismic data processing, reservoir

engineering, project management, and seismic data center

management, I finally noticed that petrophysics was the underlying

foundation of much of geology, geophysics, and reservoir

engineering. Later, with sidetracks into seismic data processing, reservoir

engineering, project management, and seismic data center

management, I finally noticed that petrophysics was the underlying

foundation of much of geology, geophysics, and reservoir

engineering.

That realization led me to my consulting and teaching career. I got to see a lot of

the world, wrote

a dozen or more

software packages, analyzed the log data from thousands of

wells, and saw even more of the world,

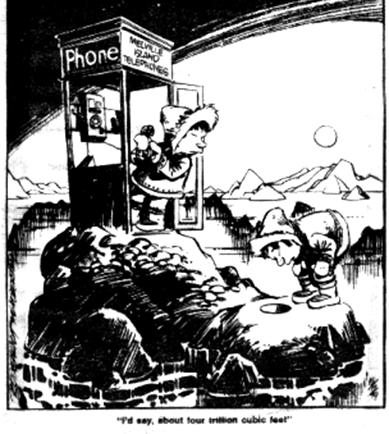

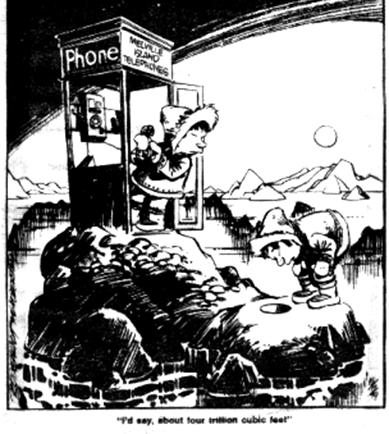

This may be the only editorial

cartoon ever published in a newspaper (Calgary Herald, circa

1974 - 75) concerning petrophysical analysis.

That's me peering down a borehole on Melville Island NWT,

estimating the gas reserves to be "four trillion cubic feet".

The final value was closer to 17 trillion. I was the log analyst

and logging supervisor on about 140 wells in the Canadian Arctic

across a 10 year period. We didn't use our eyeballs to look into

the wellbores directly, of course; we used well logs and

calculations based on those measurements

to do what our eyes could not.

We now call the business "Integrated Petrophysics" because we

use much more than well log data to get our answers. Lab data from

core analysis, such as porosity, permeability and grain density,

are critical input parameters used to calibrate our work. More

exotic lab measurements have become more common as we move into

unconventional reservoir types like shale gas and tight oil

prospects.

The rest of the

articles in this chapter will cover how we use modern logs and

will provide all the geoscience background you'll need to

understand petrophysics.

Check out the

"This Chapter" menu at the right to see where we are headed.

TYPES and USES OF WELL

LOG and LABORATORY DATA

TYPES and USES OF WELL

LOG and LABORATORY DATA

The table

below might not mean too much to someone who is not in the oil, gas,

or mineral development business, but it will give everyone an idea of the scope

of work, wealth of data types, and the multiplicity of uses to

which

petrophysical data can be applied. Although oil and gas

dominate the list, uses in aid of sedimentary minerals, potable and

near-potable water, helium and other inert gases, blue and green

hydrogen, CO2 storage, geothermal energy, and lithium

extraction from brine have been in use in many areas of the world.

|

|

Rocks

are formed in several ways, but usually end up as moderately flat

layers, at least initially (mountain building comes later). As

successive layers are laid on top of each other, the Earth

builds a sequence of rocks with varying physical properties.

Some layers will have open spaces, called pores or porosity,

that contain fluids (water, oil, or gas). A rock on Earth with

porosity cannot be "empty" -- they must contain something, even

if it is only air.

Rocks

are formed in several ways, but usually end up as moderately flat

layers, at least initially (mountain building comes later). As

successive layers are laid on top of each other, the Earth

builds a sequence of rocks with varying physical properties.

Some layers will have open spaces, called pores or porosity,

that contain fluids (water, oil, or gas). A rock on Earth with

porosity cannot be "empty" -- they must contain something, even

if it is only air.

Some

rocks have very little porosity and do not hold much in the way

of fluids. These are often called "tight" rocks. Both tight and

porous rocks can contain animal and plant residue that are

ultimately transformed into hydrocarbons such as coal, oil, or

natural gas that we can extract and use to power vehicles and

heat our homes. As the plant and animal residues mature into oil

or gas, they may migrate through porosity or natural fractures

in the rock until trapped by a non-porous rock structure.

Sometimes a rock only sources itself or an adjacent porous rock,

so little migration occurs.

Some

rocks have very little porosity and do not hold much in the way

of fluids. These are often called "tight" rocks. Both tight and

porous rocks can contain animal and plant residue that are

ultimately transformed into hydrocarbons such as coal, oil, or

natural gas that we can extract and use to power vehicles and

heat our homes. As the plant and animal residues mature into oil

or gas, they may migrate through porosity or natural fractures

in the rock until trapped by a non-porous rock structure.

Sometimes a rock only sources itself or an adjacent porous rock,

so little migration occurs.

Reservoirs

that contain oil or gas also contain water. The quantity of

water relative to the porosity is called the water saturation.

In the illustrations, the brown colour is solid rock grains and

the space around the grains is the porosity. The black colour is

the hydrocarbon and the white is the water, which forms a thin

film coating the surfaces of each rock grain. This is a

water-wet reservoir (left). In an oil-wet reservoir, the black

and white colours are reversed (right).

Reservoirs

that contain oil or gas also contain water. The quantity of

water relative to the porosity is called the water saturation.

In the illustrations, the brown colour is solid rock grains and

the space around the grains is the porosity. The black colour is

the hydrocarbon and the white is the water, which forms a thin

film coating the surfaces of each rock grain. This is a

water-wet reservoir (left). In an oil-wet reservoir, the black

and white colours are reversed (right).

The

economics of a reservoir varies with improving technology.

Bypassed reservoirs, discovered and ignored years ago, are now

economic due to technical improvements in drilling practices and

reservoir stimulation techniques. Horizontal wells and deep

water drilling are now common. The use of heat or steam to assist

production of heavy oil or bitumen, and multi-stage hydraulic fracturing to

stimulate production in tighter reservoirs are relatively new

techniques and relatively economic today. Obviously the specific

price of oil or gas after delivery to the customer plays an

important role in how much effort can be expended to recover oil

and gas from underground.

The

economics of a reservoir varies with improving technology.

Bypassed reservoirs, discovered and ignored years ago, are now

economic due to technical improvements in drilling practices and

reservoir stimulation techniques. Horizontal wells and deep

water drilling are now common. The use of heat or steam to assist

production of heavy oil or bitumen, and multi-stage hydraulic fracturing to

stimulate production in tighter reservoirs are relatively new

techniques and relatively economic today. Obviously the specific

price of oil or gas after delivery to the customer plays an

important role in how much effort can be expended to recover oil

and gas from underground.

Later, with sidetracks into seismic data processing, reservoir

engineering, project management, and seismic data center

management, I finally noticed that petrophysics was the underlying

foundation of much of geology, geophysics, and reservoir

engineering.

Later, with sidetracks into seismic data processing, reservoir

engineering, project management, and seismic data center

management, I finally noticed that petrophysics was the underlying

foundation of much of geology, geophysics, and reservoir

engineering.